Reading time: 5 minutes

Moi Composites: robot-assisted hybrid platform for composite materials

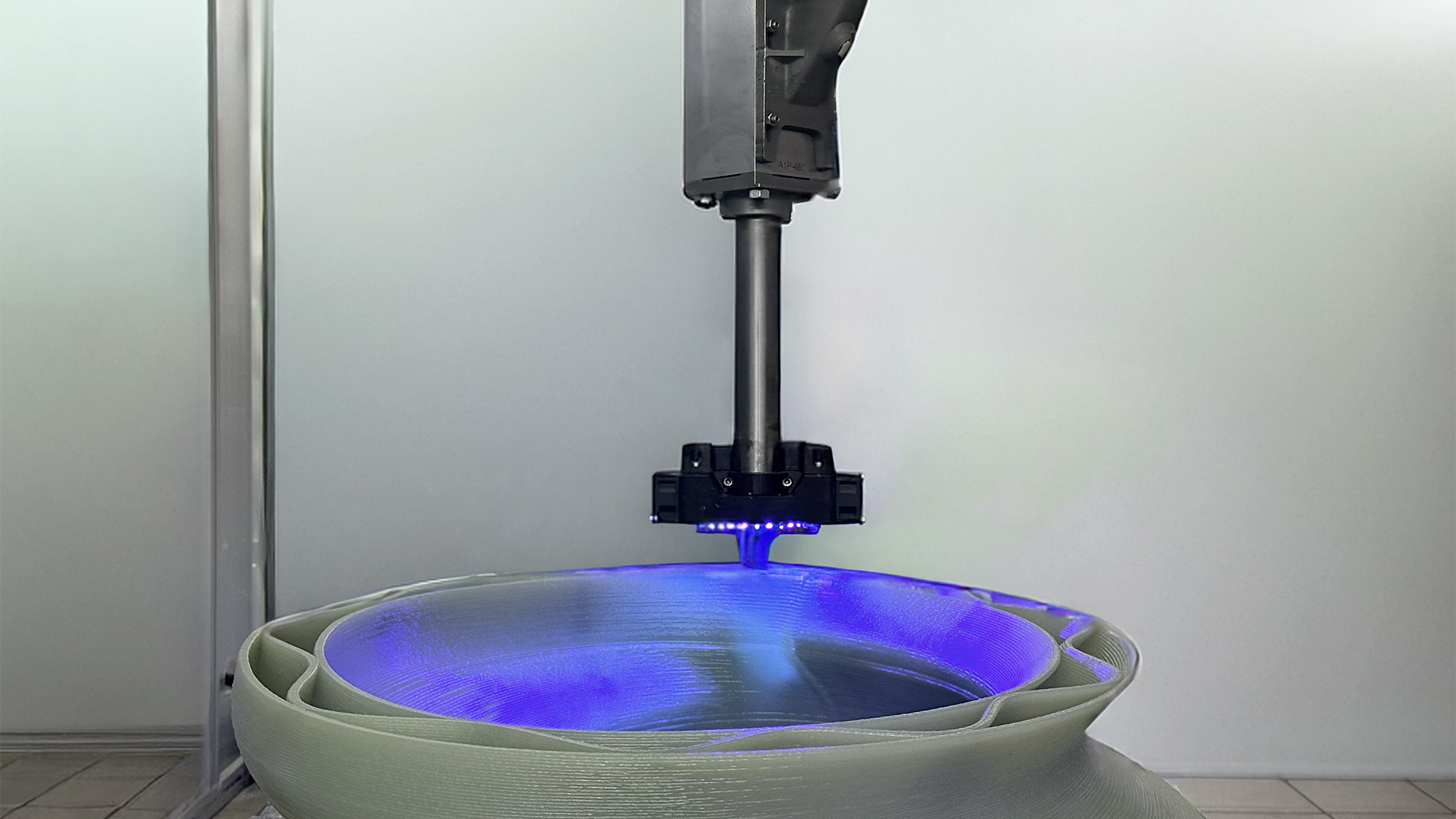

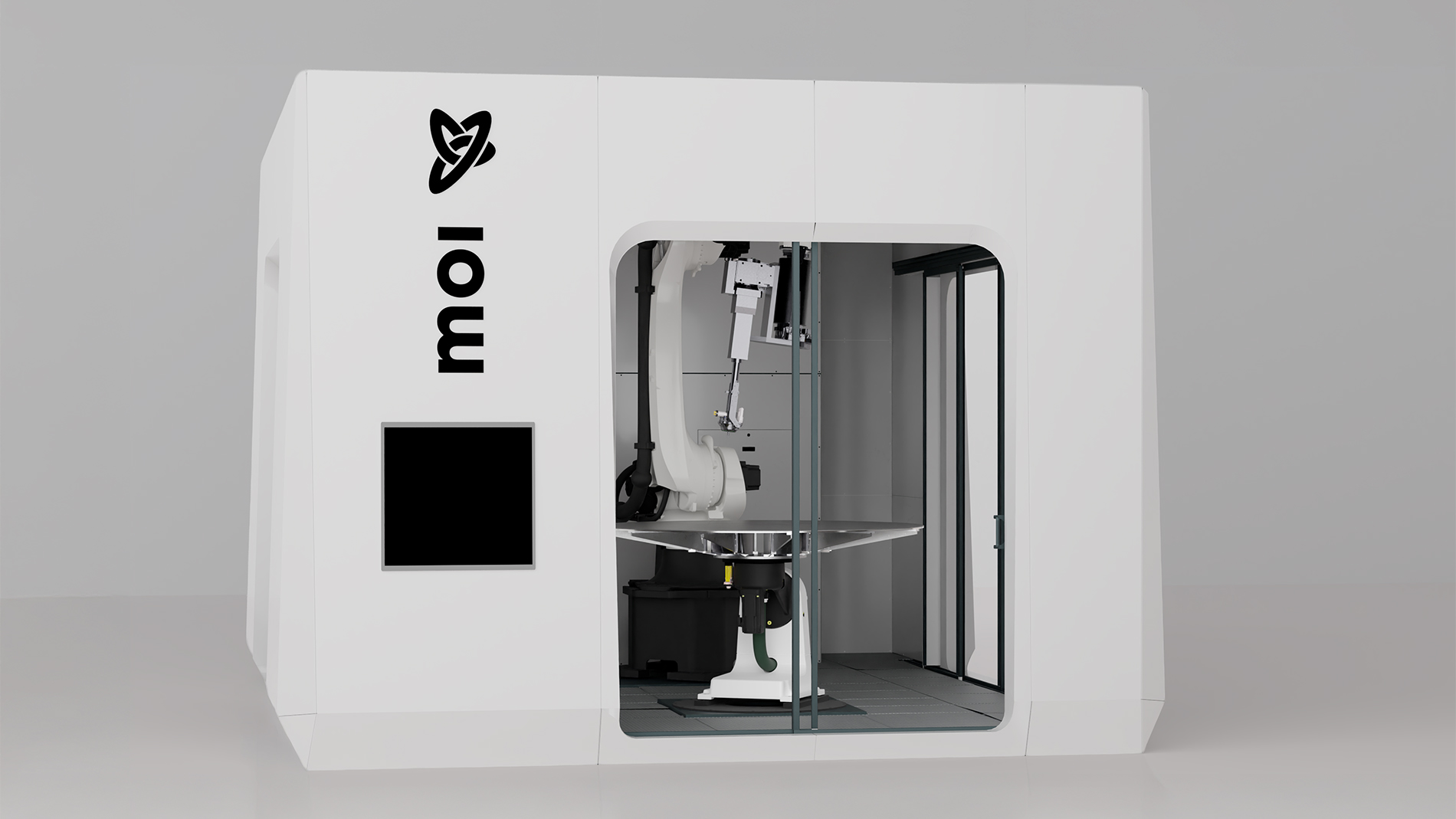

With the support of the EIC Accelerator program, Moi Composites has developed the HPF series, a robot-assisted hybrid platform for composite production. Designed as a modular plug-and-play solution, the HPF series integrates two new AM technologies and conventional machining in a digitalized manufacturing environment. The platform supports two important additive processes developed by Moi Composites. Continuous Fiber Manufacturing (CFM) enables the processing of thermally cured composite prepregs with high fiber content, which in turn facilitates the production of lightweight structural parts with optimized mechanical performance. Short Fiber Manufacturing (SFM), meanwhile, was developed for the processing of thermosetting pastes that are reinforced with short, dense fibers. This technology is particularly suitable for tools, molds, and components that require high rigidity and good machinability. A milling head is integrated alongside these additive processes. The HFP series offers a maximum coating speed of 100 mm/s.

Moi Composites at Formnext 2025: Hall 12.1, Booth C82

3Deus Dynamics: eliminating support structures affords new freedom in production

By replacing support structures with a granular medium that acts as a reusable adaptive mold, 3Deus Dynamics says it has achieved a new level of freedom in manufacturing – one that makes it possible to print standard injectable silicones in complex geometries with mechanical accuracy. Its patented Dynamic Molding Process has proven its efficiency for the first time in the healthcare sector by producing biomimetic silicone models to serve as functional organ replicas. These models, which offer a preclinical alternative to animal experiments, support surgical planning, simulation, and training. The aerospace and defense industries, meanwhile, require components over one meter in size that are manufactured at industrially compatible prices. To meet this challenge, 3Deus Dynamics is scaling up through collaborative, multi-axis robotic 3D printing, which it has integrated into its I-Demo project (part of the France 2030 investment initiative). The project was funded in 2025. This new generation of 3Deus Dynamics devices combines the flexibility of dynamic molding with the precision of cooperative robot arms that can execute complex tool paths in parallel.

3Deus Dynamics at Formnext 2025: Hall 11.1, Booth C78

Nevo3D: open FDM system for large-format printing

In the N200, Austria’s Nevo3D has presented its latest flagship model: an FDM 3D printer for industrial applications. The N200 was developed as an open system specifically for large-format printing and the series production of functional parts. It offers a 200-liter build space that can be heated up to 100° C. According to Nevo3D, this means that large-format components measuring 800 × 500 × 500 mm can be produced economically and with minimal deformation, including when using high-performance plastics. Thanks to its twin nozzles, the N200’s IDEX (Independent Dual Extruder) system offers both series production and the ability to work efficiently with support structures. The manufacturer also claims that the unit’s new "belt-free" drive technology significantly improves surface quality. In addition, the new Revo high-flow nozzle can be used to print a variety of engineering plastics, from highly versatile ABS to fiber-reinforced PC-FR. The N200 comes standard with fully automatic Z0 calibration and sensor-supported bed measurement based on 2,500 measuring points. A 32-bit processor keeps the system running smoothly at speeds of up to 500 mm/s.

Nevo3D at Formnext 2025: Hall 12.1, Booth C119

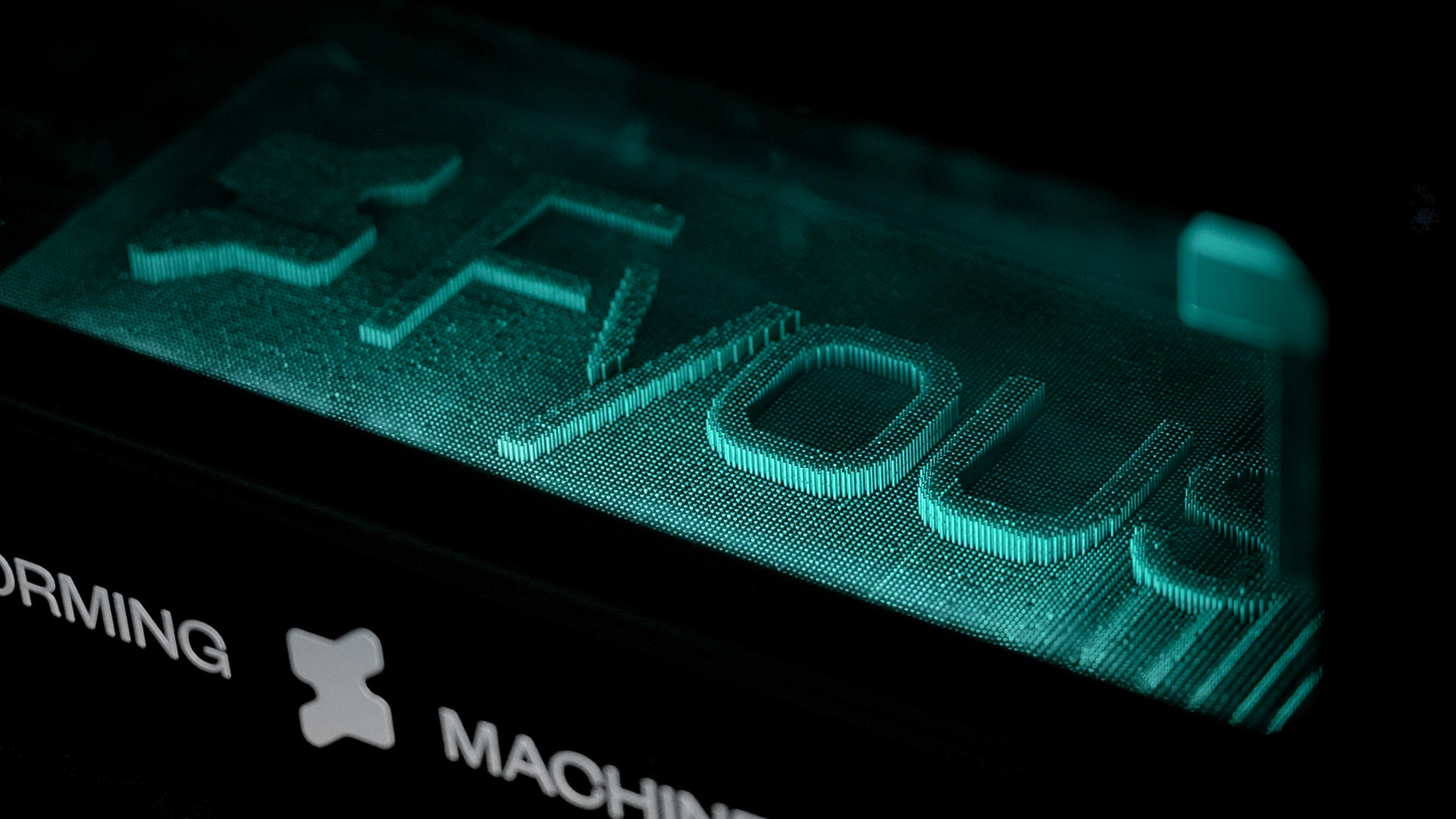

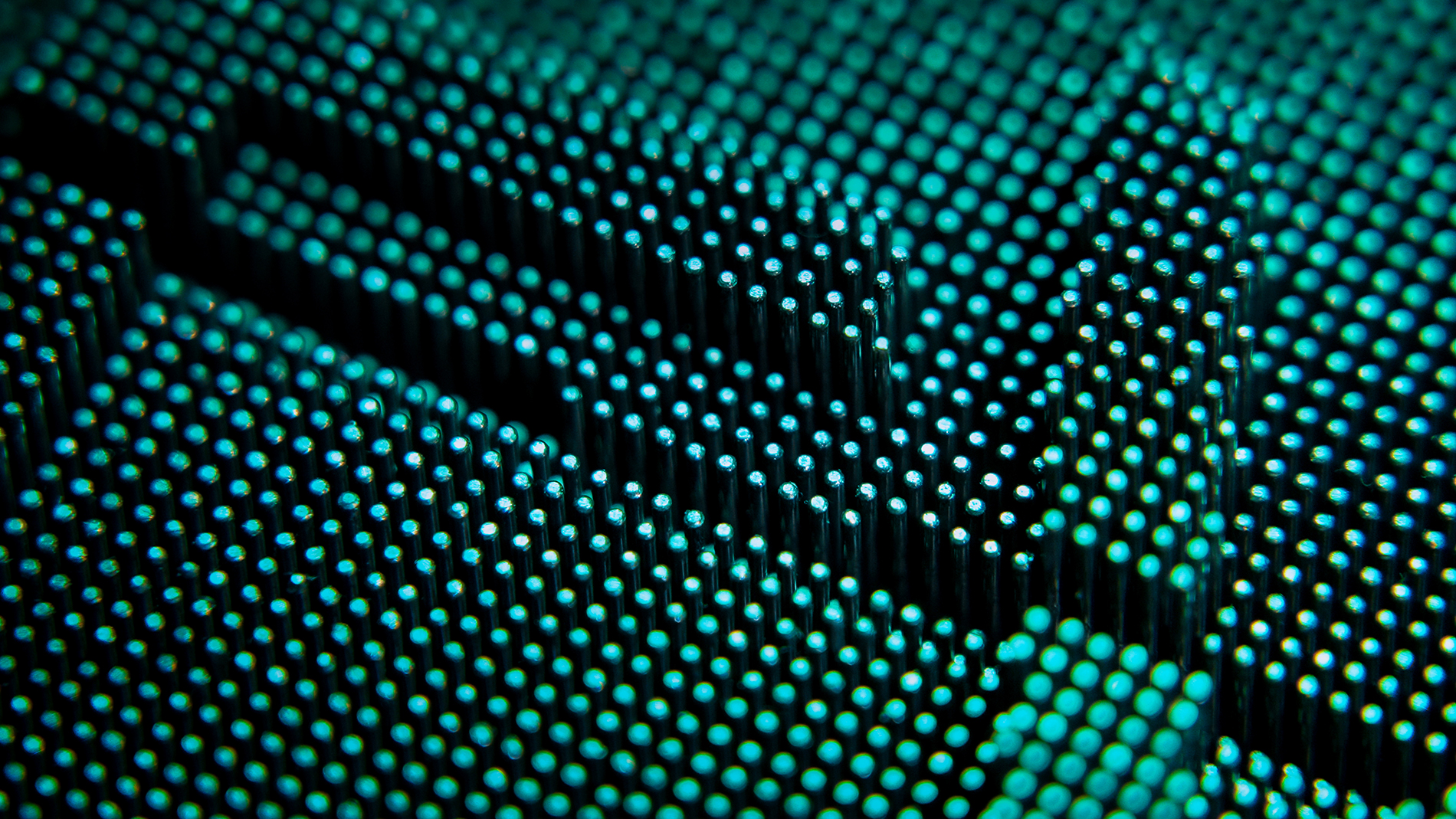

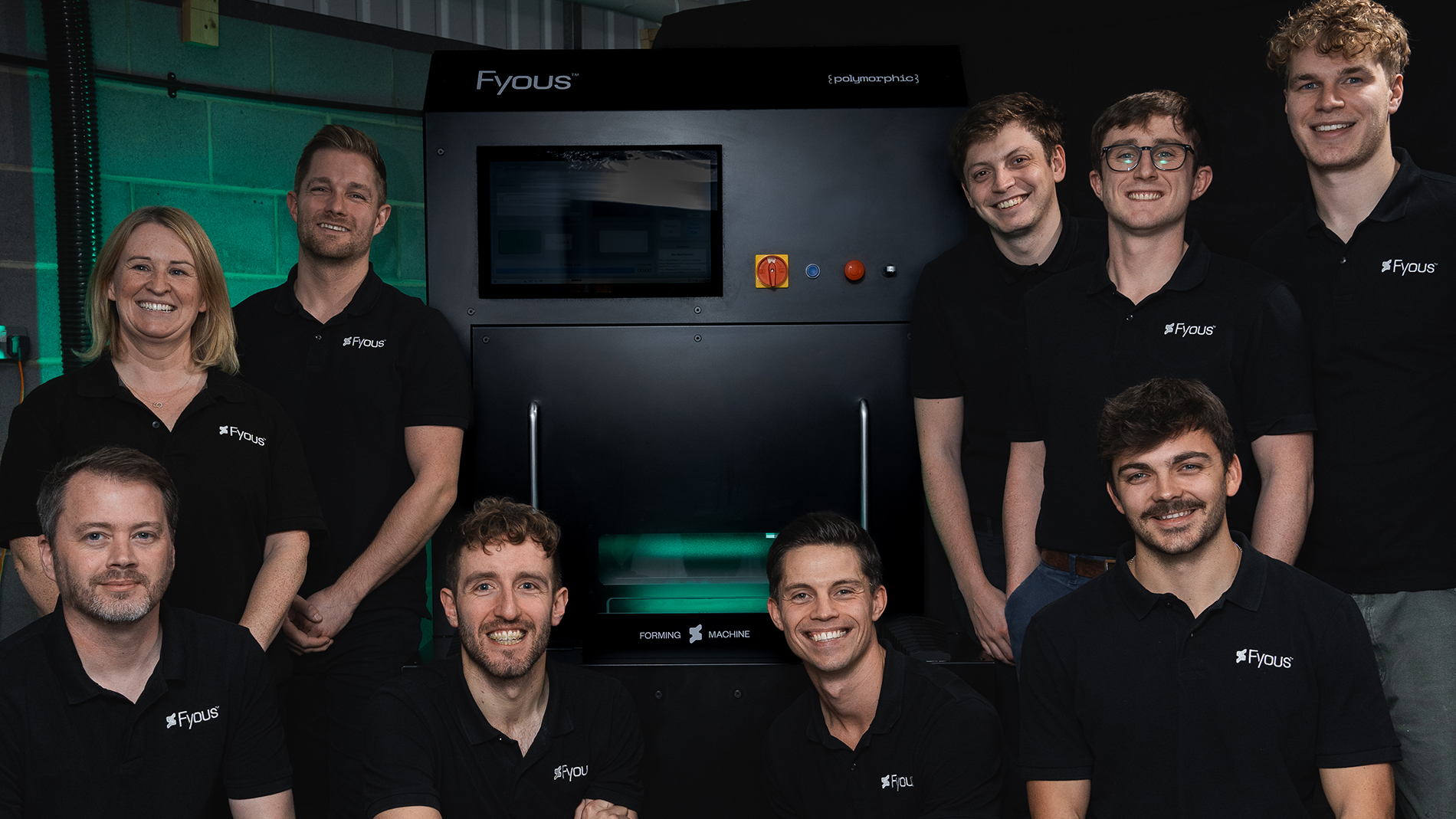

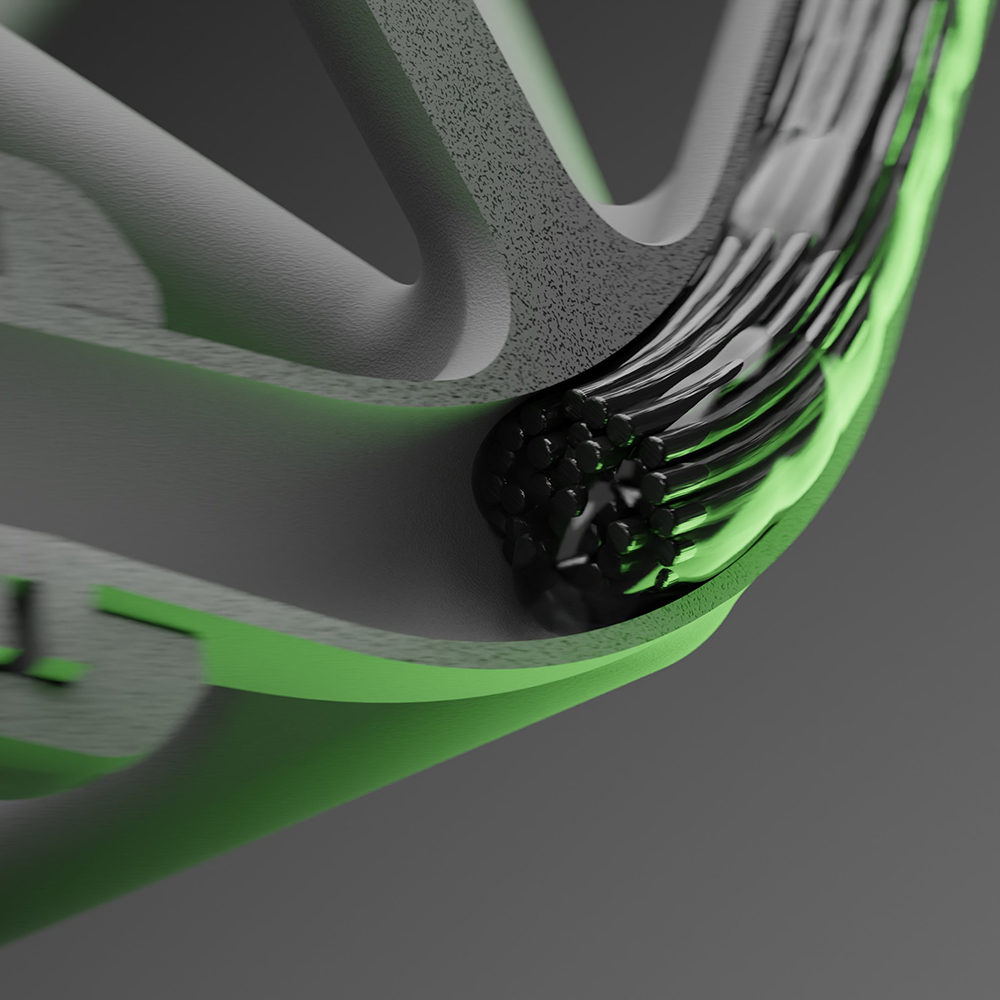

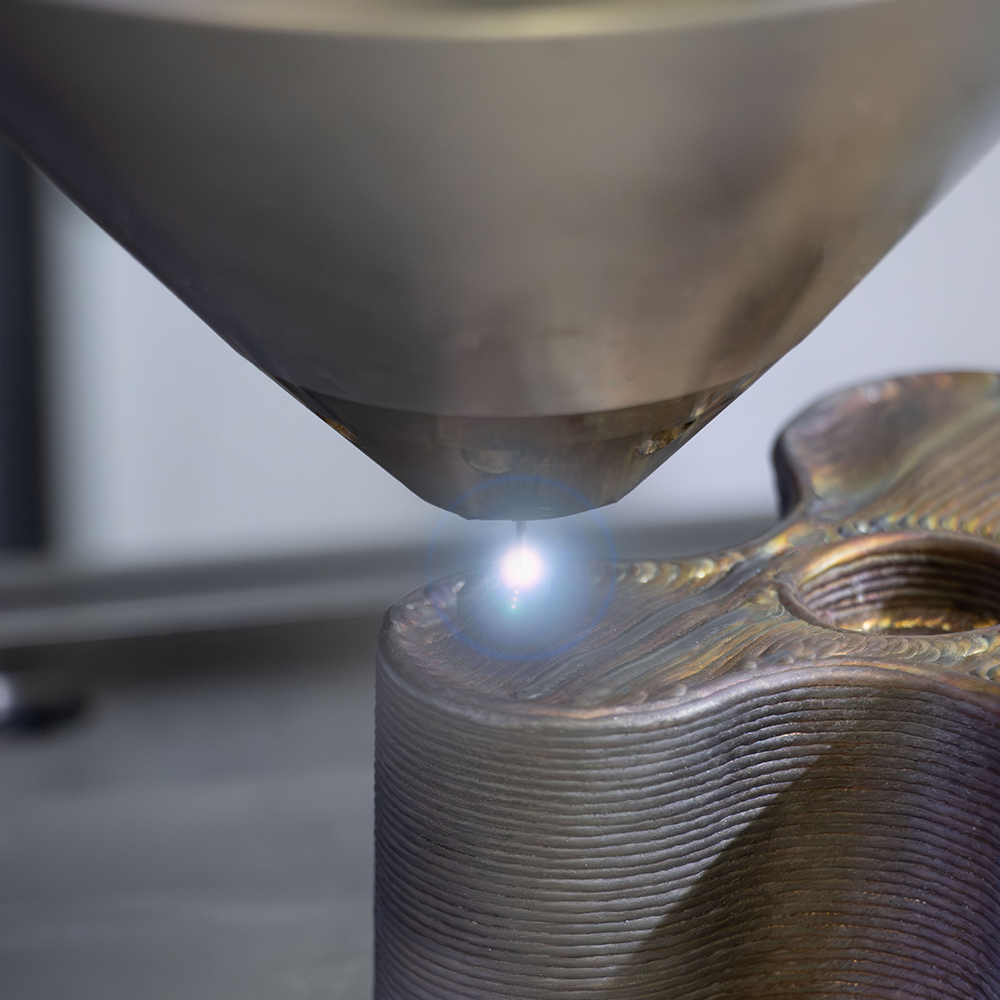

Fyous: reconfigurable molds made of pins

Fyous has created a new field in production: polymorphic manufacturing. The focus here is on polymorphic molding, a process developed by Fyous that uses digitally controlled pins capable of reconfiguring into a virtually infinite number of forms. According to the company, which was founded in 2020 by two engineers in Sheffield (UK), this invention is the first technology to offer both the scalability of traditional molding and the flexibility of Additive Manufacturing. At Formnext, Fyous will publish a white paper on polymorphic manufacturing for the first time anywhere in the world. The paper describes the technical principles, market drivers, and data behind this new area. Also on display for the first time will be footage of the PolyMorphic Moulding (PM-1) system in action on the Fyous production line. The company will also be demonstrating its pin-based molding technology live at its booth on a PF-1 molding machine.

Fyous at Formnext 2025: Hall 11.1, Booth E30

Images: Fyous

Tesseract: linear motors for FDM 3D printers

At Formnext 2025, Tesseract Technologies will present the first linear motors it has developed specifically for FDM 3D printers. In contrast to the belt-driven systems used in most printers today, the Dutch start-up states that linear motors offer a more precise and reliable alternative. Tesseract now wants to make this technology accessible to a wider range of printers. Since 2020, the company has been developing its motors from the ground up, focusing on low costs and control via simple step and direction signals. It is currently conducting pilot programs with several manufacturers of large-format FDM 3D printers.

Tesseract Technologies at Formnext 2025: Hall 11.0, Booth D62A

Gühring: diamond-reinforced nozzle tip for makers

In the Dianoz, Gühring is launching the world's first 3D printing nozzle with a diamond-reinforced tip for makers and home use. According to the manufacturer, patented technology ensures both high print quality and the tip’s high resistance to wear. The Dianoz Pro (which is already available on the market) has a tip made of synthetic black diamond that is said to offer a high level of protection against wear, even when printing abrasive materials. With the less expensive Dianoz, which Gühring is set to launch at Formnext, ambitious makers can experiment with different (and abrasive) filaments. It is also equipped with the patented black diamond tip. In addition to its durability, Gühring says the Dianoz offers an impressive level of surface quality: A specially developed filament channel ensures uniform extrusion, while a special ironing surface smoothes the surface of components during printing. Sporting interfaces for Bambu Lab, Raise3D, and UltiMaker, the Dianoz is also compatible with V6, Volcano, MK8, and Mako(FIN) hotends.

Gühring at Formnext 2025: Hall 12.1, Booth F42