Since then, 2,500 engineering projects and parts have been completed in materials such as 316L stainless steel, maraging steel, and nickel base IN718. The total production has accounted for more than 30 tons of components for ArcelorMittal’s operations across Europe.

The parts in question help optimize fluid management and heat transfer, consolidate assemblies, or functionalize captors or camera sets. This way, ArcelorMittal can better understand and anticipate the needs of heavy industries. Plus, its approach to AM makes a perfect complement to the steel powder manufacturing capacity the company built up in northern Spain just a few years ago.

»Thanks to Additive Manufacturing, reliability teams across ArcelorMittal plants are more efficient and resilient,« explains Aubin Defer, Chief Marketing Officer at ArcelorMittal. »AM allows for fast maintenance of critical operations, reduces unplanned downtime, and helps fix weak part designs thanks to rapid iteration and improvement.« Other advantages include longer component service life and higher performance, improved operational efficiency, and greater safety in operational processes.

In addition to the Additive Manufacturing of components for internal use, TheSteelPrinters now offers its services to customers from other industries, such as aerospace, defense, oil and gas, and energy. The angle ArcelorMittal is taking now relates more to improving the reliability and availability of its assets than to rationalizing its supply chain.

The angle now is more in improving reliability and availability of ArcelorMittal assets (engineering view) than in rationalizing supply chain (procurement view). “The exercise is complex to convince procurement functions driven mostly on cost and promote more the total cost of operating approaches that can justify for a procurement function to pay more for a replacement part at iso functionality”, explains Defer. “Approaching issues to fix through engineering and reliability is an easier sell of the technology as added value can be measured in terms of hours of production or quality gains.”

Coke batteries in Poland

One of the many successful examples of these additively manufactured components can be found at the ArcelorMittal plant in Zdzieszowice, Poland, the largest coke producer in the European Union. With each of its four coke oven batteries featuring 78 heating walls that transform coal into coke, the plant produces four million tons every year.

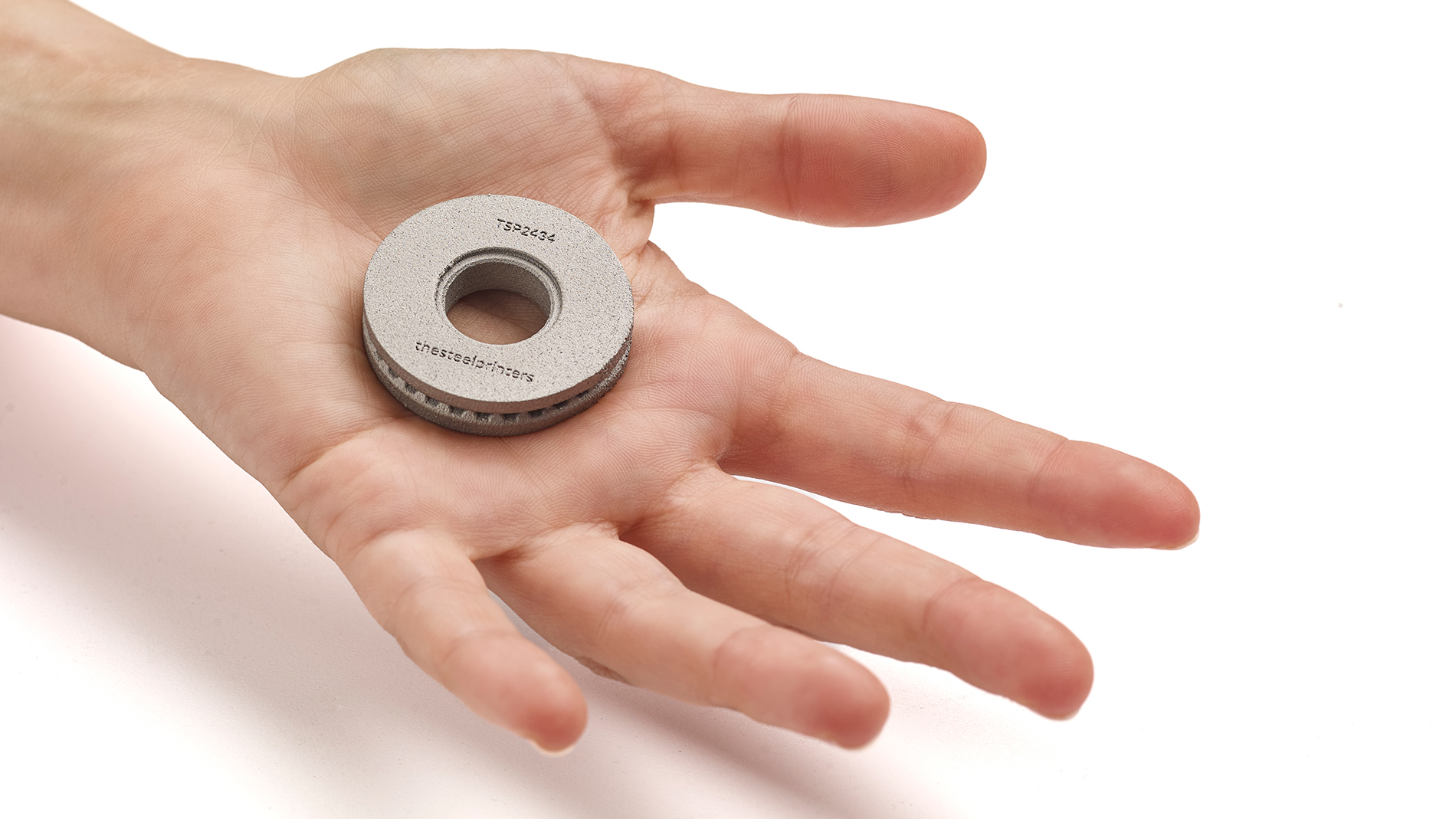

In large-scale coking operations, reliability often hinges on addressing bottlenecks, and even the smallest components play critical roles. This is the case with elements such as the coin-sized 316L nozzles that regulate gas flow in the coke ovens. Vital for maintaining the proper temperature and uniform heating along the walls, they are essential for producing high-quality coke. Any disruption in temperature distribution can result in several issues, including improperly roasted coke, non-gas chambers, elevated ejection rod currents, increased emissions, and damage to the ceramics of the heating walls.

The original part, made of polytetrafluoroethylene (PTFE), frequently experienced clogging and needed to be replaced every 6–8 weeks due to soot buildup. This required cleaning every 14 days, and after cleaning, the burner nozzles would become misaligned, significantly impacting the coking process of the coal mixture. With a weight of 8 grams and a diameter of 38 millimeters, the new AdamIQ 316L stainless steel 3D-printed parts offer improved performance, reduced maintenance costs, and a lifespan of five years instead of two months.

Reliable cooling of a blast furnace

At ArcelorMittal Ghent, the operating life of the plant’s blast furnace has increased dramatically over time, reaching 39 million tons at the time of the last relining – the longest cycle ever. Here, Steel Additive Manufacturing (SAM) has played a critical role.

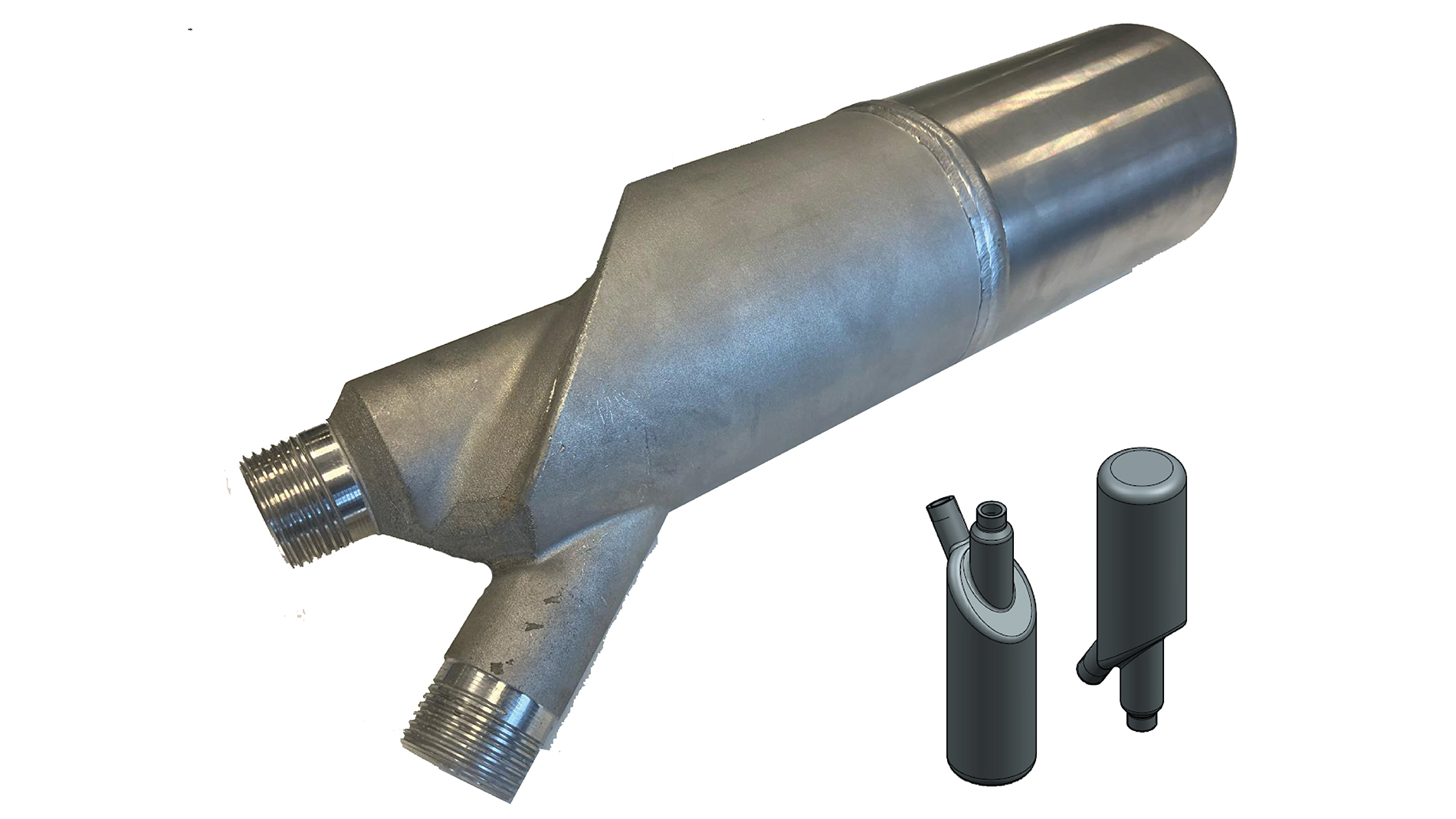

The company’s Engineering and Global R&D teams developed an innovative concept to compensate for the loss of cooling power on the interior lining, which is made of copper staves that protect the blast furnace’s shell integrity over time. A ring of 52 hybrid Monel (a nickel-copper alloy) and 3D-printed steel cylindrical cooling inserts is now used to replace the worn cooling channels. These inserts effectively stop leakages and protect the shell by precisely cooling its hot spots. The 52 cooling inserts are also equipped with a cold-water inlet. As the water circulates, it effectively absorbs the heat, thereby cooling the inserts. In the words of Alain Daelman from ArcelorMittal Ghent’s Blast Furnace and Sinter Plan Department: “Thanks to the use of fast, 3D-printed, optimized cooling elements produced by TheSteelPrinters, we managed to keep the blast furnace shell cooled for over a year until we were able to replace the failed elements.”

Steel casting ladle with internal channels

Before casting, steel can be refined in the ladle by various processes according to specifications with respect to its deoxidation state, inclusion content, and levels of different chemical elements such as phosphorus, sulfur, nitrogen, and hydrogen. At the same time, its content of carbon, manganese, and microalloying elements such as niobium, vanadium, and titanium can be adjusted.

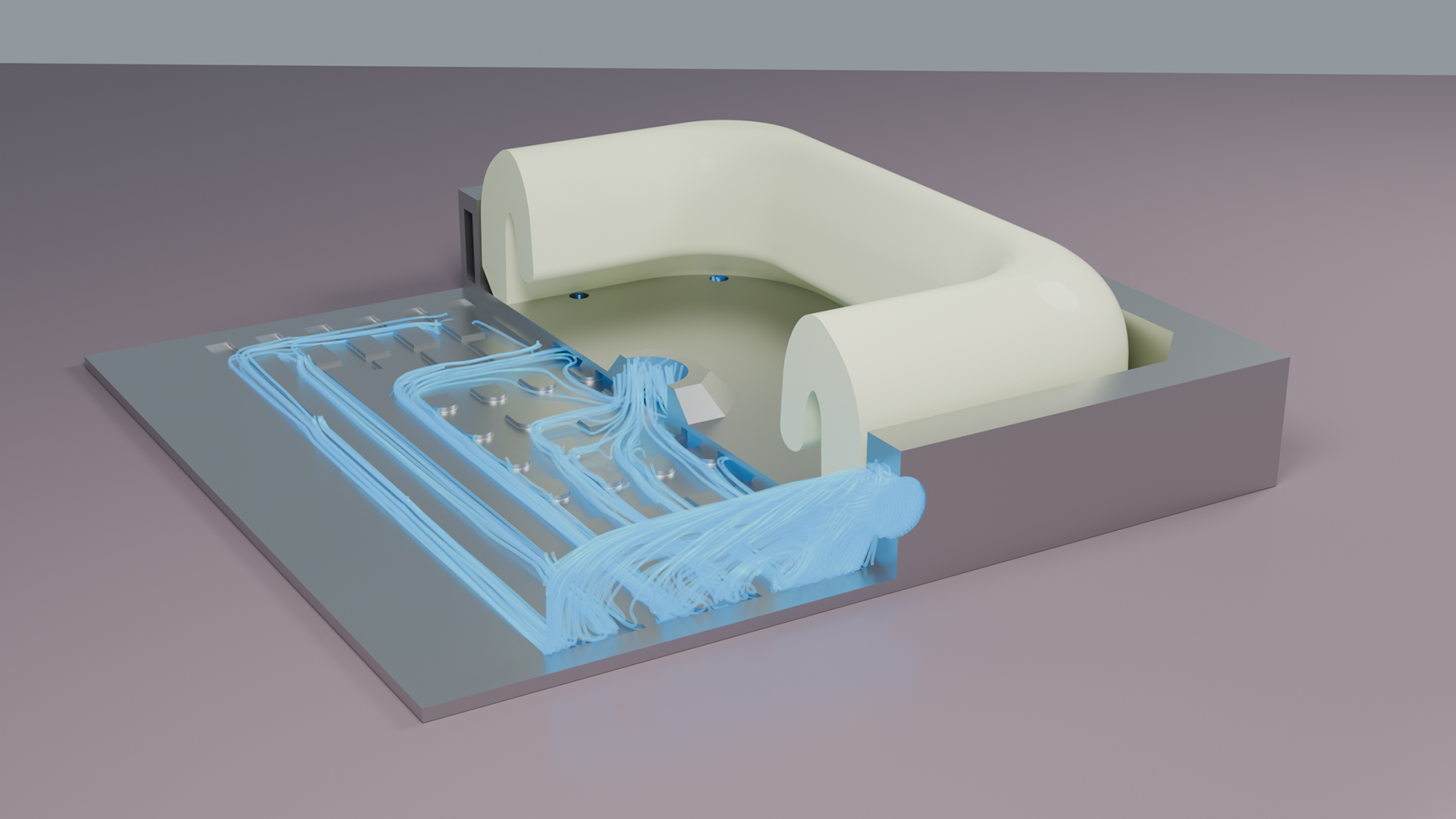

In the steel-making shop at ArcelorMittal Asturias (northern Spain), nitrogen must be blown inside the ladle to force a chemical reaction and create the right steel composition. To do this, the ladle with the molten steel is placed on a fixed structure, connecting the underside of the ladle to the nitrogen input. The coupling is made of a steel frame with a silicone joint inside. If the coupling is not properly sealed, nitrogen leaks out, causing misalignments in the steel composition and significant economic losses – up to €30,000 for each faulty casting cycle, in fact.

Using Additive Manufacturing, ArcelorMittal Asturias designed and printed a new steel frame. Equipped with several internal channels and printed from 316L, a hollow silicon joint is now used so that the joint can swell, creating a sealed coupling. Due to its high complexity and large dimensions (316 x 316 x 47 mm), the part was manufactured in two different pieces and then welded together.

Further company information

Further information

Further exclusive information on Spanish AM companies can be found in the print edition 03/2025 of Formnext Magazine or in the digital Fon Mag:

Aimen, Aimplas, ArcelorMittal, Danobat, HP, IAM3DHub, Indart3D, Madit, Meltio, Reinforce3, Recreus, Smart Materials, Market report Spain