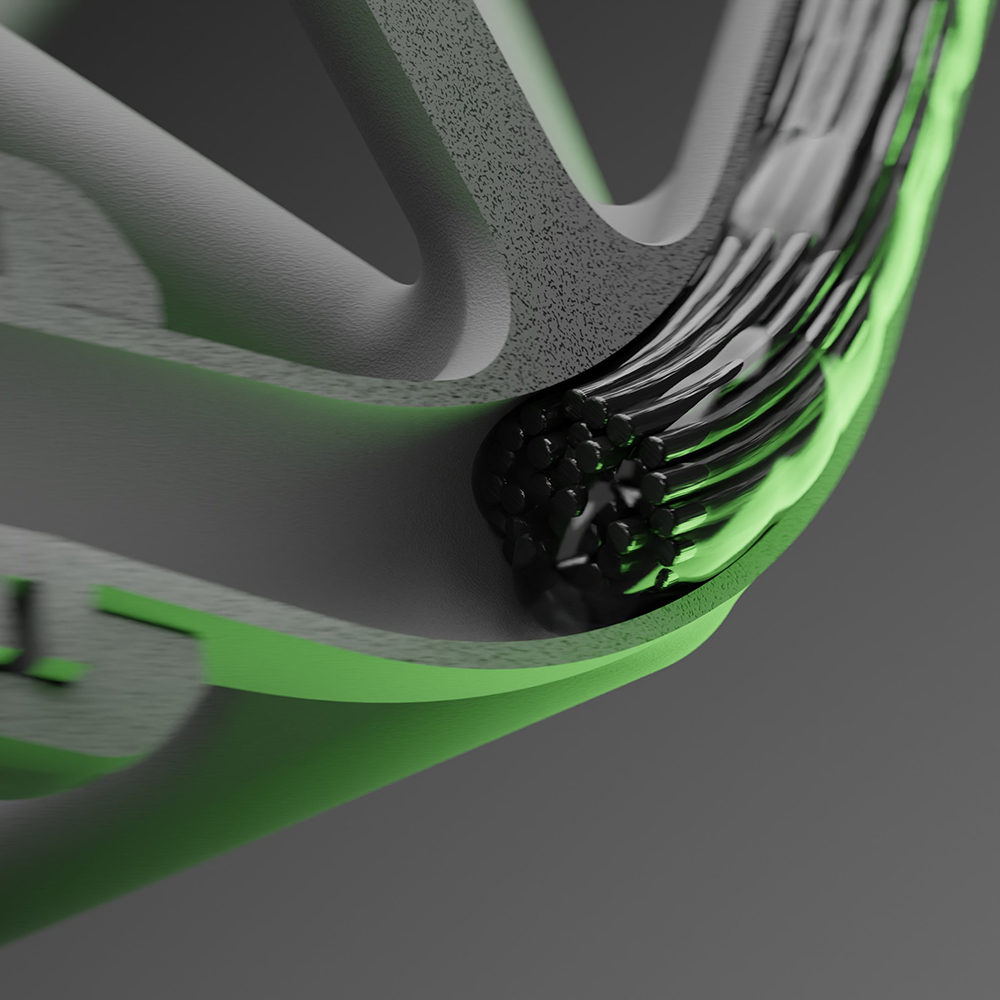

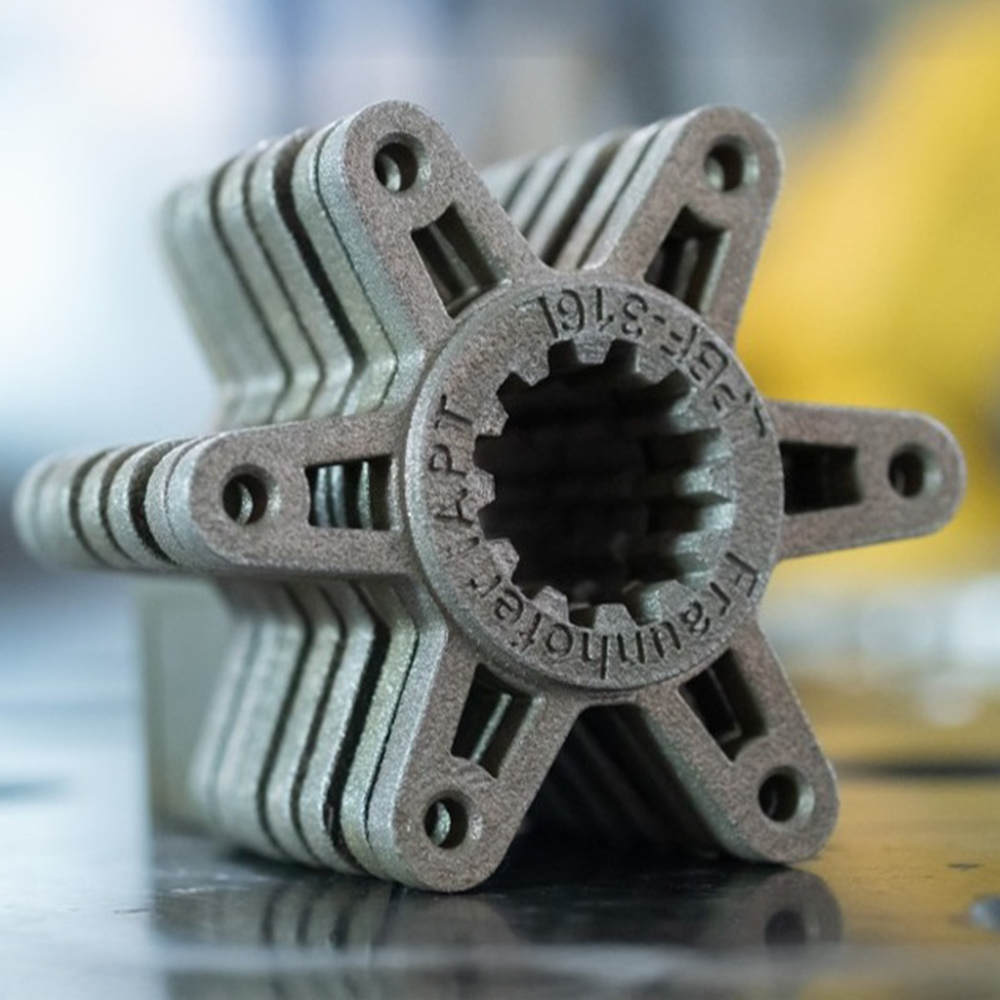

According to the company, it has now succeeded for the first time in producing secondary crowns digitally using a multimaterial AM technology (PBF-LB/MM) developed at Fraunhofer IGCV. Secondary crowns, or friction telescopes, consist of a combination of precious and non-precious metals.

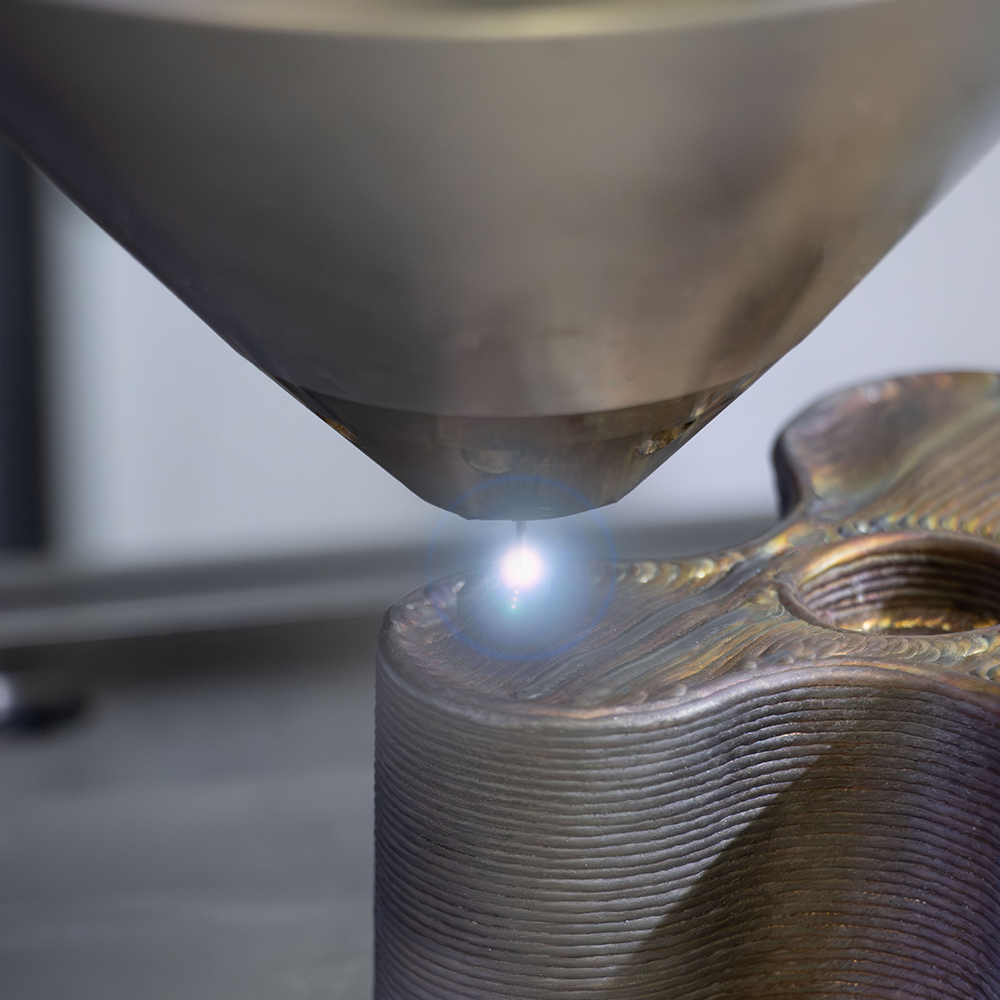

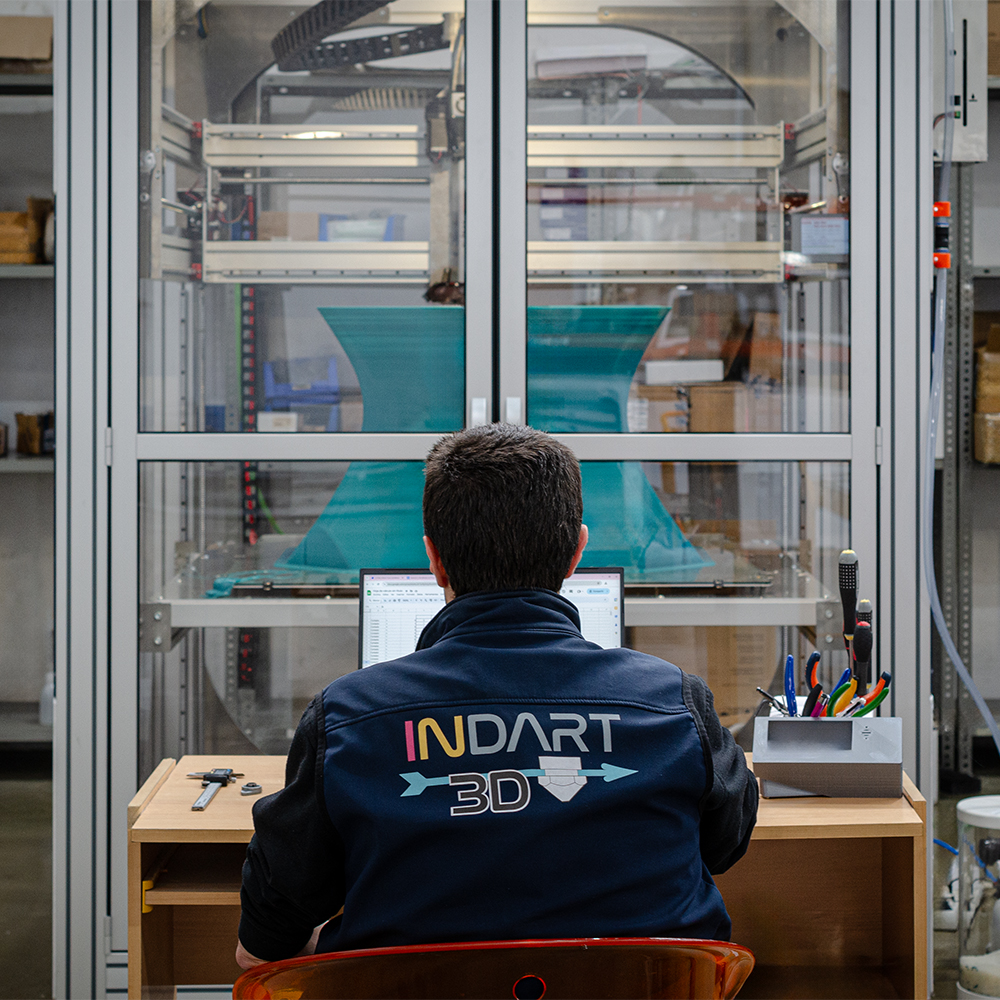

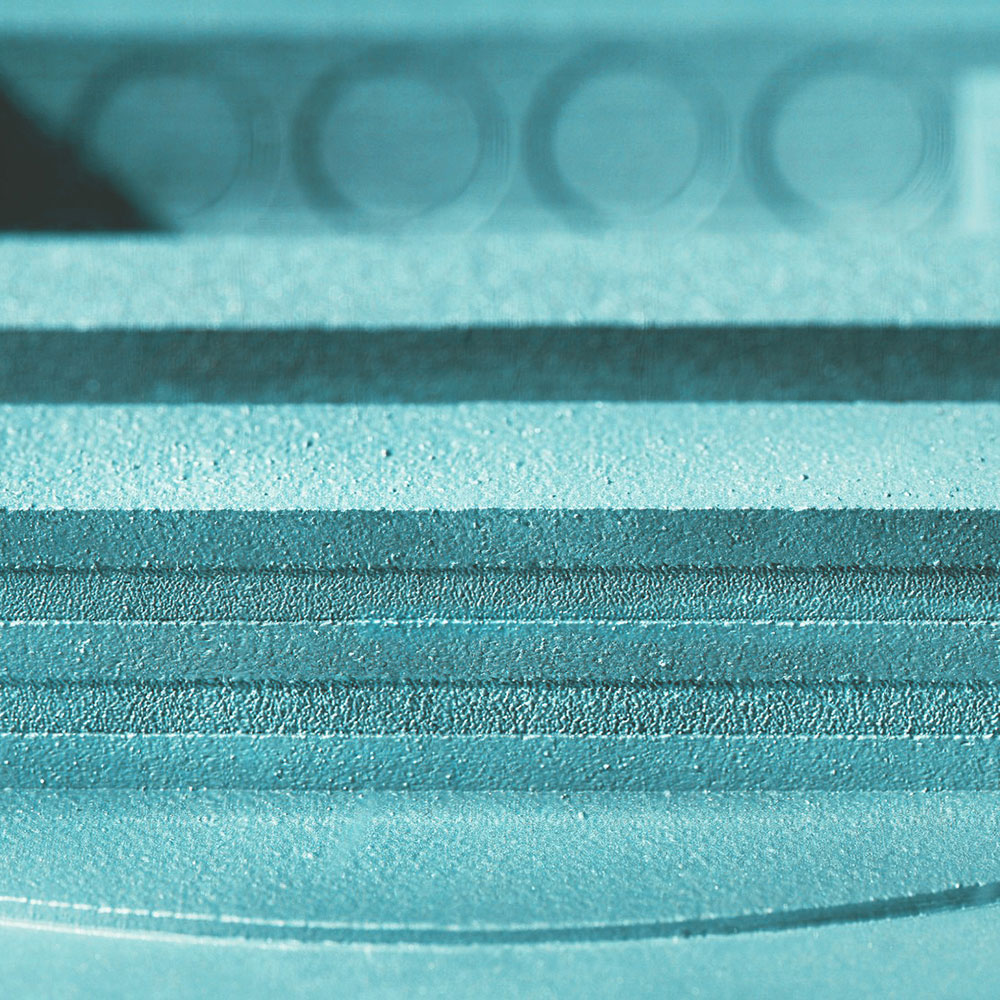

At the core of the solution is an industrial, robot-assisted powder bed process based on a modified EOS M290 system from AMCM. Two metal alloys commonly used in dentistry – for example, CoCrMo and a gold-based alloy – are automatically combined within a single build process. The geometry is digitally designed by the dental lab, and the friction surfaces are subsequently machined to specification.

High-quality friction telescopes are typically produced manually in leading dental laboratories today. Following a successful proof of concept, Fidentis – supported by Professor Christian Seidel of the Munich University of Applied Sciences as part of the Exist program – plans to launch its digital multimaterial solution on the market in 2026.