Text: Lennard Hermans (Fraunhofer IAPT)

Metal SLS, also referred to as Cold Metal Fusion, combines Selective Laser Sintering for polymer components with process technologies from conventional powder metallurgy. A study at Fraunhofer IAPT has assessed the industrial potential of the Metal SLS process chain in a comprehensive comparison with the L-PBF process. The result: The use of established SLS platforms also allows for cost-effective and scalable production, making Metal SLS particularly attractive for small- to medium-sized series.

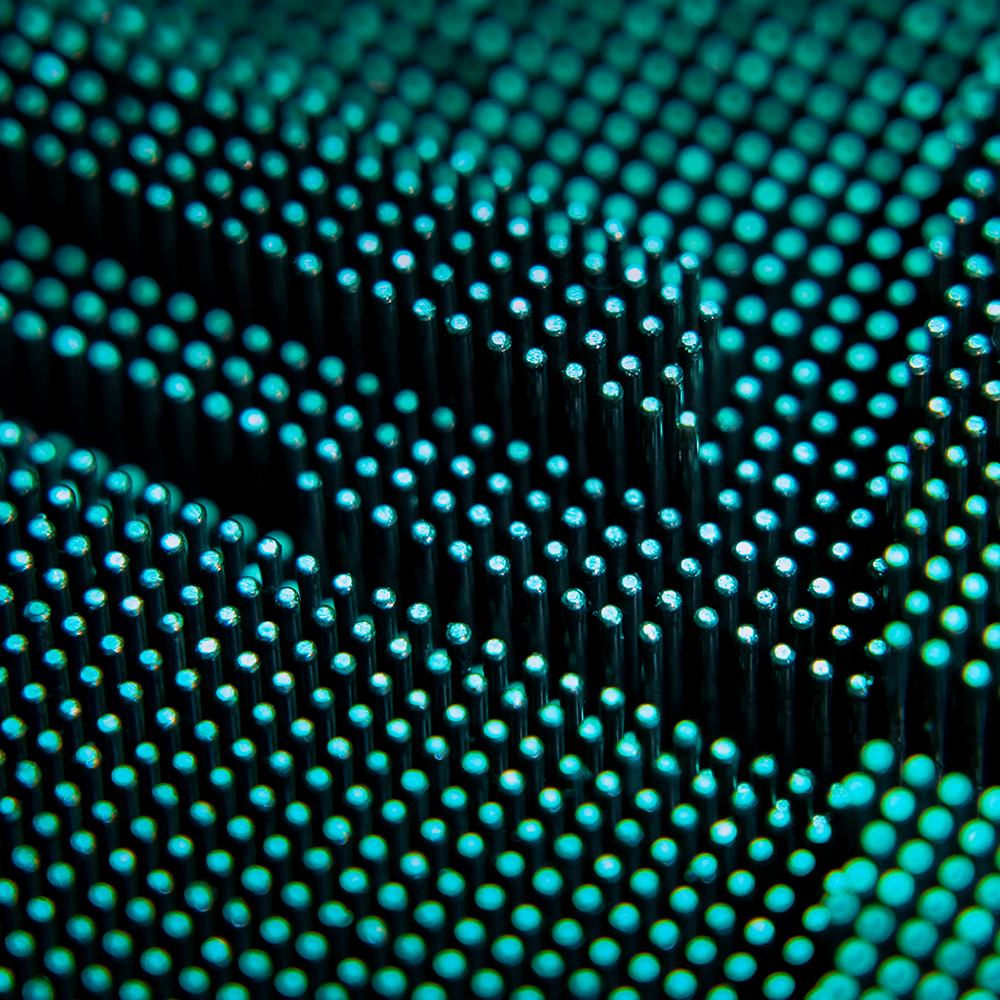

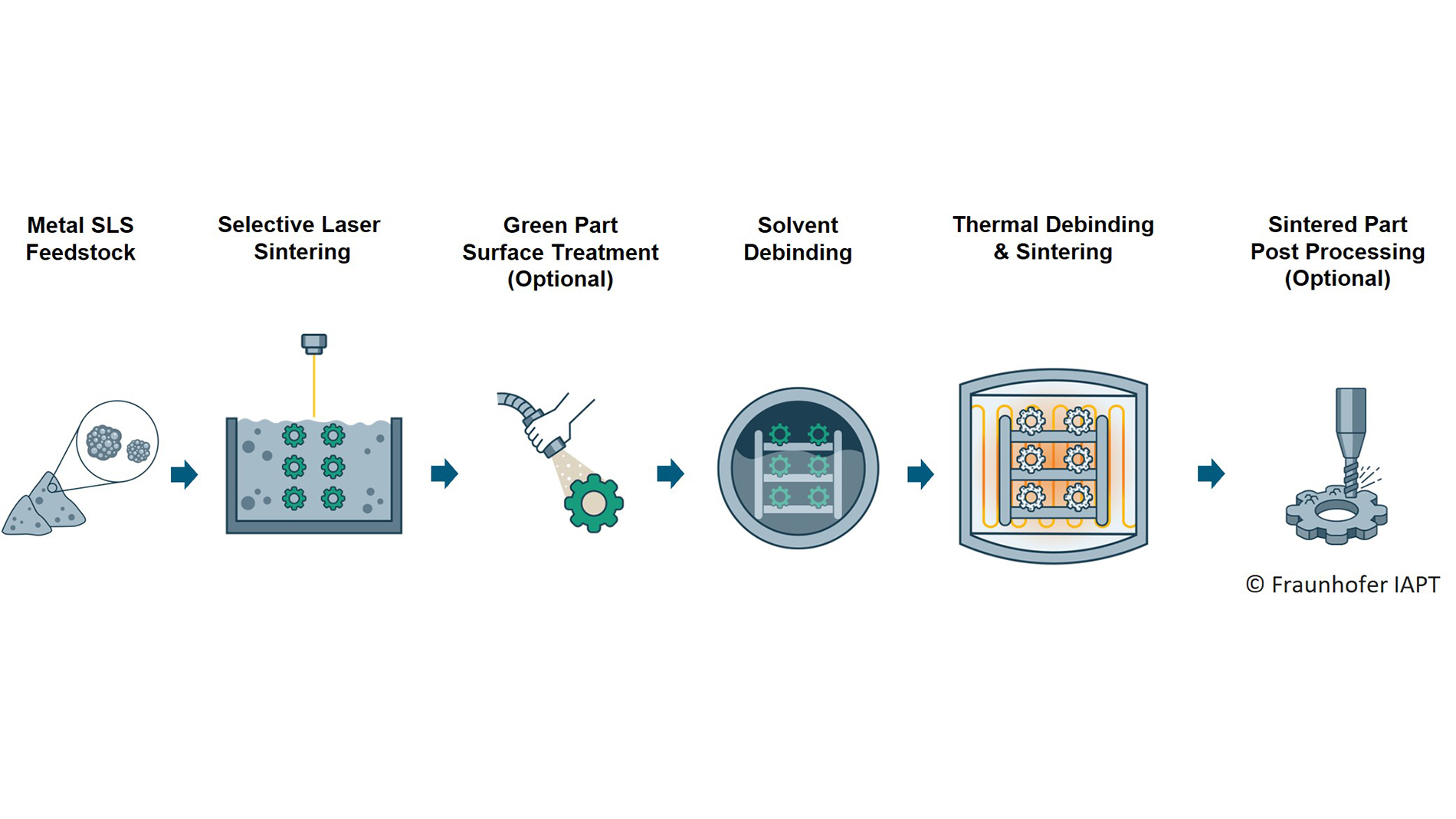

In standard SLS equipment, a specially developed composite powder is used, applied layer by layer and selectively fused, similar to polymer powders. The composite consists of metal particles encapsulated in a thermoplastic binder. Upon localized laser exposure, the binder melts and forms a dense, dimensionally stable green part. The green part subsequently follows a process chain analogous to that of Metal Injection Molding (MIM): After optional green-state post-processing, solvent and thermal debinding are performed, followed by sintering to obtain the desired metallic properties.

Process chain of the metal SLS process. Illustration: Fraunhofer IAPT

Green part processing holds significant economic potential, especially for tool- and hard metals, as post-processing is faster and tool wear is considerably lower due to the softer material state. When the dimensional or surface requirements are not met, additional post-processing on the sintered part can be performed.

Unlike laser-based metal AM processes such as Laser Powder Bed Fusion (L-PBF), Metal SLS does not involve melting of the metallic particles during the printing phase. As a result, even difficult-to-weld metals can be processed into geometrically complex components during sintering. The approach leverages the precision of laser-based polymer SLS printing while incorporating the advantages of a sintering step, such as low residual stresses.

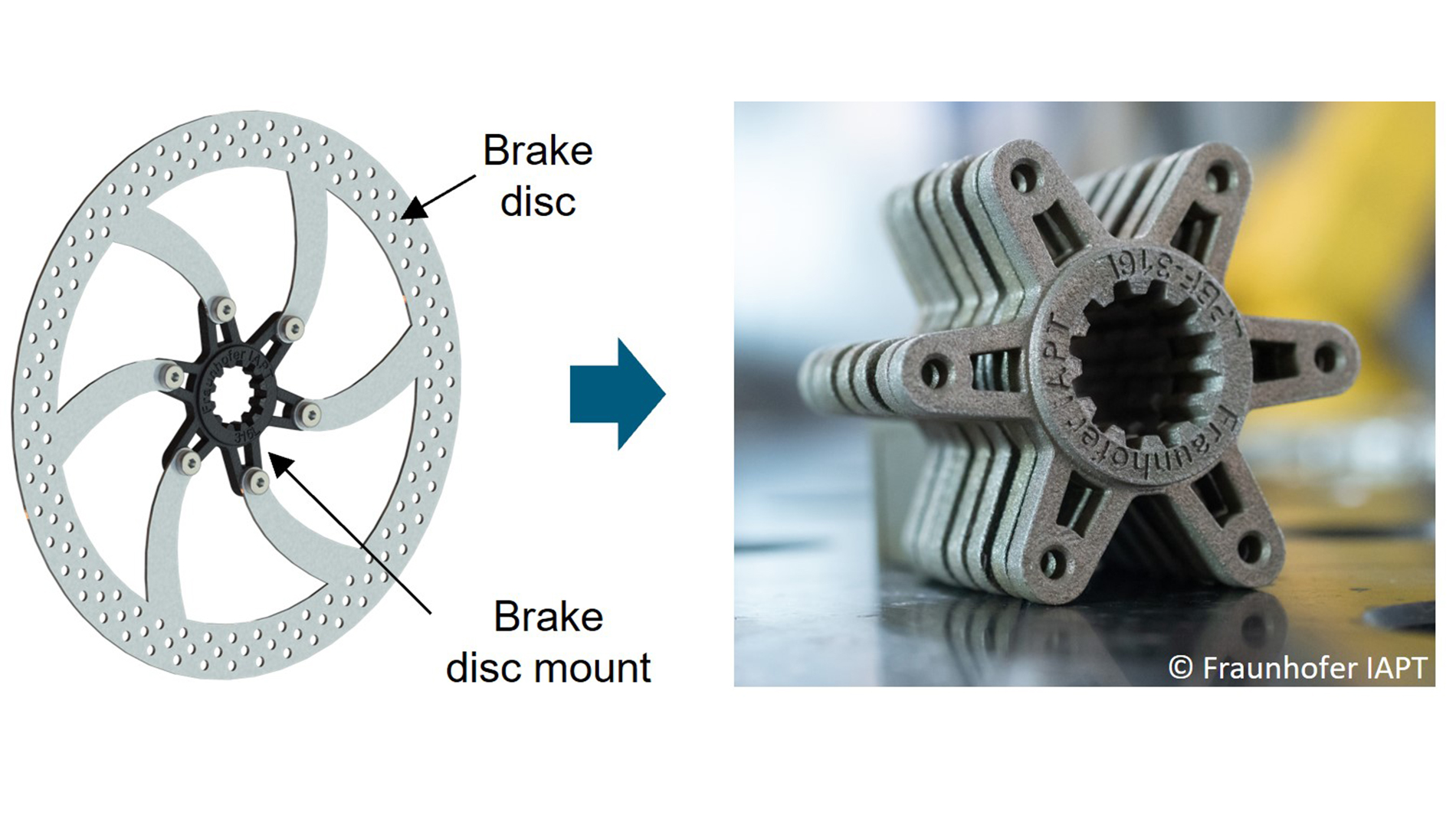

The economic evaluation was based on 1,000 bicycle brake disk mounts, which are a classic component for small to medium-scale production. Illustration: Fraunhofer IAPT

Comprehensive comparison

A study at Fraunhofer IAPT has assessed the industrial potential of the Metal SLS process chain in a comprehensive comparison with the L-PBF process. The comparison included both economic and qualitative aspects. Economically, lead time and cost structures were analyzed in detail, taking into account different furnace sizes within the sintering process chain. Qualitatively, differences in dimensional accuracy, density, hardness, tensile properties and surface roughness were examined. The economic evaluation was based on 1,000 bicycle brake disk mounts, which are a classic component for small to medium-scale production.

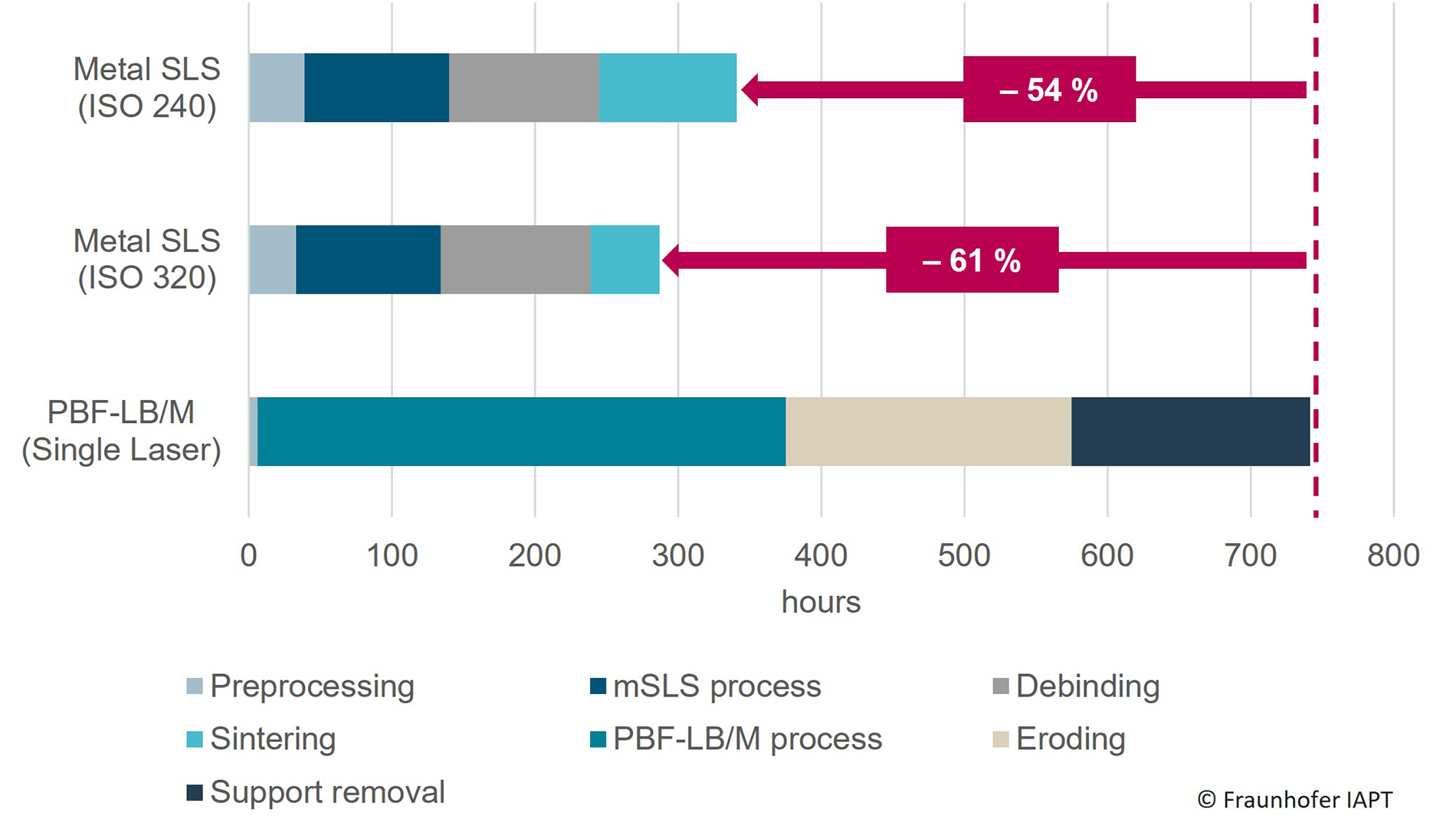

For L-PBF and Metal SLS, a single-laser system was used. Due to the high build-up rate of the SLS process, the main time bottleneck in the process chain lies not in the printing itself, but in the subsequent debinding and sintering steps.

Two ISO furnaces with a furnace volume of 11 L (ISO 240) and 28 L (ISO 320) were examined, which do not differ significantly in terms of purchase price but in terms of operating costs. High furnace utilization must be optimized with regard to electricity and gas consumption. Post-processing was not included in the calculation of the throughput time, as it depends on the individual component requirements. In comparison to L-PBF, Metal SLS offers a high build-up rate and support structure-free printing, thereby eliminating the need for support removal that involves significant additional effort. The results do not apply in the same degree to all components and process chain designs, but they do convey the economic opportunities for series production using Metal SLS.

The results of the comparative study. Illustration: Fraunhofer IAPT

Further information:

or contact Lennard Hermans: lennard.hermans@iapt.fraunhofer.de