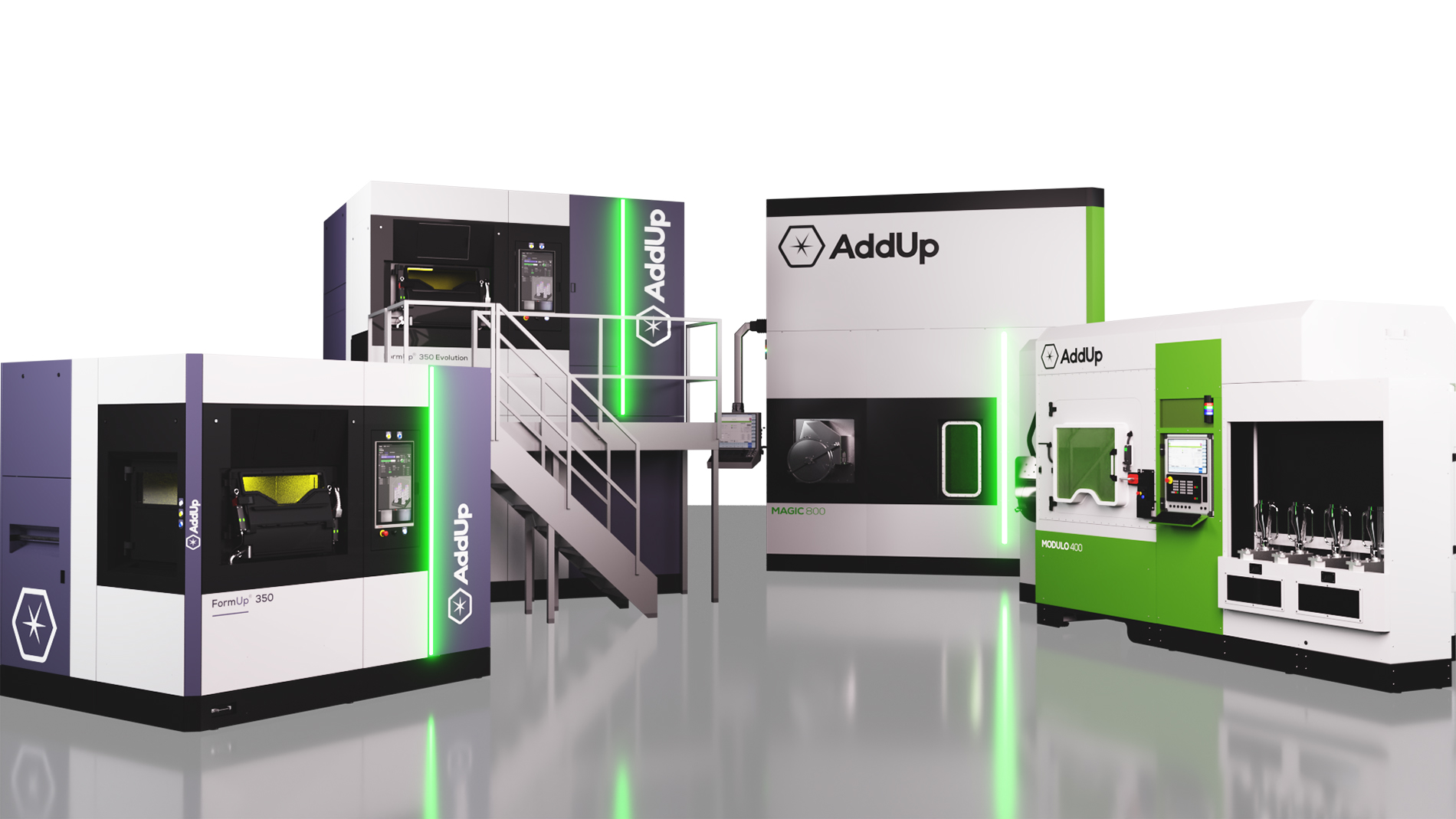

Industrialization is at the core of AddUp’s strategy. Its machines are engineered for robust real-time process monitoring, seamless integration into factory environments, and safe powder management. AddUp also stands out for its leadership in fatigue resistance, ensuring critical parts meet the highest durability standards, and for delivering best-in-class surface finish. This combination enables manufacturers to move beyond prototyping toward full-scale production of critical components. AddUp’s LevelUp services further support this transition, guiding customers from proof-of-concept to qualification and serial manufacturing.

The company will also present progress on MASSIF, a »France 2030«-backed project aimed at producing large-format metal parts with initial build volumes of 750 × 750 × 1,000 mm. Still in development, MASSIF tackles major challenges such as thermal management, distortion control, and process stability at scale. Its ambition is to enable cost-effective production of structural components for aerospace, heavy tooling, and defense systems: applications where size and reliability matter. With proven PBF and DED platforms, strong industry partnerships (such as Dassault Aviation, Thales, SOGECLAIR and major medical groups) and a clear roadmap for large-format production, AddUp is shaping the future of industrial metal AM.

Further information:

AddUp at Formnext 2025: Hall 11.0, Booth D32