Text: Thomas Masuch

Blanca Garro encounters new products and innovations almost every day. However, she is not allowed to talk about them publicly – as a rule, the managing director of Spain’s Reinforce3D signs an NDA with every new partner.

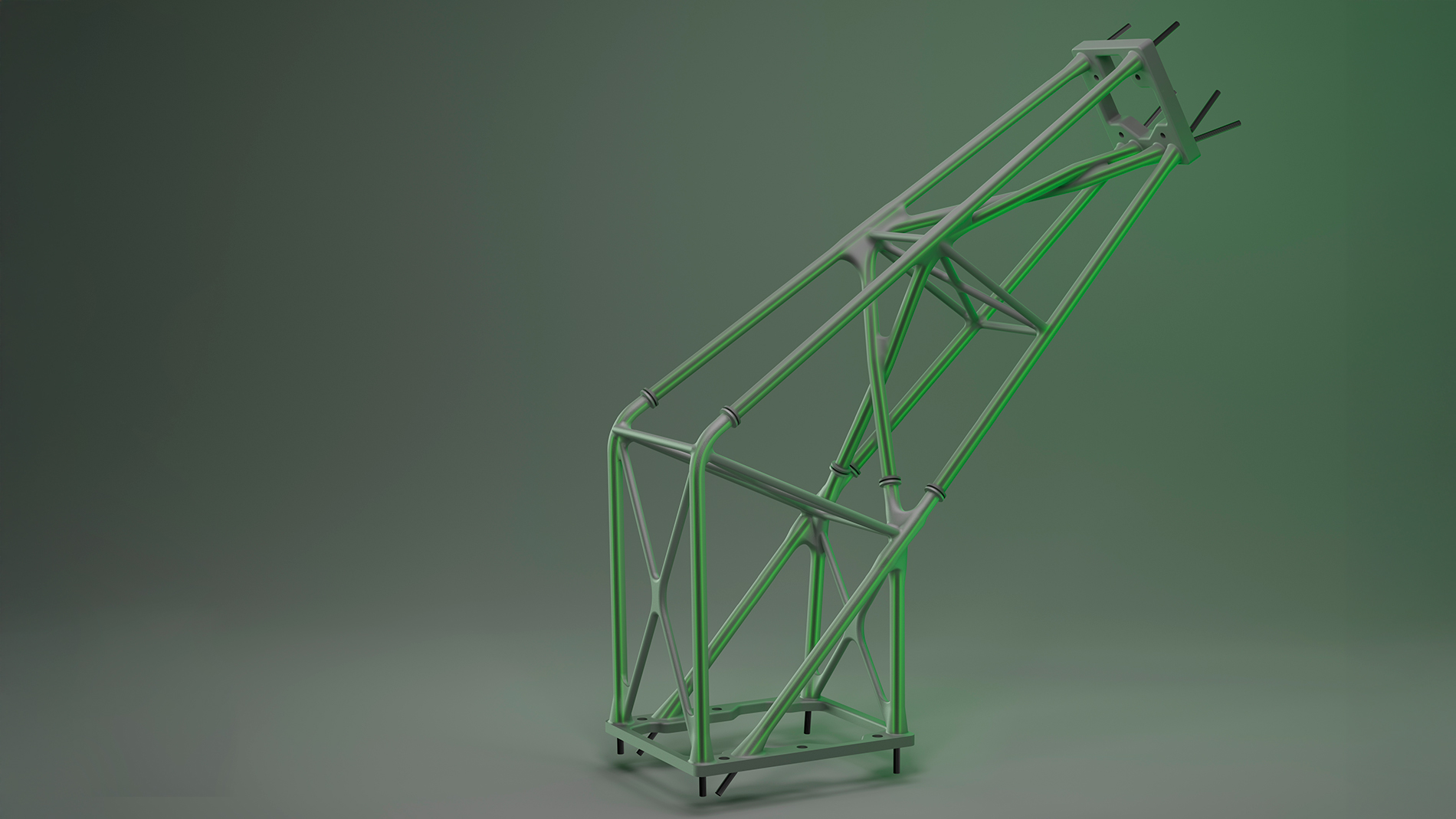

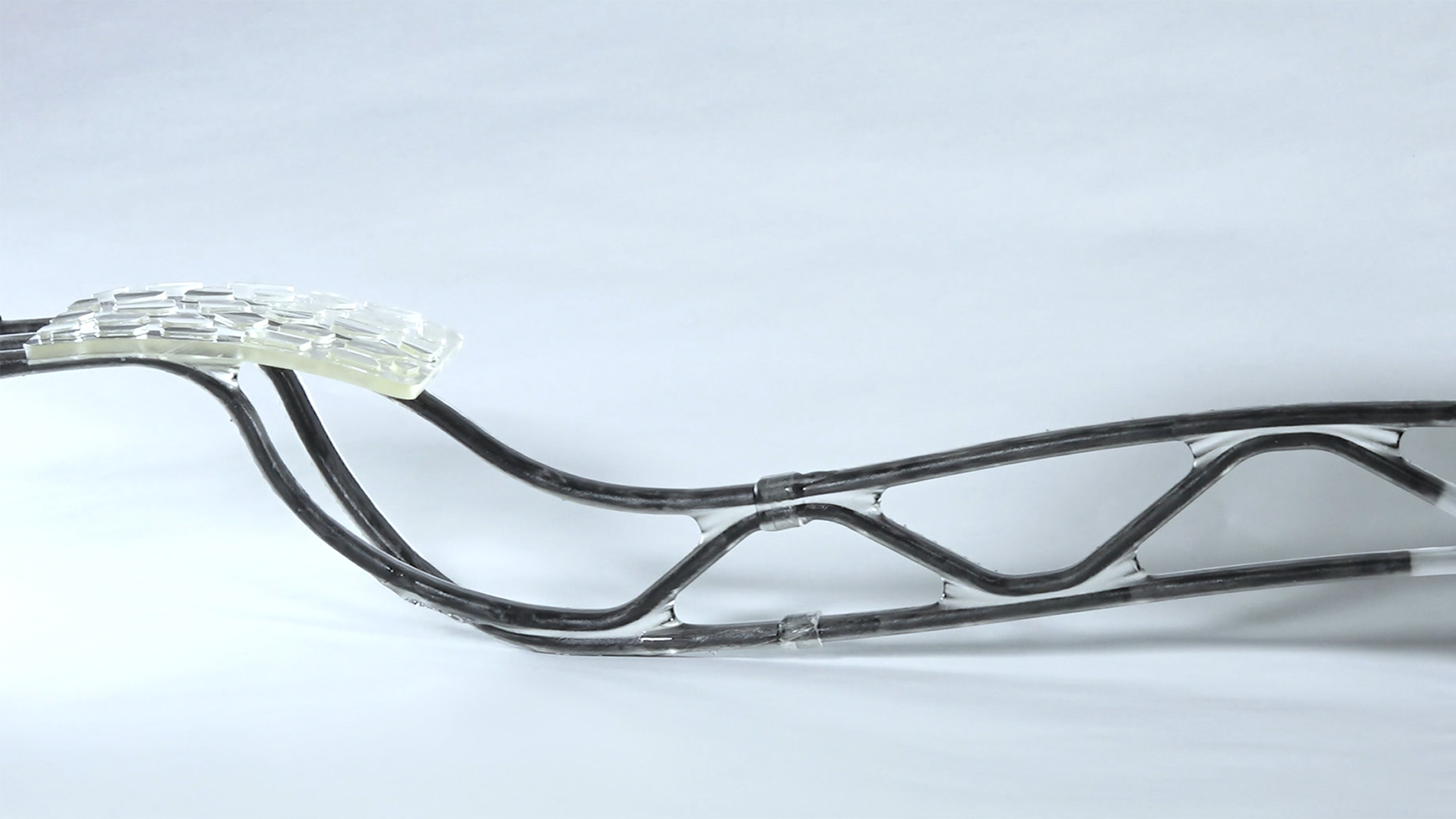

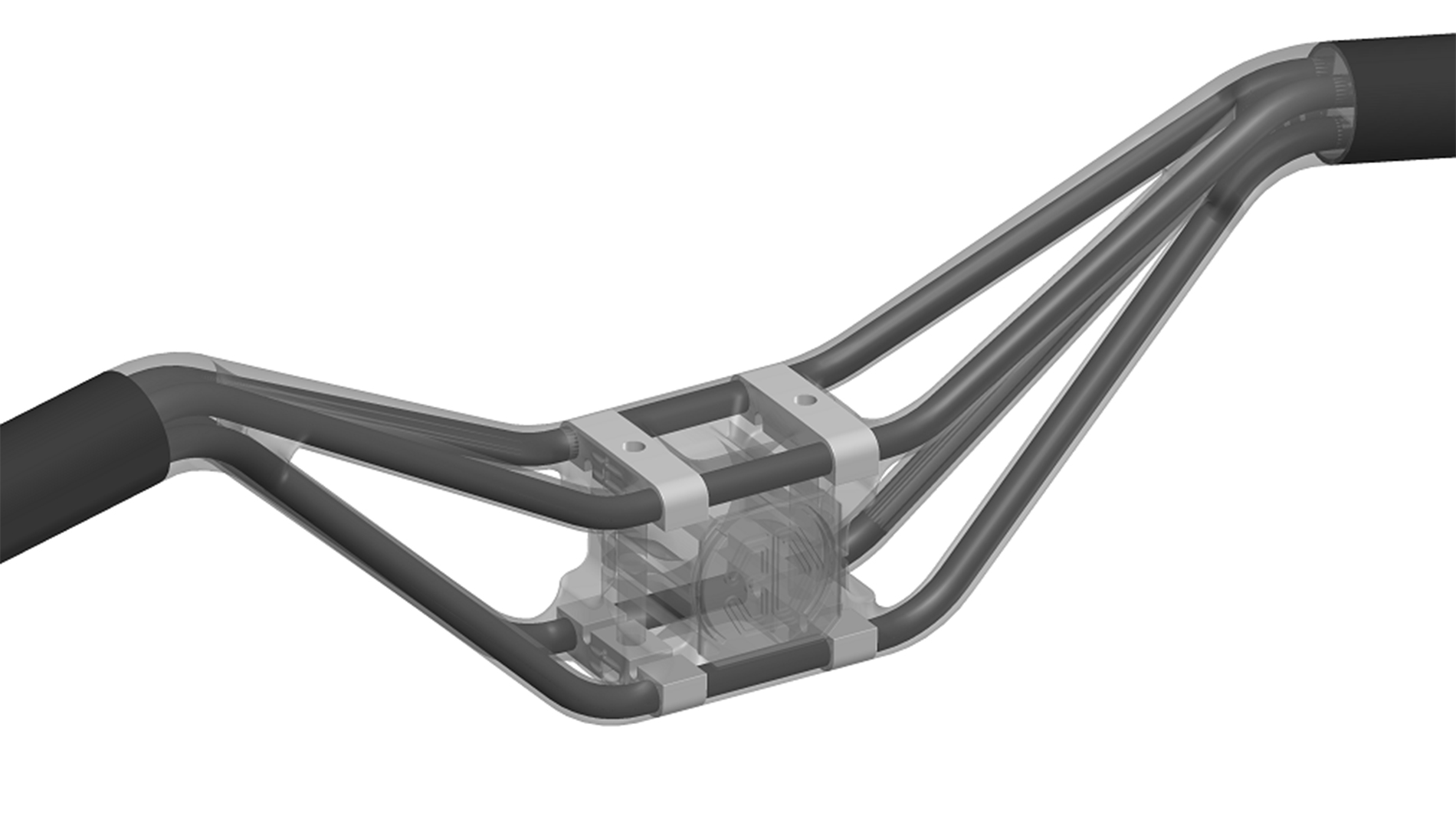

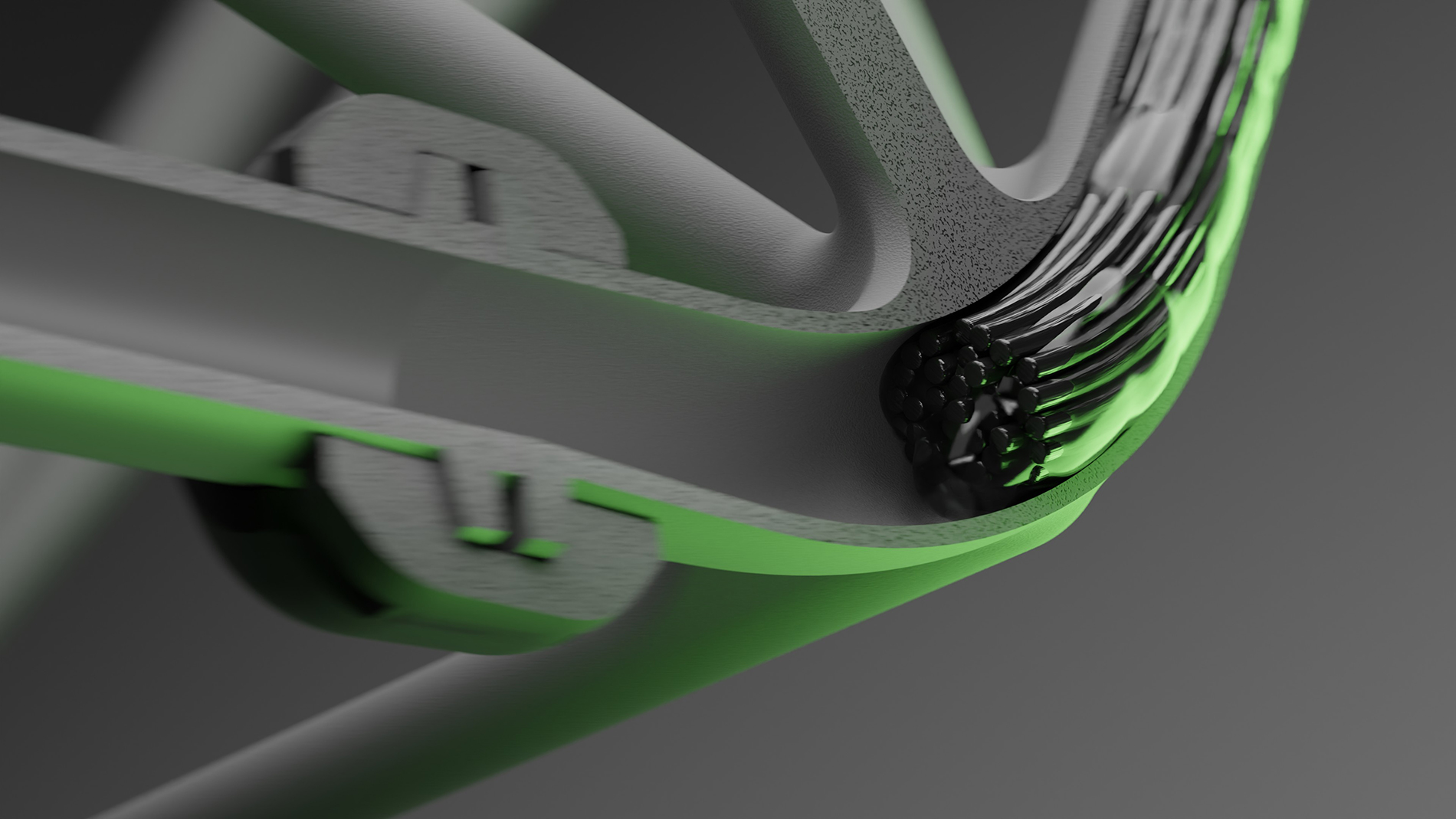

Garro operates in a world shaped by innovation because of her start-up’s CFIP technology. “This technology enables progress even in areas where innovation once seemed impossible, as everything was thought to be already perfected,” she explains. Examples include new saddles and handlebars in cycling, as well as mounts for robots in mechanical engineering. “We don’t just make these products lighter; in many cases, we also deliver significant cost advantages over traditional additive processes.” At the same time, components made of different materials can also be joined together – for example, plastic and aluminum.

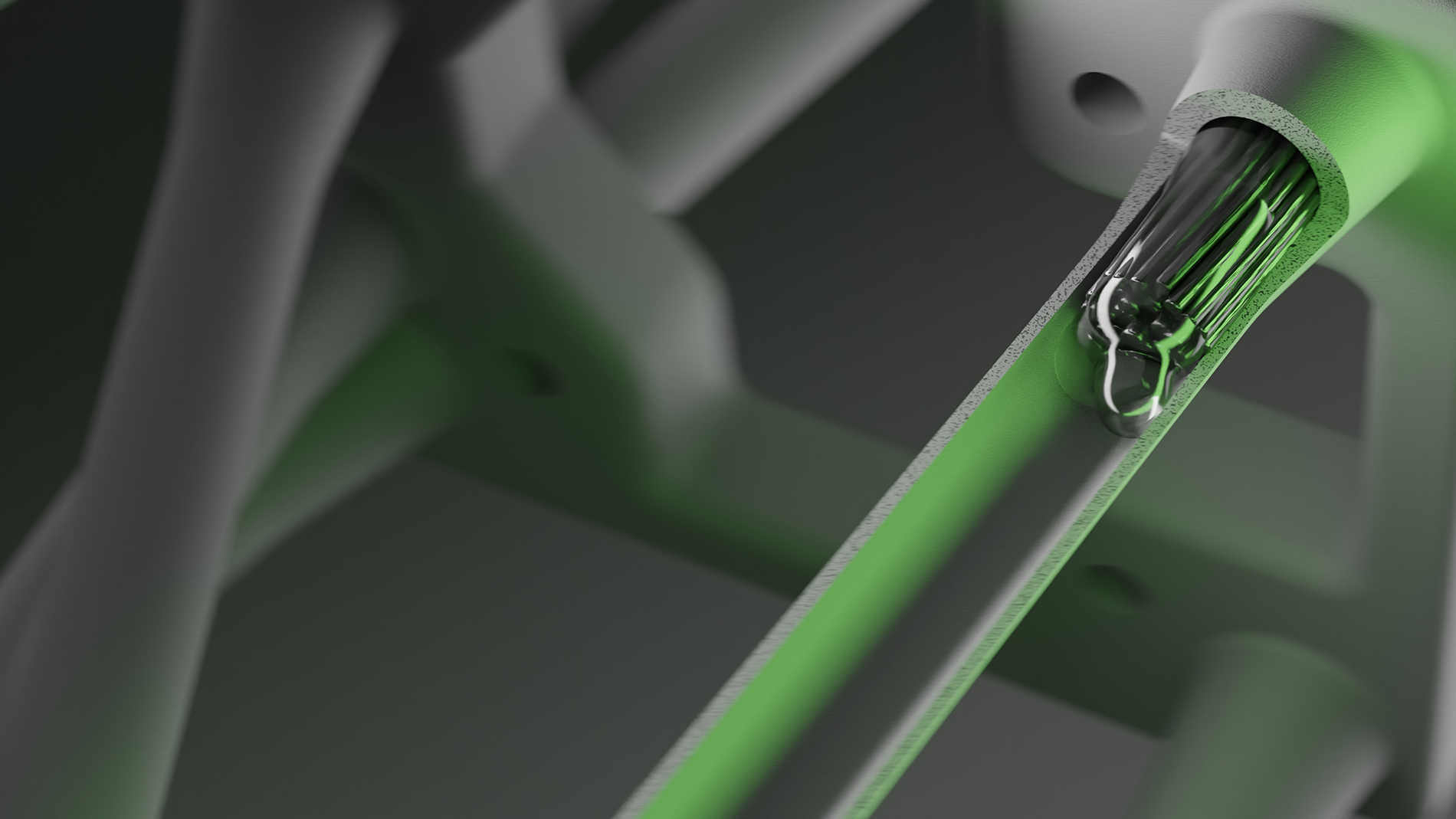

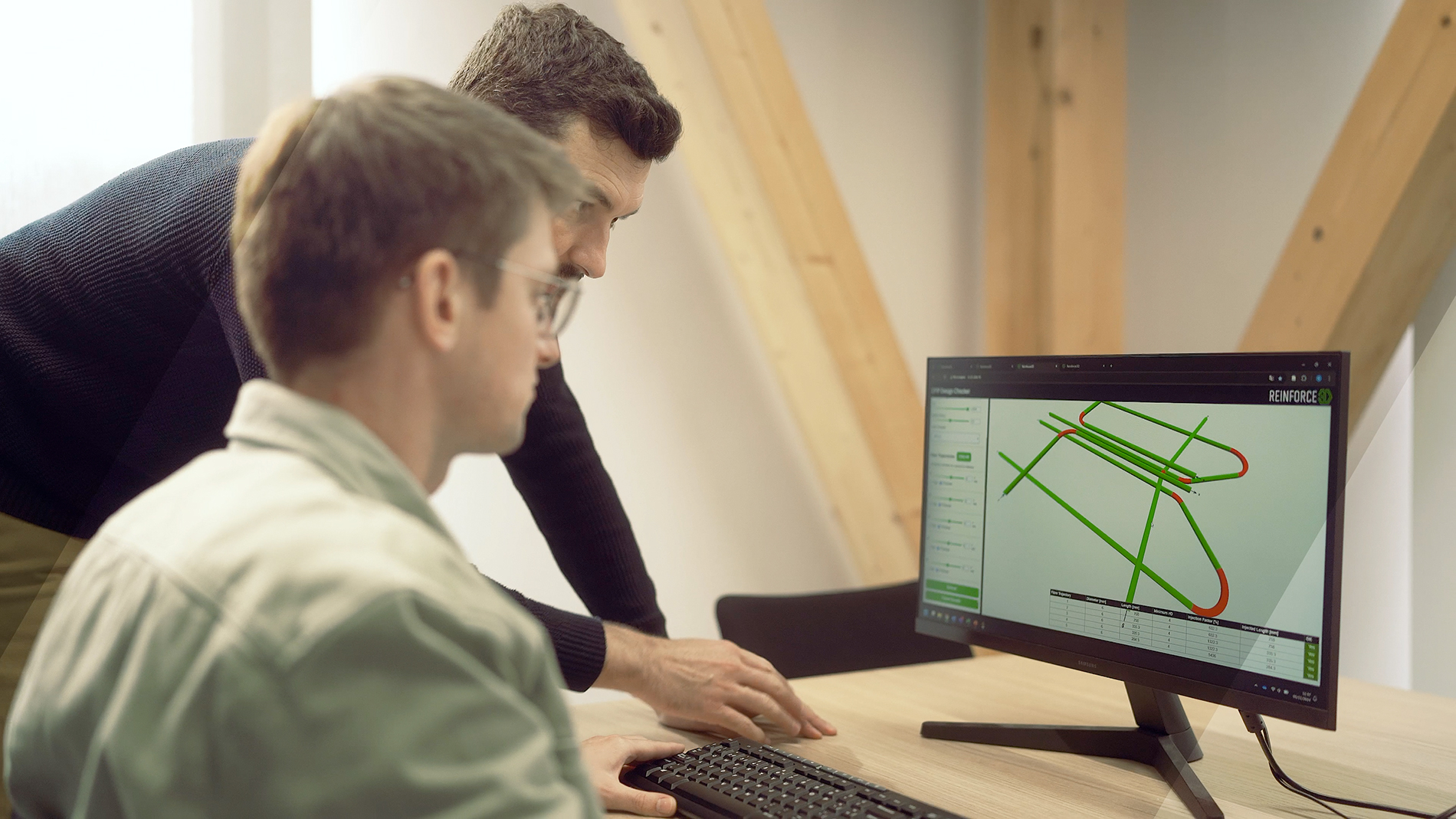

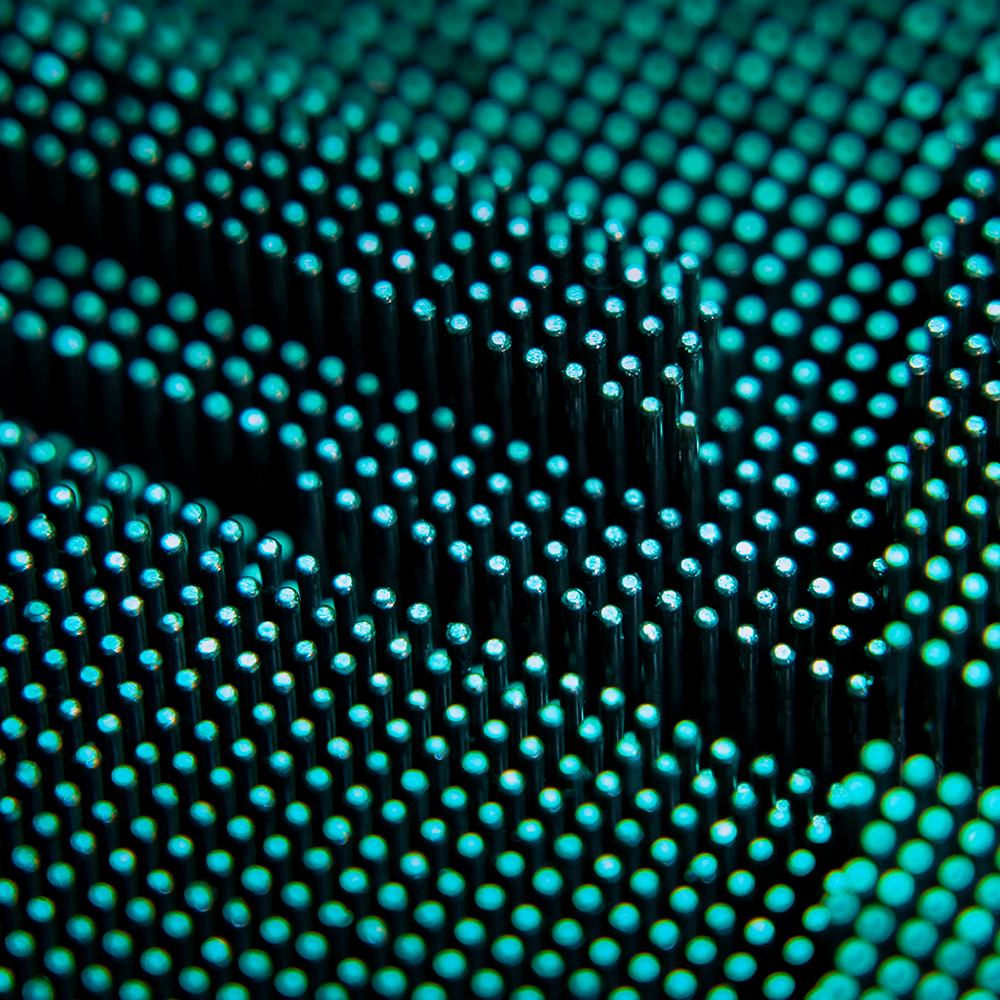

The CFIP technology Reinforce3D has developed and commercialized enables the automatic insertion of continuous fibers into prefabricated parts, improving their mechanical properties. The beauty of this patented technology – namely that it enables many new applications and innovations, especially in the field of lightweight construction – also poses a challenge for Reinforce3D: “Because the best technology is worthless if no one knows how to use it,” Garro points out. Today, the team focuses on developing and demonstrating sample applications across key industrial sectors, showcasing CFIP’s versatility and scalability while supporting partners in integrating it into their workflows. “We’re growing step by step, building strong collaborations, and expanding into more industries, with the clear goal of making CFIP a standard in advanced manufacturing,” Garro states.

Complex and robust lightweight components

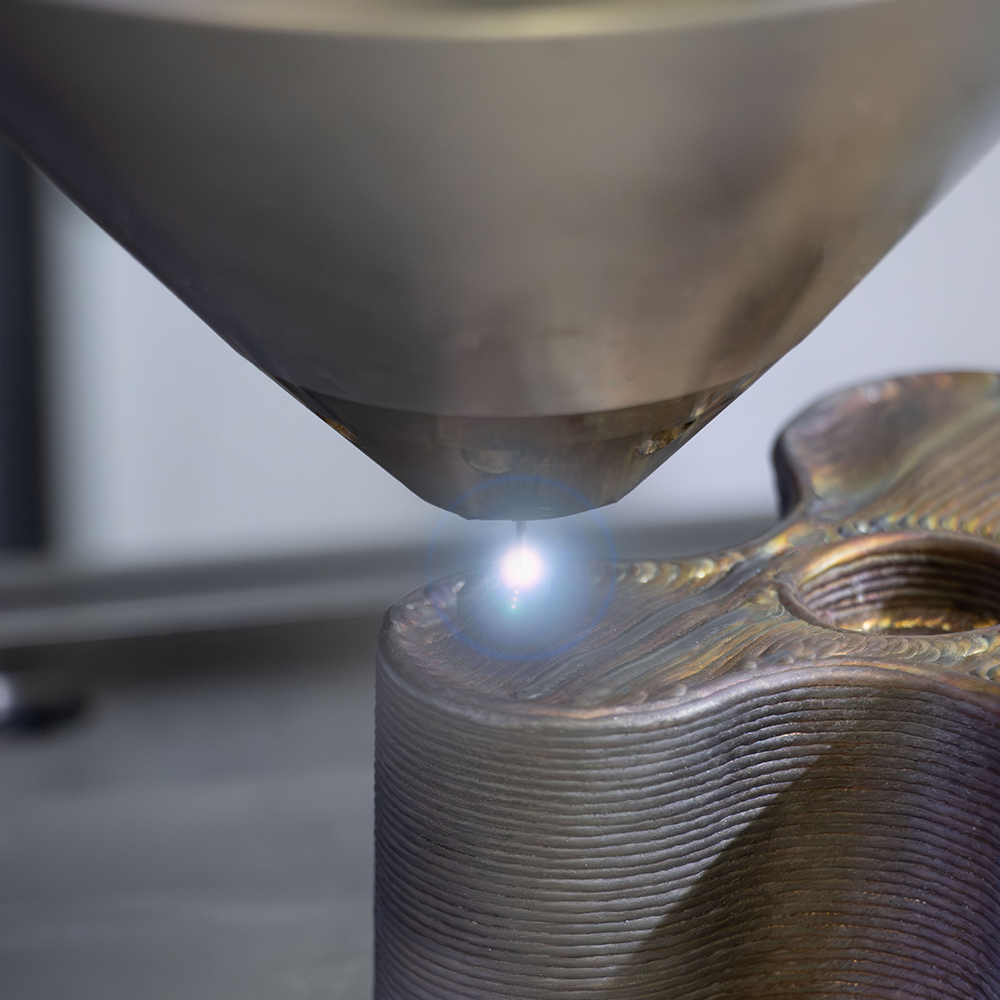

The technology was researched around 10 years ago at the Catalan technology center Eurecat in Barcelona, where a mixture of resin and continuous carbon fibers was injected into a 3D-printed casing. According to Garro, this has several advantages, including the fact that the casing can be produced using fairly simple desktop printers. The filling process allows for the creation of complex, robust, and lightweight parts – efficiently and at a competitive cost.

Reinforce3D company was founded in 2022 as a spin-off from Eurecat and former Eurecat researcher Marc Crescenti, who now serves as the company's CTO. Garro, who studied chemical engineering, has been CEO of the company since 2023, having previously worked at Materialise for several years and earned her MBA on the side. The company now has 12 employees at its site in Amposta on the Ebro Delta, halfway between Barcelona and Valencia. One third of the team operates the machines at the company, one third are engineers, and the remaining third is responsible for marketing and administration. To finance growth and technology development, Reinforce3D has investors on board, including the Spanish fund BeAble Capital, which specializes in technology start-ups and was the company’s largest VC investor in an earlier phase. In 2022, BeAble officially invested €650,000 in the company, supporting the industrialization of CFIP. The start-up is also supported by Spanish public institutions, particularly the region of Catalonia.

Potential in various industries

Since presenting its Delta machine at Formnext in 2023, Reinforce3D has earned international recognition, and its technology is already used in various sectors. The use of the Delta machine varies considerably: Garro estimates that about half of the customers use it to manufacture prototypes and short runs, while the other half use it to manufacture final products. The applications range from the aforementioned bicycle saddles and handlebars to replacement parts for trains, machine components, and components for robot arms. Important fields include sports (especially bicycle and sporting goods manufacturing) and drone manufacturing, as well as motorsports, mechanical engineering, and healthcare. Garro sees particular potential in the latter, as CFIP technology “may allow certain internal reinforcements without altering external designs or contact surfaces – potentially simplifying the regulatory pathway. However, all modifications still require case-by-case evaluation in line with medical device regulations.”

This area of application is set to grow even further in the future. Firstly, Garro and her team want to offer other materials (such as glass fiber and Kevlar) in addition to the carbon fiber embedded in resin that they currently use. Secondly, another machine is already in development that will automate the mixing of the material components and the injection of the material. First, however, comes the Robotic Injection Automation that will be showcased at this year’s Formnext. “This is how we’ll take our technology to the next level of industrialization,” declares a confident Blanca Garro.

Further company information

Further information

Further exclusive information on Spanish AM companies can be found in the print edition 03/2025 of Formnext Magazine or in the digital Fon Mag:

Aimen, Aimplas, ArcelorMittal, Danobat, HP, IAM3DHub, Indart3D, Madit, Meltio, Reinforce3, Recreus, Smart Materials, Market report Spain