Smart Materials: Lightweight and high-performance

This year, Smart Materials is coming to Frankfurt with several new developments, ranging from environmentally sustainable materials to high-performance technical materials. Among its new products are TPU Light Weight and r-PETG Light Weight. By combining elasticity, flexibility, and impact resistance, the TPU Light Weight Shore 93A aims to enable new applications in areas where energy absorption and adaptability are required. Smart Materials will also be presenting fiberglass-reinforced r-PETG at Formnext, emphasizing its commitment to using recycled r-PETG as the base material for new developments. Its r-PETG material will be available as filament and granulate in various colors. In addition, the Spanish company will be showcasing its brand-new PPS CF and exhibiting a model of a Formula 1 part made from PETG CF. Another material that has just come out of development will be a conductive TPU. Finally, Smart Materials will also be demonstrating the possible applications of PLA Light Weight at its trade fair booth. Walls and furniture will be made from this material, which enables weight reductions of up to 65%.

Smart Materials at Formnext 2025: Hall 12.1, Booth D81

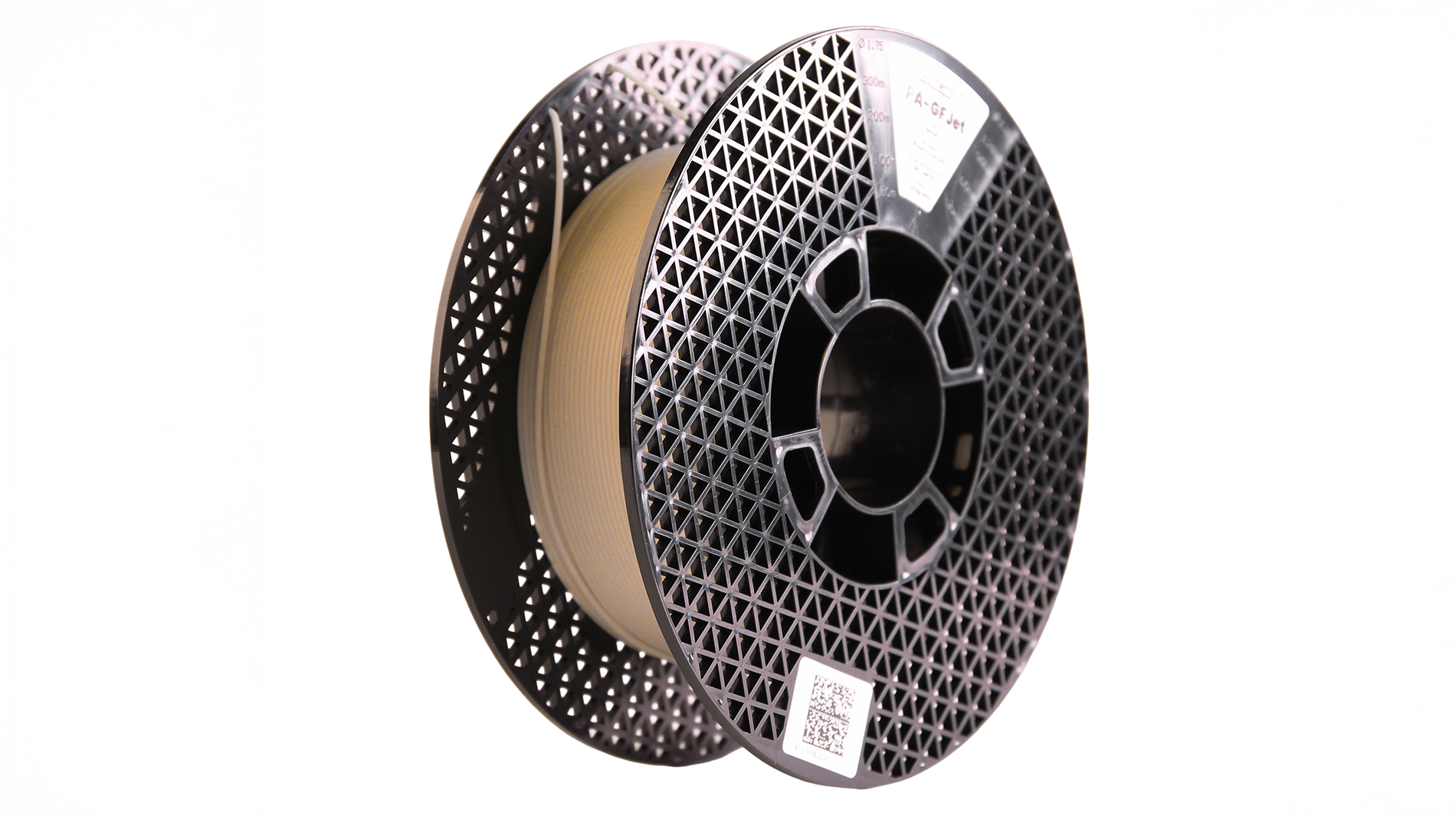

Filament PM: With carbon black and glass fibers

Filament PM is coming to Formnext armed with two new materials. “PA-GFJET 0.5 kg 1.75 mm natural” is a fiberglass-reinforced nylon that exhibits less shrinkage and temperature resistance up to 160° C. According to the manufacturer, it also has excellent mechanical properties and can be used as an insulator with glass filling. Meanwhile, “ESD-PETG filament 0.5 kg 1.75 mm black” is PETG-based and contains highly conductive carbon black, which gives the material antistatic properties during discharges. The volume resistance of printed objects with 100% filling is 2.7 ·101 Ω·cm.

Filament PM at Formnext 2025: Hall 12.1, Booth F59

Altana: For skin contact and high temperatures

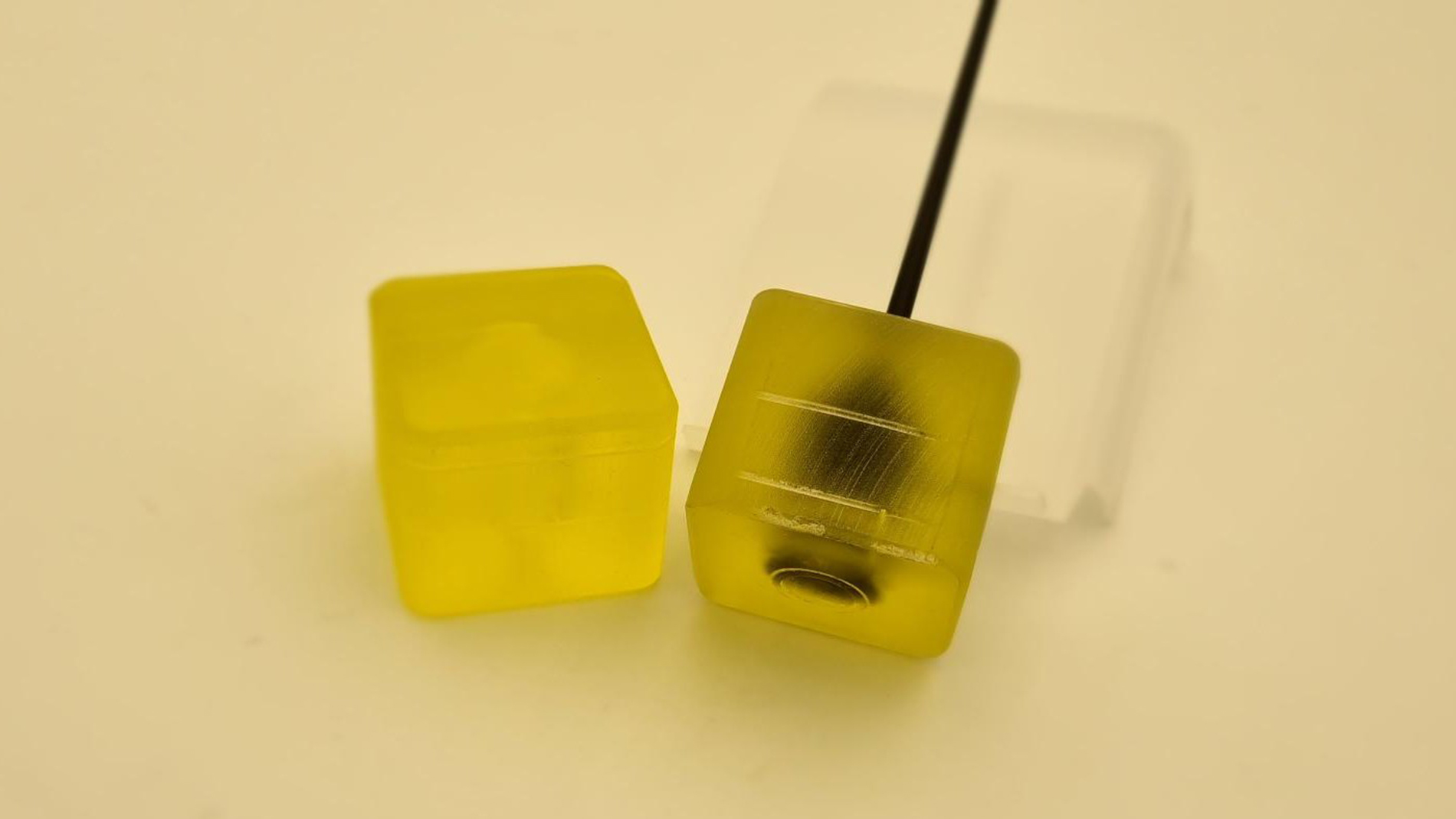

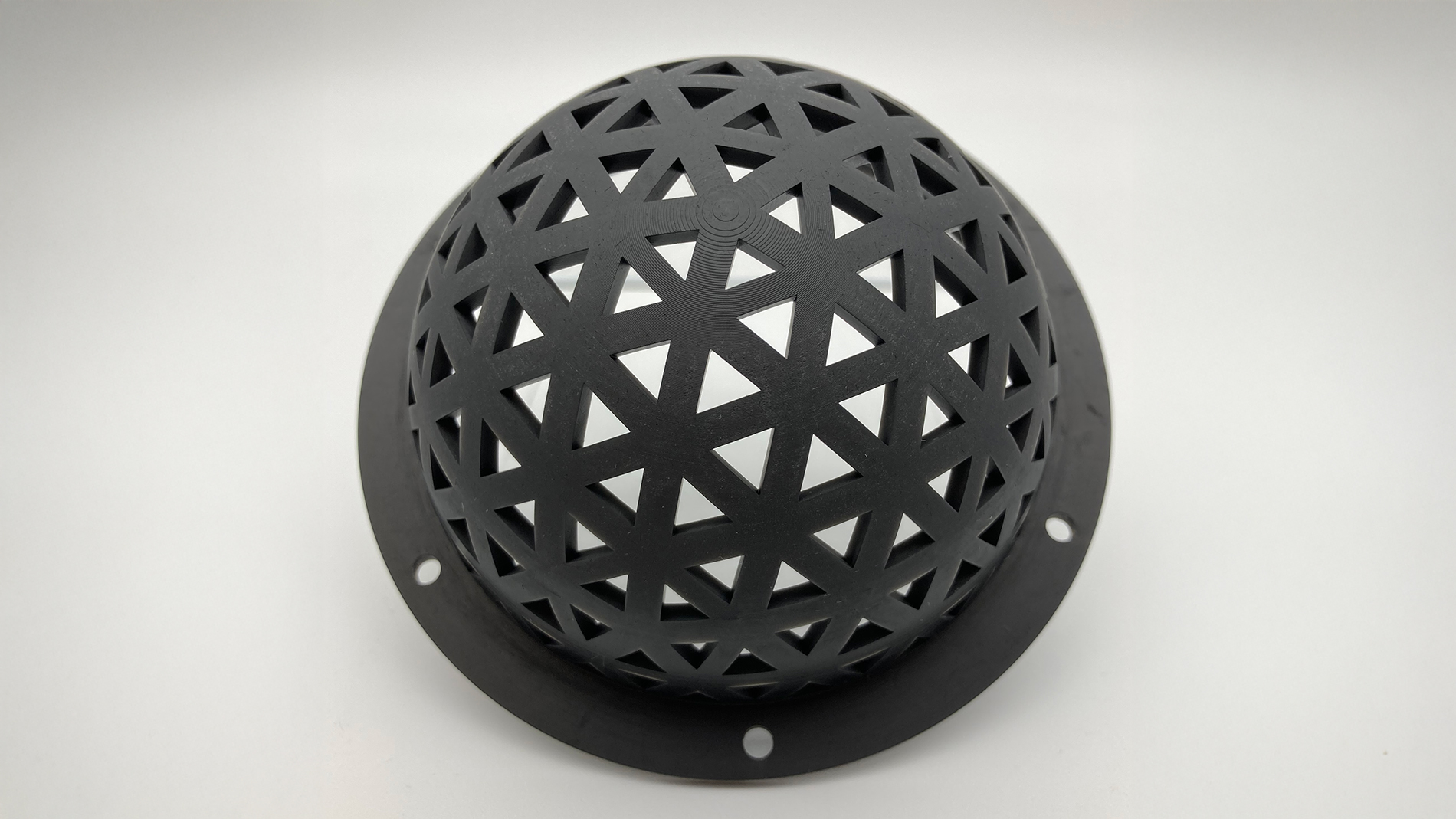

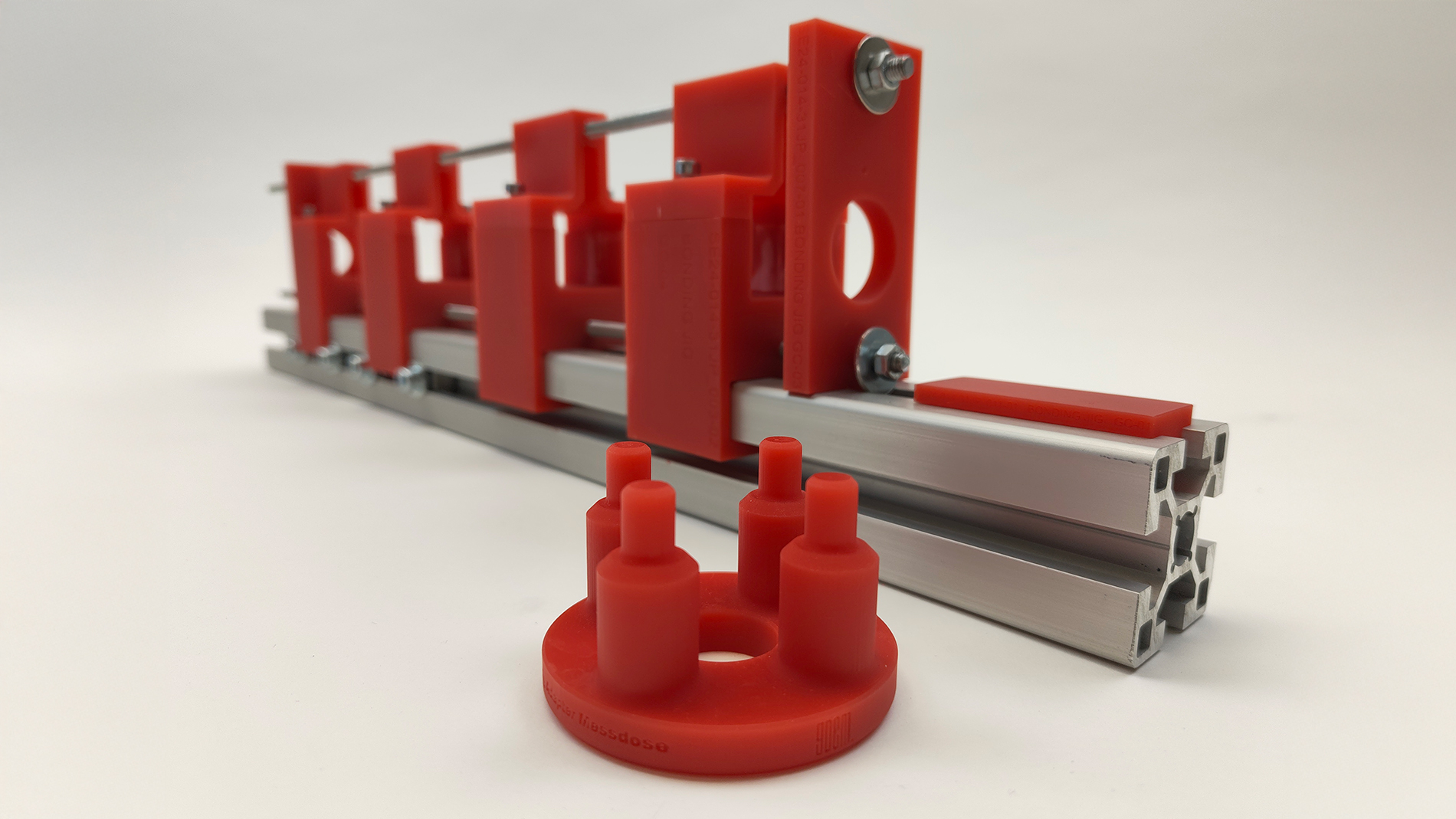

Under its Cubic Ink brand, Altana is set to present a range of new materials that are specifically tailored to the requirements of industrial applications. The focus will be on further developments in its resin portfolio and functional high-performance solutions for 3D printing. Together with its partner SK Industriemodell, Altana will demonstrate how Cubic Ink mold material can be used in injection molding. Live demonstrations at its booth will show how 3D-printed tool inserts can be used directly in production. Designed in response to the increase in 3D printing applications in the field of orthotics, Cubic Ink features high-performance 4 – 4800 VP material, which is characterized by impact strengths of over 90 J/m (Izod notched), good thermomechanical properties, balanced chemical resistance, and a scratch-resistant surface. Printed objects are also suitable for direct skin contact. In addition, Altana’s new resins (Rigid 1600 VP, Rigid 2000 VP, and Tough 2100 VP) boast increased impact strength, dimensional stability, and improved long-term performance, making them particularly suitable for functional prototypes and small series components. The company is also presenting two new materials: High Temperature 200 VP and High Temperature 1901 VP.

Altana Cubic Ink at Formnext 2025: Hall 12.1, Booth E39

Images: Altana

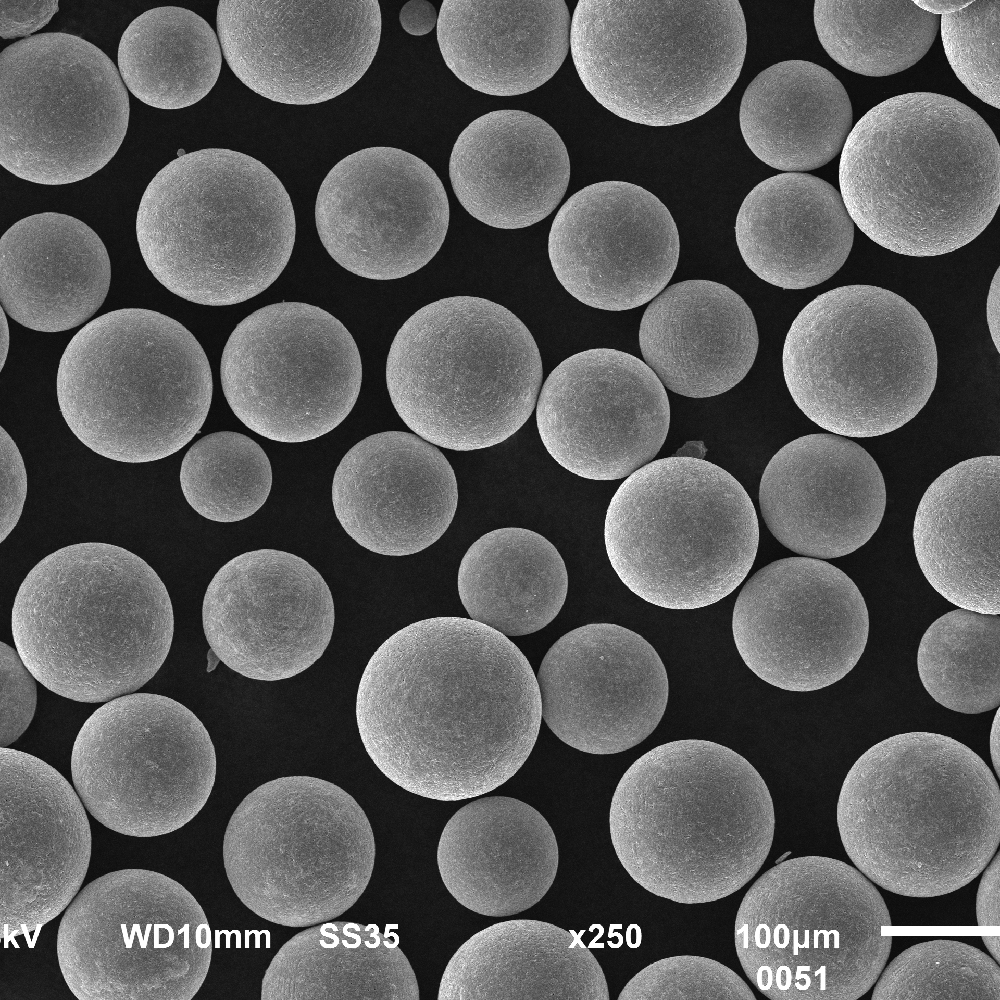

AM Polymers: Softer TPU and black flame-retardant PA11

As a further innovation on TPU, which has been available on the market for 12 years now, AM Polymers has developed a new variant, TPU-03. This enables the production of softer components in a hardness range of 50–70 Shore A, which still results in an elongation at break of over 150% in the build direction. According to AM Polymers, the material remains easy to process without significant smoke development, and the soft powder cakes are easy to unpack even when cold. To complement the flame-retardant, natural-colored PA11-01-FR (which was commercialized last year), a special black version has been developed. Thanks to its adapted absorption behavior, this material can also be processed on laser sintering systems using diode or fiber lasers. AM Polymers describes it as the first black flame-retardant material ever to be launched on the market. The material complies with UL94 V0 at a wall thickness of 3 mm and can be processed in a refreshed state.

AM Polymers at Formnext 2025: Hall 12.1, Booth C59

Graphy: From Shape Memory Aligners to elastic resins

Graphy will be showcasing new dental innovations based on its Shape Memory Aligner (SMA) at Formnext. The Korean company will also be presenting new developments in the field of medical materials and lifestyle and sports solutions based on a new elastic resin. The Shape Memory Aligner utilizes a proprietary shape-memory resin that recovers at body temperature, enabling tooth movement without the need for attachments. This technology shortens treatment duration, reduces patient discomfort, and ensures predictable outcomes. Graphy is also introducing a new elastic resin that addresses the limitations of conventional UV resins, such as slow curing speeds, surface tackiness, and insufficient durability. The new material offers fast curing, excellent surface quality, long-term resilience, and rebound elasticity. The company sees potential applications in footwear midsoles, sports equipment (e.g. basketballs), and bicycle saddles.

Graphy at Formnext 2025: Hall 11.1, Booth D51

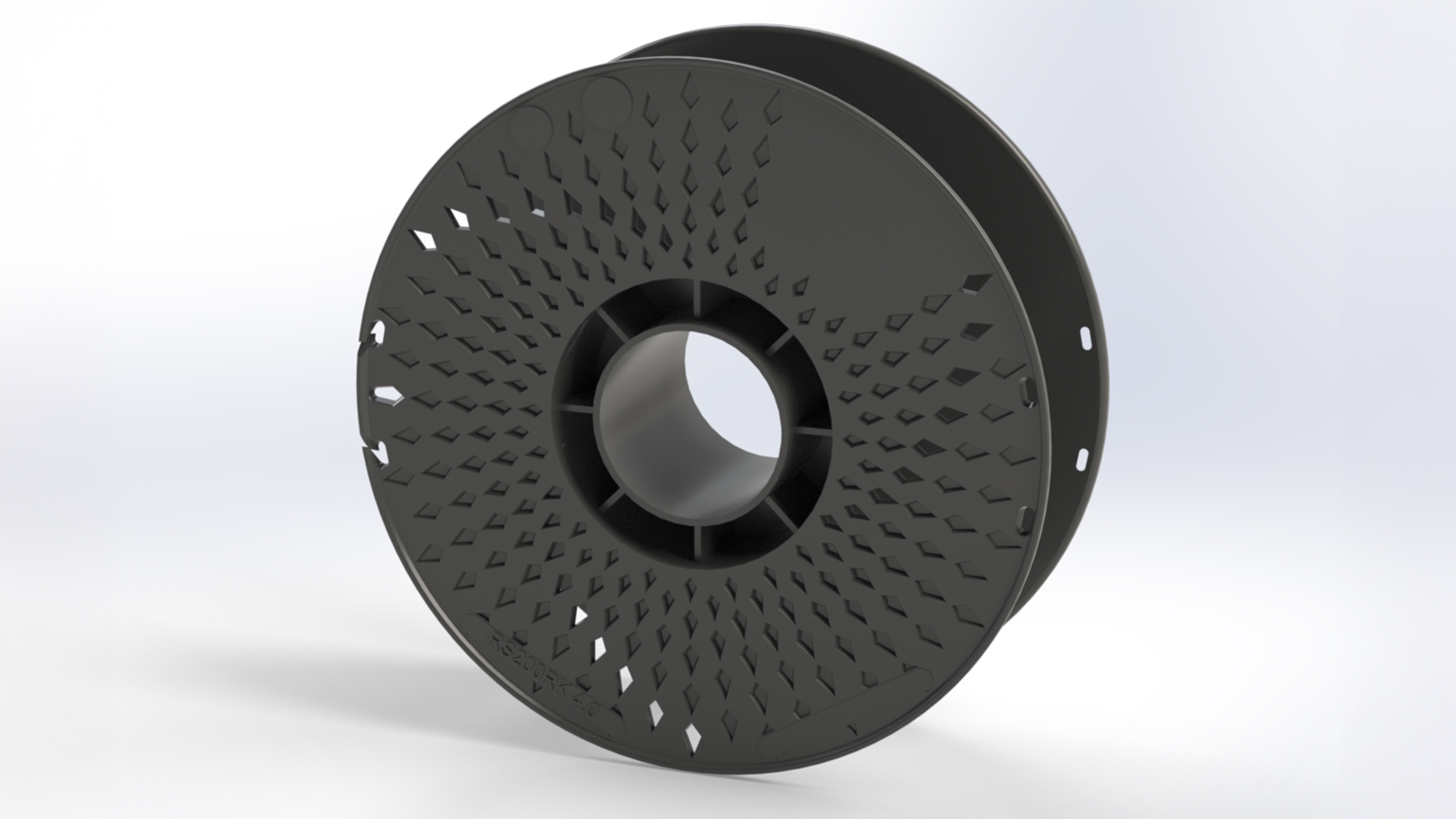

Alpaplastic: New spool with narrower inner core

At Formnext 2025, Alpaplastic is set to introduce the brand-new RS 200 RK, the latest addition to its range of 3D filament spools. Designed following the success of the widely used RS 200 KD, the new model has been developed to meet specific customer needs while maintaining the same external dimensions. The RS 200 KD continues to be a key product and a reliable solution for winding 1 kg of filament. The new RS 200 RK, with its narrower inner core, allows users to comfortably wind 1 kg of lower-density materials such as ABS — ensuring full compatibility with AMS loading systems.

Alpaplastic at Formnext 2025: Hall 12.1, Booth E46