Text: Thomas Masuch

At its new location in the Zamudio industrial park near Bilbao Airport, the production area has increased from 200 square meters to 2,000. With significantly more space, the company has also been able to invest in new equipment: in just one year, the machine park has grown from five to eleven laser melting systems (PBF) – all from Renishaw, by the way. The size of the team has also grown significantly, practically doubling to 25 employees in the past 12 months. “This makes us the largest service office for additive metal manufacturing in Spain,” emphasizes Asier Domínguez, founder and Project Manager at Madit.

The reason for this growth is an increase in orders – while Madit has mainly grown with prototypes and unitary parts in recent years, “more and more series projects are being added. This enables us to plan for the long term and significantly expand our capacities, both technically and in terms of personnel,” says Domínguez. The company also has various in-house post-processing facilities, including sand blasting, polishing, machining, welding and heat treatment. Quality assurance is handled by a specialized colleague who, for example, takes care of checking the powder as well as measuring the finished components. “Our aim is to guarantee consistent quality, especially in series production – even if the components are printed on demand at intervals of several days.”

Image: Madit

Hundreds of bike frames

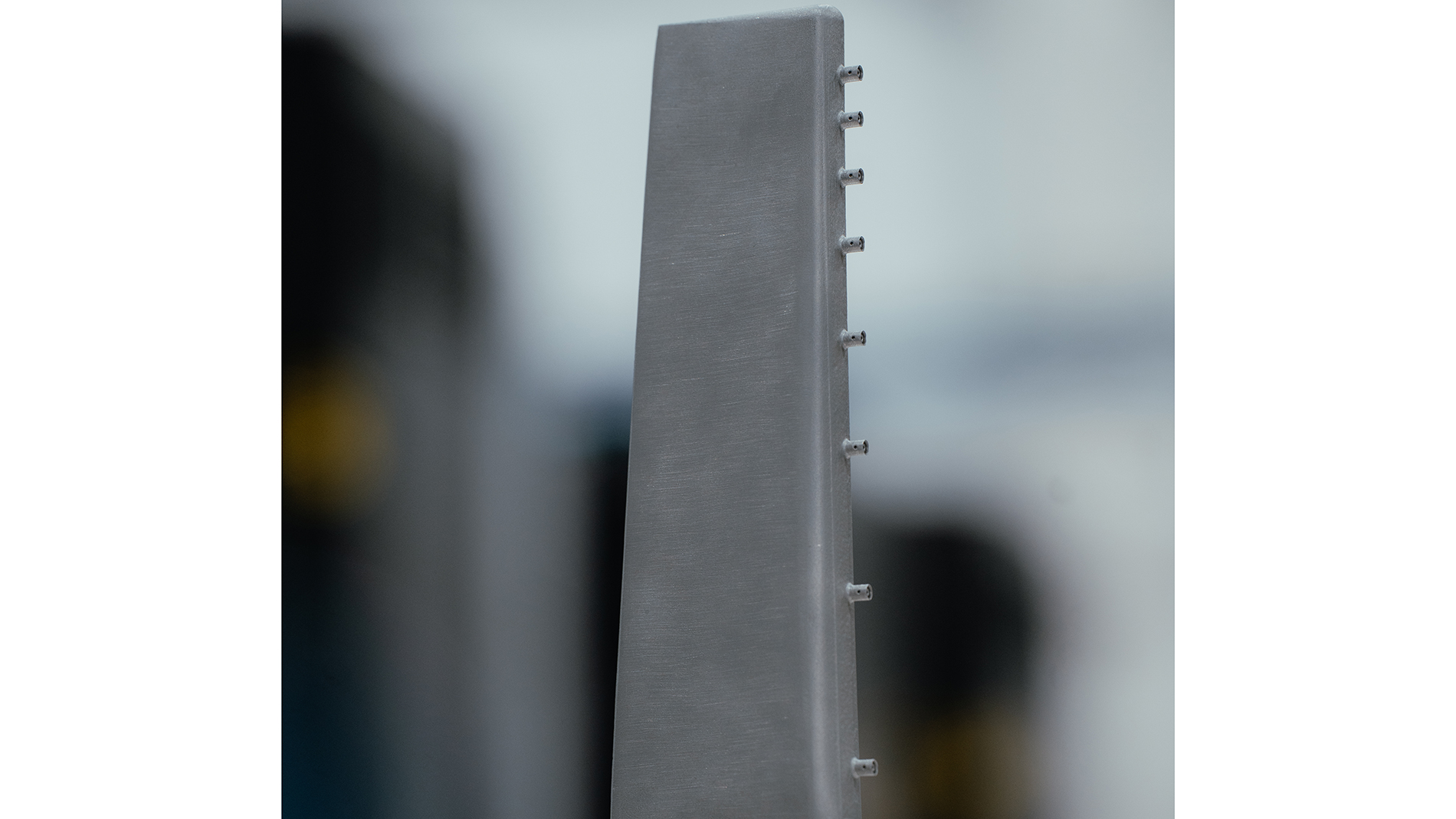

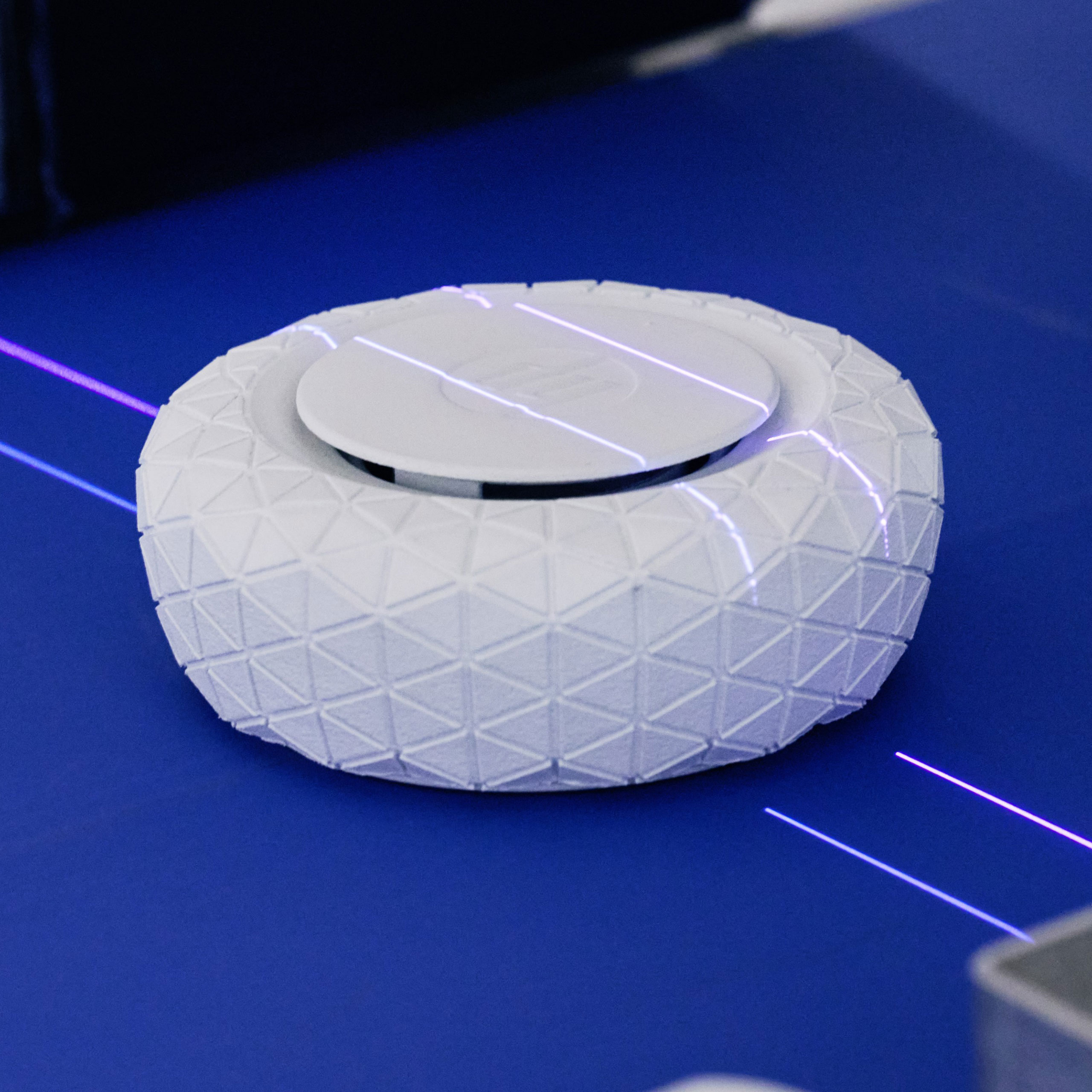

Customers come not only from Spain, but also from all over Europe. The components printed in Zamudio are supplied to the general industry (e.g., mechanical engineering), the automotive industry, and bicycle manufacturers, among others. Among other things, Madit manufactures series of 50 to 100 titanium bicycle frames in various sizes every year. Domínguez and his team also bring a current model to Formnext in Frankfurt every year.

To remain competitive internationally, Madit has focused heavily on its clear strengths: in the area of prototyping, this is primarily speed. “We respond to inquiries within one day,” Domínguez promises. And in the area of series production, the company scores points with a combination of experience in AM design, a high degree of flexibility thanks to its relatively large machine park, and cost-efficient production. “By focusing on less regulated industries, we have been able to grow and gain knowledge in order to take on now more complex projects in sectors such as aeronautics and space. This growth strategy has allowed us to keep costs low for our customers.” Efficient production also means that the machines are permanently filled with the same material: Inconel 718 is processed on four systems, aluminum on three, and stainless steel 316 and 17-4PH, maraging steel, and titanium on the rest.

Image: Madit

Lean organization

Overall, Madit has a very lean structure. “We don't have a sales team,” explains Domínguez. Advertising is done almost exclusively via LinkedIn or Instagram – the latter generates high traffic, especially in the bicycle sector. The only investments in marketing go toward trade fair appearances – with Formnext being the only event outside Spain in which Madit participates as an exhibitor. “Formnext is a great window to European and international clients from the AM world and from many other industries. There is no event like this in Spain, in Frankfurt we can achieve a very important promotion of its capacities and services”, Domínguez says.

Despite its relatively rapid growth, the company is still owned by the three founders (Asier Domínguez Olabe, CEO Javier Díaz Gutiérrez, and Engineering Director Pablo Rojo Bilbao), who launched Madit in 2020 after quitting their jobs at an aircraft turbine manufacturer in northern Spain. The three engineers have driven the entire growth themselves, aided in part by their excellent partnership with Renishaw. "In the future, we would like to be one of the major players in European metal 3D printing and enable the industry to take full advantage of this technology.”

Further company information

Further information

Further exclusive information on Spanish AM companies can be found in the print edition 03/2025 of Formnext Magazine or in the digital Fon Mag:

Aimen, Aimplas, ArcelorMittal, Danobat, HP, IAM3DHub, Indart3D, Madit, Meltio, Reinforce3, Recreus, Smart Materials, Market report Spain