AIM Sweden: New E-PBF system expands machine park

AIM Sweden is the first European contract manufacturer to use Colibrium's Point Melt technology for electron-beam powder bed fusion (E-PBF). Installation of the Colibrium Spectra L system was scheduled for early October 2025. The new Spectra L expands AIM Sweden's E-PBF fleet to six total systems (alongside two Q10plus and three Q20plus units). It will be validated for medical production using Ti6Al4V and optimized for manufacturing complex impellers for the energy sector. Founded in 2016 as a Mid Sweden University spin-off, AIM Sweden specializes in contract manufacturing using E-PBF technology. The company, which maintains ISO 13485 and ISO 9001 certification, has produced over 50,000 medical implants since 2019 and is the innovator behind the FreeFlow tooling solution for sustainable packaging.

AIM Sweden at Formnext 2025: Hall 11.0, Booth D69

Amace: Compact LPBF system for medical technology innovators

Indian company Amace Solutions is excited to present its compact LPBF platform STLR 120, which was developed for research laboratories, universities and competence development, start-ups, tool applications, and medical technology innovators. According to the manufacturer, the system minimizes setup time and powder consumption and accelerates the path from concept to finished part. With a build volume of Ø120 × 200 mm, the STLR 120 is equipped with a 400-W fiber laser that can process layers between 20 and 60 µm. The first build can start with as little as 1 kg of powder, significantly reducing both downtime and powder inventory for rapid iterations. The STLR 120 also supports a wide range of qualified materials, including aluminum alloys (AlSi10Mg), stainless steels (SS316L, 17-4PH, 15-5PH), maraging steel (18Ni300), cobalt-chromium (CoCr), Inconel (IN625, IN718), and titanium alloys (Ti-6Al-4V). The construction process is prepared using Materialise Magics Print LM software. The machine has a footprint of 950 × 1250 × 1750 mm and is powered by single-phase 220 V (50 Hz) with a peak load of 3.7 kW.

Amace Solutions at Formnext 2025: Hall 11.0, Booth F51

BLT: Demonstrating the latest possibilities with metal

For years, the AM world has promised that lighter, faster, and smarter solutions are coming – but BLT aims to offer a different perspective. Under the motto “The Power of Now,” the company will demonstrate what is already possible with metal AM at Formnext 2025. BLT will also present an improved range of printers and devices, various materials, new processes, and innovative parts that create real added value. Among the applications on display will be Earfit's TitanIEMs, the world's first fully customized in-ear monitors made of titanium. Thanks to the acoustic properties of this material, the monitors can meet the high standards of touring musicians and professional sound engineers. Meanwhile, Italian BLT customer Extreme Manufacturing Engineering is changing both rollercoaster rides and hydraulics with metal AM, and BLT's Slovenian customer, HTS, is producing tools for large-scale die casting and plastic injection molding. BLT will also be presenting a new real-time monitoring system and a new process for material handling, as well as the new S400 and S210 metal AM systems and the QF400 for smooth, easy depowdering.

BLT at Formnext 2025: Hall 12.0, Booth D81

Images: BLT

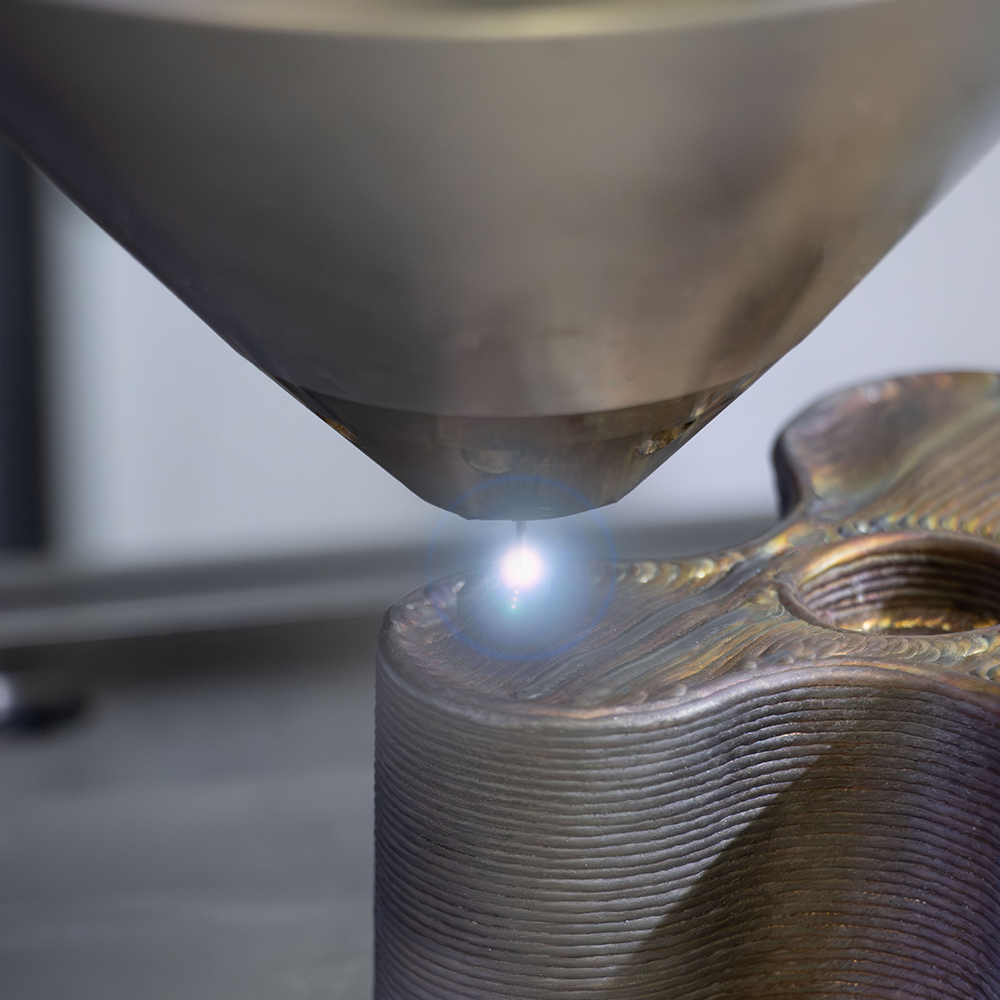

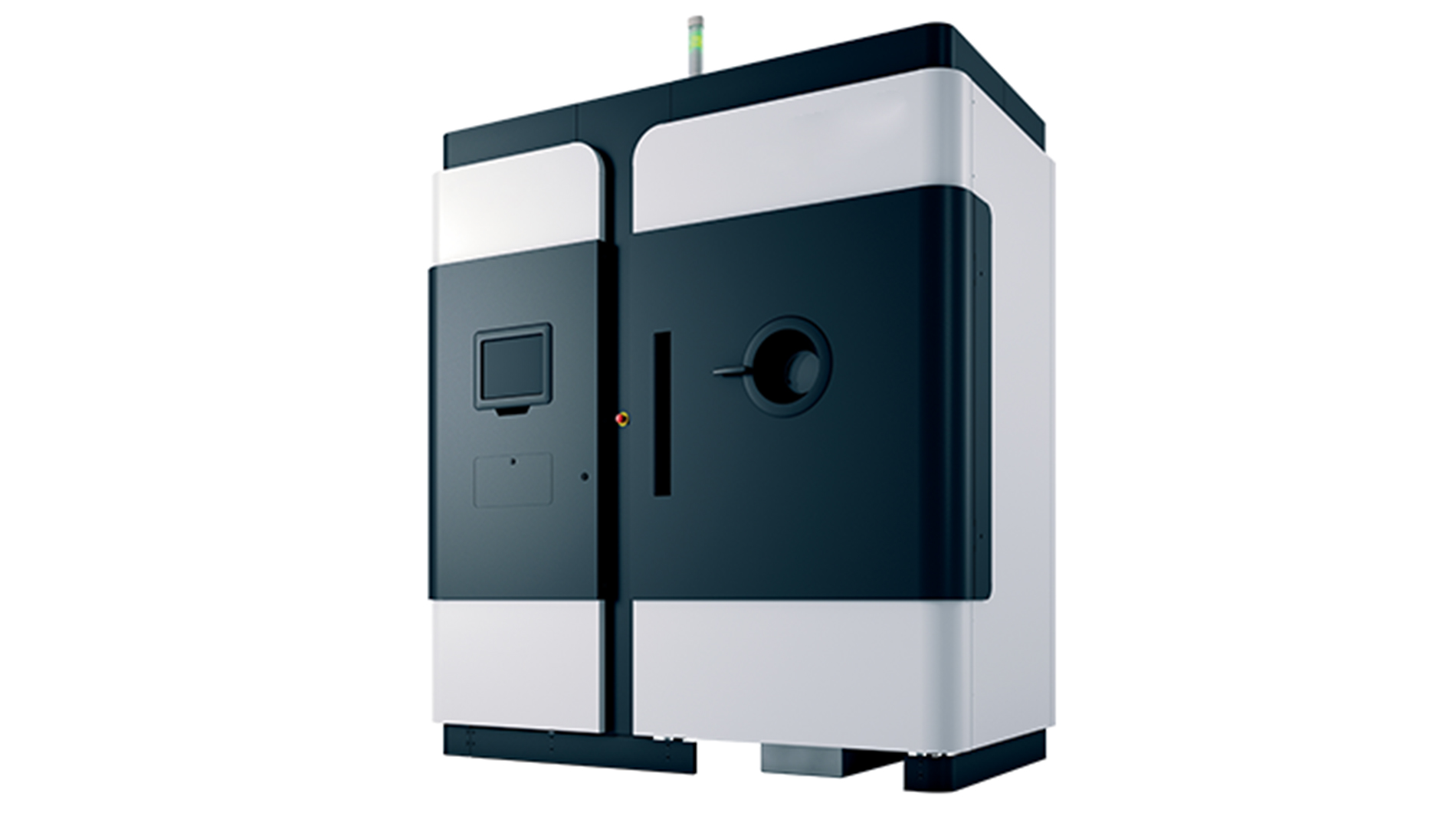

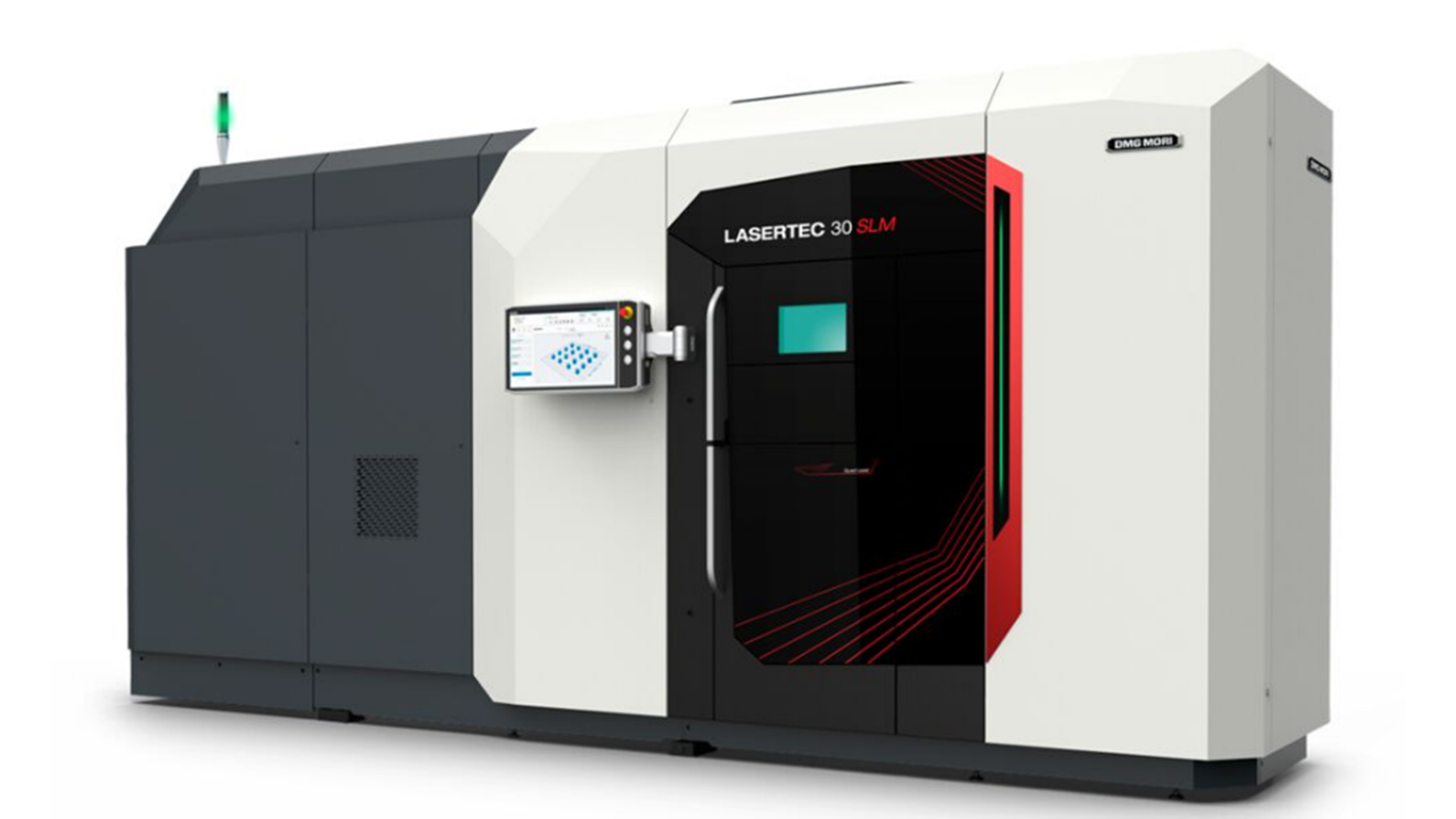

DMG: Technological updates

DMG Mori has continued to develop its Additive Manufacturing machines both for laser cladding, the Lasertec DED hybrid models, and powder bed fusion, the Lasertec SLM series. Controlled component preheating has been implemented in the Lasertec 65 DED hybrid, for example, which minimizes stress and prevents cracks between the base and weld materials. In addition, DMG Mori has expanded the integrated monitoring and safety functions of the Lasertec 30 SLM (third generation). A new feature projects the layer data of the workpiece onto the respective camera image. This makes it easier to assess whether a detected defect actually affects the component or is limited to non-critical areas.

DMG Mori at Formnext 2025: Hall 12.0, Booth D139

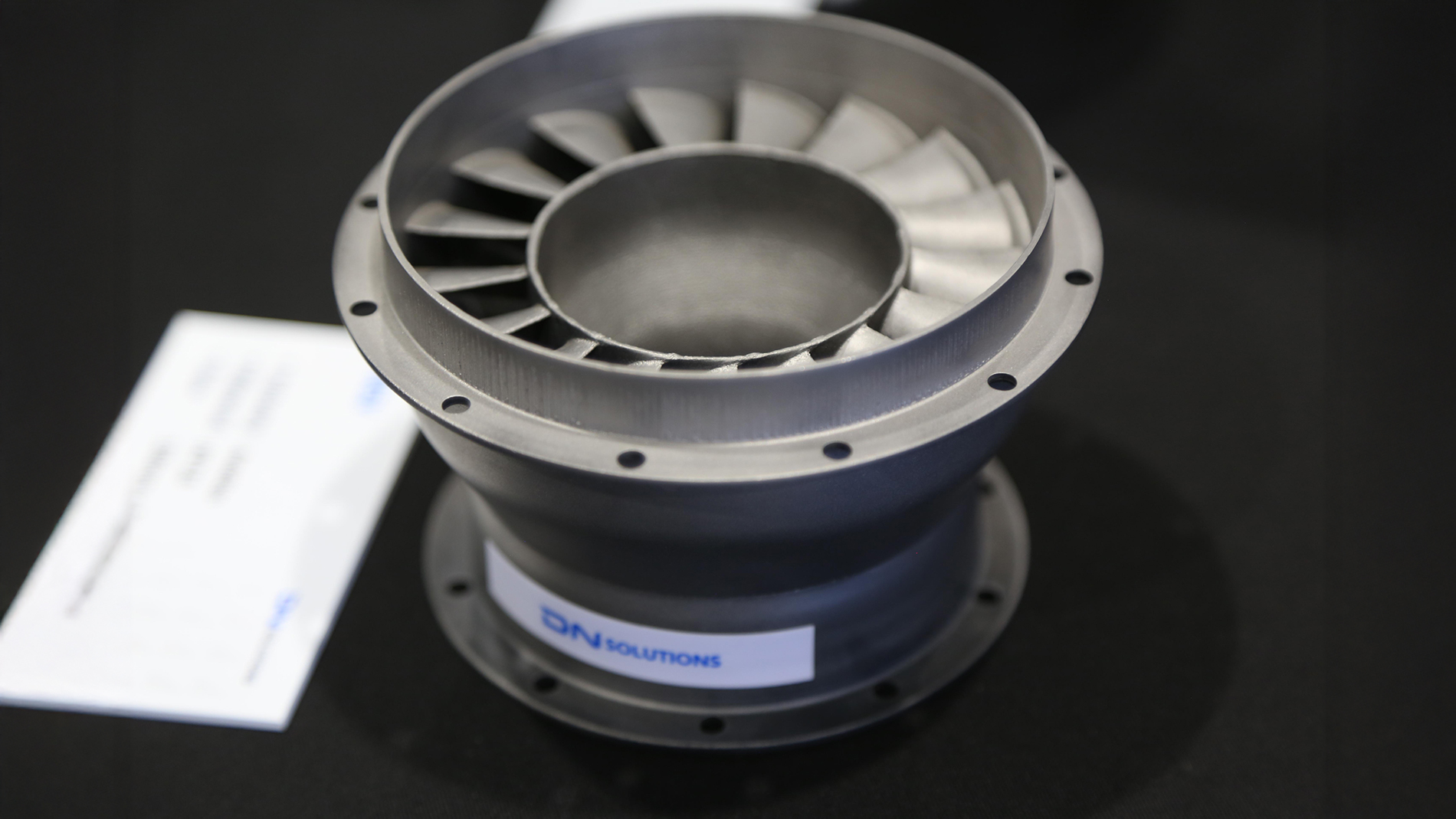

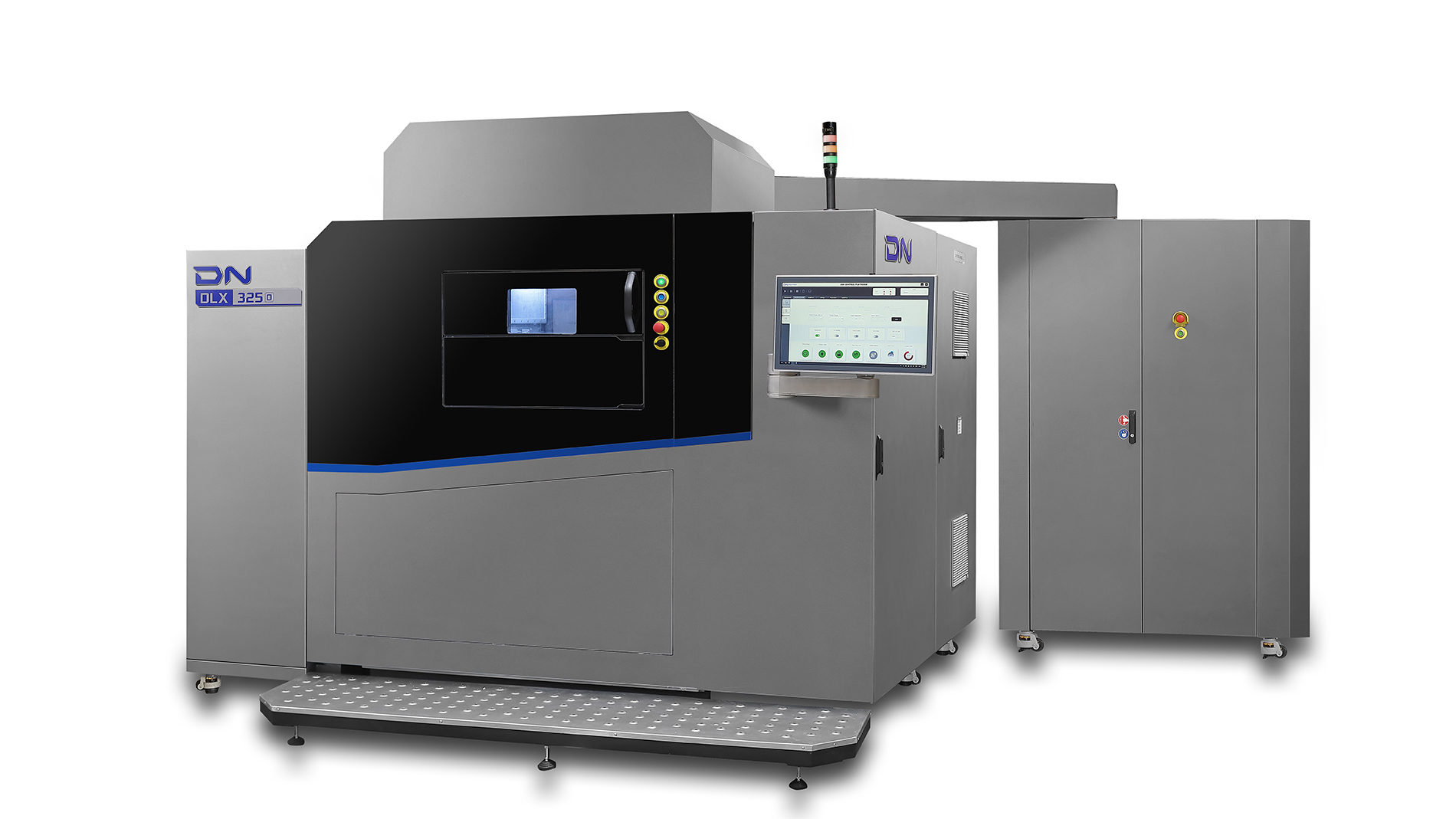

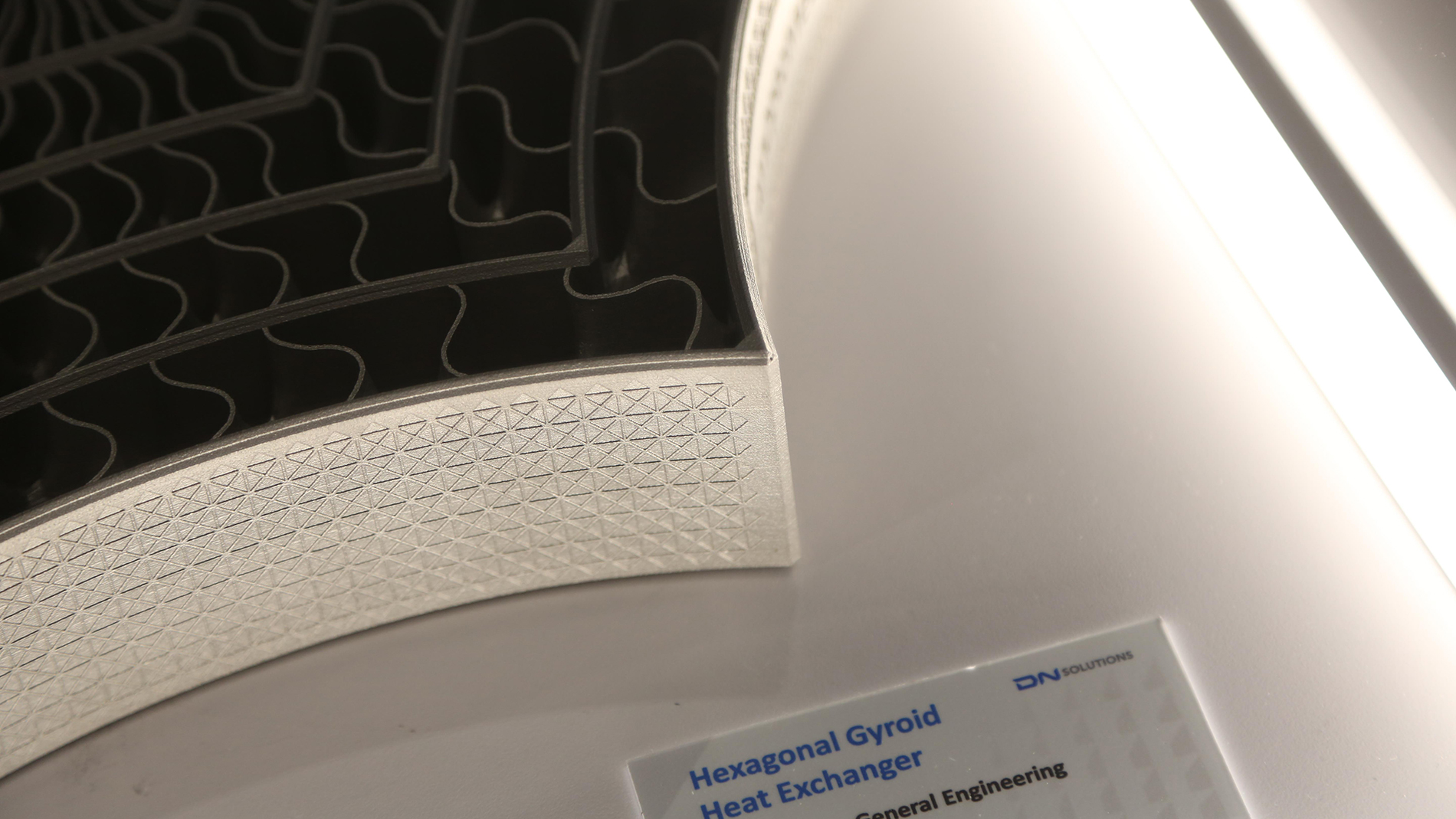

DN Solutions: Symbiosis of metal 3D printing and CNC machining

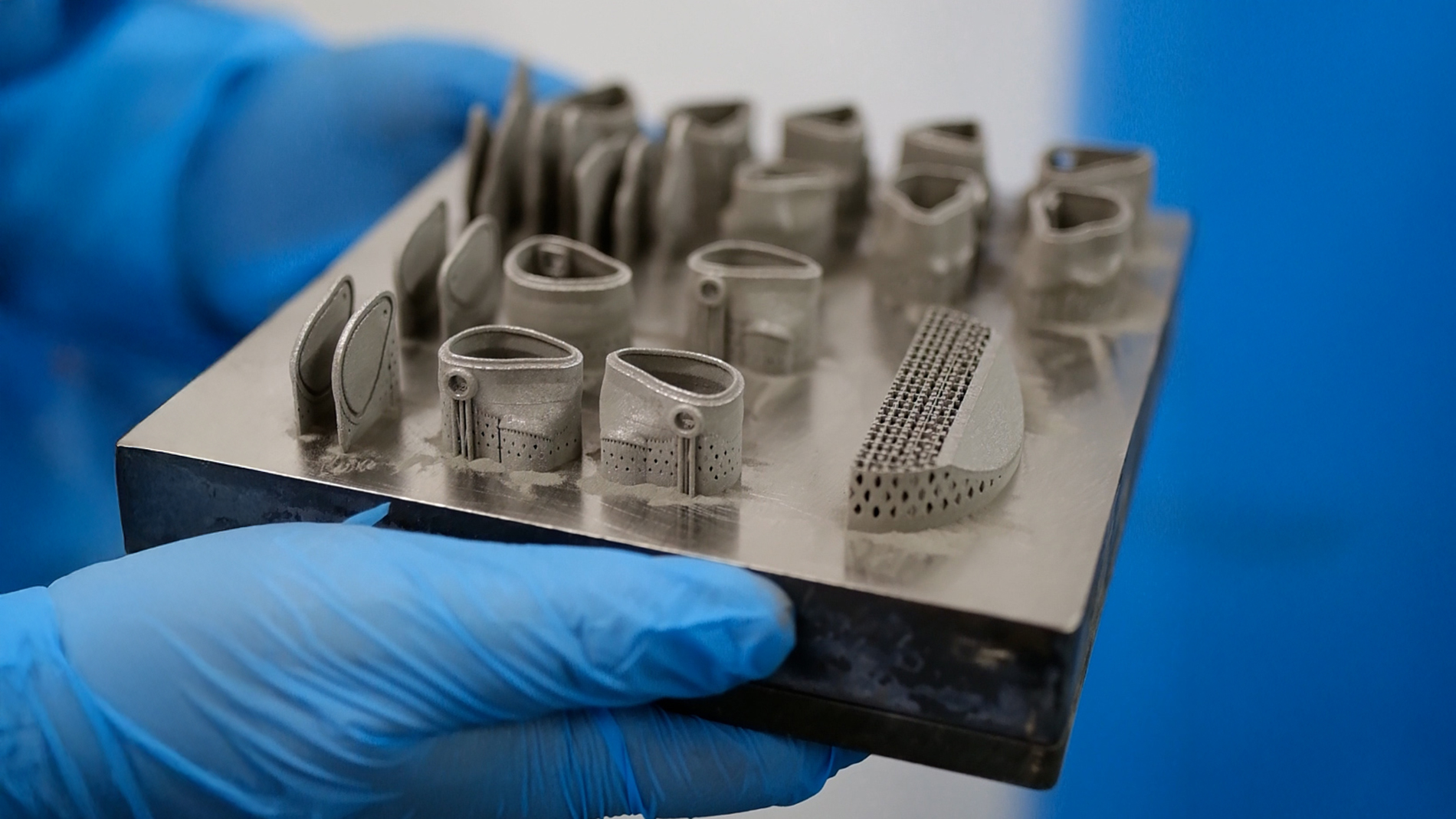

DN Solutions, one of the world's largest machine tool manufacturers, will be exhibiting at Formnext for the first time and presenting its new DLX series together with the proven five-axis CNC DVF5000. This demonstrates how AM and subtractive manufacturing can interact effectively. With the new DLX series – consisting of the DLX150, DLX325, and the high-end DLX450D system – DN Solutions is bringing to market proven powder bed fusion technology in various sizes. The company has also developed its own in-house software for construction job preparation. The resulting end-to-end control over hardware and software makes it possible to flexibly implement customer requirements and tailor Additive Manufacturing specifically to CNC-compatible component preparation. At Formnext, DN Solutions will demonstrate how AM can be introduced into existing production processes. An example workflow begins with additive construction on the DLX450D and continues via an unpacking station to automated pallet transfer. This is followed by CNC finishing on the DVF5000.

DN Solutions at Formnext 2025: Hall 12.0, Booth C61

Images: DN Solutions

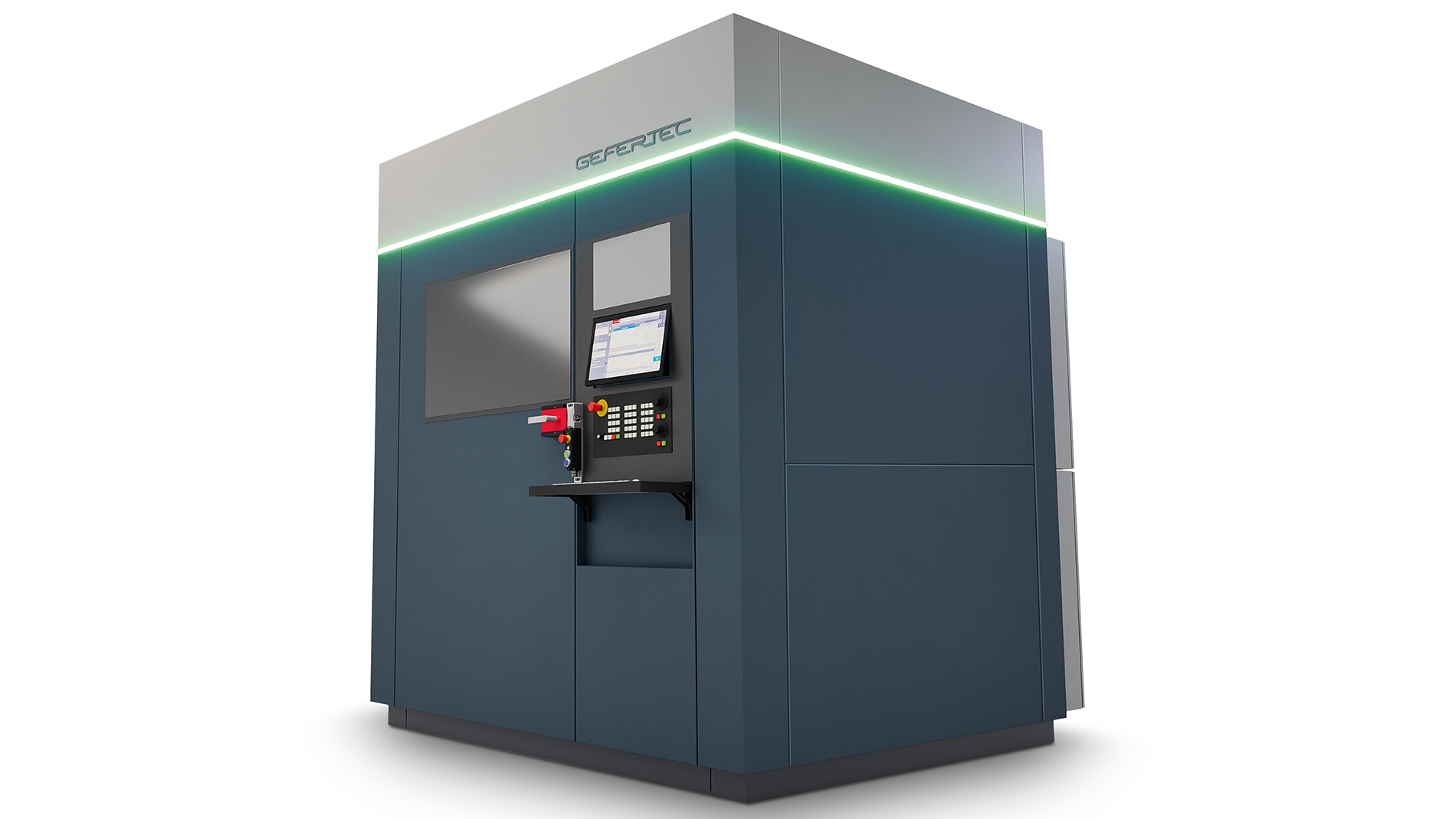

Gefertec: WAAM system for education and research

Having expanded its portfolio with the new ArcLab, Gefertec is now offering a solution that is specifically tailored to the requirements of universities and research institutions. The aim is to make it easier to integrate wire arc Additive Manufacturing (WAAM) technology into education and research. The ArcLab requires approximately five square meters of space and is equipped with the Siemens Sinumerik One control system. The multi-axis CNC system enables the production of components up to 1,200 x 1,200 x 1,200 mm³ made of steel, aluminum, and other alloys. It also features a 42-inch monitor that can display images from multiple cameras and process data live. For research work and student projects, the ArcLab offers comprehensive sensor technology and a process monitor. Three camera systems, a pyrometer, and a gas flow measurement system are integrated, allowing users to record and evaluate process parameters in detail.

Gefertec at Formnext 2025: Hall 11.1, Booth D31

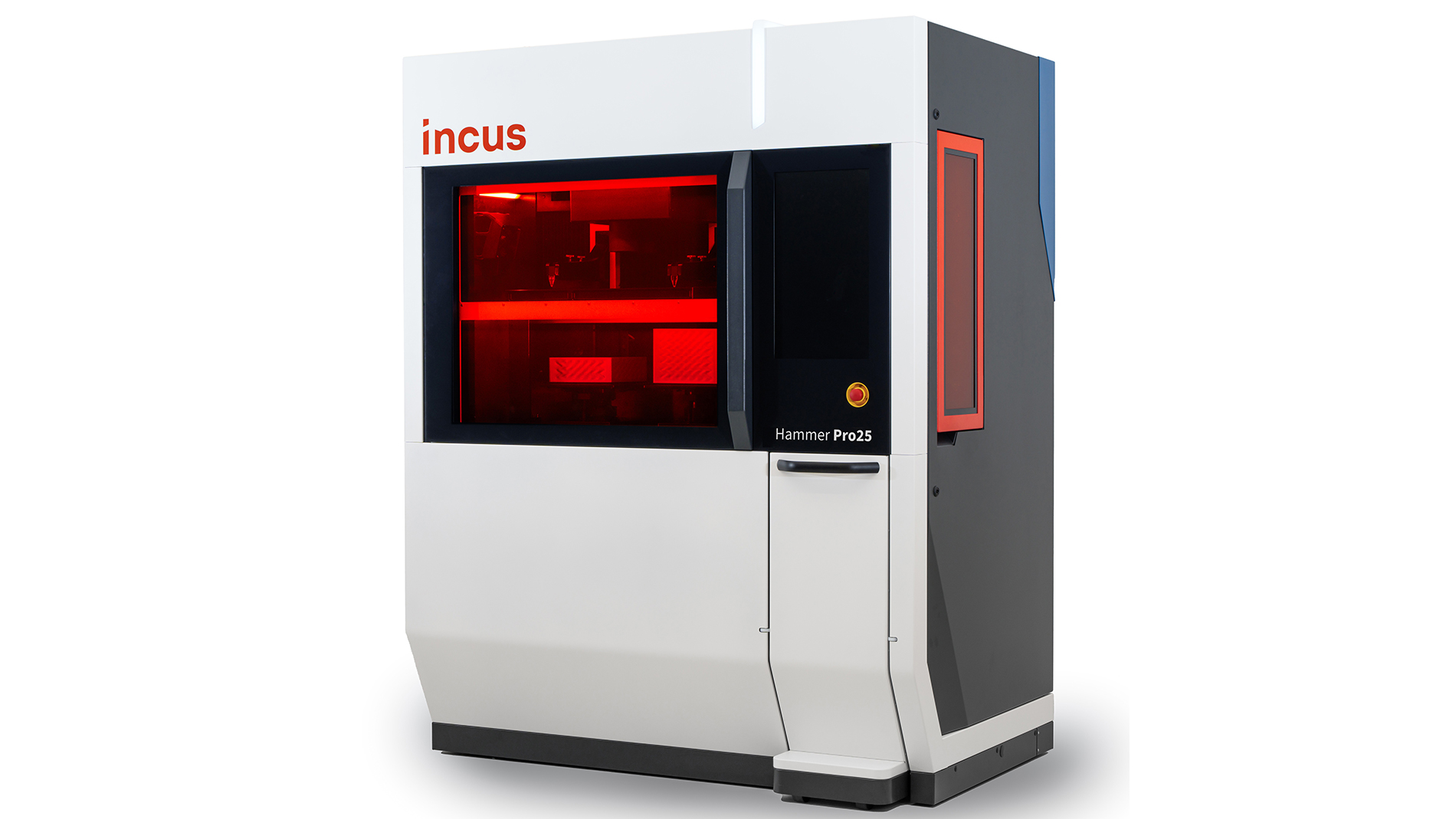

Incus: Large volume, high throughput

With its new Hammer Pro25 machine, Incus GmbH promises new possibilities for the scalability of metal Additive Manufacturing – particularly through the combination of precision, automation, and throughput. The system is designed for 24/7 operation and supports fully automated production (“lights-out manufacturing”). The new machine offers a large build volume of 200 × 204.55 × 140 mm and a material throughput of up to 980 cm³/h with automatic material refilling and removal of finished parts. Two synchronized projectors printing simultaneously on two build platforms enable a resolution of 25 μm lateral resolution and flexible layer thicknesses between 10 and 100 μm. According to Incus, the surface quality after sintering (Ra approx. 2 μm) often eliminates the need for post-processing.

Incus at Formnext 2025: Hall 11.1, Booth E59

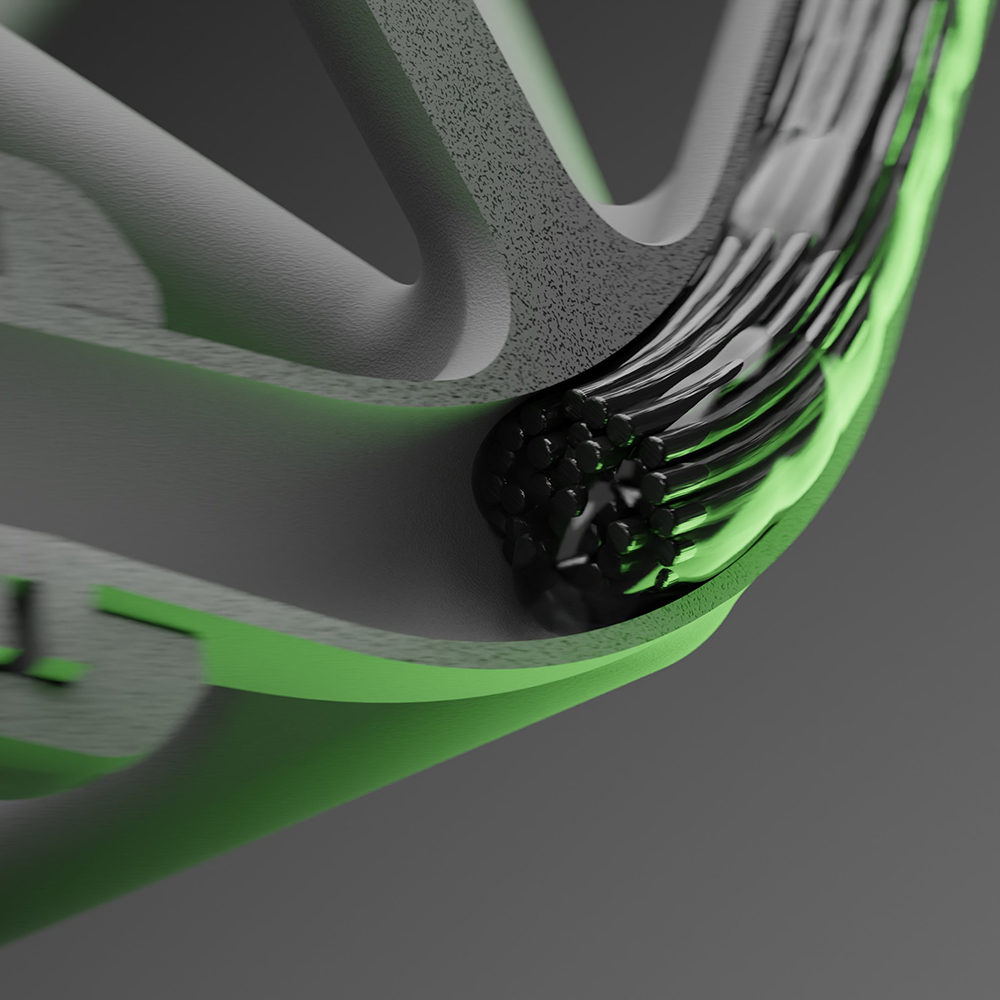

Schaeffler: Multi-material AM for research and series production

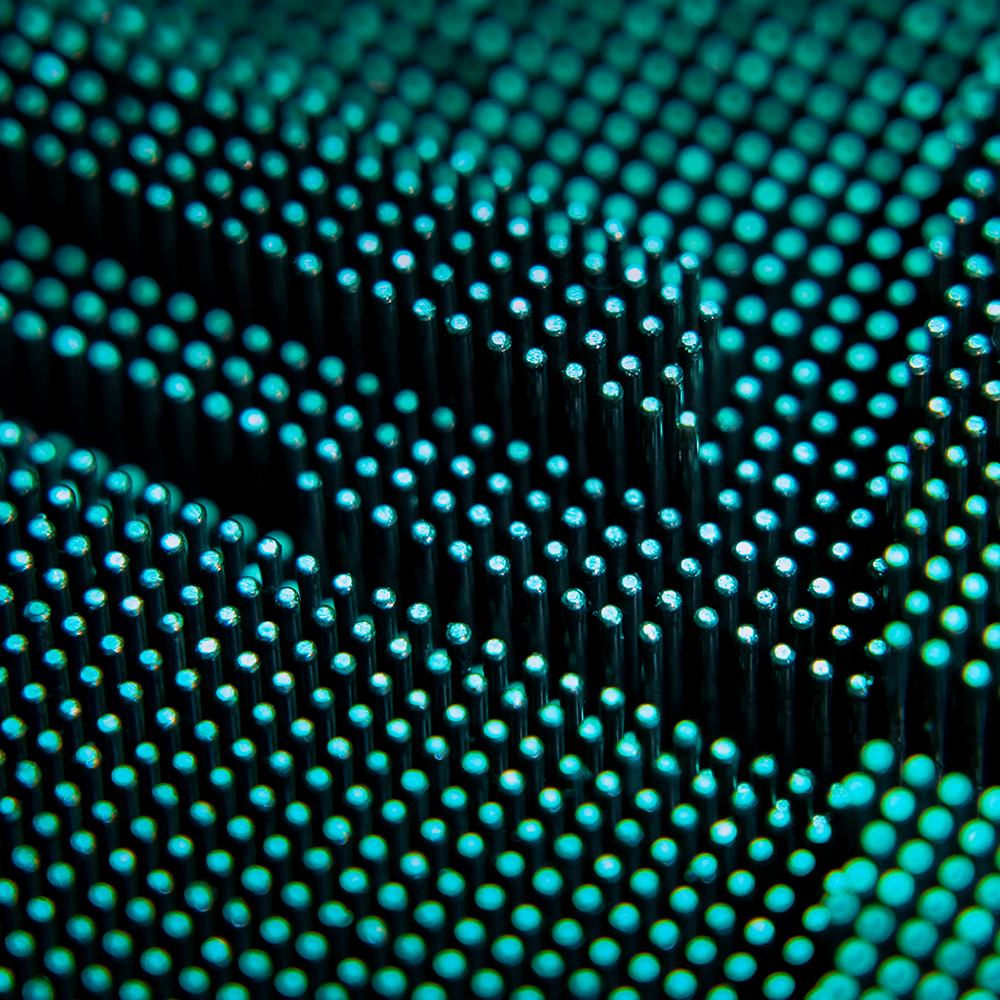

With its new OmniFamily systems, Schaeffler Special Machinery is rethinking Additive Manufacturing from the ground up. An innovative key technology, Selective Powder Deposition (SPD), represents the foundation of two systems at present: OmniFusion, which involves multi-material Additive Manufacturing using the LPBF process for demanding applications; and OmniForm which offers a flexible printing platform for cost-effective entry into the world of multi-material manufacturing through subsequent conventional sintering processes. At the heart of OmniFusion and OmniForm is the so-called recoater, which is based on SPD technology – a patented innovation originally developed by the start-up Aerosint. Aerosint is now fully integrated into the Schaeffler Group under its Schaeffler Special Machinery Belgium unit. Selective Powder Deposition enables the precise, selective deposition of different powder materials within a powder layer – without binders and without suction, according to Schaeffler. This makes it possible to create multi-material components with customized properties – metallic, ceramic, or a combination of both. The materials are applied layer by layer and with pinpoint accuracy only where they are actually needed. OmniForm is aimed at research institutions, laboratories, and development departments looking for a cost-effective entry point into multi-material manufacturing.

Schaeffler Special Machinery at Formnext 2025: Hall 11.0, Booth C28