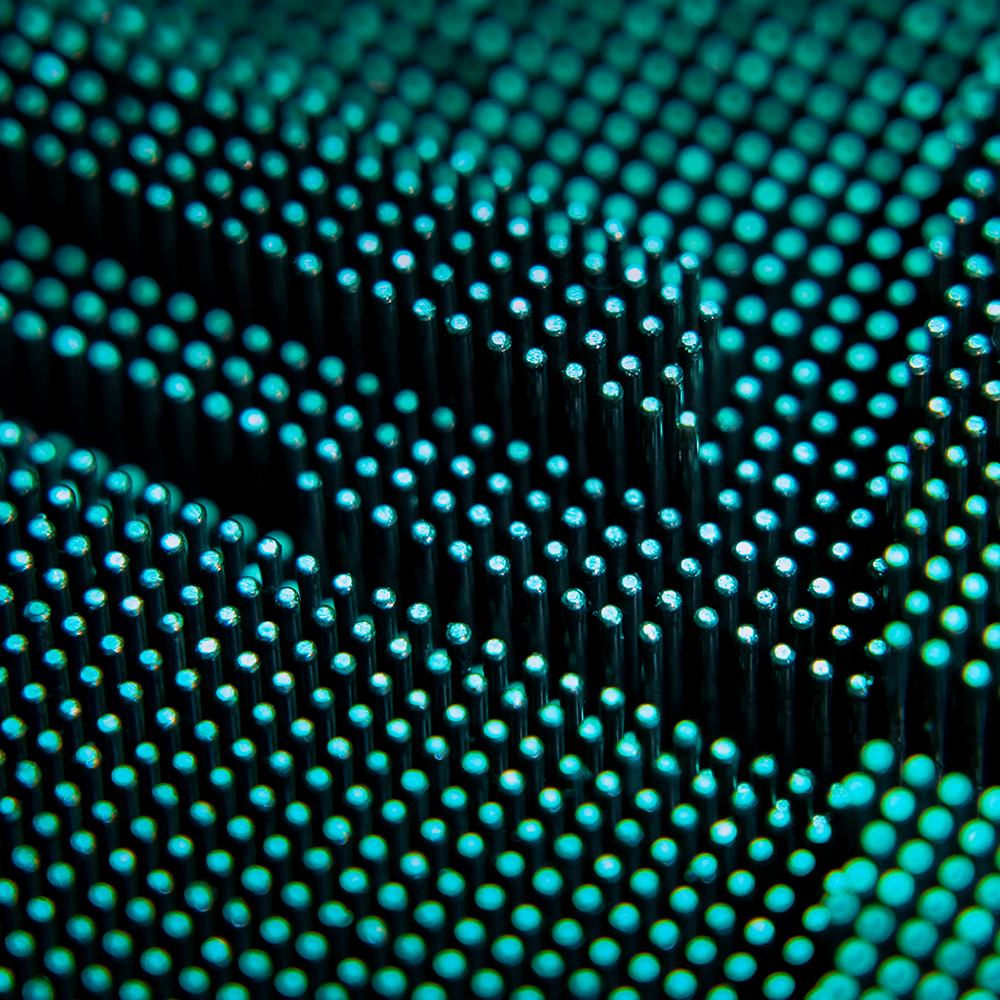

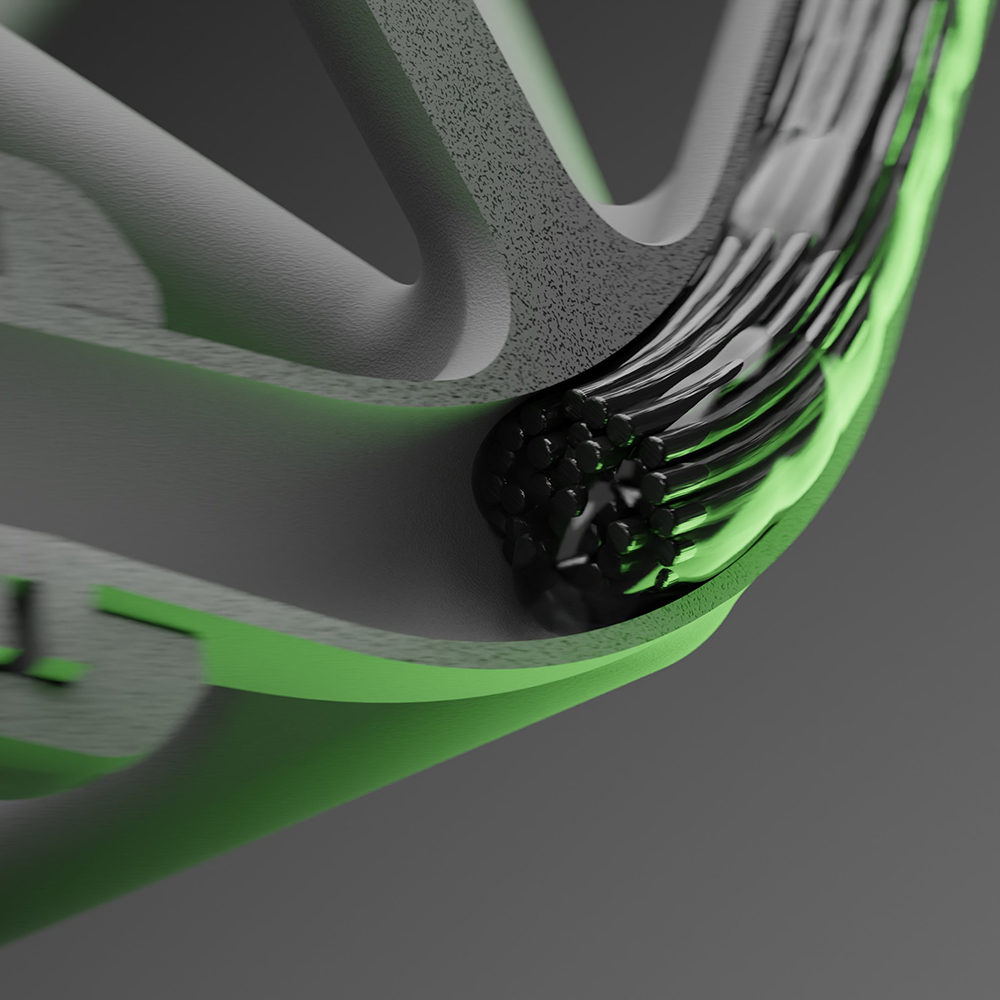

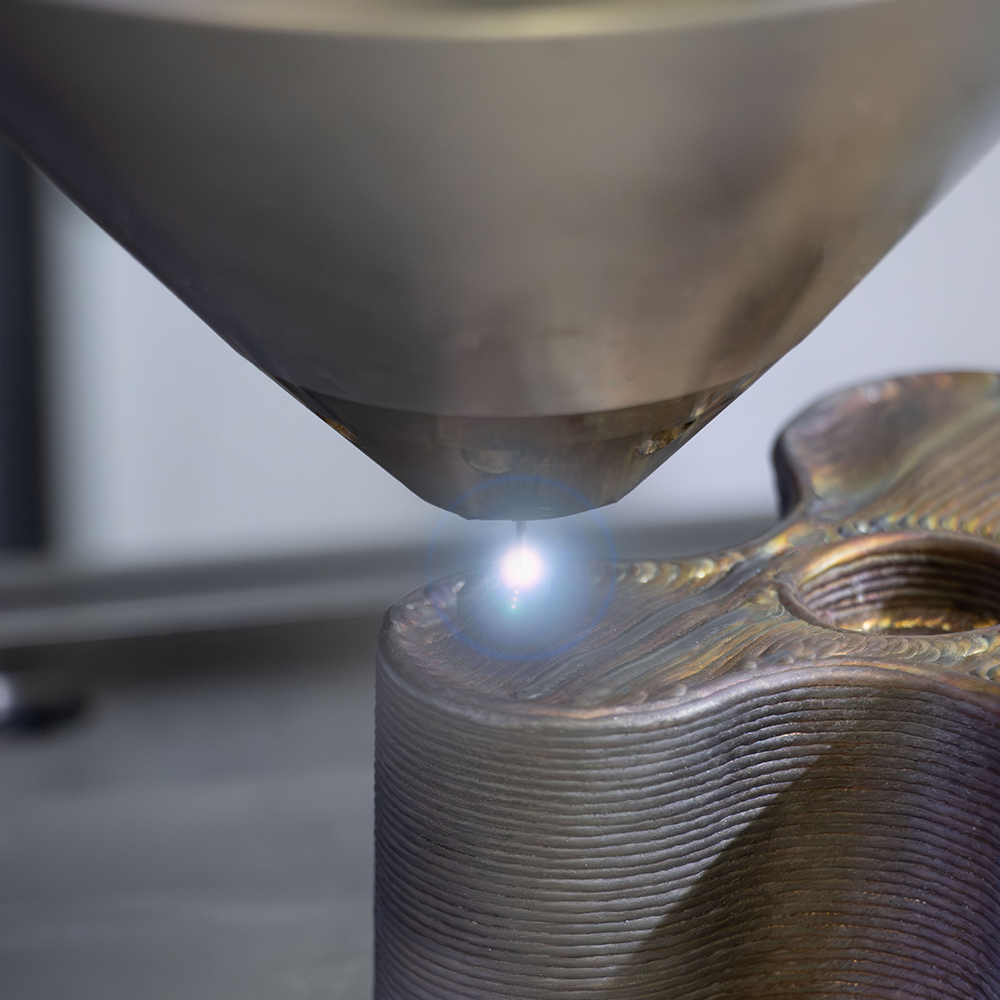

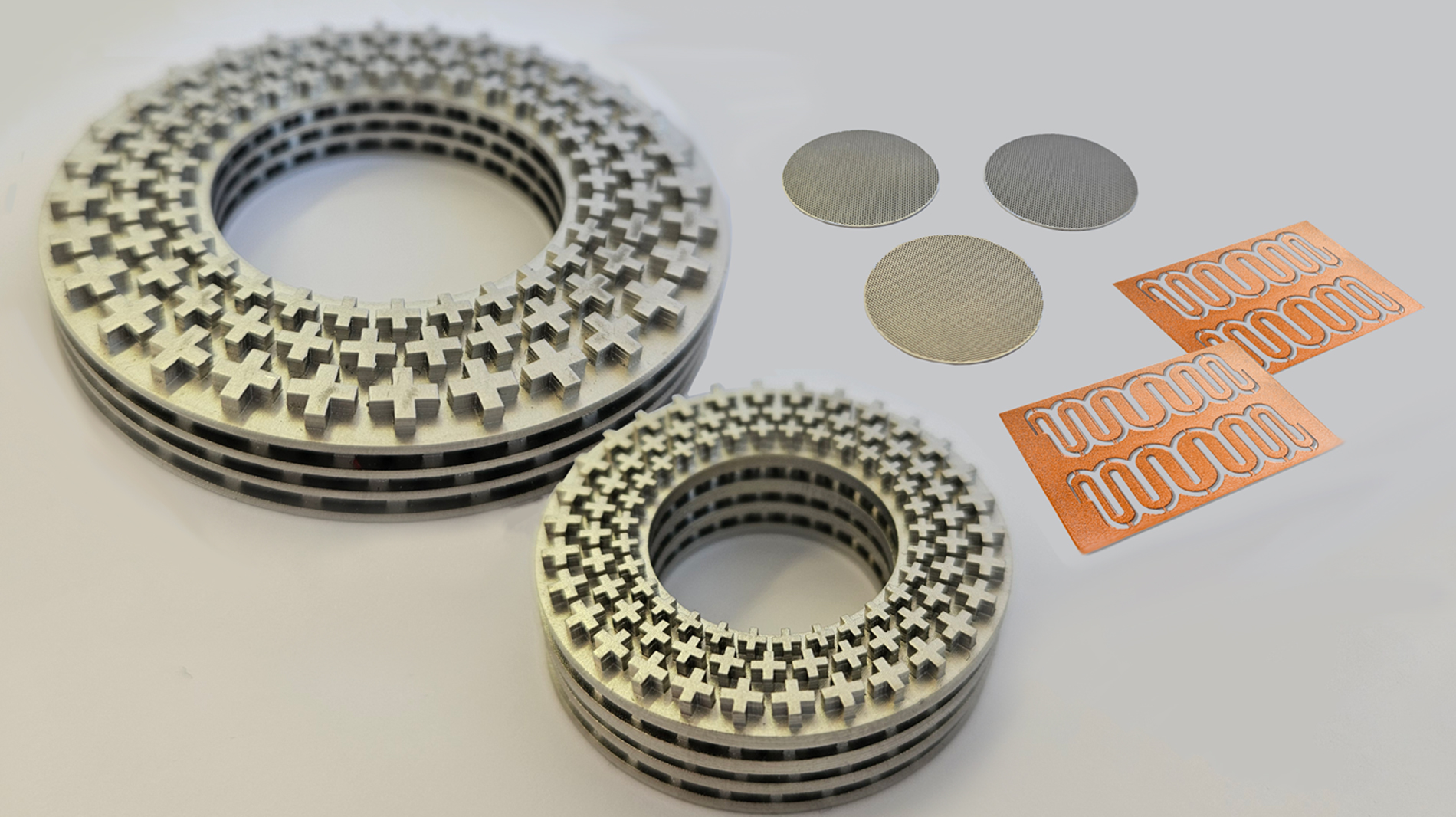

Exentis 3D Mass Customization Technology® is a sustainable AM process. The material in question is efficiently applied layer by layer through screens in the form of paste. The production systems have a modular design and can be flexibly configured for industrial and cleanroom applications. They can produce very small components with ultra-fine structures (web or channel widths of up to 125 μm), but also larger components up to 400 mm in diameter. Additional functions, such as cooling structures or internal channels, can be integrated in a single step without the need for support structures. At the same time, a wide range of materials can be used, including many available powdered materials such as ceramics, metals, active pharmaceutical ingredients, and biomaterials. Exentis will also be presenting new components made of pure copper at Formnext 2025.

In contrast to other AM processes, the company’s technology – which can achieve a production volume of more than five million components or 200 million tablets per system and year – makes true large-scale production possible. This, combined with the tremendous design freedom Exentis affords and Ra values of up to 2 micrometers, is exceptional in the world of AM.

Further information:

Exentis at Formnext 2025: Hall 11.0, Booth C38