When the company first participated as an exhibitor at Formnext in 2019, “we were almost the only company at the entire trade fair presenting pellet technology,” recalls Iván Sardón, CEO and co-founder of Indart3D. Competition in pellet 3D printing has become much more intense in the meantime, but Indart3D still sees itself having a technical advantage. “Because we clearly focus on pellet extrusion technology as the core of our offering,” Sardón adds.

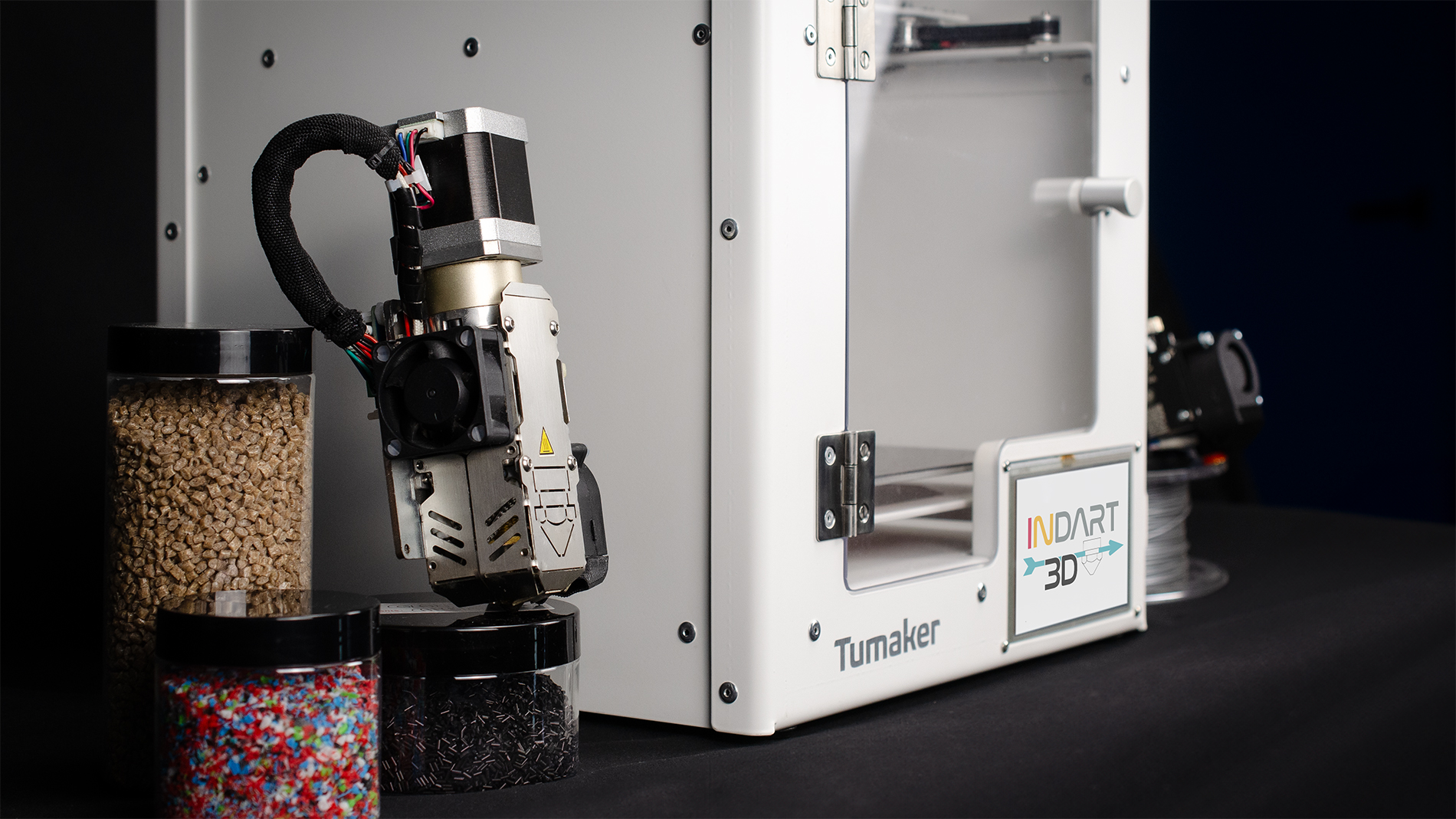

The company was founded in 2013 under the name Tumaker and reorganized itself in 2020 as the Indart3D cooperative while continuing to offer 3D printers under the Tumaker brand. Indart3D has already sold more than a thousand units, particularly to research centers, universities, and the automotive, textile, and defense industries.

Indart3D is headquartered near the French border in the northern Spanish city of Irun, where it employs 10 people. Support is provided by an international network of distribution partners and strategic partners. Sardón sees the location as very advantageous for “combining strong engineering talent with an agile and creative approach to industrial design. Our location in the Basque Country gives us access to a dynamic industrial ecosystem as well as leading research centers and universities.”

The company's cooperative structure has also brought it a number of advantages in recent years. “It allows us to make decisions in a more horizontal and participative way, which strengthens the commitment of the team and encourages long-term thinking,” explains Sardón. “It also fosters a culture of shared responsibility and transparency, helping us align individual contributions with our collective goals of innovation and customer service.”

Despite its focus on pellet 3D printing, Indart3D remains as technically flexible as possible and, since 2020, has been pursuing a modular approach to integrating filament and pellet heads on a single platform. “In 2024, we launched the new Tumaker series, which allows tool heads to be changed in less than five minutes,” says Sardón. This makes it possible to process a wide range of materials, from various metals and plastics to wood and ceramics. According to Indart3D, over 500 materials have already been successfully tested.

Further company information

Further information

Further exclusive information on Spanish AM companies can be found in the print edition 03/2025 of Formnext Magazine or in the digital Fon Mag:

Aimen, Aimplas, ArcelorMittal, Danobat, HP, IAM3DHub, Indart3D, Madit, Meltio, Reinforce3, Recreus, Smart Materials, Market report Spain