A desktop 3D printer is a compact, (relatively) affordable, plug-and-play AM system designed to be operated in an office, studio or light workshop environment. Unlike large industrial machines, you won’t require three-phase electricity, specialised HVAC systems and acres of space for ancillary equipment. While the desktop definition used to be applicable to a handful of systems and effectively a single technology class, today the field is far broader.

FDM-based desktop systems remain the mainstay for the consumer and hobbyist user. In commercial and industrial settings, however, FDM/FFF is joined on the ‘desktop’ by SLS, SLA, binder jetting and even metal systems.

Familiar adoption drivers

Much like the rest of the 3D printing ecosystem, developments in four key areas are driving the adoption of desktop 3D printing in commercial and industrial applications:

Speed — FDM/FFF-based desktop systems have become far quicker than their predecessors thanks to advances in throughput and motion control. A 3DBenchy that would have taken ~60 minutes to complete in 2015 can be printed in ~15 minutes with stock commercial machines today.

Automation — The desktop 3D printer is the building block of the print-farm, an infinitely scalable production system thanks to workflow automation. The Formlabs Automation Ecosystem automates part removal and starts the next job without intervention. Bambu Labs has free software — Farm Manager — that allows local network control of multiple printers.

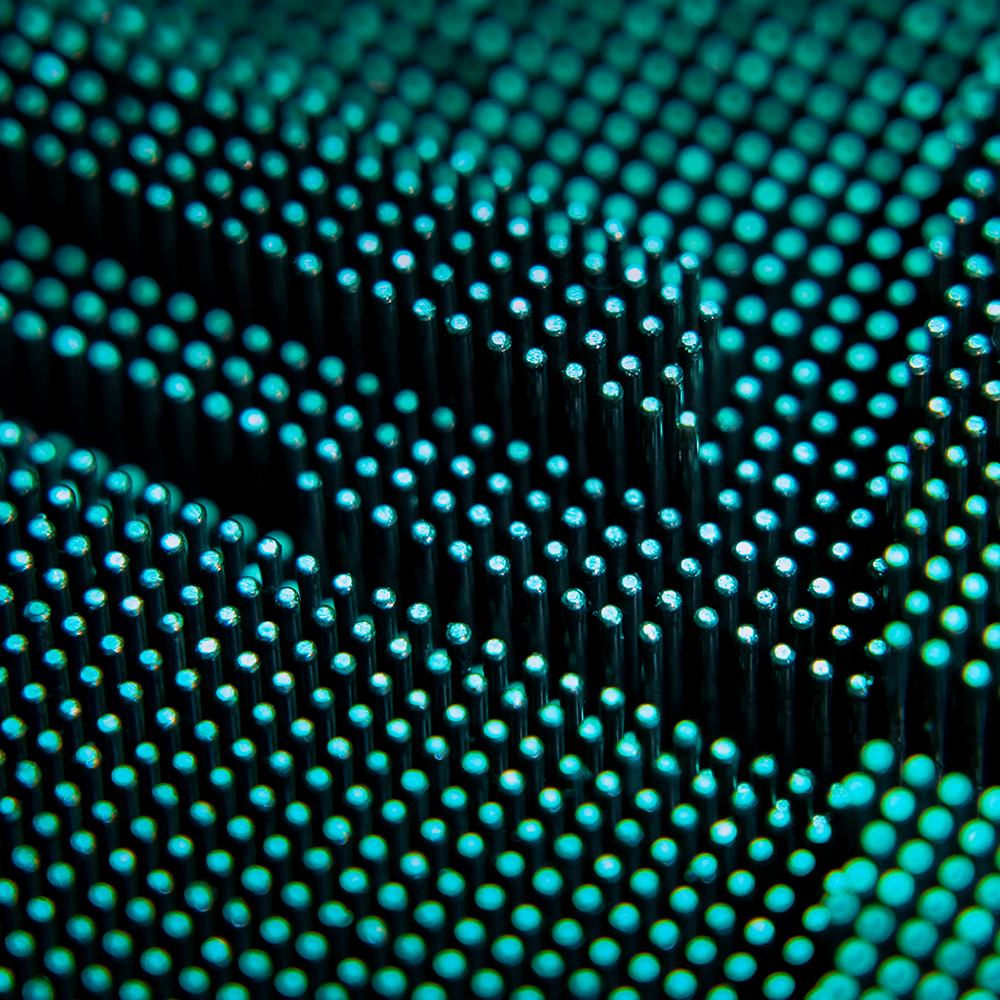

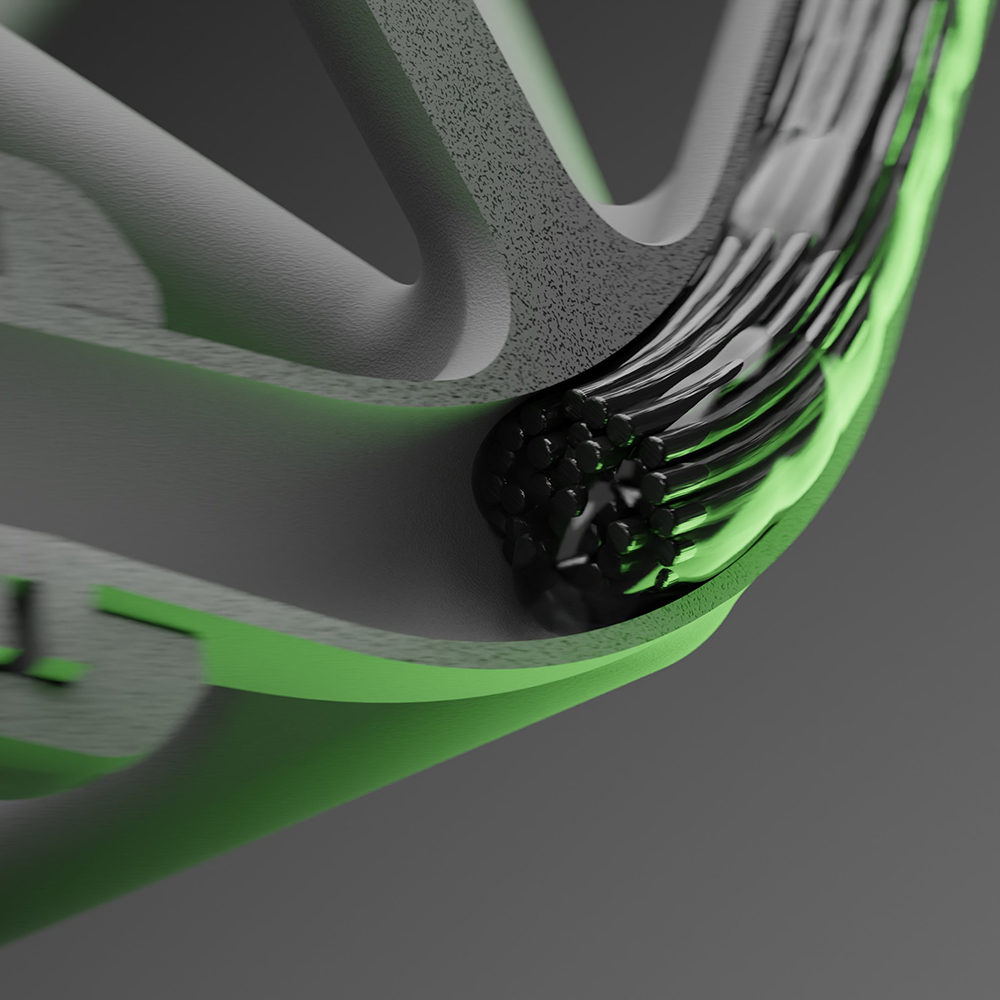

Materials — Multi-material parts, multi-colour parts and parts in high-performance materials have greatly opened up the opportunities for desktop 3D printing within industry. While systems like the Stratasys J35 Pro push the cost envelope, they do tick the boxes of true multi-material parts in an office-friendly package. FDM/FFF-based multi-colour and multi-material options are now widely available, making functional prototyping easier to reach. High-performance materials are increasingly commonly offered by lower-cost, office-friendly systems. Carbon-fibre reinforced nylon can replace metal parts for jigs and fixtures. With nozzle temperatures exceeding 300°C, heated chambers and tuned profiles allow for polycarbonate, nylon or even PEEK and PEI alongside traditional PLA and ABS materials.

Usability — encompassing advances in safety, reliability and ease of use — has moved desktop 3D printing significantly away from the trial-and-error of early systems. Print monitoring using latest-generation sensors and AI (see Bambu Lab’s and Creality’s AI-powered LiDAR systems) improves quality dramatically, brings failure rates down and reduces the burden of expertise on the user.

Closed-loop air filtration, as seen in the UltiMaker S7 and others, alongside better noise damping and tidier setups make desktop systems more at home in the office and easier to live with day-to-day.

Widespread utilization

It is no surprise, given the significant advancements in speed, reliability, materials choice and usability, that this class of 3D printer is seeing significant uptake in usage. Ford Motor Company has demonstrated how harnessing multiple technologies — namely SLA and SLS — in the Formlabs Form 4, 3L and Fuse systems has allowed it to prototype more quickly, create parts for mechanical testing and 3D print inserts for injection moulding to reduce lead times from 2–3 months to 2–3 weeks.

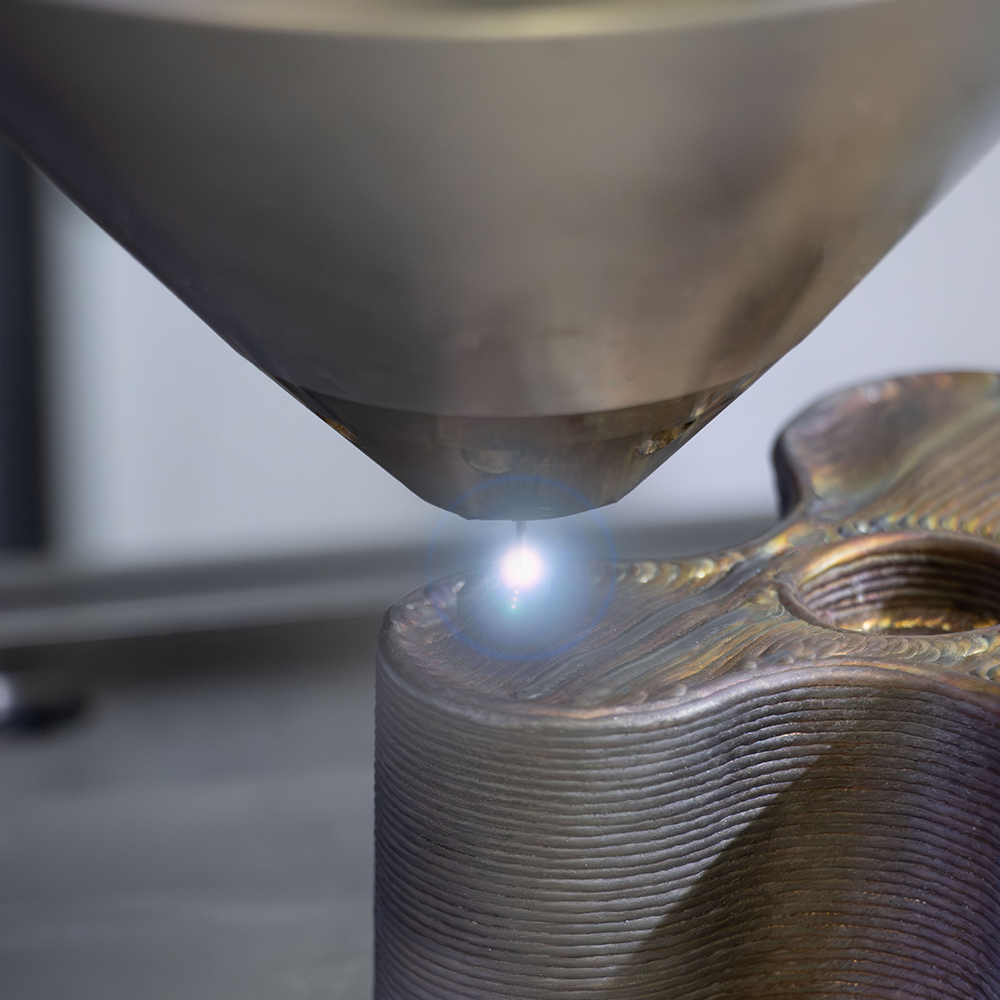

Alstom has a global network of 3D printing hubs, opening up on-demand spare parts to its global user base. While the company offers a mix of technologies, desktop systems feature prominently. Indirectly, they have pioneered the use of metal FDM/FFF for spare parts through service provider Replique, using BCN3D’s Epsilon W27 desktop 3D printers.

Desktop 3D printers are being put to use producing jigs and fixtures across all manner of manufacturing application areas, in virtually all vertical industries.

The future on the desktop?

Not all parts are desk-friendly in size, of course, but a huge proportion of parts and assemblies across all industries would comfortably fit within a desktop machine. As the technology advances and opens up ever-quicker and more capable systems, with materials that match or exceed those already available, desktop systems will surely continue to push the boundaries in terms of their real — and of their own — definition.