The aim is to develop sustainable, adaptable, and high-performance products for the wind energy and construction industries.

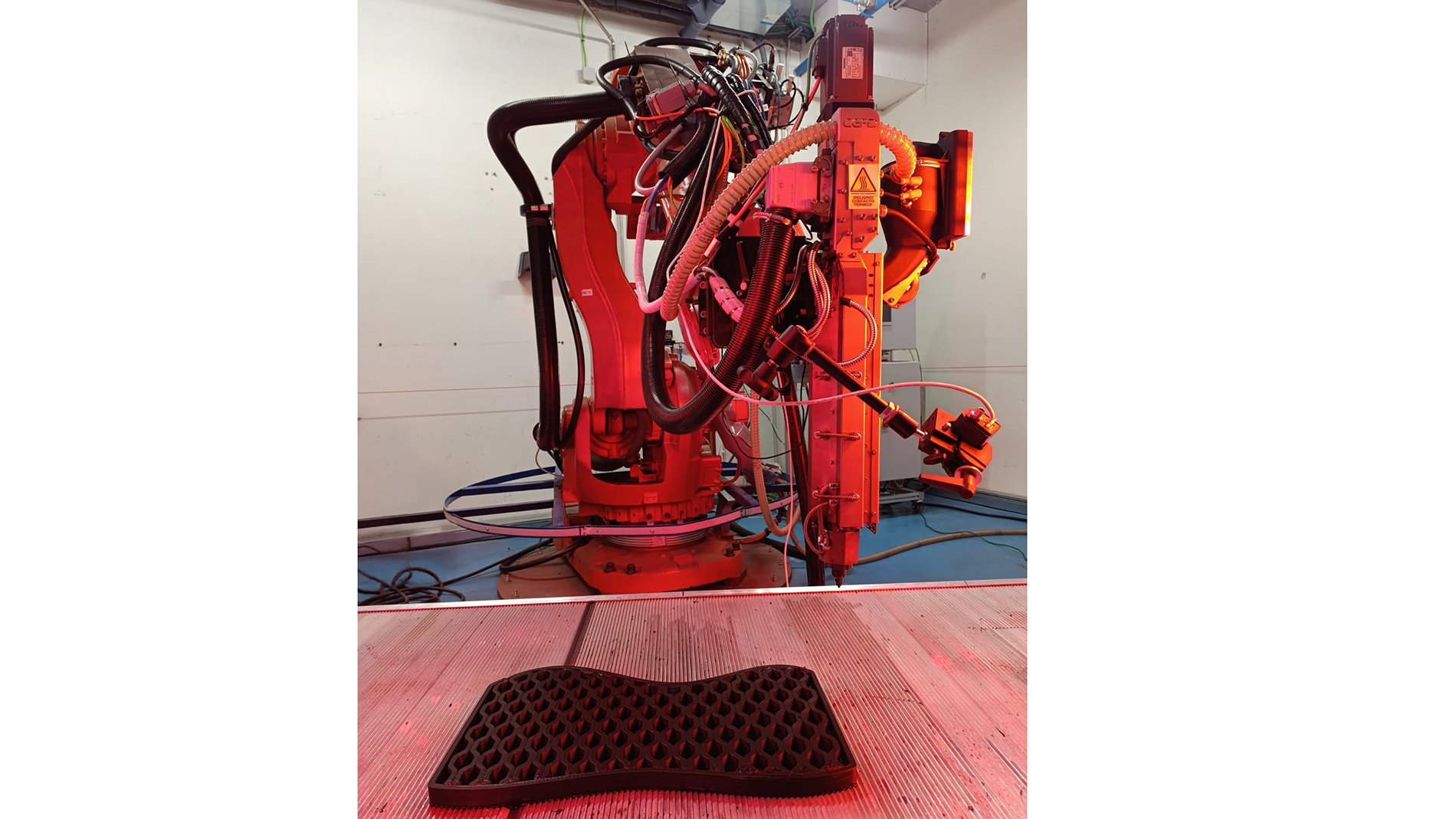

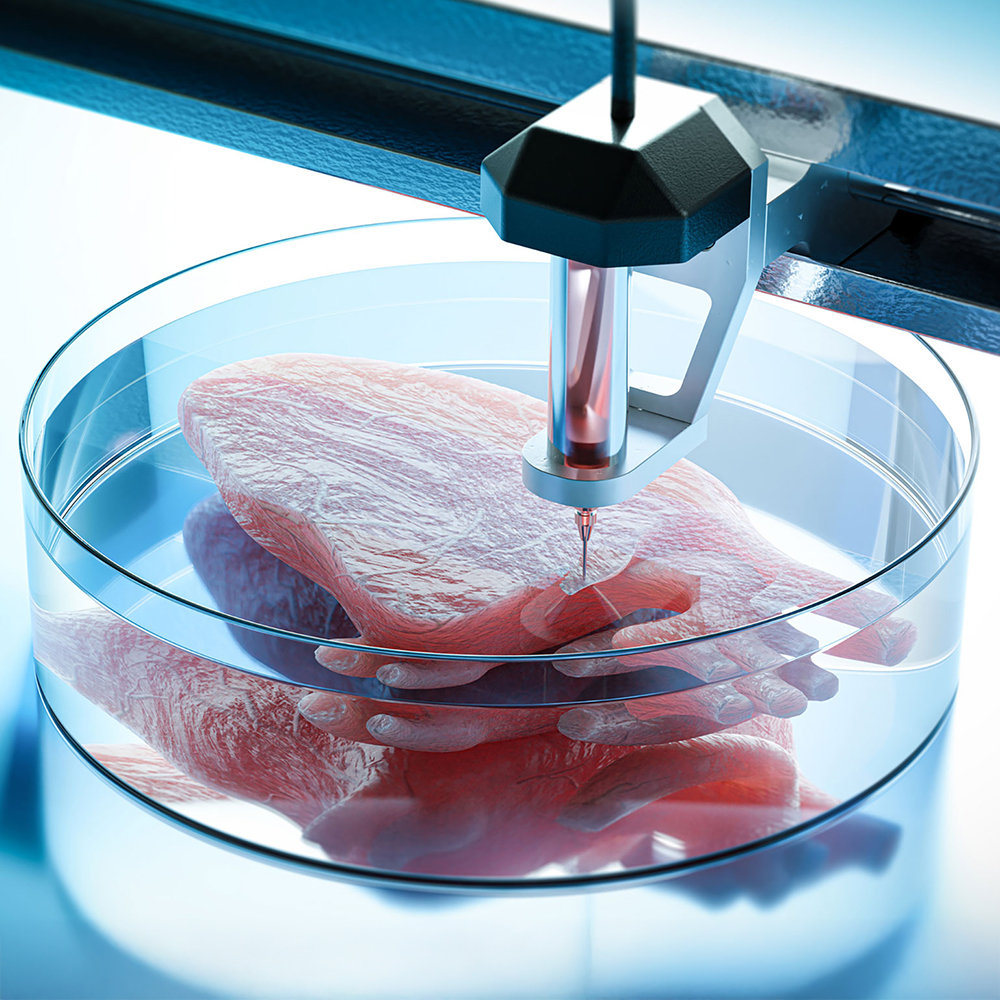

As part of the Organic project, Aimen is coordinating the development of an autonomous, bio-intelligent Additive Manufacturing system based on fused granulate fabrication (FGF). The project integrates bio-inspired lattice structures, bio-based materials, and a cognitive control architecture capable of self-monitoring, self-optimization, and self-healing.

A generative AI system called gentelligence will ensure the continuous evolution of the printing process, enabling each generation of components to improve based on its experience – much like a living organism. Aimen is responsible for coordinating the project, designing the FGF printhead, developing generative design tools, and implementing reinforcement learning models that guide the system’s learning and adaptation. The technology will be validated through the production of large, bio-inspired blade cores for offshore wind turbines, which should ensure structural efficiency and sustainability from the first print.

As part of the Biogemse project, Aimen is helping to transform the construction sector by developing bio-intelligent, sustainable and circular modular building systems. The project combines bio-based and recyclable materials with flexible, robotized 3D printing technologies. A generative AI tool will enable the design of biomimetic structures optimized for functionality and environmental performance. Aimen is leading the development of sustainable construction mortars with tailored functionalities, the implementation of a robotic Additive Manufacturing system for large and complex geometries, and the simulation of acoustic behavior to optimize product performance. The solutions will be validated in three Smart Living Labs targeting diverse climates and use cases.

Aimen is a multi-sector innovation and technology centre with 58 years of history. Its goal is to transfer the technologies it develops to industry to make current factories not only smarter, but more efficient, sustainable, and globally competitive.

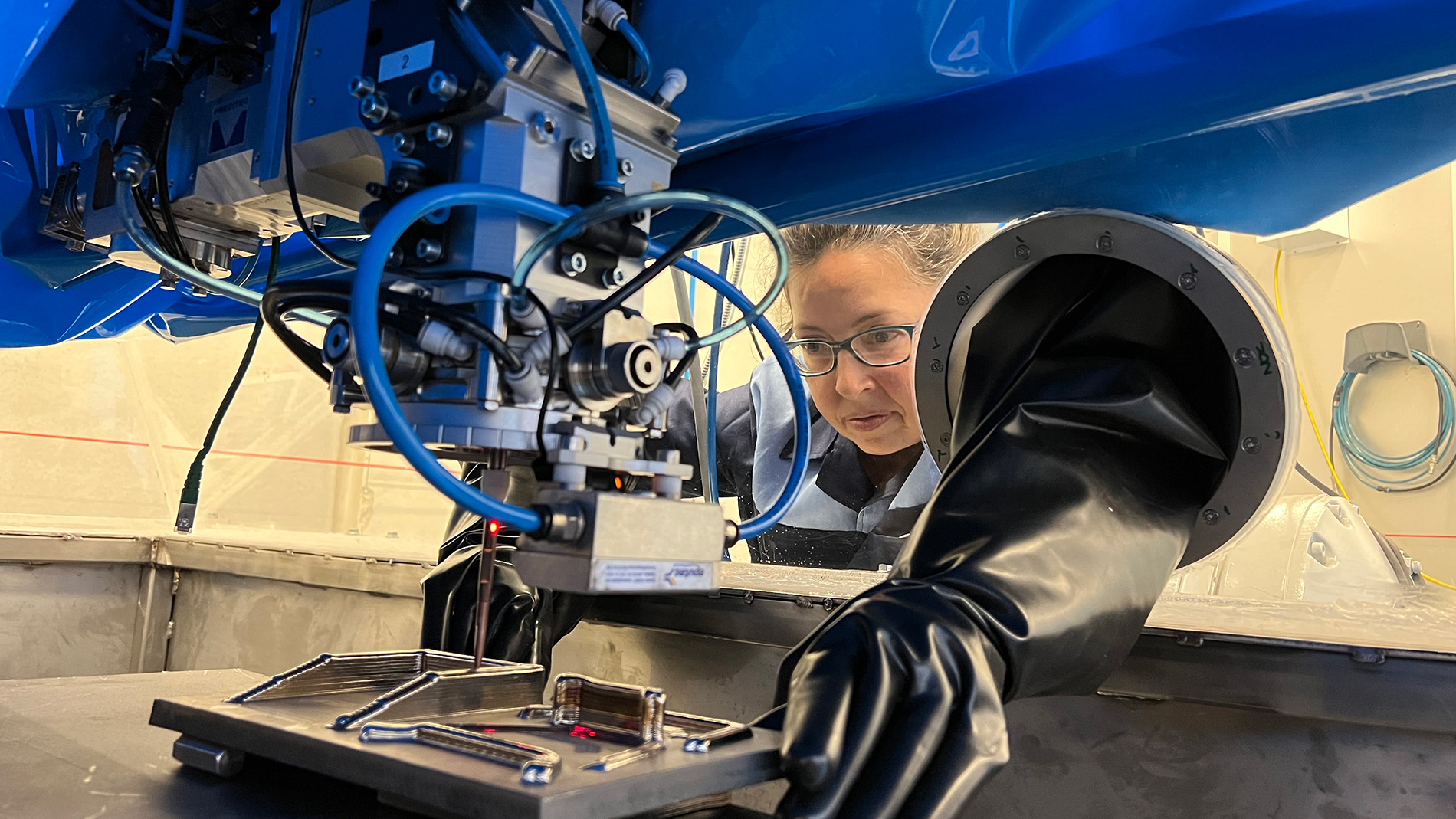

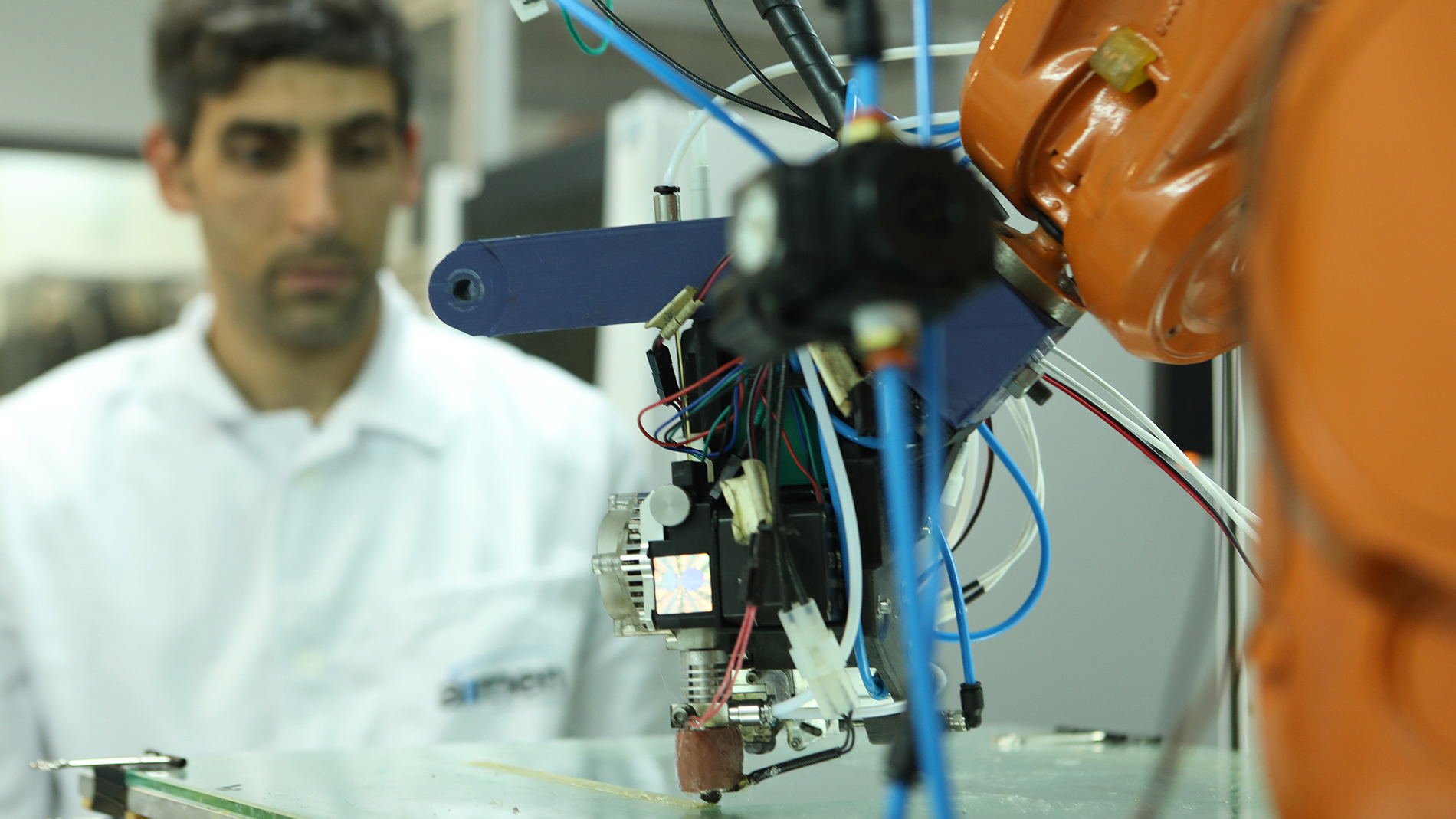

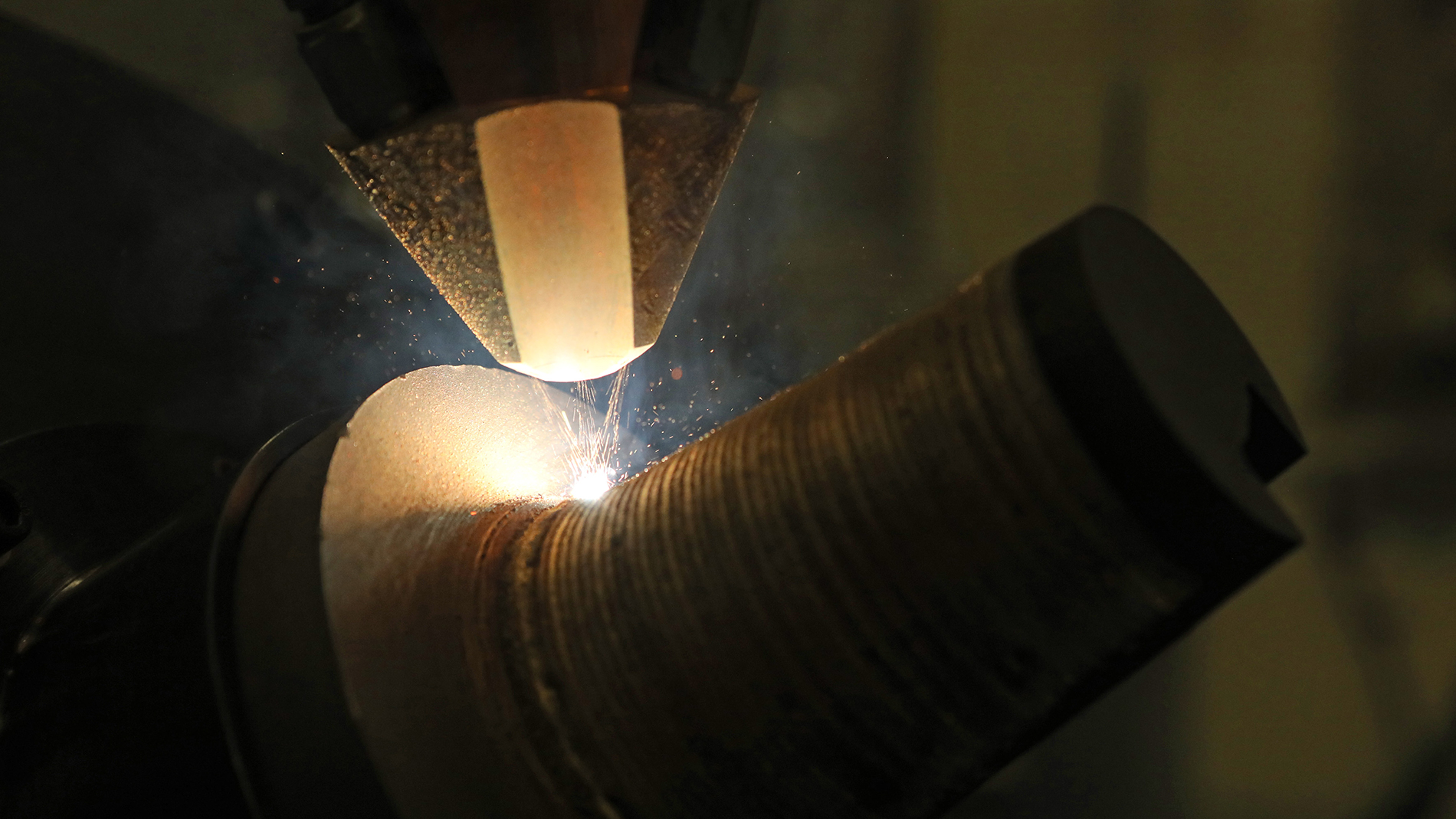

The technology centre offers extensive expertise and infrastructure in AM with a strong focus on metal, composites, and sustainable concrete, including a growing cement manufacturing line. Aimen is equipped with a broad range of industrial-grade infrastructure, including high-power lasers (up to 16 kW), multiple DED heads (wire and powder), WAAM sources, robotic and CNC LMD systems with multi-axis control, and inert environments for reactive materials. Its composite AM facilities feature flexible AFP heads, robotic FFF platforms, and integrated laser and IR heating.

Further company information

Further information

Further exclusive information on Spanish AM companies can be found in the print edition 03/2025 of Formnext Magazine or in the digital Fon Mag:

Aimen, Aimplas, ArcelorMittal, Danobat, HP, IAM3DHub, Indart3D, Madit, Meltio, Reinforce3, Recreus, Smart Materials, Market report Spain