The Doze project (which involves advanced manufacturing of multifunctional aero-structures for zero-emission aircraft) aims to advance aerospace design through lightweight composite structures made of multiple materials, combining thermoplastics and thermosets with functional additives such as graphene and its derivatives, ensuring optimal performance in terms of heat management and mechanical strength. The project’s other partners include Aerotecnic, Idaero, Nasika, and the Aimen Technology Center.

The Fauno project is also dedicated to the further development of mold and tool design using multi-material Additive Manufacturing. It focuses on OoA (out-of-autoclave) composite processes – in particular liquid resin infusion (LRI) – for the production of sustainable, high-performance composite parts. In this project, Smart Materials 3D is responsible for developing the materials used. Specifically, PPS and PA matrices have been developed that are reinforced with carbon fiber and contain additives to ensure thermal conductivity and heat resistance. The other companies involved are Inespasa, Nexus Projexts, Idaero, and the research centers Aimen and Imdea Materials.

These two strategic initiatives are funded by national and European programs, including Spain's Recovery, Transformation, and Resilience Plan and Next Generation EU.

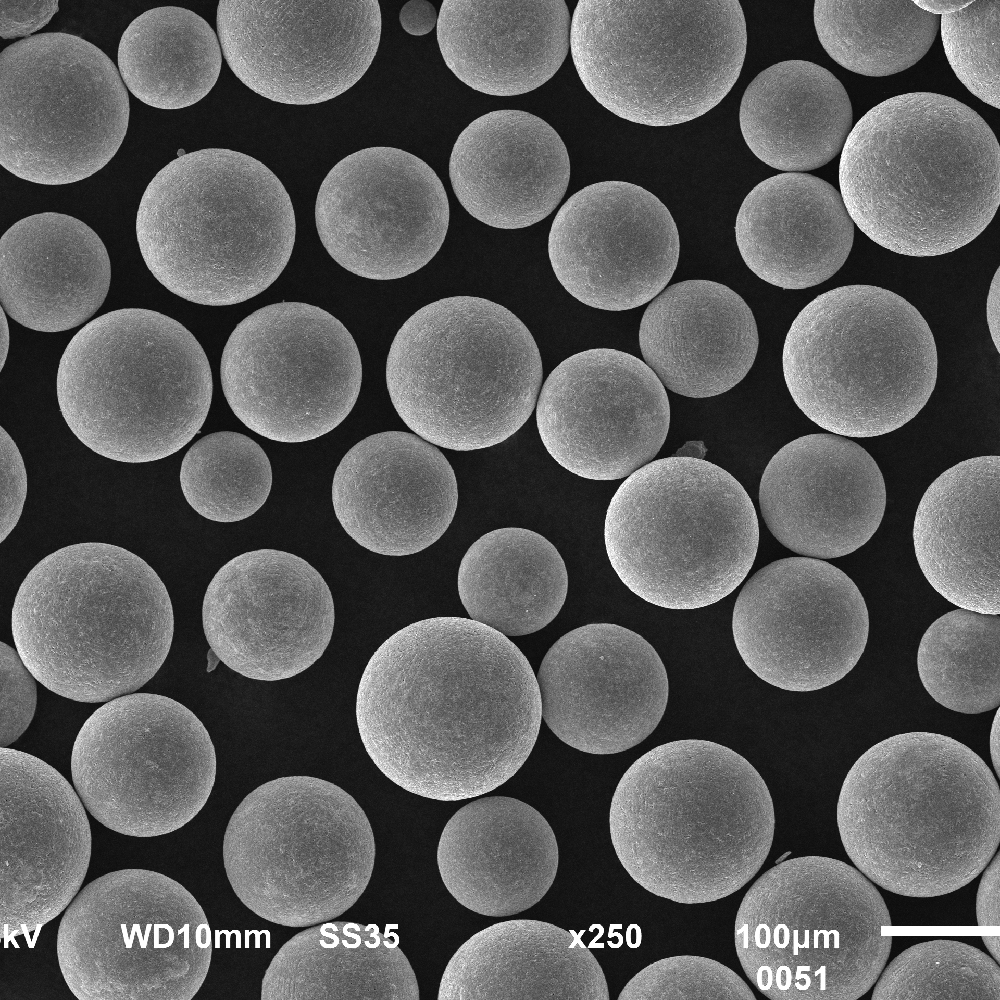

Ever-expanding product range

Smart Materials 3D is also continuously expanding its product range. Building on its PLA filaments with organic reinforcements, the company now uses recycled PET-G and recycled polypropylene (rPP) as new base polymers. These base polymers are combined with natural fillers such as spirulina, olive pits, pine, coffee, date seeds, and rice husks and are manufactured entirely in Spain.

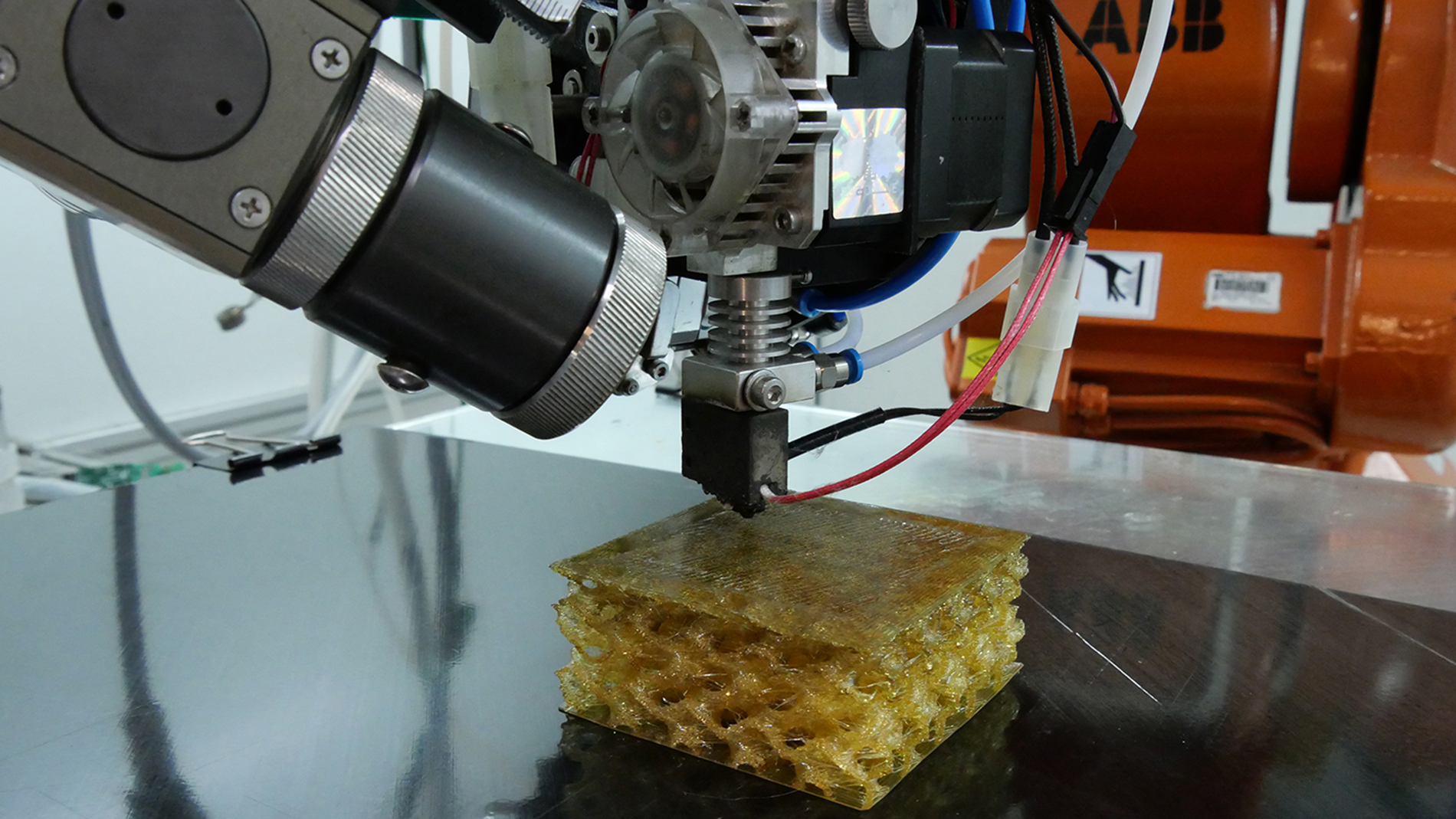

Recycled PET-G remains a favorite in the industry due to its durability, chemical resistance, and compatibility with robotic arm printing. It is particularly well suited to aesthetic and structural applications in outdoor and interior design, as it meets all the requirements of designers and architects looking for sustainable materials.

Low density for 3D-printing furniture

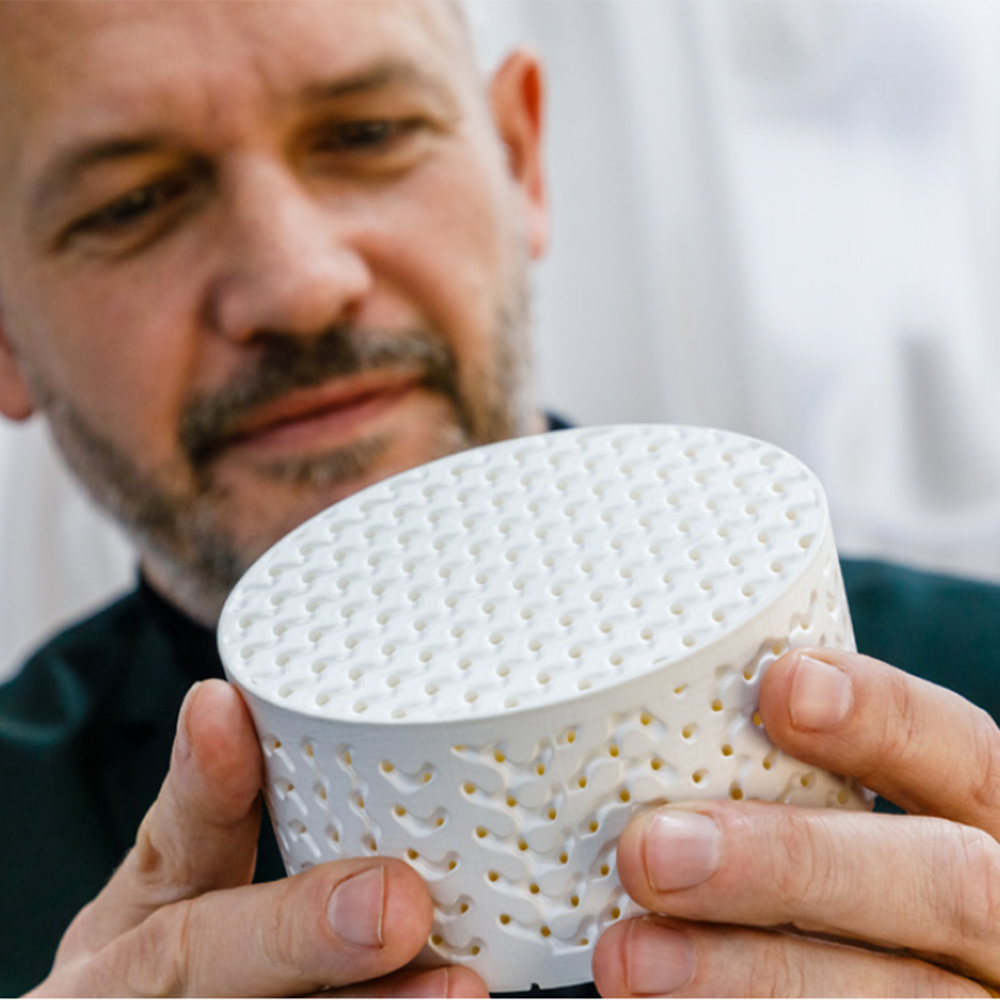

In addition, Smart Materials 3D has developed five materials designed for industrial robotic printing: carbon-fiber- and glass-fiber-reinforced ABS and ASA, as well as a low-density PLA formula that is ideal for printing large pieces of furniture. According to the company, this PLA variant reduces the weight of furniture by up to 65% without compromising mechanical integrity.

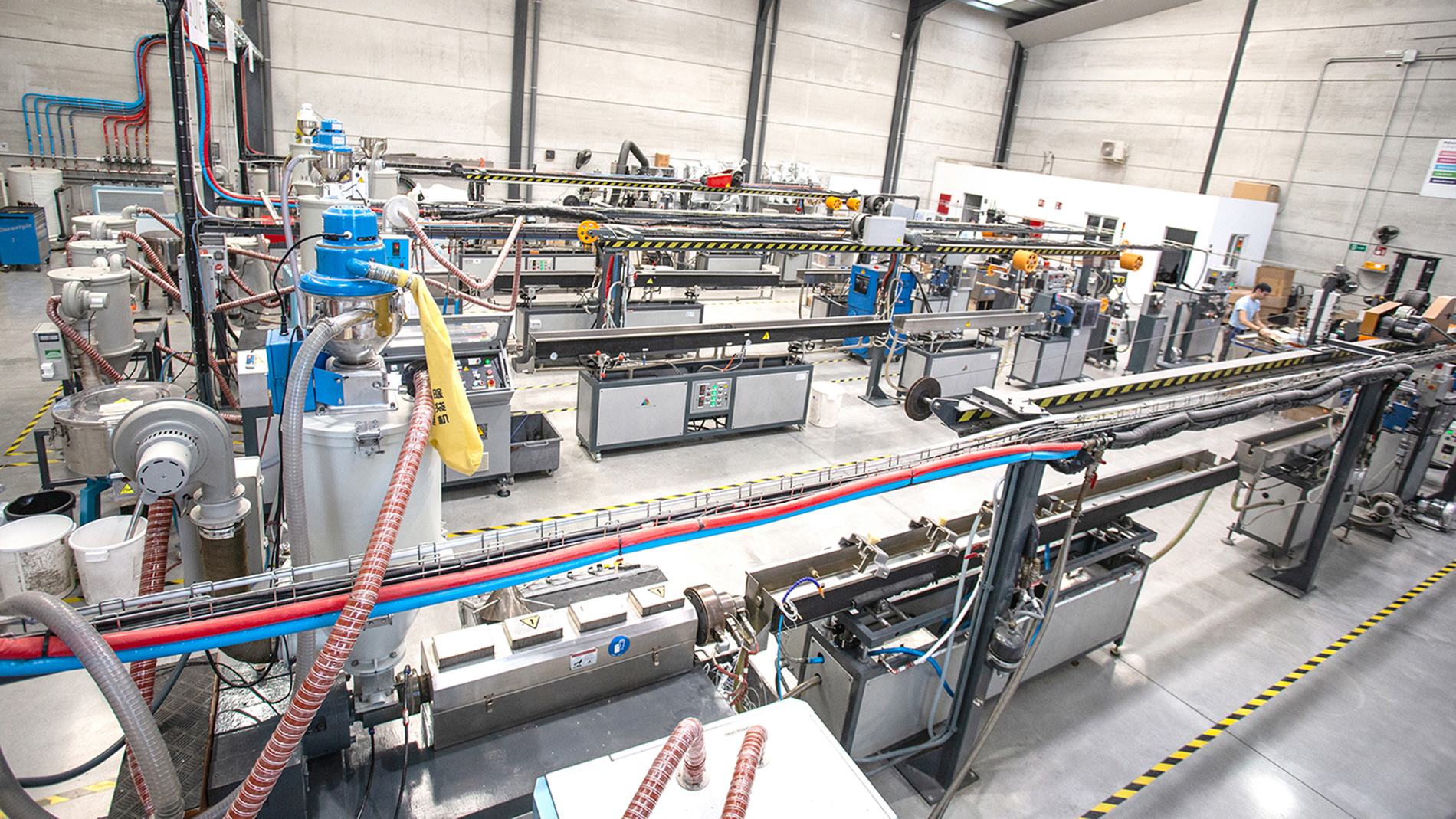

Smart Materials 3D was founded in 2014 and specializes in the development, manufacture, and marketing of materials for 3D printing. It currently has 42 employees and offers a portfolio of over 59 products, exporting to more than 50 countries in EMEA and LATAM. At its headquarters in Alcalá la Real (near Granada in southern Spain), the company has six extrusion lines with an annual production capacity of 480 tons of filaments for 3D printing. In addition, two compounding lines have a capacity of 850 tons per year. Smart Materials 3D’s waste treatment plant can also process up to 495 tons annually.

Further company information

Further information

Further exclusive information on Spanish AM companies can be found in the print edition 03/2025 of Formnext Magazine or in the digital Fon Mag:

Aimen, Aimplas, ArcelorMittal, Danobat, HP, IAM3DHub, Indart3D, Madit, Meltio, Reinforce3, Recreus, Smart Materials, Market report Spain