While the focus of Additive Manufacturing has so far been on producing components that are as dense and resilient as possible: “We are bringing a new functionality to 3D Printing – permeability as a designable feature,” explains Andreas Vogelpoth from the LPBF Process and System Technology group at Fraunhofer ILT. The process is particularly interesting wherever gases or liquids need to be distributed, filtered, or conducted in a controlled manner.

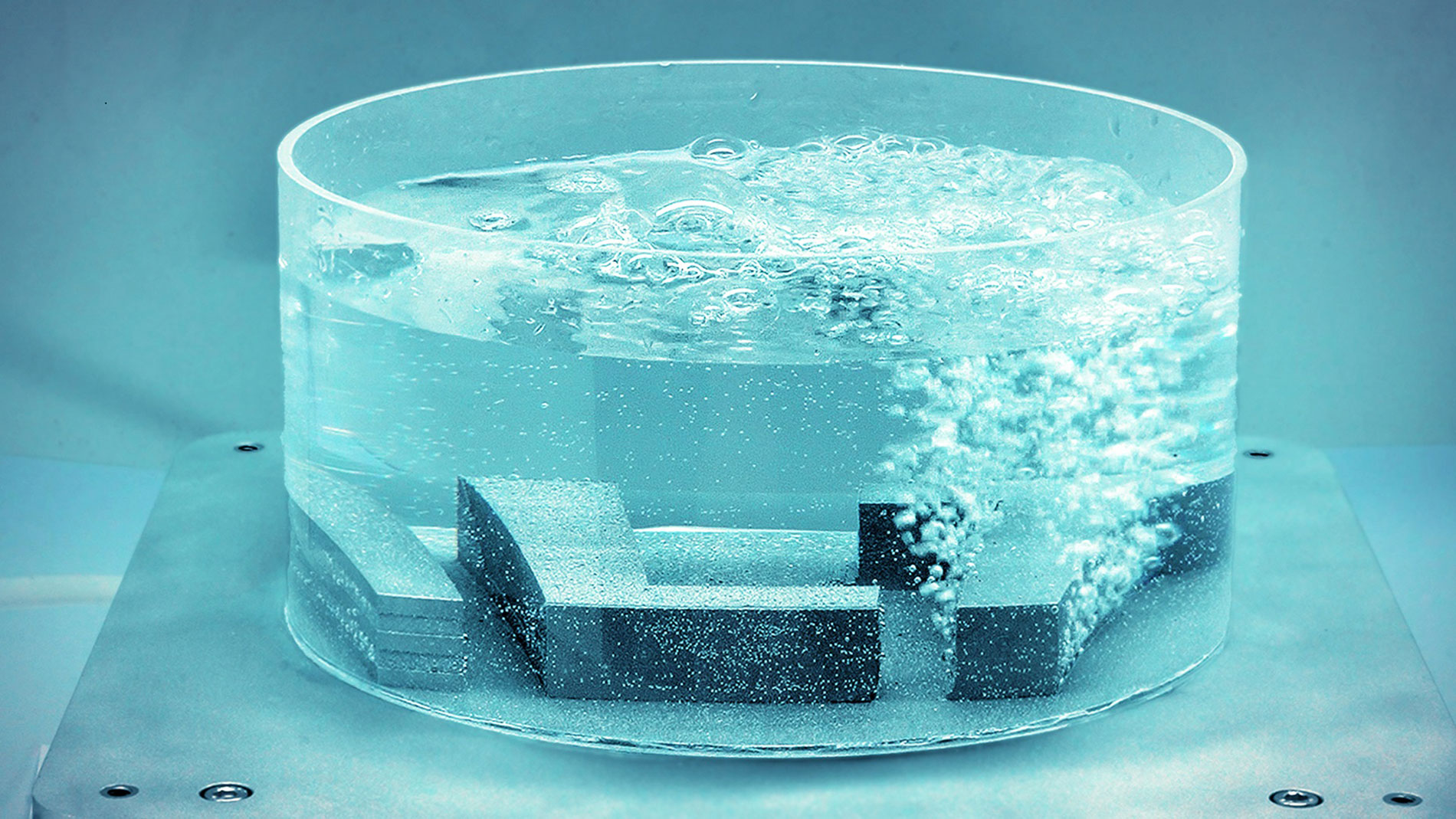

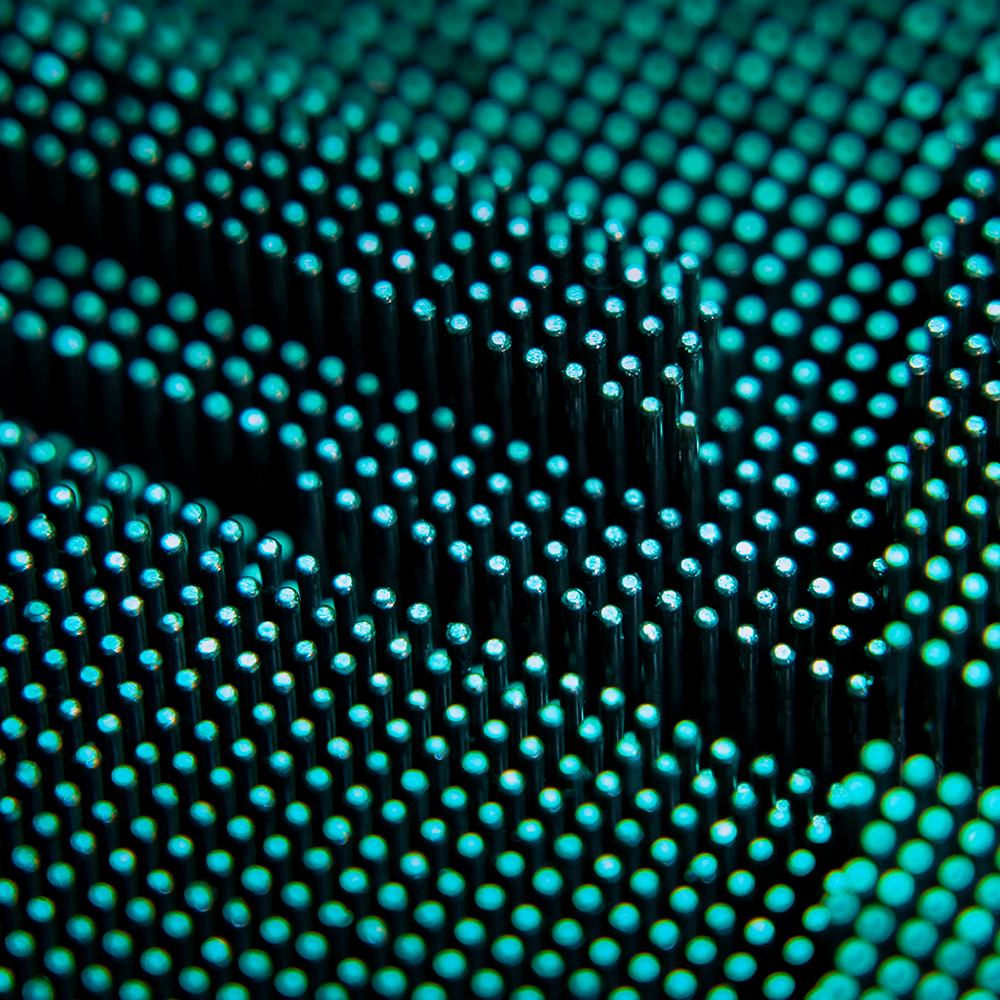

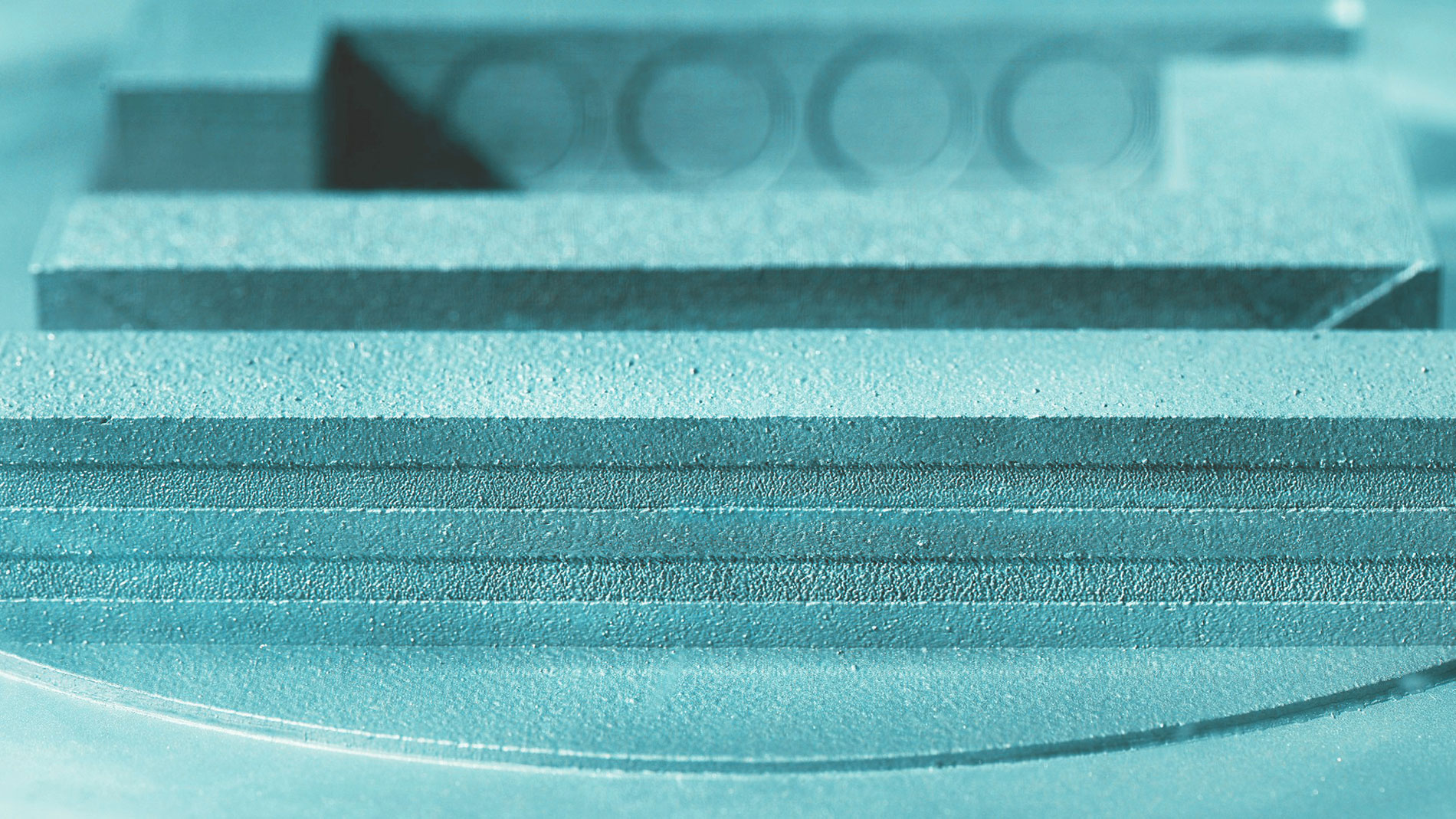

Controlled permeability is achieved by allowing locally targeted porosity – for example, through modified process parameters. This results in completely metallic components that are locally permeable – such as to gases or liquids – but still have the required mechanical integrity. The trick is that areas with different densities can be combined within one component thanks to LPBF. Fraunhofer ILT can also make transitions either with sharp or graded separation.

Porous zones directly in the component

Conventional metal foams or fabric structures fulfill similar functions, but usually need to be produced separately and incorporated into components. This not only takes time, but also limits design freedom and leads to changes in the physical properties of the component due to seams and joints (which can increase thermal and electrical resistance, for instance). The Fraunhofer solution integrates porous zones directly into the component. According to ILT, post-processing is not necessary, and even complex geometrical shapes with internal structures can be made in this way.

Electrolysis, mechanical engineering, heat exchangers, and more

A key area of application is hydrogen technology, specifically for electrolyzers. These consist of complex cell stacks with various functional layers. Fraunhofer ILT is currently investigating whether these layers can be additively manufactured directly, including with specific permeable areas. Its experts are aiming to reduce the number of individual parts and thereby improve efficiency while reducing material usage and production costs. Meanwhile, the Fraunhofer ILT team is also already in contact with end users in other areas of applications, such as turbomachinery, toolmaking, heat exchangers, filters, and chemicals.

According to Fraunhofer ILT, porous areas can be reproduced reliably, which the researchers have already demonstrated using computer tomography and cross-sections. They are currently working on the next step as part of a research project: the precise control of permeability via process parameters. “Our plan is for users to tell us how much permeability is required in which component areas so we can supply the appropriate design and process parameters," says Vogelpoth.