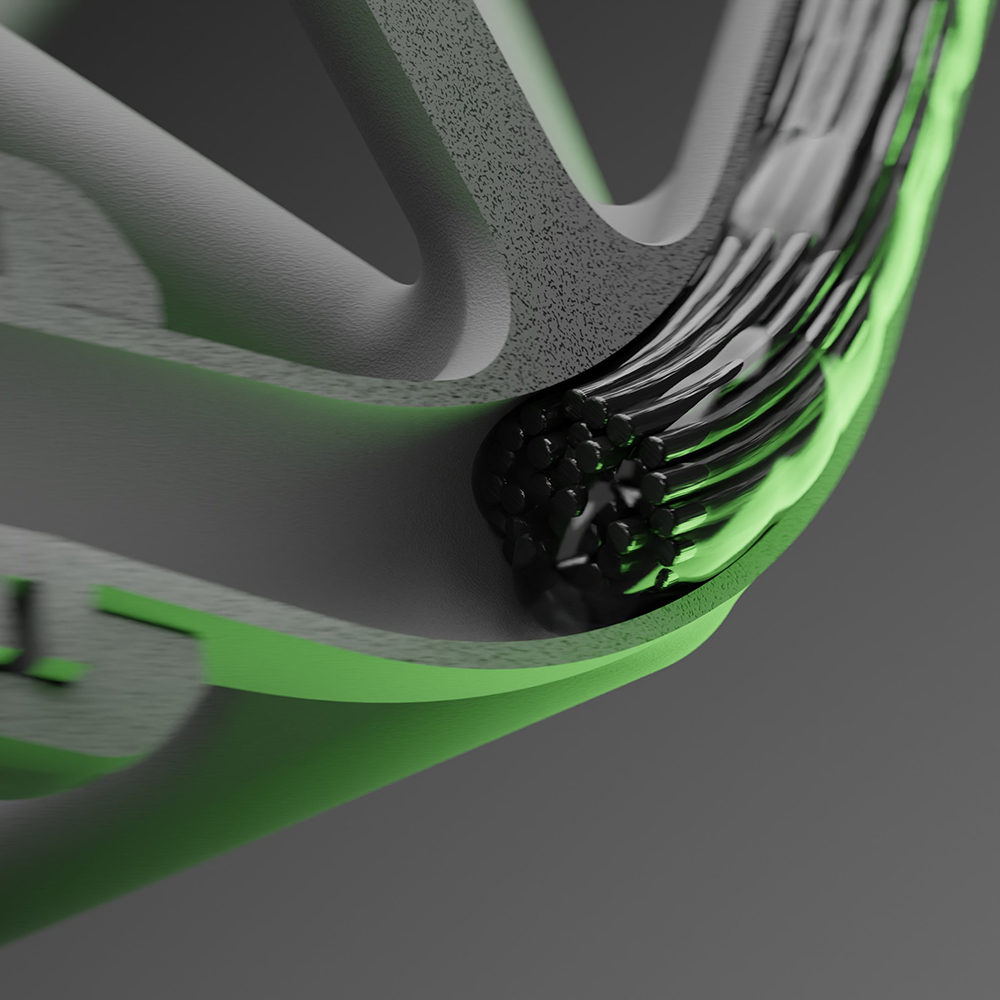

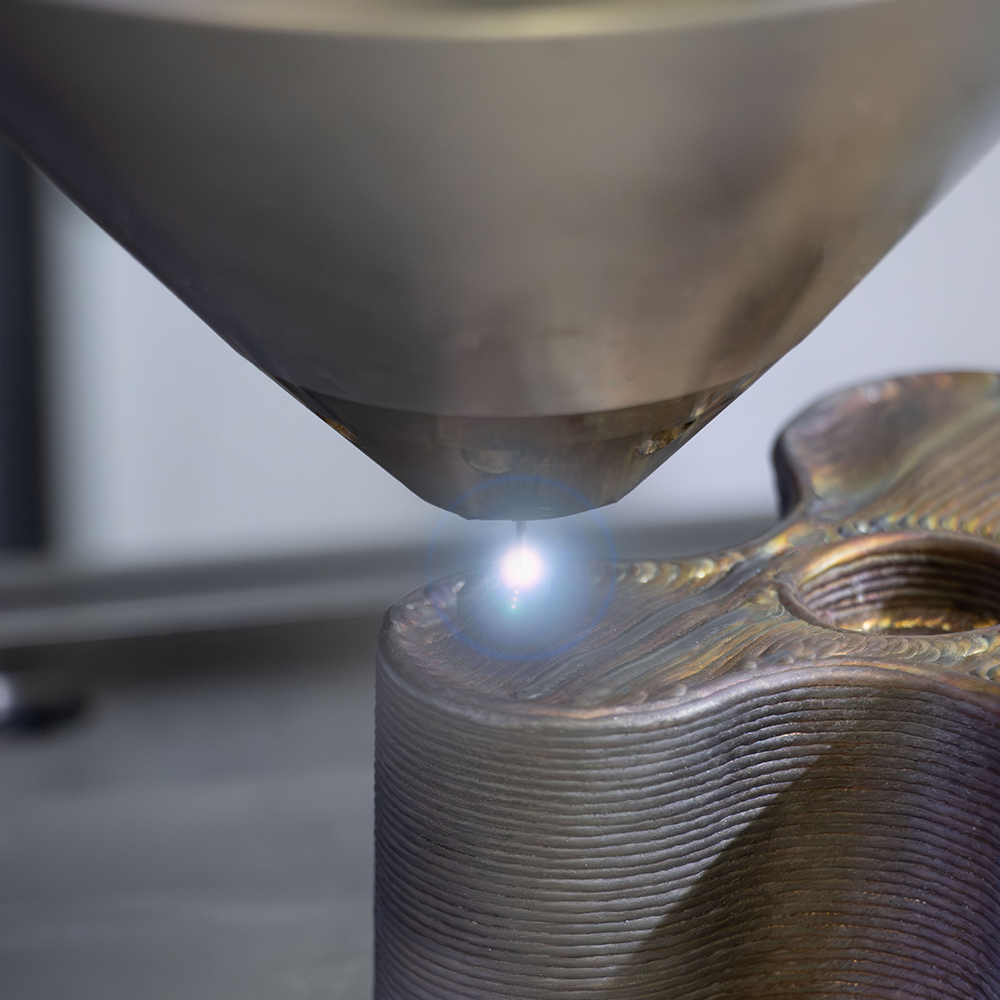

Danobat has developed a solution with its new dBOT robot system, which can be used to manufacture and finish large metal and composite parts for various industries using both additive and subtractive processes.

At its headquarters in Elgoibar (Basque Country, Spain), Danobat manufactures machine tools primarily for demanding industries such as aerospace, automotive, rail transport, and energy. In order to further diversify within the industry, Danobat ventured into CNC precision robotics this year. “dBOT is not just another robot; it combines machine tool technology in terms of rigidity and precision with the agility of a robot system,” explains Xabier Alzaga, CEO at Danobat. dBOT's strengths therefore lie particularly in the areas of precision, repeatability, and stiffness.

The company currently offers two models of the robot: dBOT S2, with a payload of 220 kg and a reach of up to 2,900 mm; and dBOT S7, with a payload of up to 700 kg and a reach of up to 3,315 mm. The robot has an open architecture, which, according to Danobat, allows for fully configurable solutions. The possible applications include nozzles for aerospace manufacturing and the repair of turbine parts for power generation. Alzaga also cites the defense industry and heavy machinery manufacturing – industries in which large, complex, and powerful parts are indispensable – as important areas of application.

Danobat was founded in 1954 and employs around 650 people, around 40% of whom work internationally. In addition to its headquarters in Elgoibar, the company has production facilities in Germany and the Netherlands, as well as sales and technical service offices in the US, Mexico, China, the UK, Italy, and other countries.

Further company information

Further information

Further exclusive information on Spanish AM companies can be found in the print edition 03/2025 of Formnext Magazine or in the digital Fon Mag:

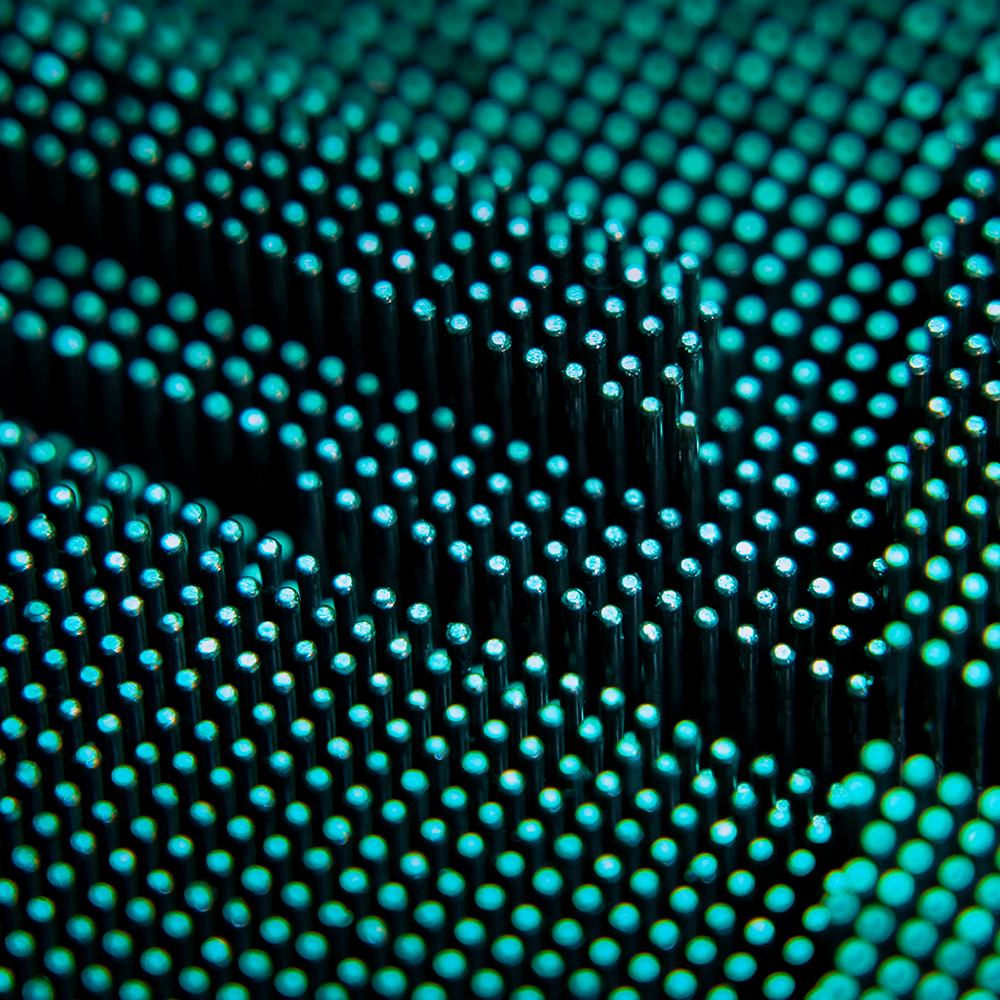

Aimen, Aimplas, ArcelorMittal, Danobat, HP, IAM3DHub, Indart3D, Madit, Meltio, Reinforce3, Recreus, Smart Materials, Market report Spain