Text: Thomas Masuch

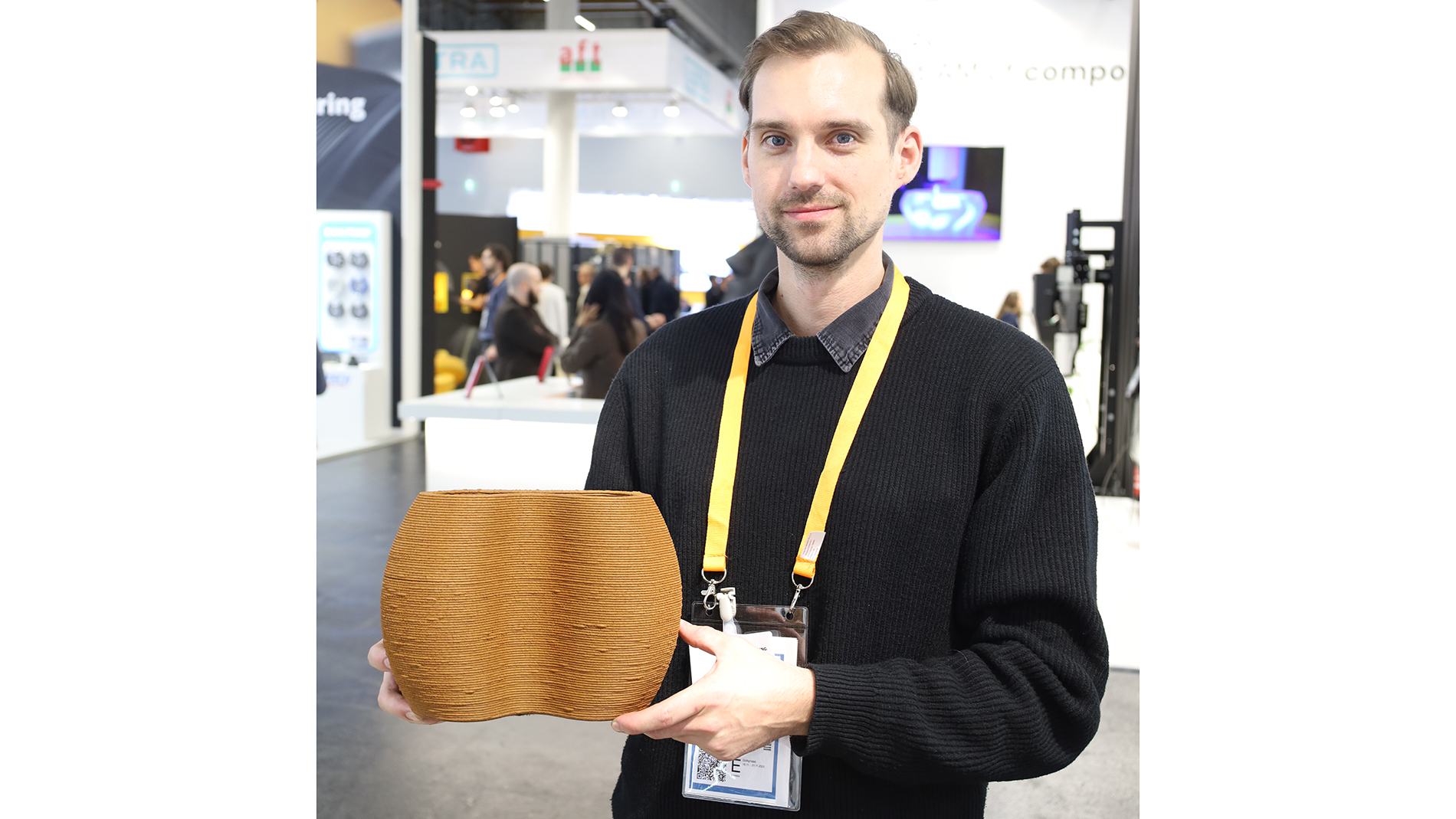

Even though sustainability was not quite as prominent as in previous years, the topic was still present at many exhibition booths at Formnext 2025. Sustainable materials are an important factor here, and researcher Danny Ott from the Design Department at the Anhalt University of Applied Sciences | Dessau is breaking new ground in their development: He has developed a fiber-reinforced composite material made entirely from renewable raw materials. He presented the first applications of the pellets at Formnext 2025. In addition to its sustainability, the material impresses with its intense woody aroma.

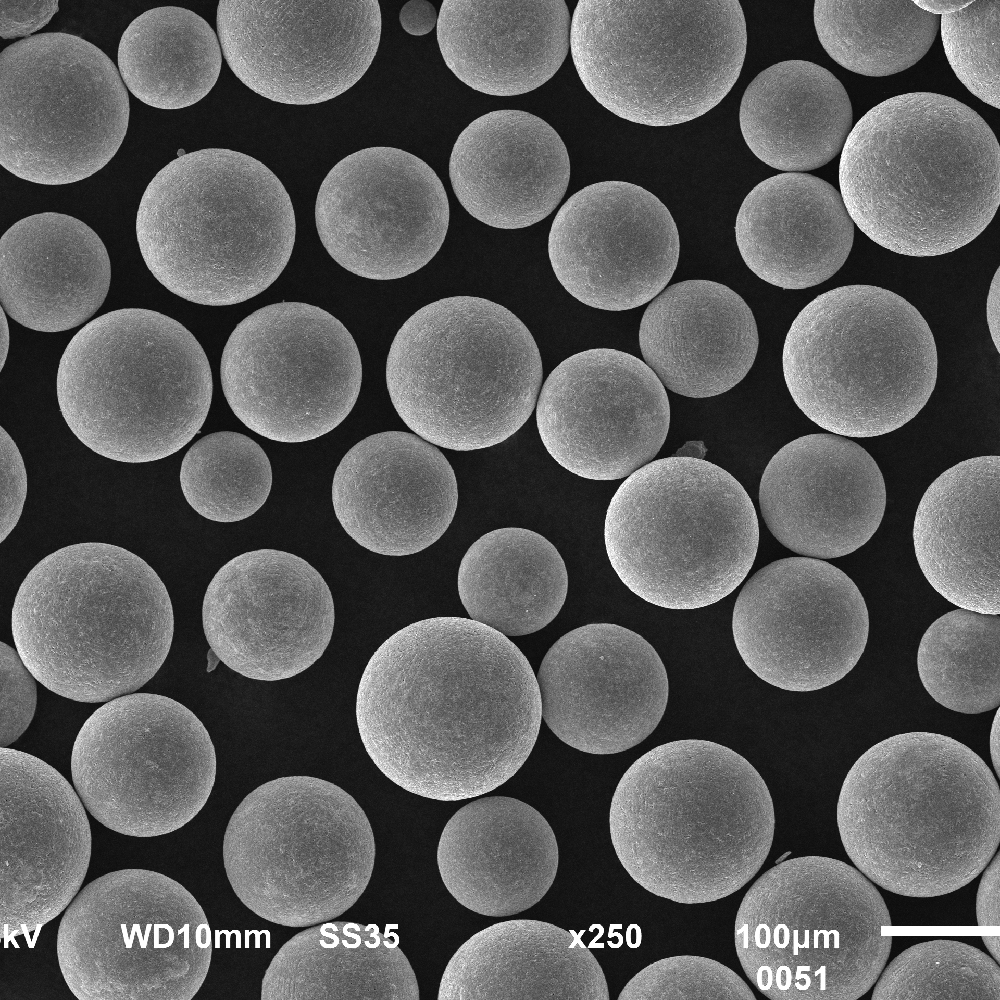

Talking to the young researcher gives you an impression of how complex material development is in the context of research alone. The main component of the pellets is lignin, a by-product of pulp production, which accounts for 50 to 60 percent of the material. Usually burned for energy, it is also used to a lesser extent in industries like concrete and cement. Ott mixes in additional biopolymer components and various natural fibers from different types of wood, which stabilizes the material in a manner similar to reinforced concrete. “The big challenge in the composition is that the materials are made from 100-percent renewable raw materials and no petrochemical-based plastics are used,” he explains.

Mixing, kneading, shredding…

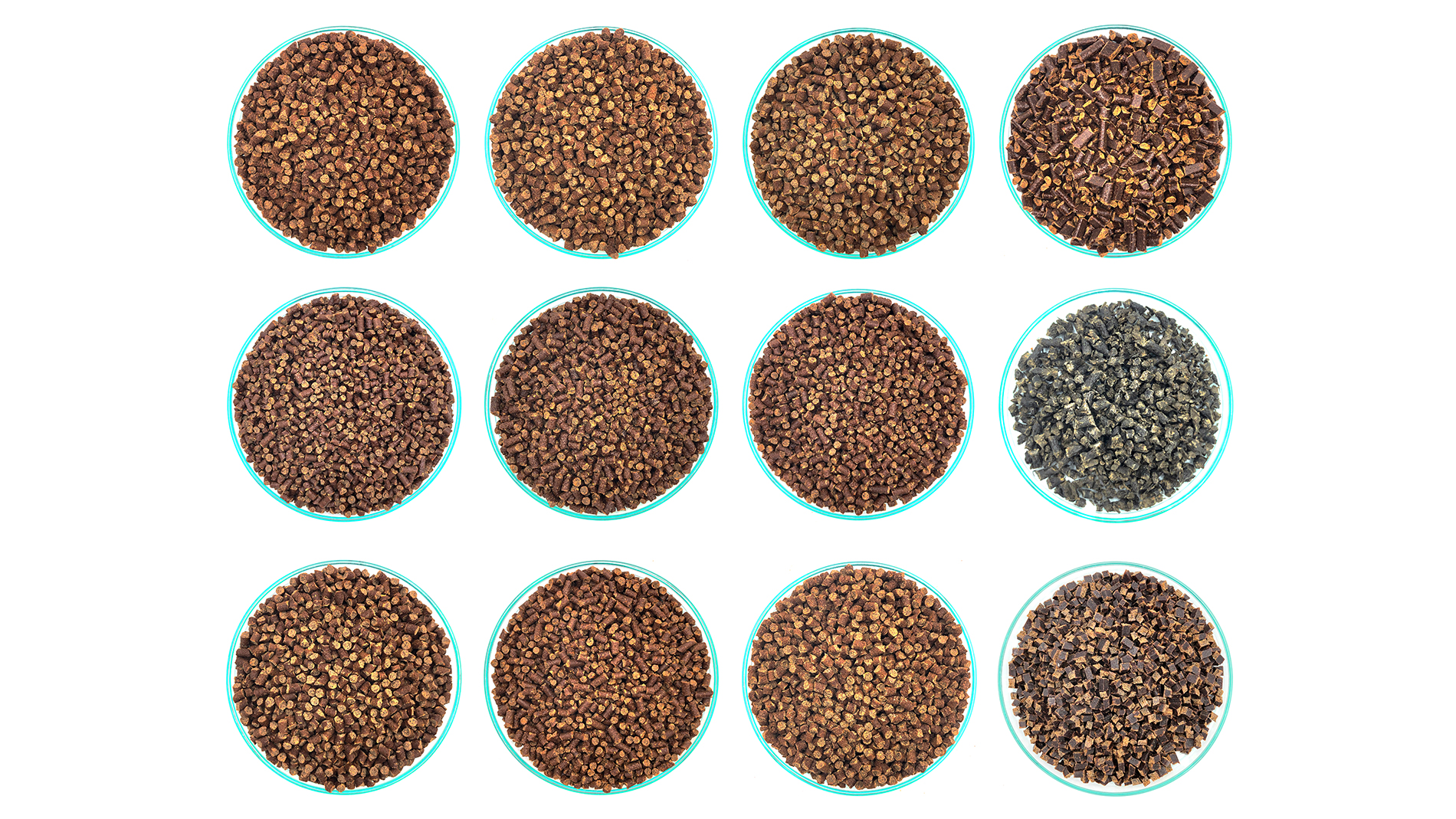

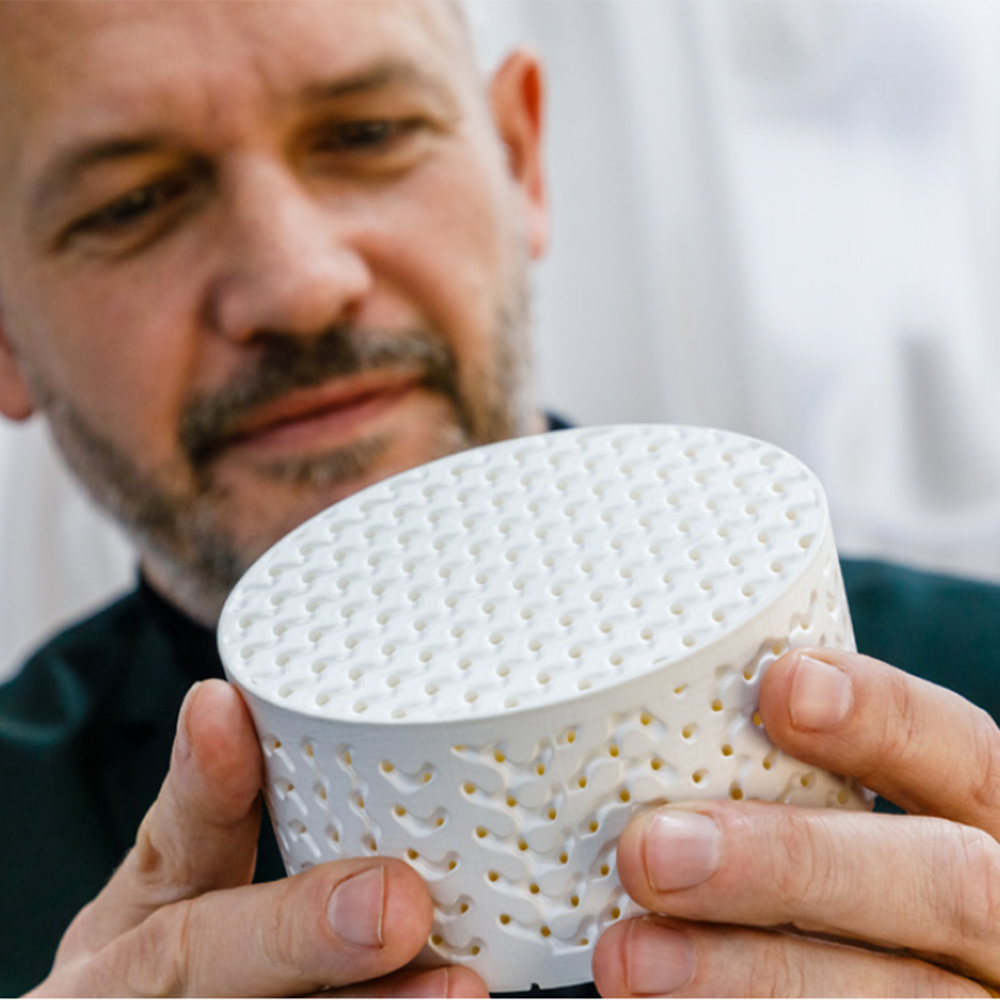

Since 2022, Ott has been conducting research on fiber-reinforced composites for sustainable 3D printing as a doctoral student in Dessau as part of Professor Manuel Kretzer's Materiability Research Group. He obtains the base material from a chemical factory. In the laboratory, the other components are then precisely measured, mixed, kneaded, pressed into filaments, dried, and chopped into pellets. This requires a lot of manual work using small, manually operated, repurposed devices. It is a laborious and time-consuming process, but at the same time more resource-efficient at the scale of an experimental laboratory. Ott needs several hours to produce a kilogram of pellets, which means careful consideration must be given to which applications will ultimately be printed.

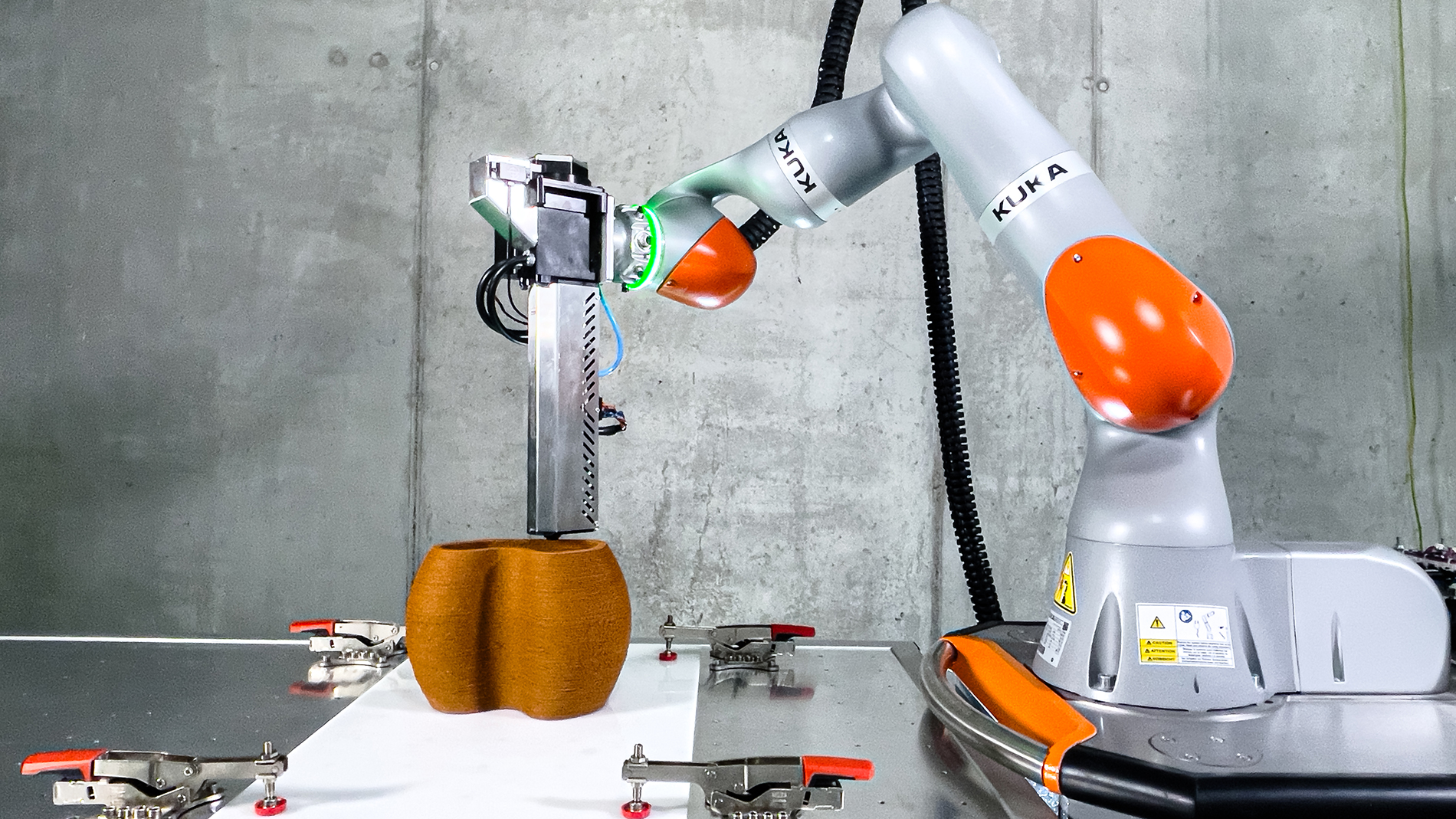

The research series and initial applications are being created in the laboratory on a large-format pellet printer using FGF (fused granulate fabrication) printing. This involves the use of a robotically controlled system consisting of a collaborative robot from Kuka (an LBR iiwa) and an end effector from Dyze Design (a Pulsar pellet extruder). In order to find the optimal composition for his sustainable pellets, Ott printed and evaluated dozens of different material compositions and almost 200 material badges. One of the questions his research is attempting to answer relates to how different fibers, fiber lengths, and fiber concentrations affect the material’s mechanical properties. It is important to find a good combination of uniform flowability during the printing process and the strength of printed objects.

Temperature window is crucial

In parallel with the material tests, Ott is also investigating the optimal parameters for 3D-printing the pellets. A key factor here is the correct temperature: At what temperature is each material composition softest and easiest to process? This processing window is crucial for thermoplastics because unlike metals – which become increasingly fluid at higher temperatures – thermoplastics generally become viscous and then solid again beyond their optimal processing window and eventually begin to thermally decompose (or even char).

Once one or more lignin-based materials have been fully developed, the next, equally important step is to find economically viable applications. Ott’s appearance at Formnext 2025 also made a significant contribution to this development. “The trade fair was a complete success,” he says happily. “We had numerous discussions, which have led to further inquiries and possible collaborations that we are currently pursuing.” Among others, there was interest from material suppliers who want to run more in-depth tests on the lignin-based pellets for either 3D printing or injection molding purposes before presenting them to their customers. Danny Ott is also excited about other partners, and interested parties and can well imagine applications in interior design, such as room cladding. For instance, attractive lampshades have already been printed in tests.