3D Lab: Next generation of ultrasonic atomizers

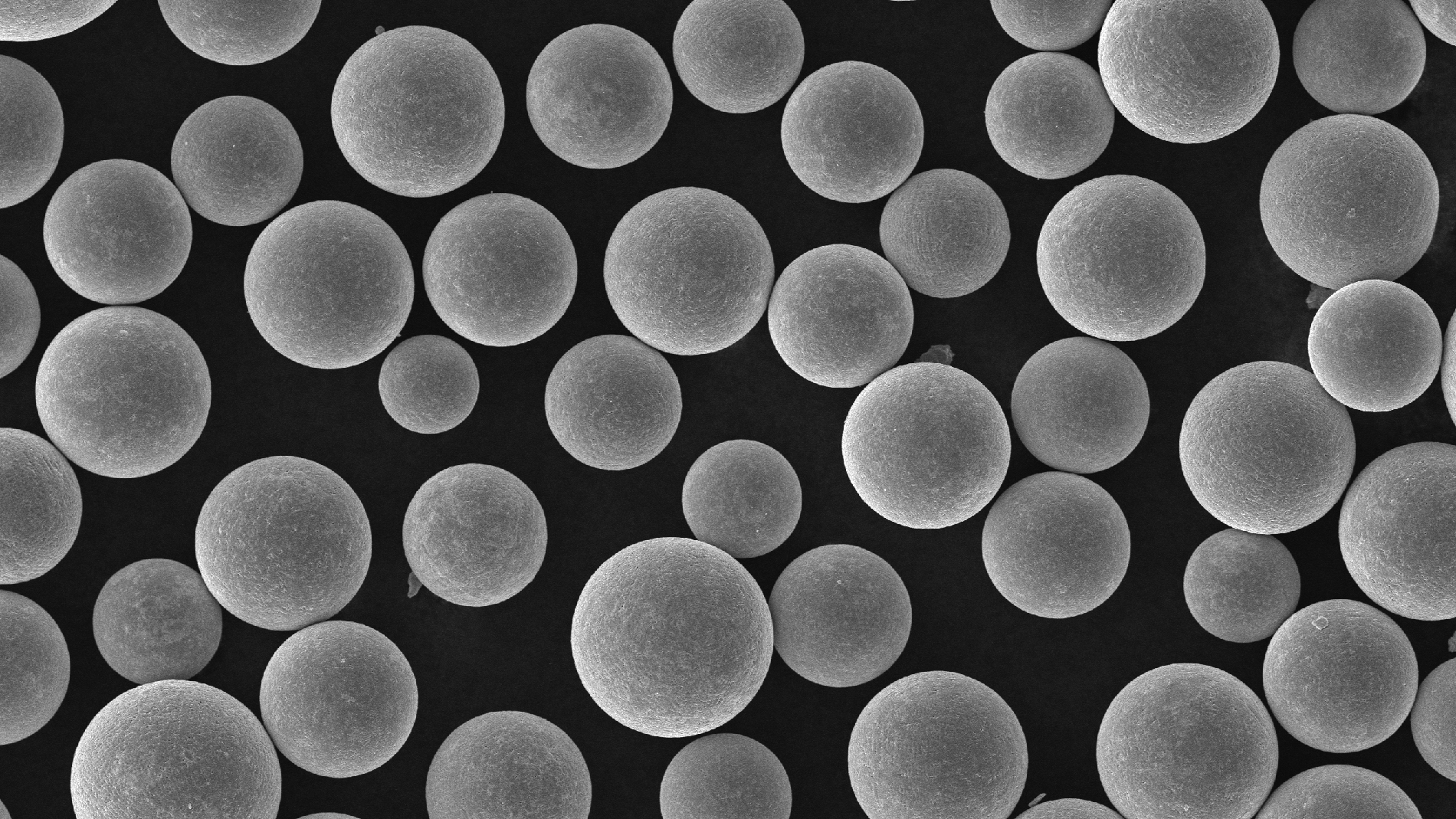

At this year’s Formnext, 3D Lab will unveil the next generation of ATO ultrasonic metal atomizers alongside equipment for powder processing and handling. Its system is intended for both research environments and industrial production. According to the company, it enables in-house metal powder production with controlled, repeatable outcomes for Additive Manufacturing and beyond. The system is modular, with atomizer capabilities that adapt within an interconnected suite of devices. Additionally, the suite supports circular economy practices that make it possible to recover manufacturing scraps and turn them into valuable powder, thereby conserving resources and tightening cost and supply control.

3D LAB at Formnext 2025: Hall 11.0, Booth B21

Images: 3D Lab

Fomas: For acidic and corrosive environments

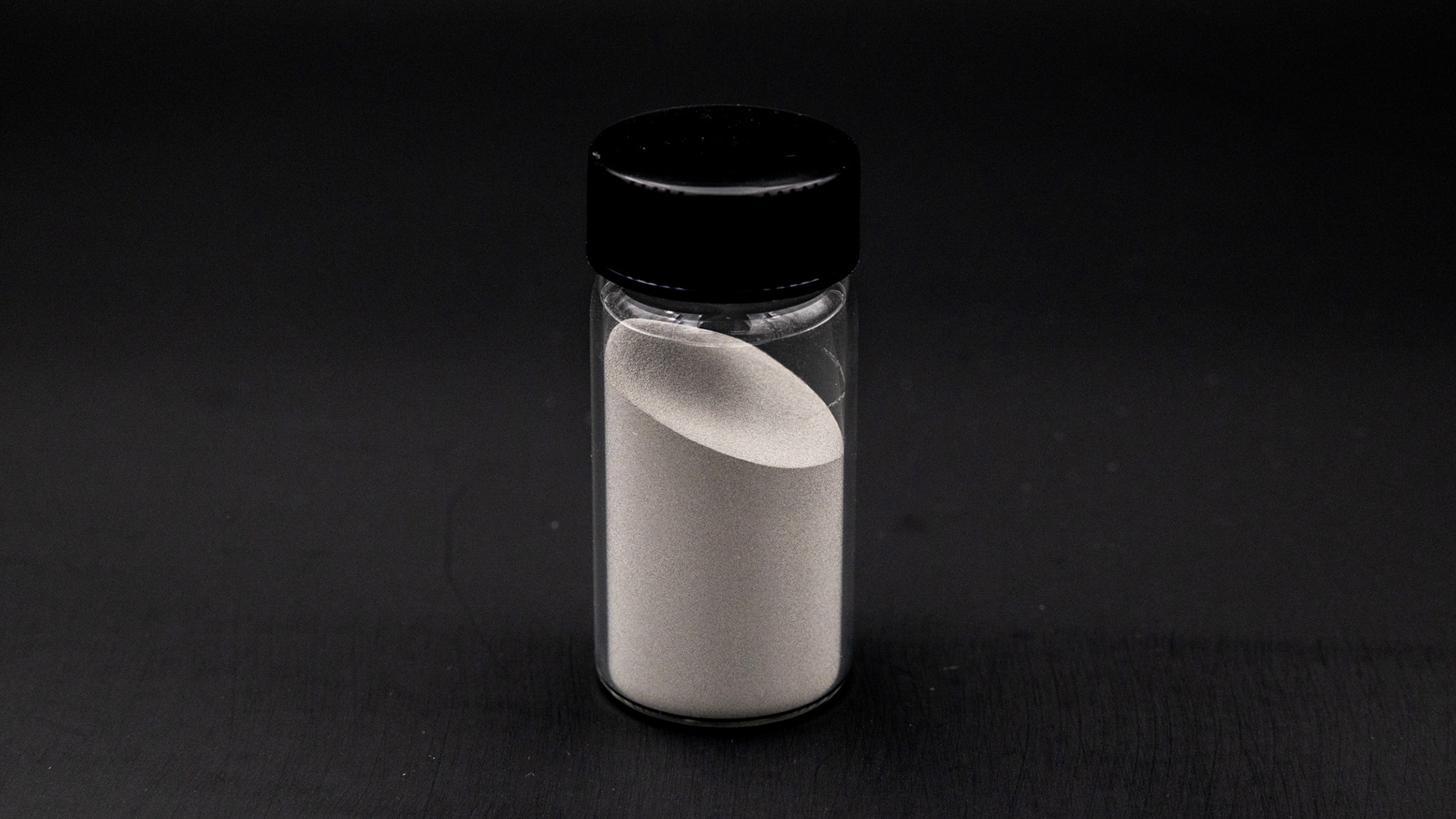

The Fomas Group has announced the qualification of Mimete V 625 NACE, a nickel-based powder suitable for highly acidic and corrosive environments. This alloy has been developed to meet the stringent requirements of NACE MR0175 / ISO 15156 and is suitable for critical components in the subsea oil and gas and energy sectors. According to Fomas, the new material offers high resistance to stress corrosion cracking and hydrogen embrittlement, remains stable even at extreme temperatures and pressures, and is easy to weld and machine. The powder has undergone a rigorous qualification program that included chemical analysis, mechanical testing, and corrosion resistance evaluation.

Fomas Group at Formnext 2025: Hall 12.0, Booth C51

Images: Fomas

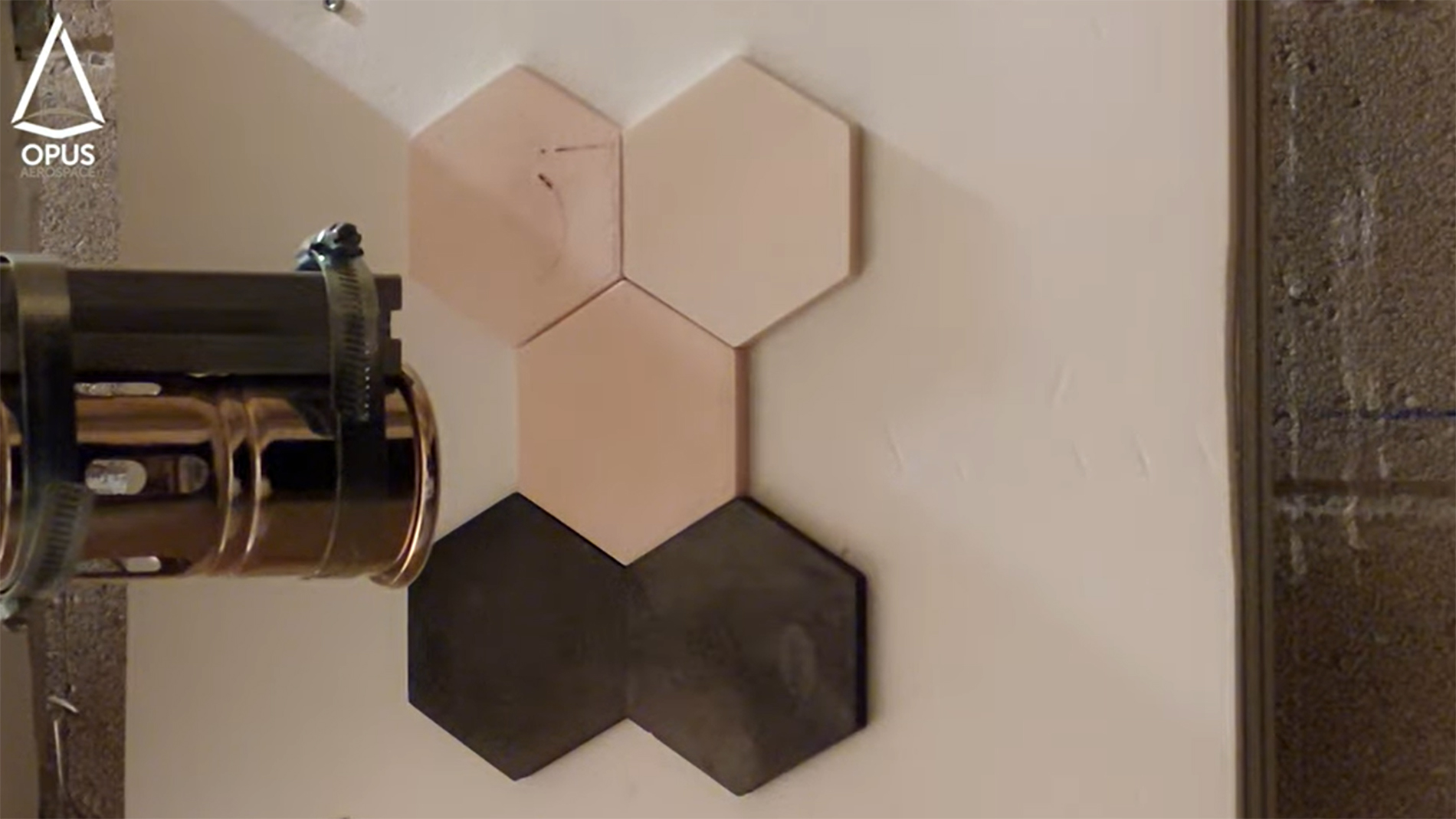

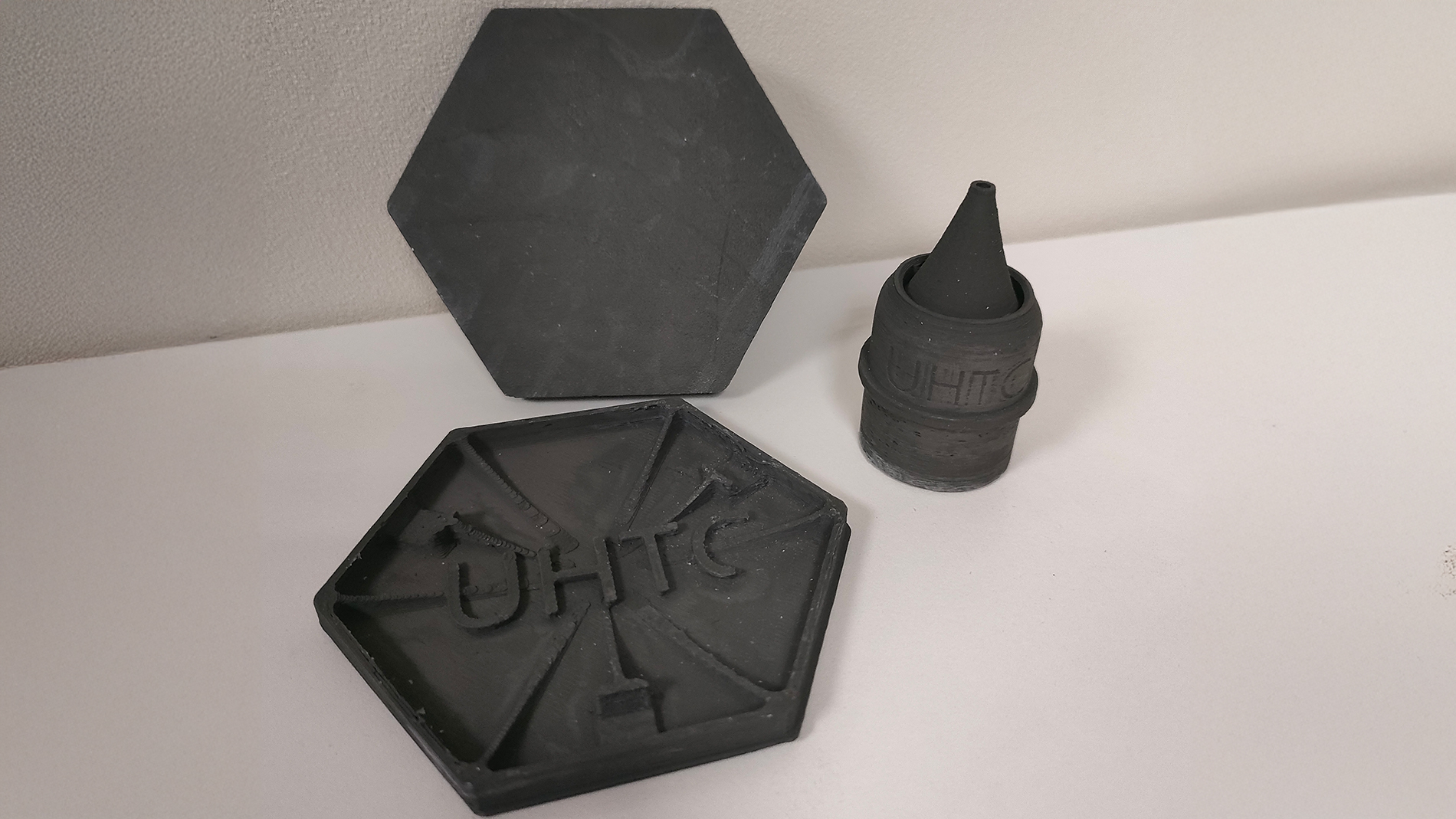

Nanoe: New ultra-high-temperature ceramic

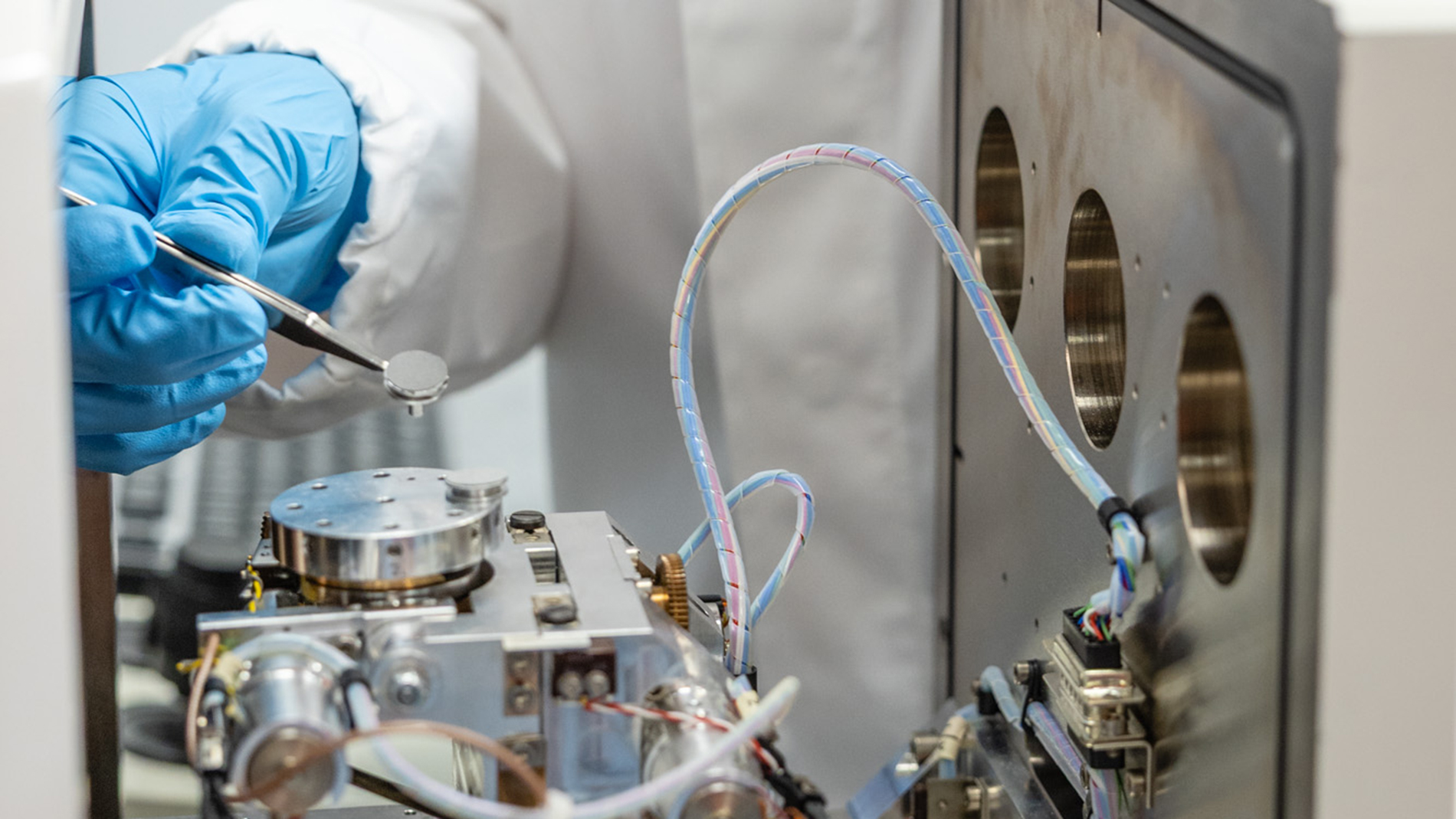

Nanoe is set to launch a new ultra-high-temperature ceramic (UHTC) composite at Formnext. This composite is a blend of two high-temperature materials: zirconium diboride (ZrB₂) and silicon carbide (SiC). It will be available in powder form for pressing and injection molding, as well as in filament form for 3D printing. "UHTC ceramics have been the subject of extensive research in recent years, particularly with a view to developing materials capable of withstanding hypersonic conditions. However, the market has so far lacked ready-to-use commercial products that are needed for industrial applications to emerge,” states Guillaume de Calan, CEO of Nanoe. The new composite consists of 80% ZrB₂ and 20% SiC, with additional doping elements such as B₄C enabling pressureless sintering at 2,000° C under partial argon pressure. According to Nanoe, the first customers for this material include laboratories in aerospace and defense, such as NASA and ONERA, as well as a New Space startup and a major European defense contractor.

Nanoe at Formnext 2025: Hall 12.0, Booth B31

Images: Nanoe

Qualloy: From iron to titanium alloys

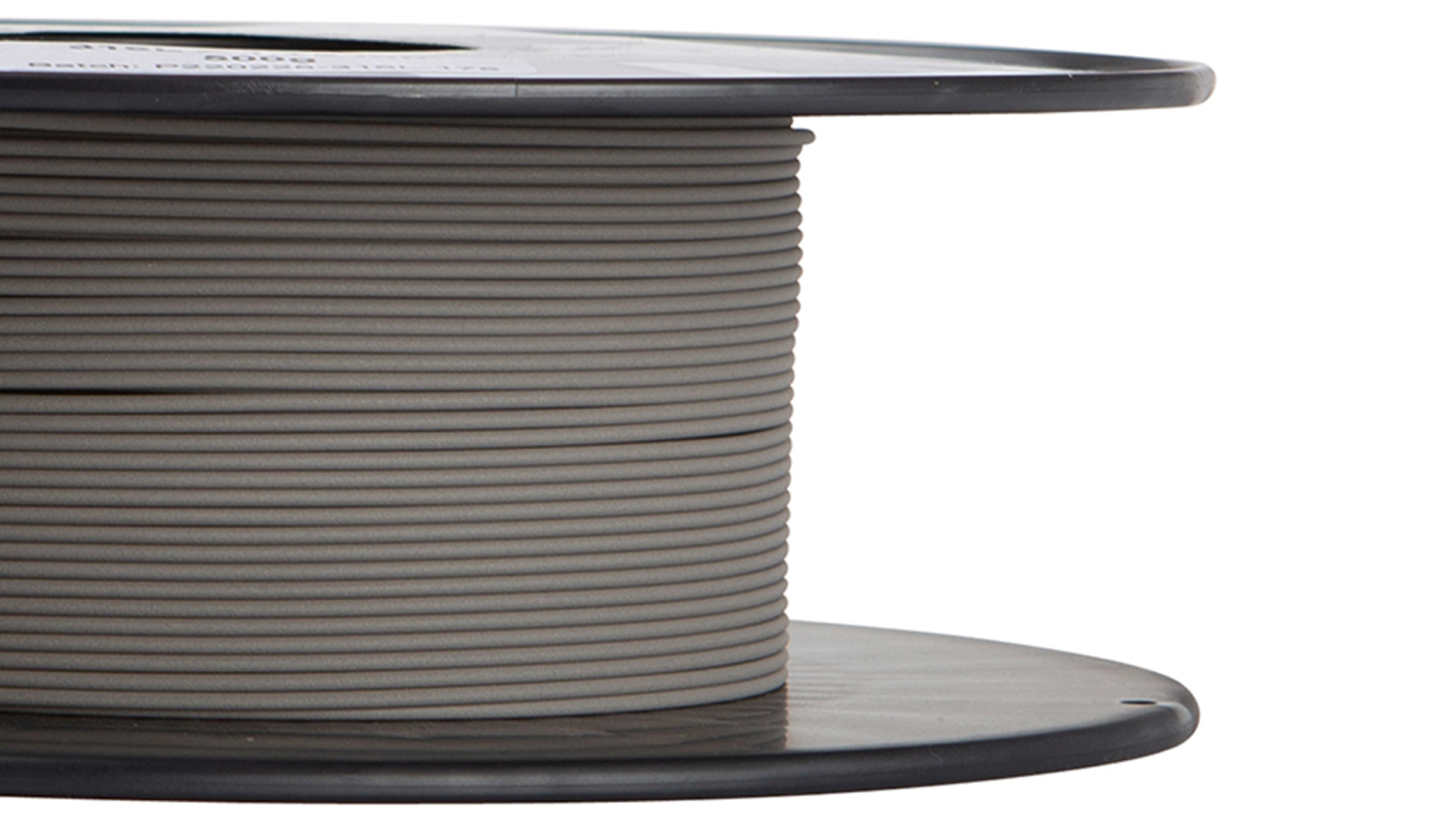

Qualloy, the digital marketplace for metal powders, recently introduced its own powder brand, Qualloy Select, as a complement to its existing range. Tested and certified in the Rosswag Engineering laboratory, Qualloy Select powders are now available from stock in Germany for fast delivery throughout the EU. Qualloy says it wants to position itself as “one of the price leaders in Europe” with its new powder brand. In addition, the company is focusing on transparency: Customers can view its entire product range online, including detailed specifications, delivery times, and daily price updates. The Qualloy portfolio includes iron-based, nickel-based, aluminum, and titanium alloys, among others.

Qualloy at Formnext 2025: Hall 11.0, Booth C62