With the Formnext Awards, we shine a spotlight on innovative concepts that have the potential to transform industrial manufacturing in a lasting way. Formnext gives groundbreaking ideas the stage they deserve.

What are the Formnext Awards?

The AM world shines thanks to talented, motivated people who continue to advance the technology and thus drive the entire industry. It’s therefore only fitting that their ideas should receive the time in the spotlight they deserve – for the good of the industry and the forward-thinking development of modern production as a whole.

Winners & finalists

Decided together: The AM community made it happen! The public vote counts as an additional jury voice: both visitors attending Formnext in person and those joining online can vote for one of the finalists in each of the six categories and help determine the final outcome.

+++ The voting is officially closed and the results are in! – a huge thank you for your amazing participation. +++

A big round of applause for our winners! And a heartfelt thank you to everyone who joined and supported us – you made this incredible.

AMbassador Award

The AMbassador Award honors individuals or organizations who provide real impact on the industry through training and educational programs or their personal advocacy.

The winner

SKZ - Das Kunststoff-Zentrum

The IHK certificate program closes a key qualification gap in Additive Manufacturing and provides hands-on expertise across the entire process chain – without academic entry requirements.

Technological advances and the increasing relevance of additive manufacturing processes in a wide range of industries are leading to a steadily growing demand for qualified specialists. Additive manufacturing (AM) is considered a key technology of the future – but so far, there is a lack of structured concepts for sound professional qualification. Therefore, the Chamber of Industry and Commerce (IHK) Würzburg-Schweinfurt and the SKZ are jointly offering a practical course leading to the qualification of “Certified Industrial Technician in Additive Manufacturing.” The recognized IHK degree is aimed at those who are interested in gaining a comprehensive overview of additive manufacturing. The further education program covers the entire 3D printing process chain – from the materials used and their processing to design and procedures to complementary topics such as energy, hydraulics, and occupational safety. This prepares participants for the practical requirements of the industry. In many places, knowledge acquisition still takes place informally, through trial and error or with the help of online sources such as YouTube videos and forums. Officially recognized educational formats have not been available until now. With the Certified Industrial Technician in Additive Manufacturing (IHK), we are setting a unique nationwide precedent for securing skilled workers and, for the first time, closing the knowledge gap at the intermediate education level, based on DQR level 6. The practical and industry-oriented continuing education program, which has no academic entry barriers, can be completed part-time over two years while working. The program takes into account both the dynamic technological environment and the diversity of additive processes. The close integration of education and research results in an innovative offering that enables skilled workers and companies to build AM expertise in a targeted and sustainable manner—a decisive contribution to actively counteracting the shortage of skilled workers. Two compact practical weeks round off the training program: one takes place at SKZ with a focus on additive manufacturing with plastics, the second at AMbitious with a focus on metal 3D printing. In addition to the theoretical content, the focus is on process-reliable application, in-depth understanding of materials, and industrial implementation. The Chamber of Industry and Commerce expands the curriculum to include topics such as business organization and production management, while also offering graduates the opportunity to pursue further studies. The training concept marks a shift away from purely academic formats toward practical expertise. An interdisciplinary team of 19 experts ensures that the content is technologically up-to-date and of high quality. In this way, the continuing education program makes a lasting contribution to the innovative strength of the industry.

You can experience the project presentation live at the Formnext Awards Showcase: Hall 11.0, D82

Finalists

ADDIMAT - Additive Manufacturing Association of Spain

Positioning Spain’s AM industry on the global stage and fostering connections with industry leaders

Naiara Zubizarreta is Director of ADDIMAT, the Spanish Association for Additive Manufacturing. Since 2015, she has been leading the strategy and growth of Spain’s AM ecosystem, shaping a strong community that today brings together more than 100 members. Under her leadership, Spanish AM has gained international visibility through her presence at international conferences, the organization of joint booths at Formnext, strategic collaborations in Europe (AM-Europe), and strong representation in policy and standardization forums. Her role involves promoting collaboration, driving initiatives that support research, workforce development, and technological advancement. Today, Spain is one of Europe’s fastest-growing AM markets and will showcase this momentum at Formnext as Partner Country 2025.

This year, ADDIMAT celebrates its 10th anniversary. Being a finalist of the AMbassador Award means a recognition of this journey and collective achievement. It is also an opportunity to amplify Spain’s voice in the global AM community, foster collaboration across Europe and beyond, and inspire the next generation of women to lead the manufacturing sector.

Addimat at Formnext: Hall 12.0, C121 and at the Formnext Awards Showcase: Hall 11.0, D82

RWTH Aachen University - Digital Additive Production DAP

The project is developing a data-driven, technology-focused education strategy for Additive Manufacturing that intelligently connects industry needs, immersive learning formats, and labor market analysis.

My PhD (Dr.-Ing.) project proposes a comprehensive, technology-enhanced, and data-driven methodology for Additive Manufacturing education that directly addresses Industry 4.0 skill requirements. Its novelty lies in combining four dimensions: (1) systematic analysis of industrial needs, (2) modular and flexible curricula design, (3) immersive AR/VR applications to teach complex concepts such as DfAM and PBF process, and (4) data-driven monitoring through NLP analysis of thousand of job postings. This integration creates a unique feedback loop that ensures content is always updated with current and emerging skills. By merging structured pedagogy, advanced digital technologies, and labor market intelligence, the initiative represents a novel, scalable, and transferable blueprint that not only strengthens AM education but also serves as a model for other fast-evolving advanced manufacturing fields.

You can experience the project presentation live at the Formnext Awards Showcase: Hall 11.0, D82

Design Award

By identifying concepts that balance both aesthetic and functional aspects, the Design Award highlights the importance of intelligent and inventive design in additive manufacturing.

The winner

Grabbit - Hochschule für Gestaltung Schwäbisch Gmünd

Grabbit is a project designed for people with hand impairments, combining design, technology, and sustainability. Three distinct shapes enable exercises, hot and cold applications, and adjustable resistance.

Grabbit was developed from a strongly human-centered perspective. The project is aimed at people with hand problems and combines design, modern technology and sustainability into simple and tangible solutions. The starting point was very personal. My grandmother struggled to pick up small objects like coins or needles, and my grandfather, after a stroke, could only use his hand in a limited way. During my research it became clear that many other people are affected, including those with Parkinson’s disease, rheumatism, arthrosis, aging-related weakness or injuries. To better understand these needs, I visited senior centers and worked closely with physiotherapists and occupational therapists. Their feedback helped me to develop Grabbit step by step, to test it and to refine it in a targeted way.

The product family is based on three geometric forms that are intuitively understood. The ball enables a variety of grip exercises and, for the first time, fully integrates the thumb into training. The ring activates the extensor muscles and helps to prevent stiffness after injuries or neurological conditions. The cone contains a silicone insert with phase-change material that functions like a hand warmer. It can be used in the morning to activate the hands or in the evening to relax them. The 3D-printed lattice structure supports these functions by distributing heat or cold evenly, improving blood flow and providing adaptive resistance.

Additive Manufacturing is the key to Grabbit. TPU lattice structures, produced with SLS, create resistance that adapts to pressure and open up new training possibilities for different medical conditions. PA12, manufactured with MJF, forms the bayonet lock that precisely connects the 3D-printed parts with ash wood. The wood adds warmth, sustainability and a pleasant tactile quality that contrasts with the technical character of the plastics. Together, these elements create an aesthetic that avoids the stigma of medical devices and turns the products into everyday companions.

Grabbit goes beyond a therapy device. It restores independence, reduces stigma and brings joy into everyday life. At the same time, the project shows how design and technology can help address central societal challenges and make innovation both tangible and accessible.

You can experience the project presentation live at the Formnext Awards Showcase: Hall 11.0, D82

Finalists

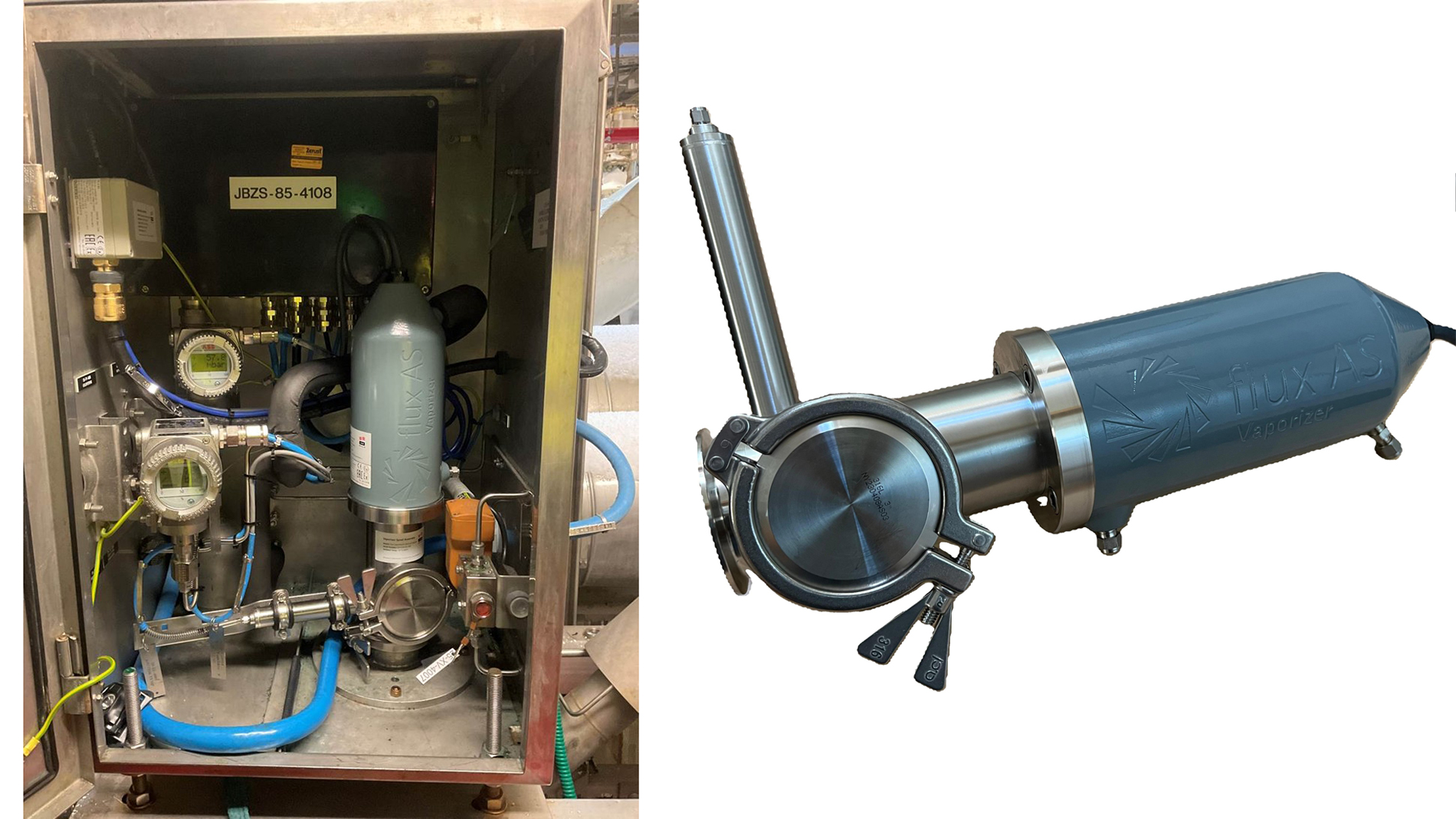

IKM Flux Vaporizer - IKM Flux, EOS, Valland, ToffeeX

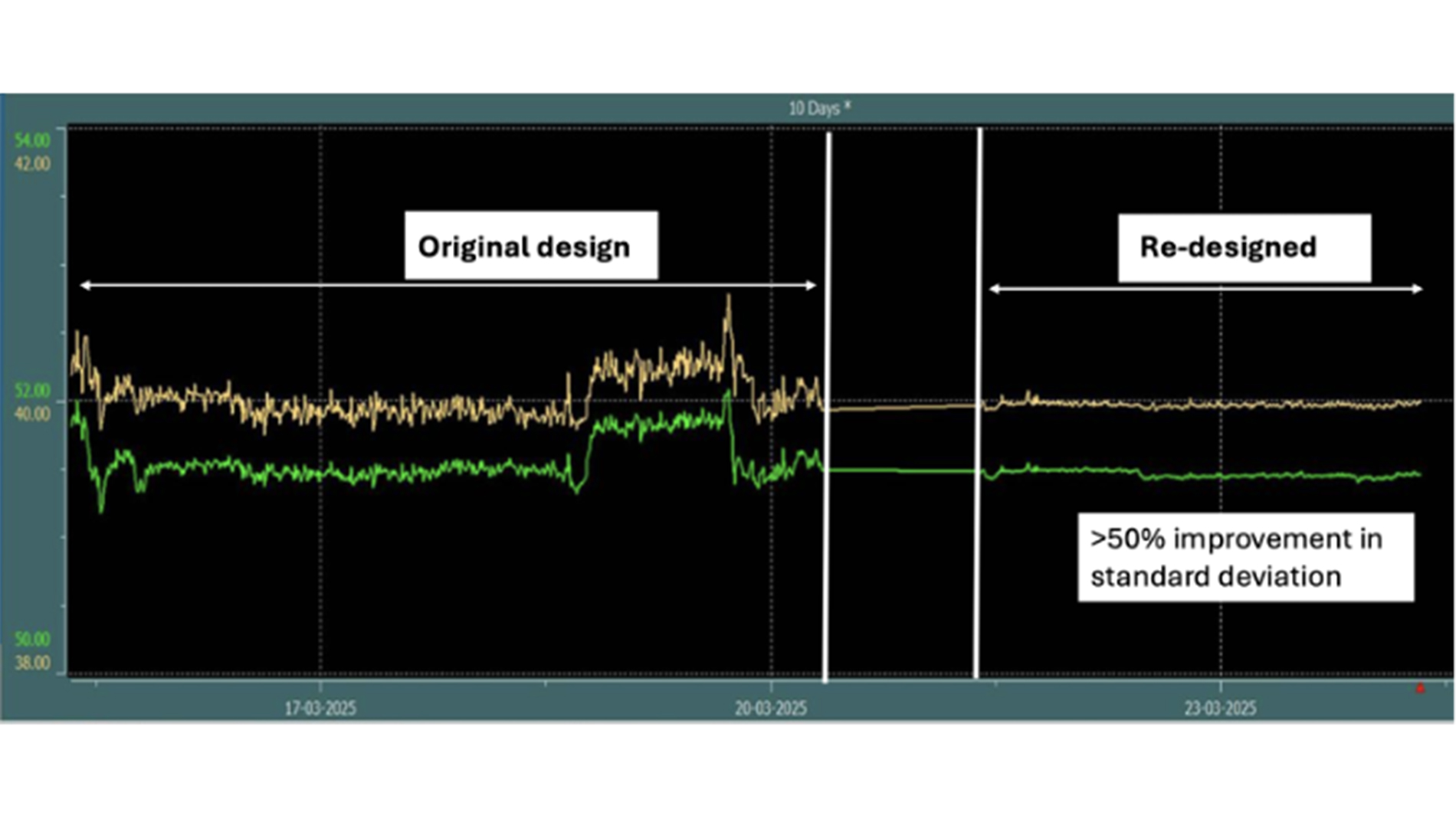

The IKM Flux Vaporizer is a newly developed LNG evaporation solution that uses generative design and Additive Manufacturing to more than double measurement accuracy.

The IKM Flux Vaporizer is a groundbreaking redesign of a critical piece of energy infrastructure that supports global trade in liquefied natural gas (LNG). LNG is considered one of the cleaner transition fuels, produced by cooling natural gas to -162 °C for safe storage and transport. Each year, LNG shipments worth more than $7.5 trillion are traded worldwide, and their value depends on precise measurement of energy content.

To make these measurements, LNG must first be converted back into gas using a vaporizer. However, conventional vaporizers often struggle at the extreme temperatures and pressures involved, leading to small but costly inaccuracies. Even a variation of just 3% key measurements of energy content can change the value of a single LNG cargo by more than $1.5 million.

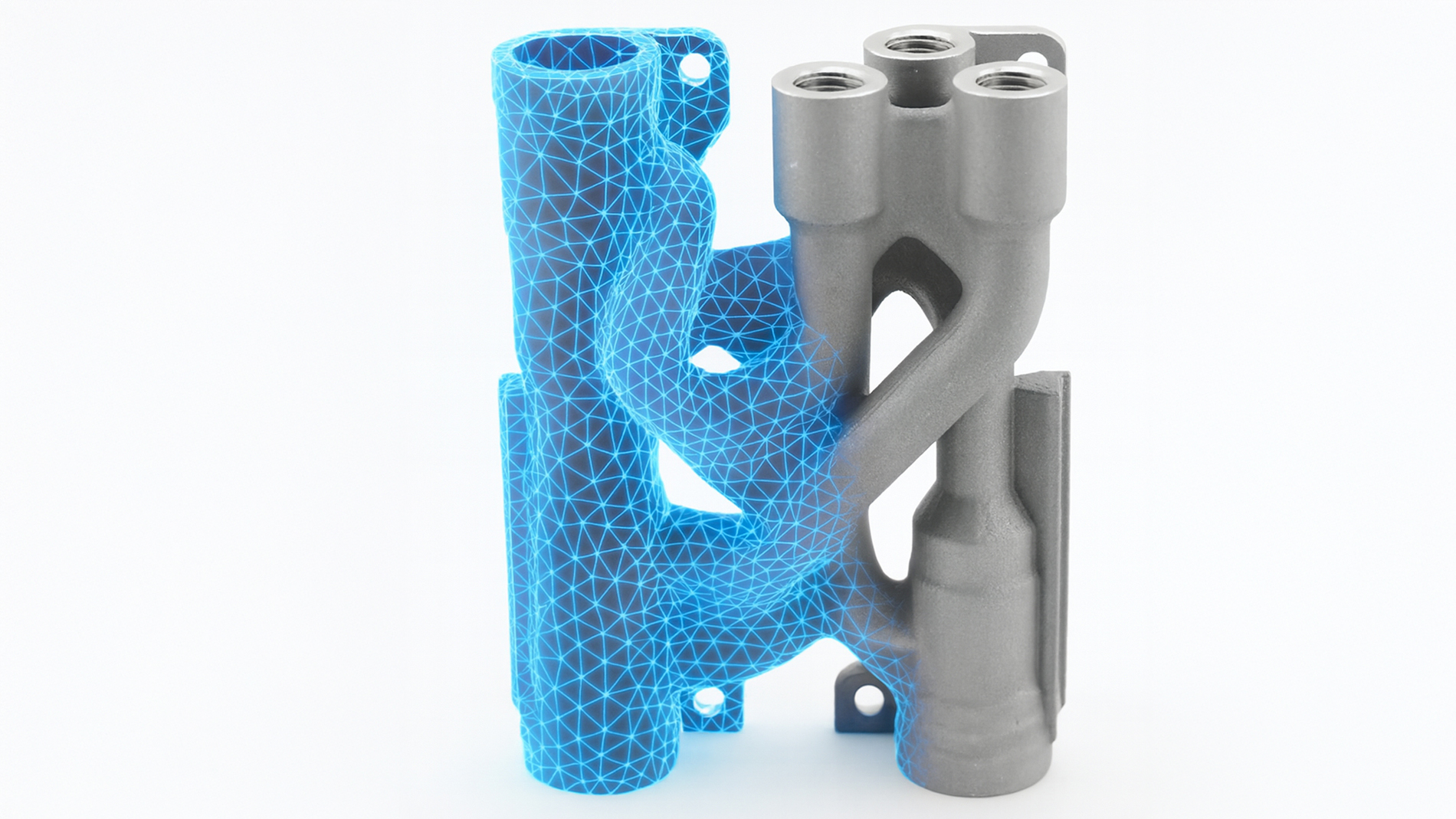

To solve this, Jiskoot Solutions for IKM brought together a multidisciplinary consortium including EOS, Valland, and ToffeeX. The team used advanced digital tools such as thermo-fluid topology optimization and computational fluid dynamics to design flow channels that maximize heat transfer and mixing while minimizing losses. Generative design techniques then produced an organic, fully self-supporting structure that integrates lattice elements to hold vacuum-based insulation.

The result is a compact, sculptural component that could only be produced by additive manufacturing. It is both visually striking and highly efficient, delivering more than double the measurement accuracy of legacy devices. Field trials at Equinor’s Melkøya LNG plant in Norway confirmed the performance, with operators reporting a “massive improvement in stability” of energy measurements.

This achievement was only possible through cross-industry collaboration and the fusion of physics-driven design, generative algorithms, and additive manufacturing. The IKM Flux Vaporizer is not just a new product -- it is a proof of how digital design and additive manufacturing can transform critical infrastructure and support a more sustainable, transparent global energy future.

You can experience the project presentation live at the Formnext Awards Showcase: Hall 11.0, D82

Limb Kind Foundation Inc. – The Limb Kind Project

In Kenya, the Limb Kind Foundation and HP used 3D printing to create custom prosthetic sockets that were fitted free of charge for children. This project demonstrates how modern technology can restore mobility.

The Limb Kind Foundation partnered with Hewlett-Packard and global collaborators to pioneer a groundbreaking 3D Printing project in Kenya. Using HP’s Multi Jet Fusion technology, we created custom prosthetic sockets — the upper portion of the prosthesis that is specially designed to fit the child’s residual limb.

These sockets, fabricated abroad and transported to Kenya, were assembled by our prosthetists and fitted to children free of charge. This innovative approach not only restored mobility and independence to children but also demonstrated how advanced technology can open new doors for sustainable, accessible prosthetic care in underserved communities.

You can experience the project presentation live at the Formnext Awards Showcase: Hall 11.0, D82

(R)Evolution Award

Groundbreaking products, technologies, or services that offer exceptional added value for users are honored with the (R)Evolution Award.

The winner

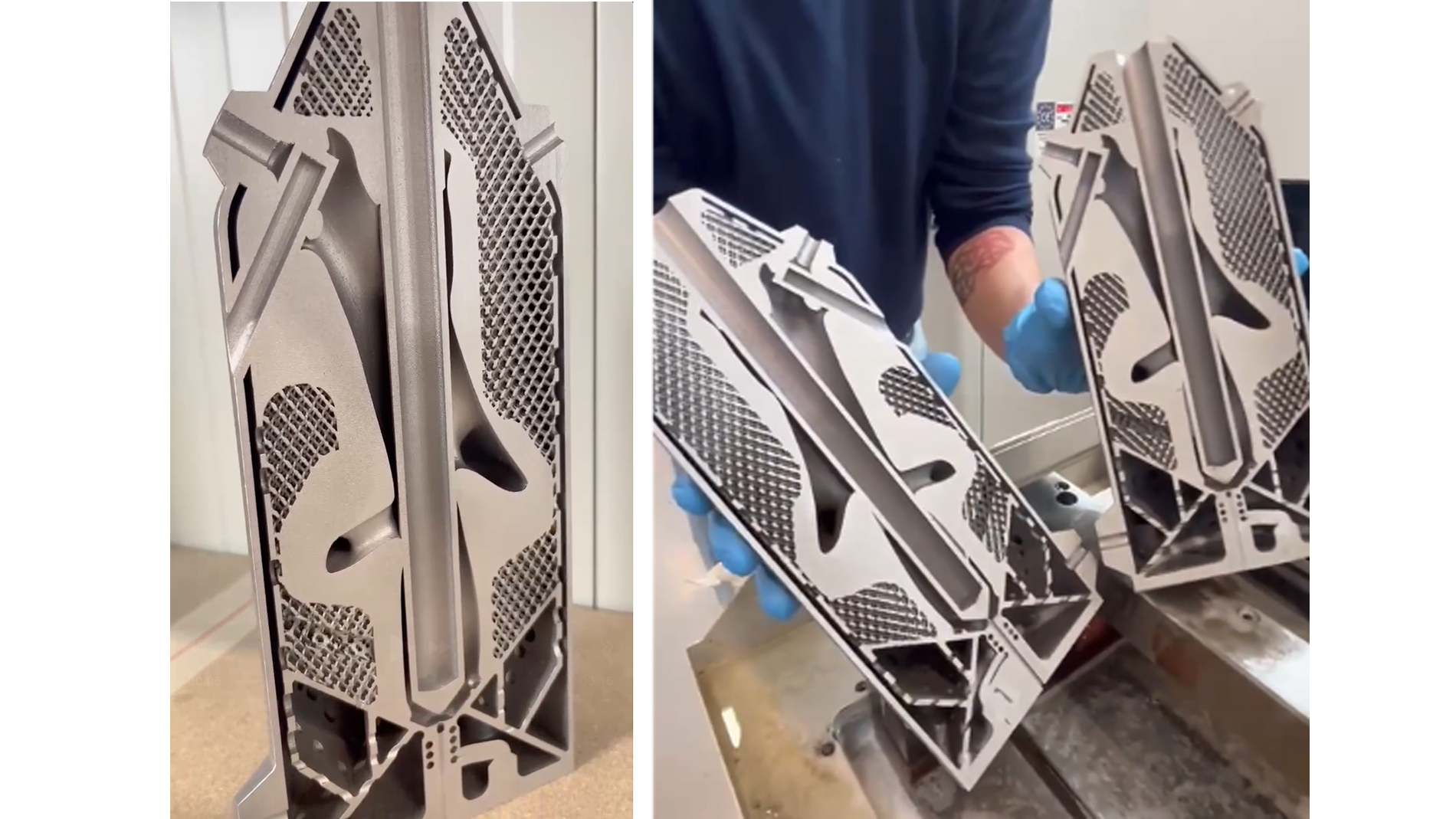

Laempe Mössner Sinto GmbH

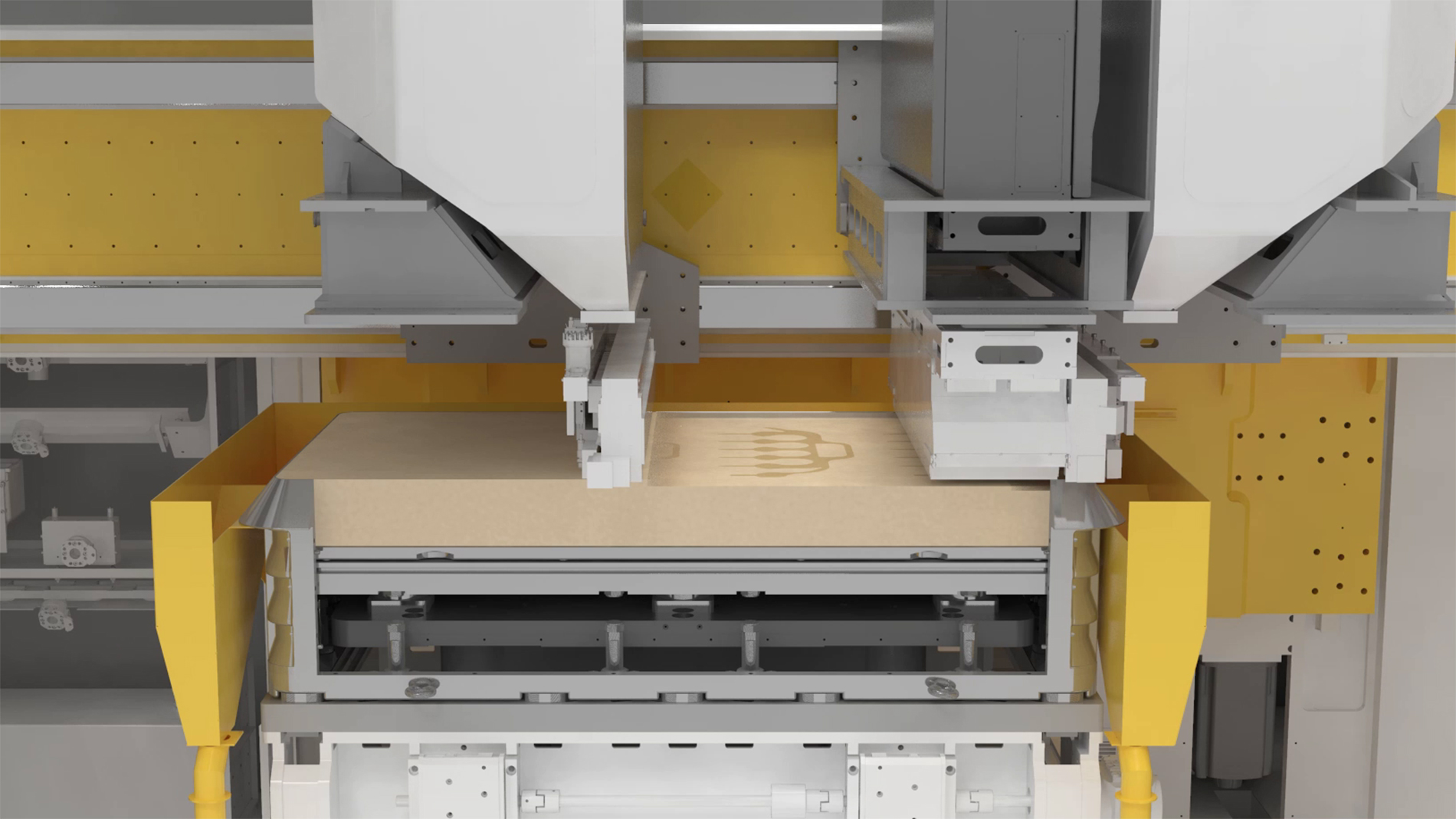

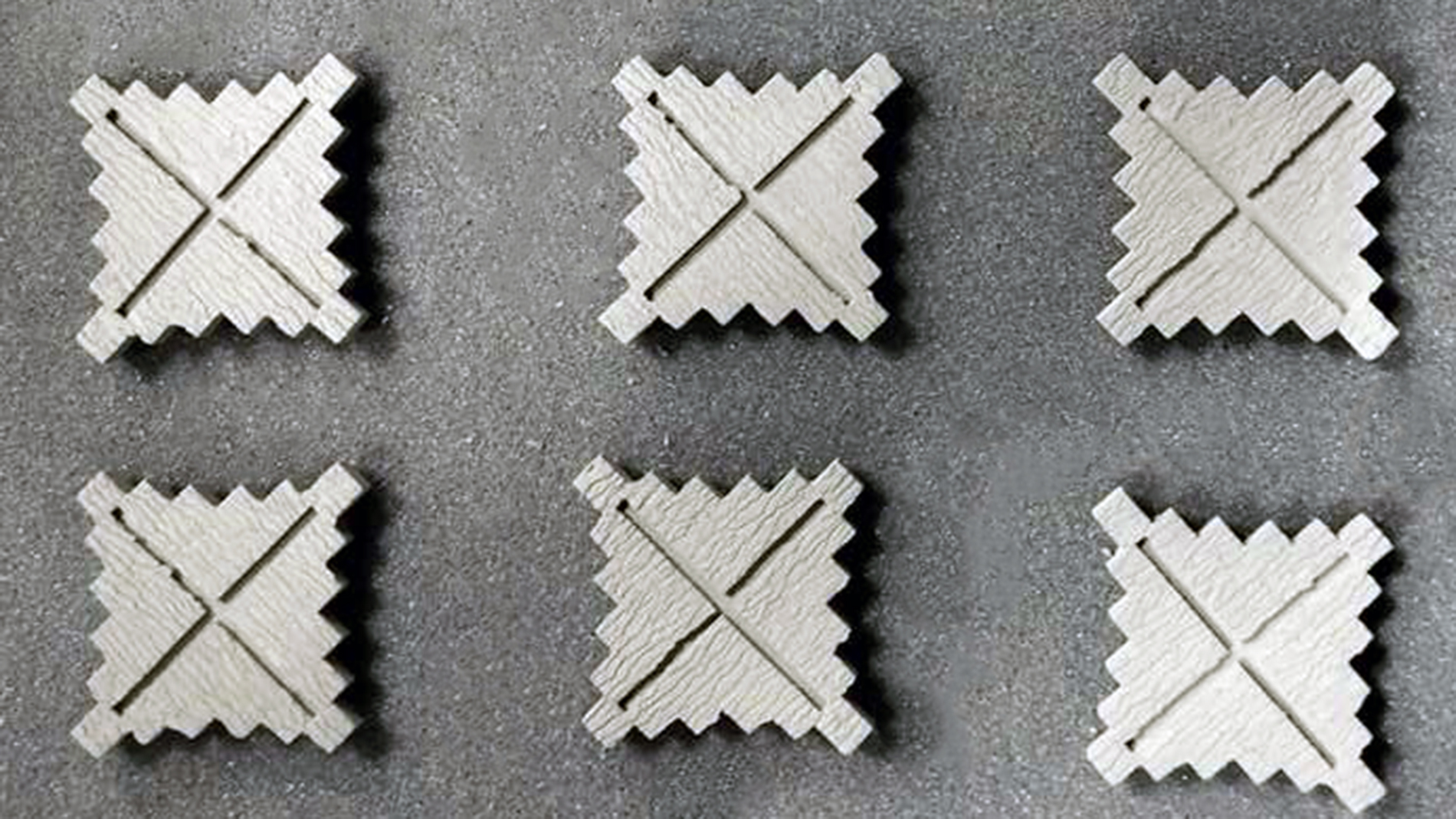

Laempe Mössner Sinto has developed a 3D printing system for high-volume production of sand cores. The solution offers a high level of automation, energy efficiency, and enables complex core geometries for the foundry of the future.

Laempe Mössner Sinto brings 3D Printing to large-scale production

Laempe Mössner Sinto GmbH has developed a 3D Printing system for the large-scale production of sand cores and successfully put it into operation at the BMW Group. The system is precisely tailored to requirements and produces more than 1,100 cores per day, making it one of the fastest binder jetting printers in the world.

The integrated solution covers the entire process chain: raw material storage, molding material preparation, printing process, automated desanding, cleaning and measuring of the cores. In collaboration with R. Scheuchl GmbH, a high degree of automation has been achieved, significantly reducing manual eort. The system is complemented by the specially developed “Laempe Printing Wizard” software with functions for slicing, scaling and flexible adaptation of print jobs.

Technological highlights:

- Printing speed up to 850 mm/s

- Bidirectional operation

- Inline monitoring of construction site

- Manufacturing accuracy of +/- 0.3 mm

- Fully automated handling, desanding, and cleaning

- 100% optical measurement of all cores

Sustainability & future

3D printing enables optimized core geometries and improves the carbon footprint of cast parts. Examples include heat exchangers, electric motor housings, and water jacket cores for combustion engines, which achieve up to 15% lower fuel consumption. In addition, an inorganic binder is used that does not release harmful gases during printing or in the casting process. With a view to e-mobility and alternative drive systems, the demand for additive cores will continue to rise. At the same time, shorter printing times, more economical drive systems, and energy recovery are ensuring lower energy consumption. Laempe's 3D printing is thus a central component for core production in the future.

Laempe Mössner Sinto at Formnext: Hall 11.1, E52 and at the Formnext Awards Showcase: Hall 11.0, D82

Finalists

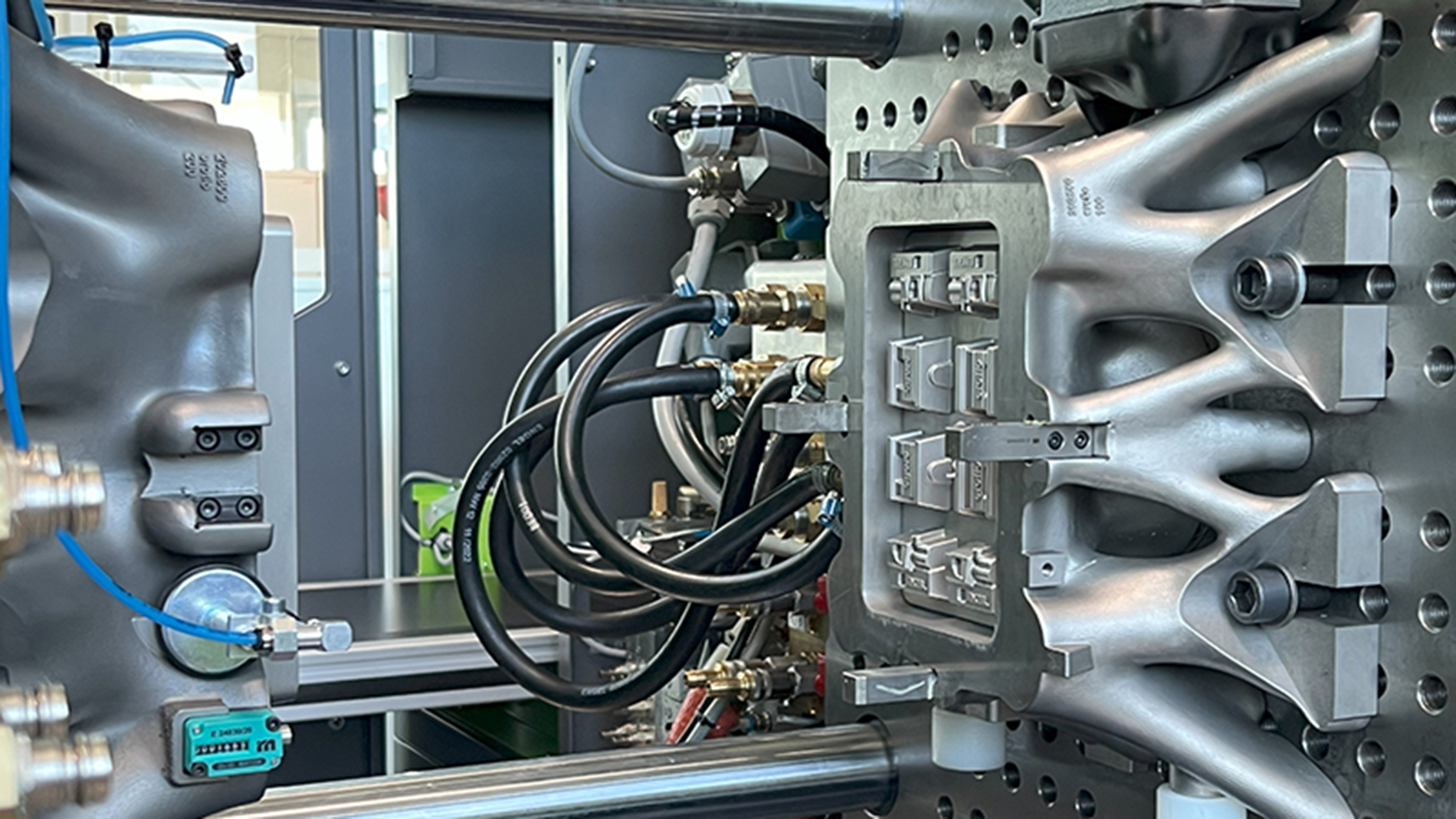

Erofio - Engenharia e Fabricação de Moldes, SA

The INOV.iQ project demonstrates how Additive Manufacturing and digital injection molding technology are revolutionizing toolmaking: a 3D-printed metal mold tool reduces weight, saves energy, and shortens cycle times.

The INOV.iQ project demonstrates how advanced engineering, and Additive Manufacturing can transform traditional injection moulding. In collaboration with ENGEL, we developed a fully metal 3D-printed mould tool specifically for a 100-ton injection moulding machine with the full iQ solutions set, designed specifically for ultra-thin parts with wall thicknesses as low as 1 mm.

Key innovations include:

- Optimised heat exchange via conformal cooling channels

- Full digital integration with ENGEL iQ clamp control and iQ flow control

- Lightweight construction: mould weight reduced by 75% (to 80 kg)

- Improved sustainability: 30% energy savings in the moulding process

- Increased productivity: cycle time reduced by 10 seconds

- Flow control for Ultra-thin parts with wall thicknesses as low as 1 mm.

This project exemplifies the potential of combining digital injection moulding technology with cutting-edge additive manufacturing to deliver smarter tools, faster production, and significant energy efficiency gains.

Erofio at Formnext: Hall 11.0, A79 and at the Formnext Awards Showcase: Hall 11.0, D82

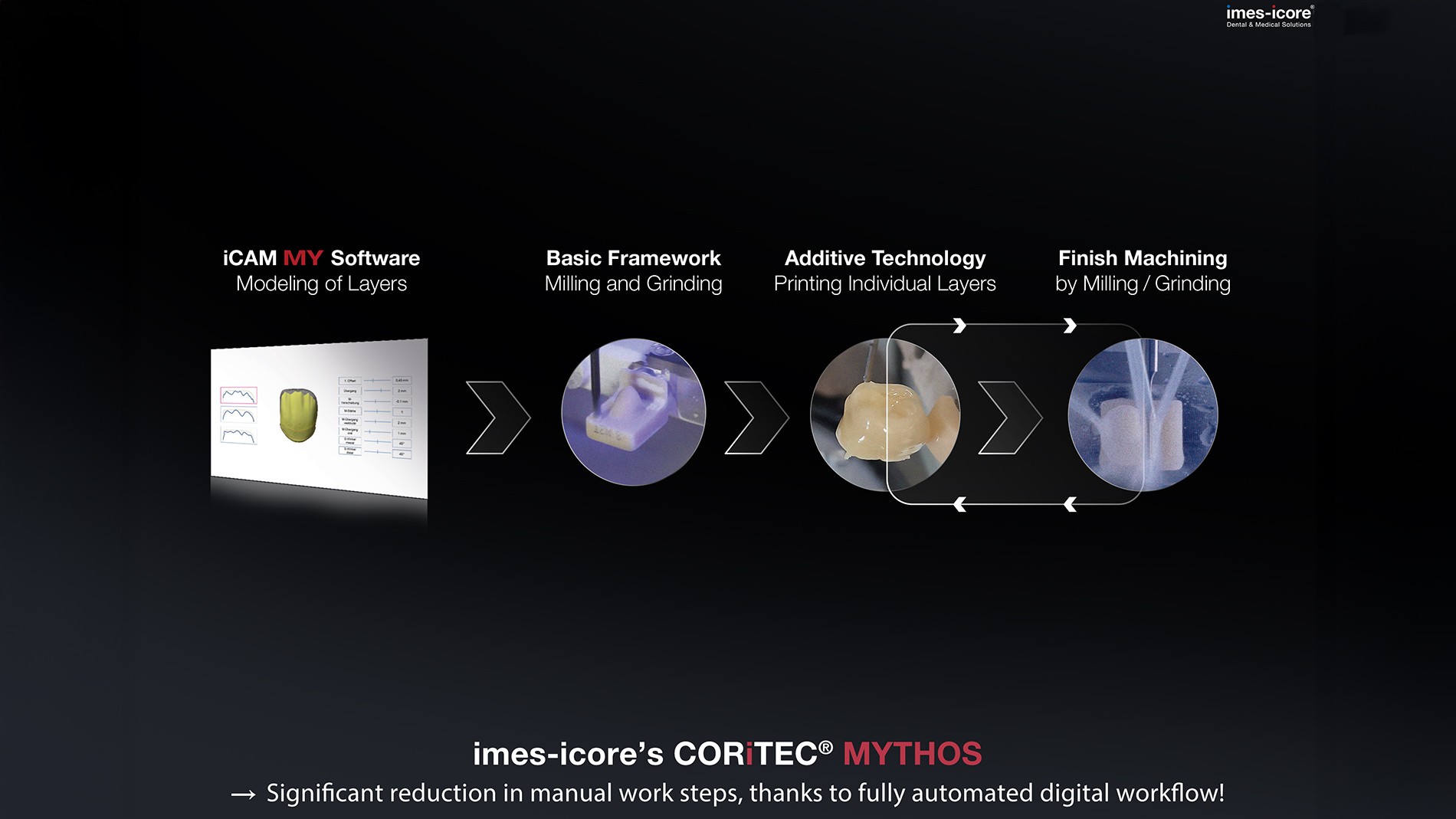

imes-icore GmbH

imes-icore introduces CORiTEC Mythos, the world’s first fully automated hybrid manufacturing system that combines additive coating with precision 5-axis milling and grinding. It enables multi-material restorations with the highest precision.

CORiTEC Mythos – the revolution in dental manufacturing

imes-icore introduces CORiTEC Mythos, the world’s first fully automated hybrid manufacturing system that combines additive coating (PEM) with precision 5-axis milling and grinding. This innovation enables multi-material and multi-color dental restorations with superior surface quality, accuracy, and aesthetics – from crowns and bridges to implant frameworks.

The fully digital CAD/CAM workflow drastically reduces manual steps, shortens production times, and enhances process reliability. Mythos processes up to seven materials – including ceramics, composites, polymers, and zirconia – setting new benchmarks in efficiency, sustainability, and reproducibility.

Scheduled for market launch in 2026, Mythos represents the next evolutionary step in CAD/CAM technology and empowers the digital future of dental laboratories.

Imes-icore at Formnext: Hall 12.0, C101 and at the Formnext Awards Showcase: Hall 11.0, D82

Rookie Award

The Rookie Award honors individuals with promising business ideas who have either not yet founded their company or have done so within the past year.

The winner

DIGIFAB in collaboration with IAM3DHUB - International Advanced Manufacturing 3D Hub

3DMyMask develops custom silicone masks for premature infants based on 3D scans and Additive Manufacturing. The solution reduces air leakage by up to 60%, improves fit, and enhances comfort.

Respiratory distress remains one of the most frequent complications in neonatal intensive care, with up to 75% of premature infants requiring non-invasive ventilation. Current nasal interfaces are standardized and fail to address the delicate variability of neonatal anatomy, leading to persistent air leaks, pressure injuries, and craniofacial deformations.

3DMyMask establishes a new paradigm in neonatal respiratory care by introducing tailor-made masks manufactured through 3D facial scanning and additive technologies. This approach ensures anatomical adaptation, minimizes leaks, distributes pressure more safely, and enhances patient comfort. Validation on neonatal simulators has demonstrated up to 60% fewer air leaks and improved pressure profiles.

The project is driven by a clinical–industrial alliance that connects medical validation, technological innovation, and industrial expertise. Hospital Clínic de Barcelona provides clinical insight and testing; Digifab, the Additive Manufacturing Node of the Catalan Society of Technology, anchors the development within the IAM3DHUB ecosystem; and strategic partners including Lynxter, Shining 3D, Elkem, 3Deus, and SiOCAST strengthen the technological foundation.

3DMyMask represents a scalable, clinically relevant, and technologically advanced solution that positions neonatal care at the forefront of personalization and innovation. Ultimately, it is a call to give the most fragile patients the innovation they deserve. Neonates and preterm infants, too often left behind in technological progress, must be heard and supported from the very first breath.

You can experience the project presentation live at the Formnext Awards Showcase: Hall 11.0, D82

Finalists

FIDENTIS GmbH

FIDENTIS has developed the world’s first commercial multi-material additive manufacturing solution for dental technology. The system enables fully automated, digital production of telescopic prostheses.

FIDENTIS is a spin-off from Fraunhofer IGCV, pioneering the world’s first commercial multi-material additive manufacturing process for dental prosthetics. The technology enables the combination of precious and non-precious metal alloys within a single build – a breakthrough that directly addresses one of the most demanding challenges in prosthodontics: telescopic crowns.

Today, premium telescopic dentures are the gold standard of removable prosthetics, yet their production remains highly manual, labor-intensive, and costly. Dental technicians must invest years of craftsmanship to achieve reliable friction fit, limiting scalability and patient access.

FIDENTIS changes this paradigm by digitizing and automating the process. With a qualified PBF-LB/MM process on an industrial AM platform, alloys such as CoCrMo and gold can be fused with micrometer precision. This enables patient-specific prosthetic frameworks with friction fit engineered directly into the build, eliminating manual adjustment. At the same time, the process reduces precious metal consumption, ensures reproducibility, and opens the door to scalable production of the highest quality prosthetics.

By bridging digital CAD/CAM workflows with industrialized multi-material AM, FIDENTIS establishes the first fully digital process chain for high-end removable dentures. The young company has proven the feasibility in collaboration with Fraunhofer and dental labs, and is now preparing for series production in 2026, including a dedicated digital order platform for labs.

FIDENTIS is setting a new global standard in multi-material production. And this is just the beginning.

You can experience the project presentation live at the Formnext Awards Showcase: Hall 11.0, D82

Tesseract Technologies B.V.

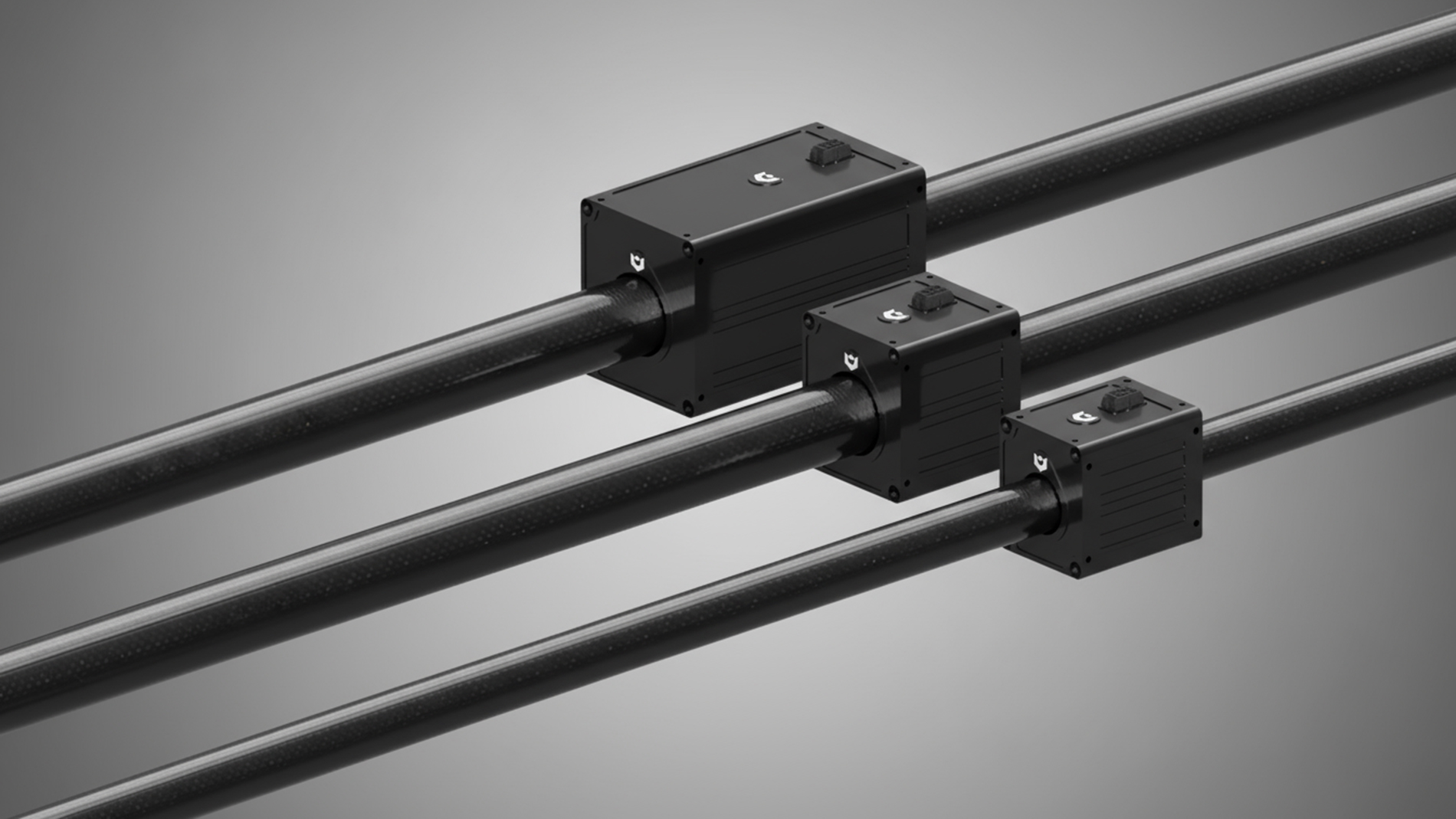

Tesseract Technologies is developing linear motors for large-format FDM 3D Printing that replace belt drives. The result: greater precision, speed, and reliability.

At Tesseract Technologies, we are redefining motion technology for large-format FDM 3D printing. Traditional printers rely on stepper motors with belts. While this works well for smaller machines, it quickly becomes a limitation as printers grow in size. Longer belts introduce stretch, vibrations, and wear, all of which reduce speed, accuracy, and reliability. The result: large-format printing that is slow, inconsistent, and prone to quality issues.

Our solution is a new generation of linear motors, engineered specifically for 3D printing. Unlike belt-driven systems, our motors move directly over a magnetic rail with no mechanical transmission. This ensures smooth, precise, and self-correcting motion. The closed-loop design requires virtually no maintenance while enabling higher speeds and reliable print quality, regardless of printer size.

Conventional linear motors are extremely expensive, often costing thousands of euros per motor, and deliver industrial-grade sub-nanometer precision that far exceeds the needs of additive manufacturing. That’s why we built our own motors from the ground up: cost-efficient, accessible, and tailored to the unique requirements of 3D printers. This approach has enabled us to cut costs by 5 to 10 times.

We are already piloting our technology with several 3D printer manufacturers and will showcase our motors at Formnext in the Startup Area, where we look forward to connecting with more manufacturers and strategic partners.

Our ambition is clear: to accelerate the shift from traditional to additive manufacturing by making high-performance linear motion technology accessible to every 3D printer maker.

Curious to experience the strength of linear motors firsthand? Join us for an arm-wrestling match with our motors at the Startup Area (Hall 11.0, booth D62A).

Tesseract at Formnext: Hall 11.0, D62A and at the Formnext Awards Showcase: Hall 11.0, D82

Start-up Award

supported by Fluxo Technologies

The Start-up Award recognizes young, inspiring companies with actionable business models.

The winner

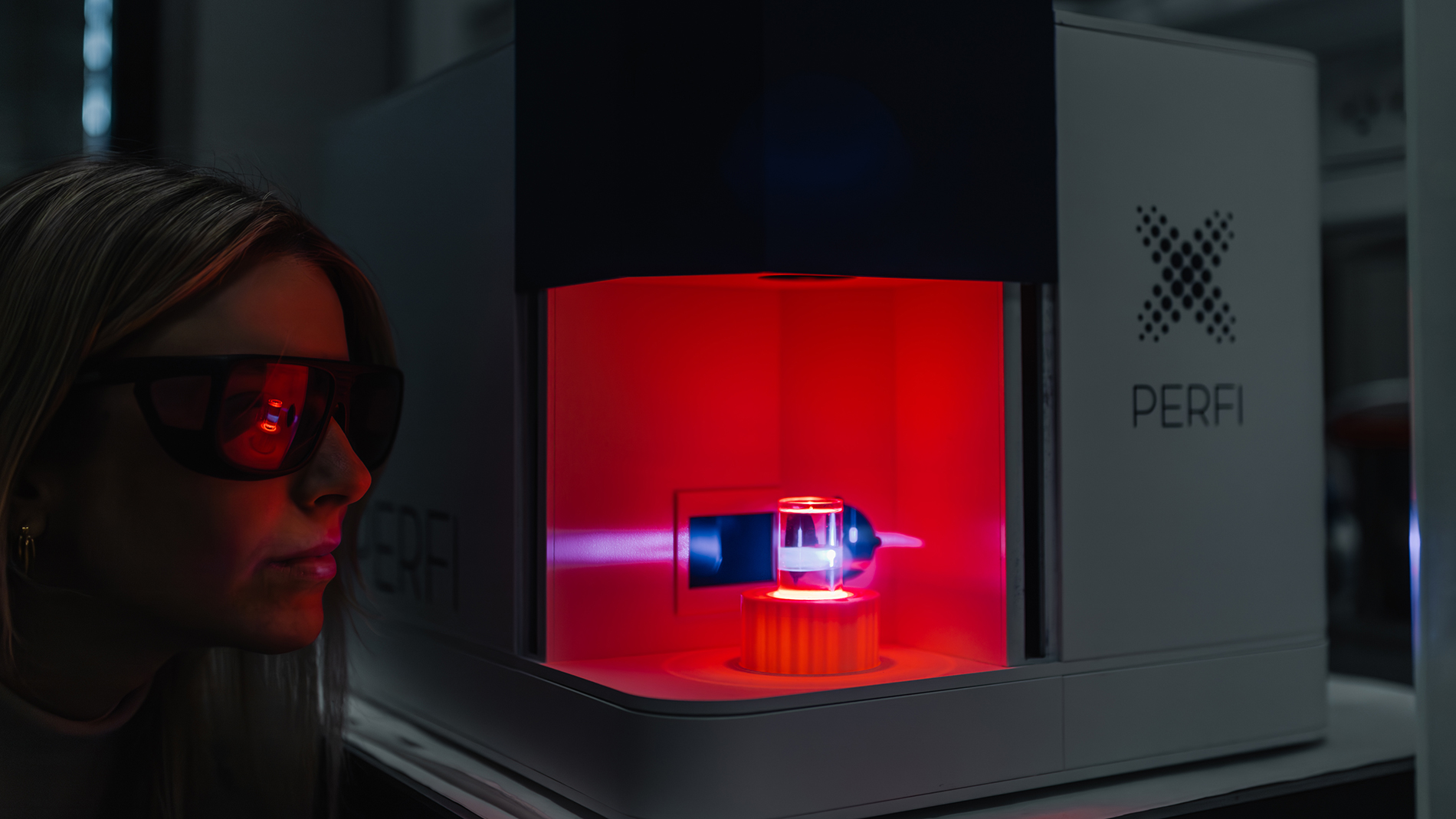

PERFI Technologies

PERFI Technologies enables ultra-fast, sustainable point-of-care production of highly personalized medical devices with its patented VAM technology—eliminating layers, support structures, and solvents.

PERFI Technologies is pioneering the next generation of 3D printing with Volumetric Additive Manufacturing (VAM), a breakthrough method that creates complete 3D objects in seconds rather than hours. Instead of building parts layer by layer, VAM projects dynamic light patterns into a rotating vat of photosensitive resin, solidifying the entire component at once. This eliminates layers, support structures, and typical post-processing bottlenecks, enabling ultra-fast, waste-free, high-resolution production. PERFI has developed a desktop VAM unit suitable for decentralised, point-of-care manufacturing, ideal for industries where personalisation is critical - such as hearing aids, dental applications, and patient-specific medical devices.

The VAM unit also features an automated, solvent-free post-processing system that recovers and reuses uncured resin in a closed loop, drastically reducing material waste and chemical footprint. Our proprietary resin system has been pre-validated for biocompatibility, enabling safe, direct-to-patient use. By combining precision, speed, and sustainable post-processing, PERFI’s patented technology makes on-site production of highly customised devices user-friendly and available on demand.

Perfi Technologies at Formnext: Hall 11.0, D62B and at the Formnext Awards Showcase: Hall 11.0, D82

Finalists

Allonic Ltd.

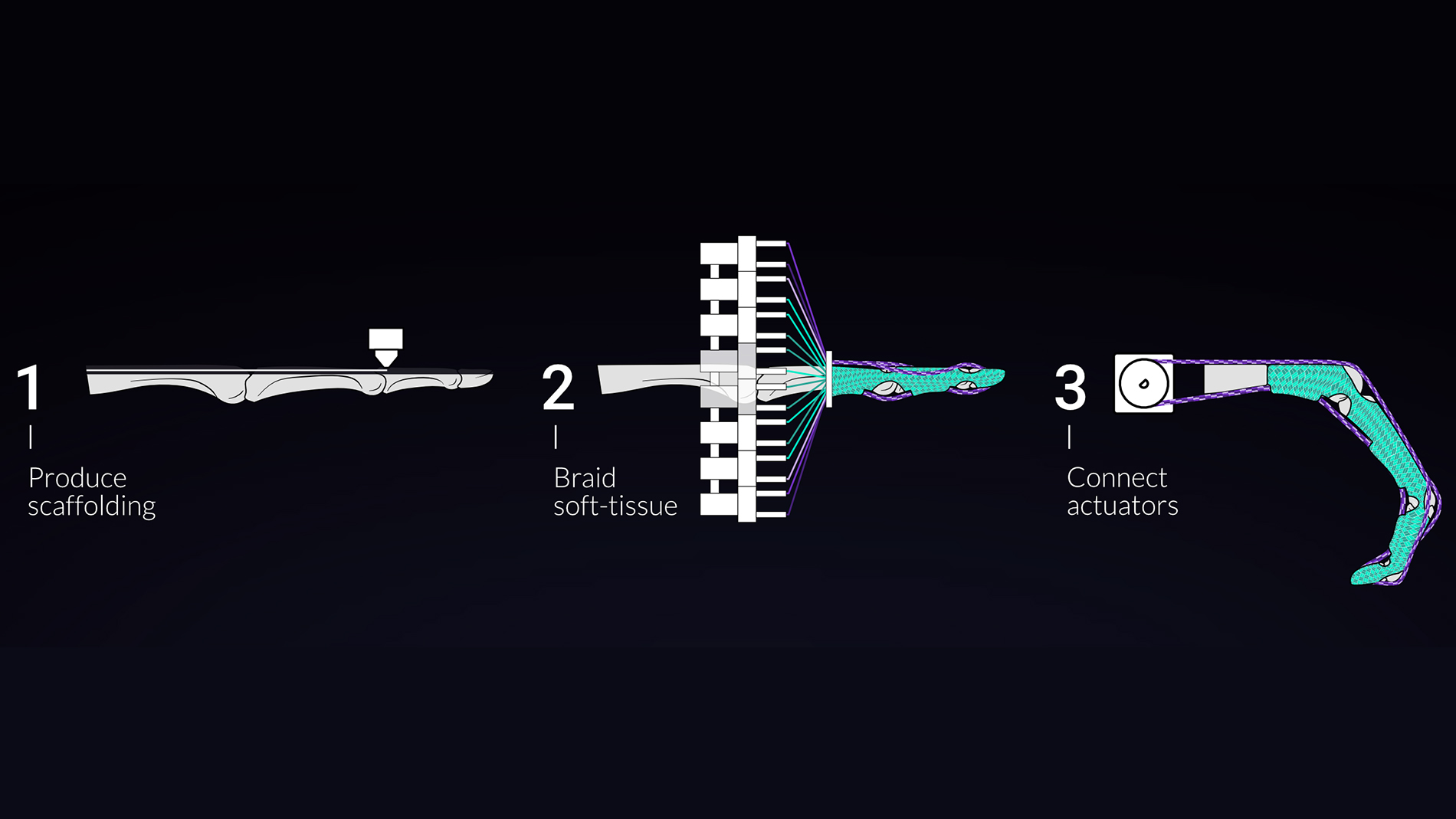

Allonic is revolutionizing robotics manufacturing with 3D Tissue Braiding – a technology that enables fully automated growth of complex, movable robot bodies directly from functional fabrics.

Allonic is building 3D Tissue Braiding: a new production technology that enables the seamless, fully automatic fabrication of the most intricate subsystems in robotics – moving mechanical structures such as fingers, arms, and legs.

We are developing a highly automated software + hardware platform where complex mechanisms can be designed quickly and effectively, with machinery that "grows" fibrous, durable functional tissues directly on a few pre-manufactured parts, and outputs a fully functional robotic body. No need for assembly – just connect your actuators and deploy.

With a Tissue Braider, you will:

- reduce the production cost of robotic bodies by an order of magnitude – a single, fully automated platform instead of fragmented supply chains;

- get from a design idea to a complex mechanical prototype in a matter of hours instead of weeks – build custom hardware with any team, not just specialists;

- create integrated, multimaterial 3D structures – save space and parts count by embedding elastics, sensing, wiring and more in functionalized components;

- leverage the advantages of technical textiles – build nimble robotics that are inherently soft, strong and human-safe.

Allonic at Formnext: Hall 11.0, D62C and at the Formnext Awards Showcase: Hall 11.0, D82

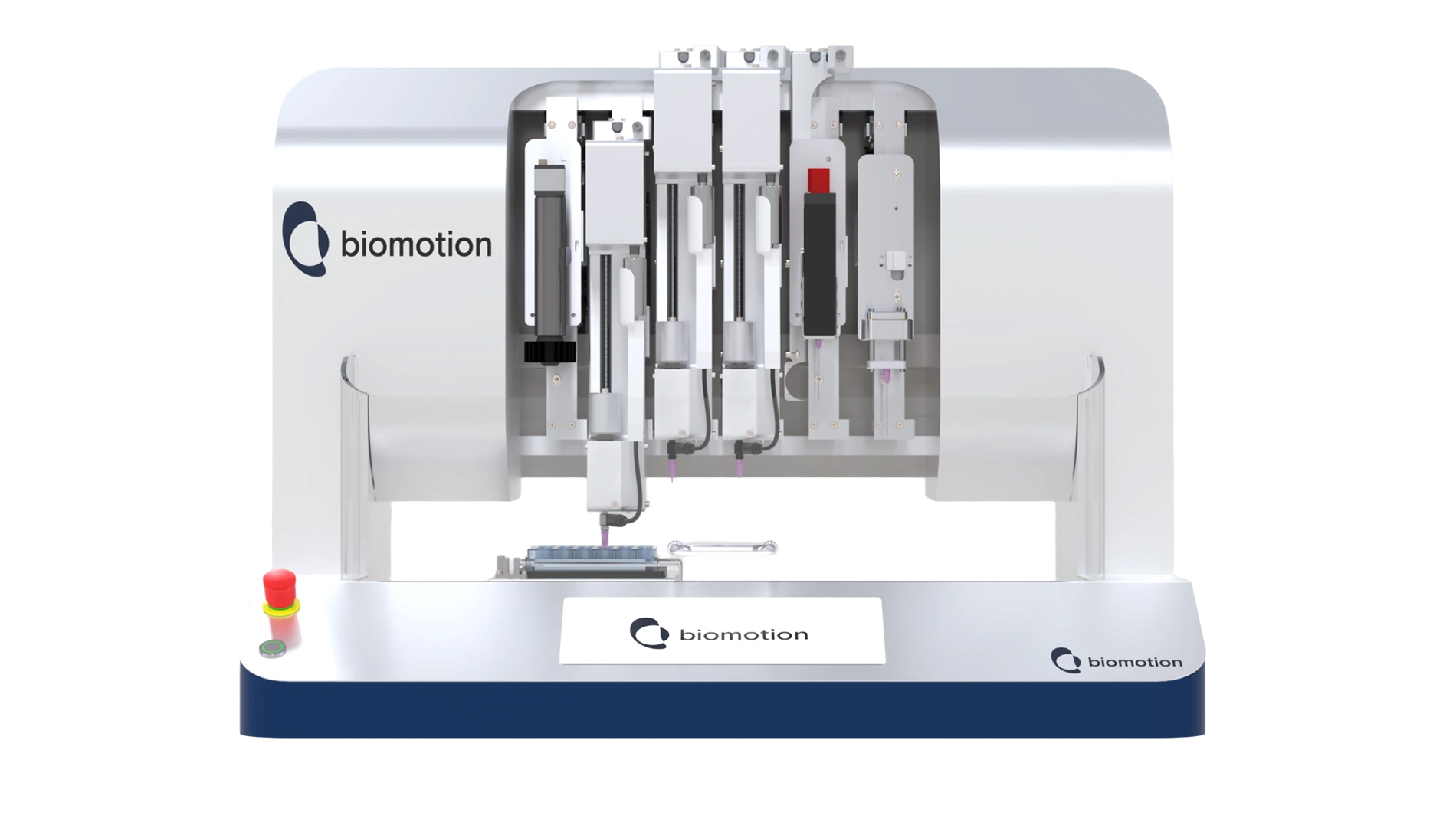

Biomotion Technologies FlexCo

Biomotion is making 3D bioprinting as reliable and accessible as industrial manufacturing – enabling reproducible cell models, faster drug research, and scalable therapies without animal testing.

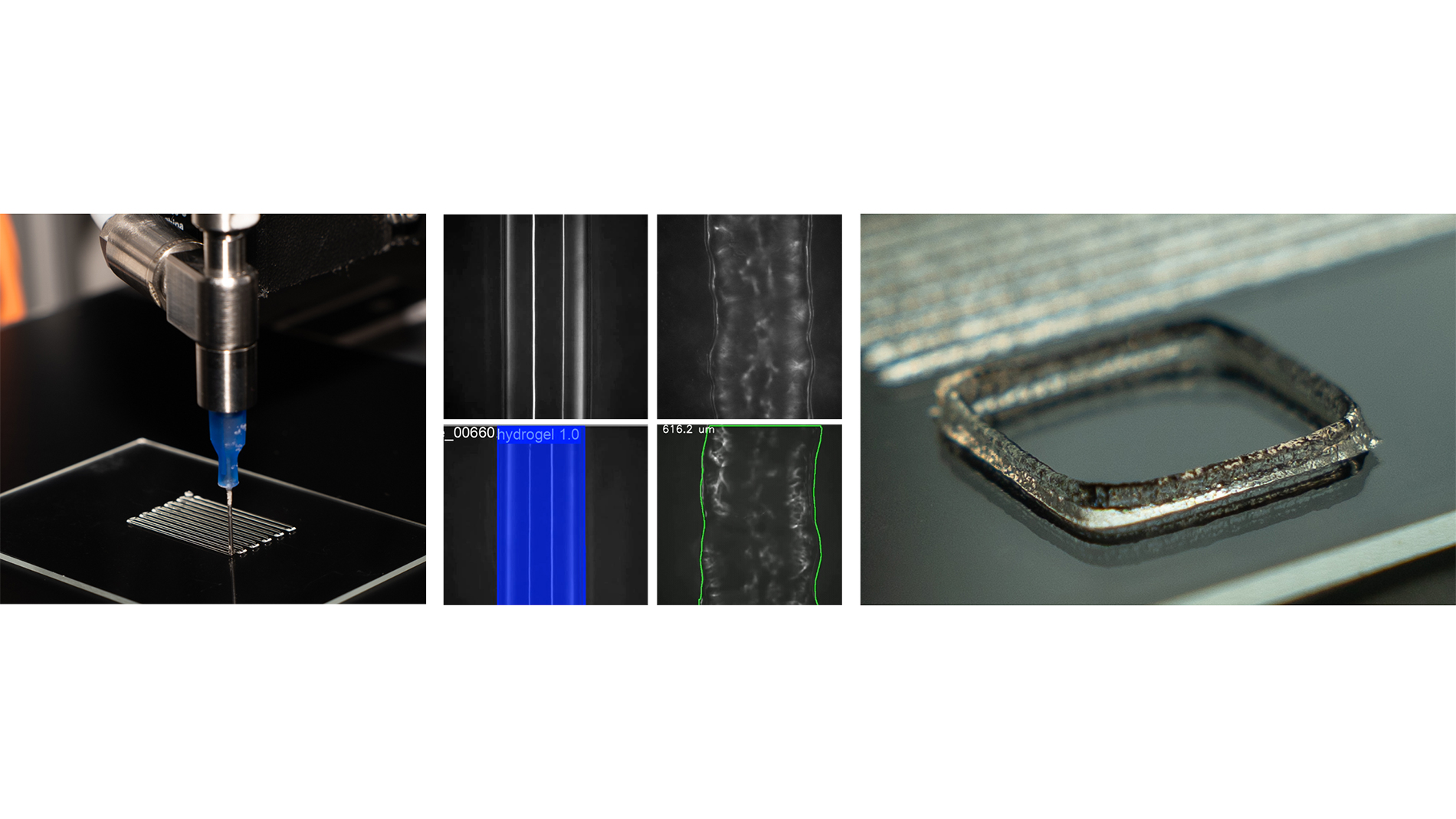

Biomotion is redefining how life sciences approach drug testing by making 3D bioprinting as simple and reliable as industrial manufacturing. Our platform combines a high-precision bioprinter with automated parameter optimization and intelligent process supervision, ensuring that every print is consistent and reproducible. All without the need for highly specialized operators.

This innovation enables pharmaceutical companies and CROs to move beyond traditional 2D cell cultures toward advanced 3D cell culture models that better mimic human biology. By standardizing complex workflows, Biomotion accelerates preclinical research, reduces variability, and supports the global shift toward animal-free testing. Beyond drug discovery, our technology also addresses clinical workflows in advanced therapy manufacturing, making next-generation living implants accessible, scalable, and ready for real-world applications.

Biomotion at Formnext: Hall 12.0, D62L and at the Formnext Awards Showcase: Hall 11.0, D82

nureo AG

nureo develops 3D design tools that automate engineering tasks and generate production-ready designs for Additive Manufacturing within minutes.

nureo builds 3D design tools that automate repetitive and time-consuming engineering tasks by capturing engineering logic in software. Our offers include custom CAD plug-ins, online configurators, and standalone tools, dependent on our customers’ preferences. Our tools save time, reduce costs, ensure manufacturability, and unlock new design possibilities and applications.

Nureo at Formnext: Hall 11.0, D62H and at the Formnext Awards Showcase: Hall 11.0, D82

OsseoLabs

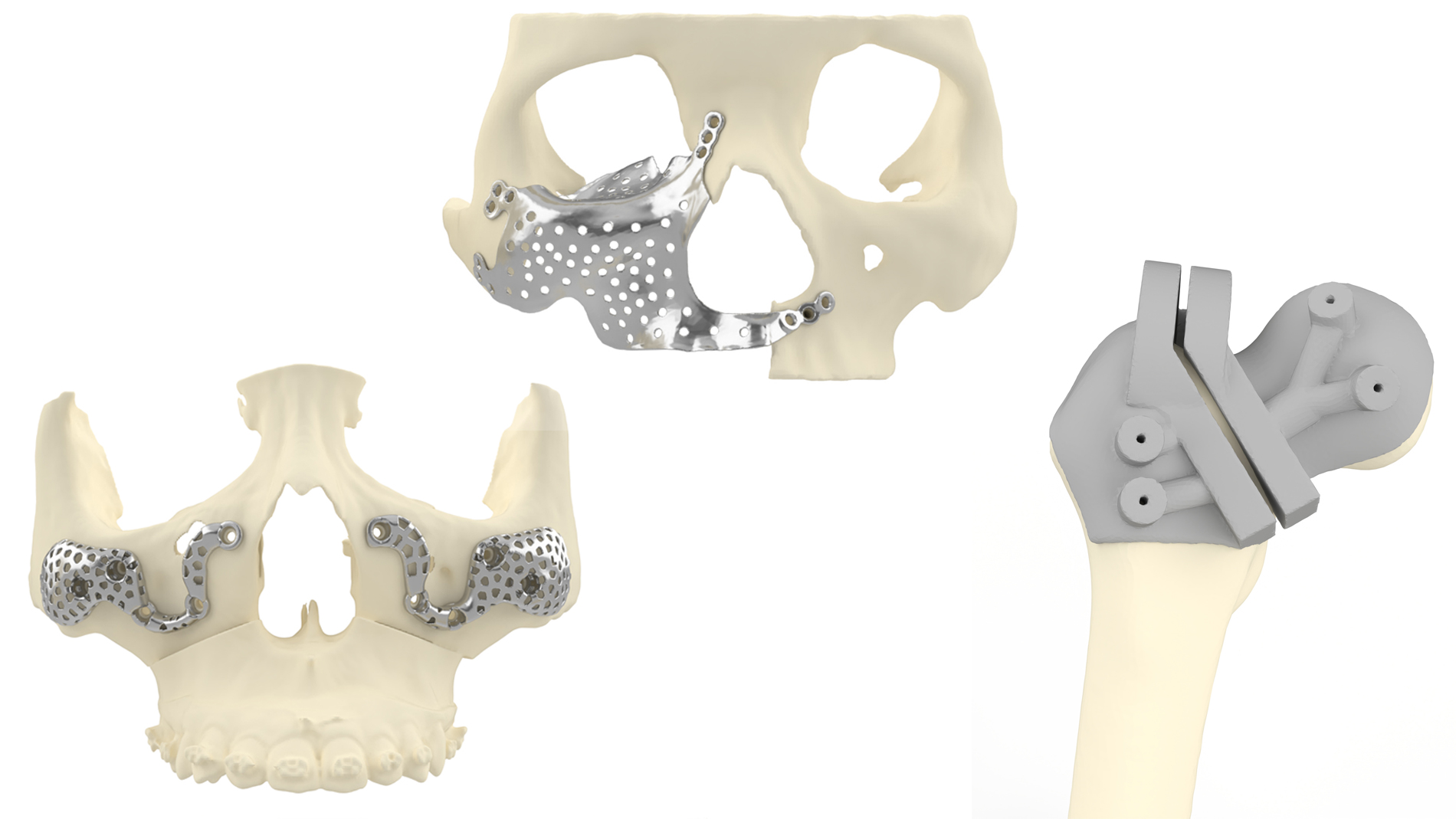

OsseoLabs develops AI-powered, personalized implants for orthopedics and facial surgery—using 3D printing, bioresorbable magnesium, and clinically validated precision to achieve better outcomes with fewer procedures.

OsseoLabs is an AI-powered medtech company specializing in personalized, 3D-printed orthopedic and craniomaxillofacial implants. Our platform integrates AI-driven surgical planning (OsseoVision™), patented porous scaffolds (OsseoMatrix™), and one of the world’s first 3D-printed bioresorbable magnesium implants. With ISO13485-certified manufacturing and clinical validation in over 250 cases, we deliver precision implants that reduce surgical time, improve outcomes, and eliminate unnecessary surgeries.

Osseolabs at Formnext: Hall 11.0, D62J and at the Formnext Awards Showcase: Hall 11.0, D82

Sustainability Award

supported by Renishaw

The Sustainability Award recognizes AM applications and products that deliver sustainable impact throughout their entire lifecycle - beyond just the manufacturing process.

The winner

EOS GmbH Electro Optical Systems

EOS reduces waste and emissions in metal AM by over 90% with a new filtration system that neutralizes reactive particles, recovers powder, and sustainably lowers costs.

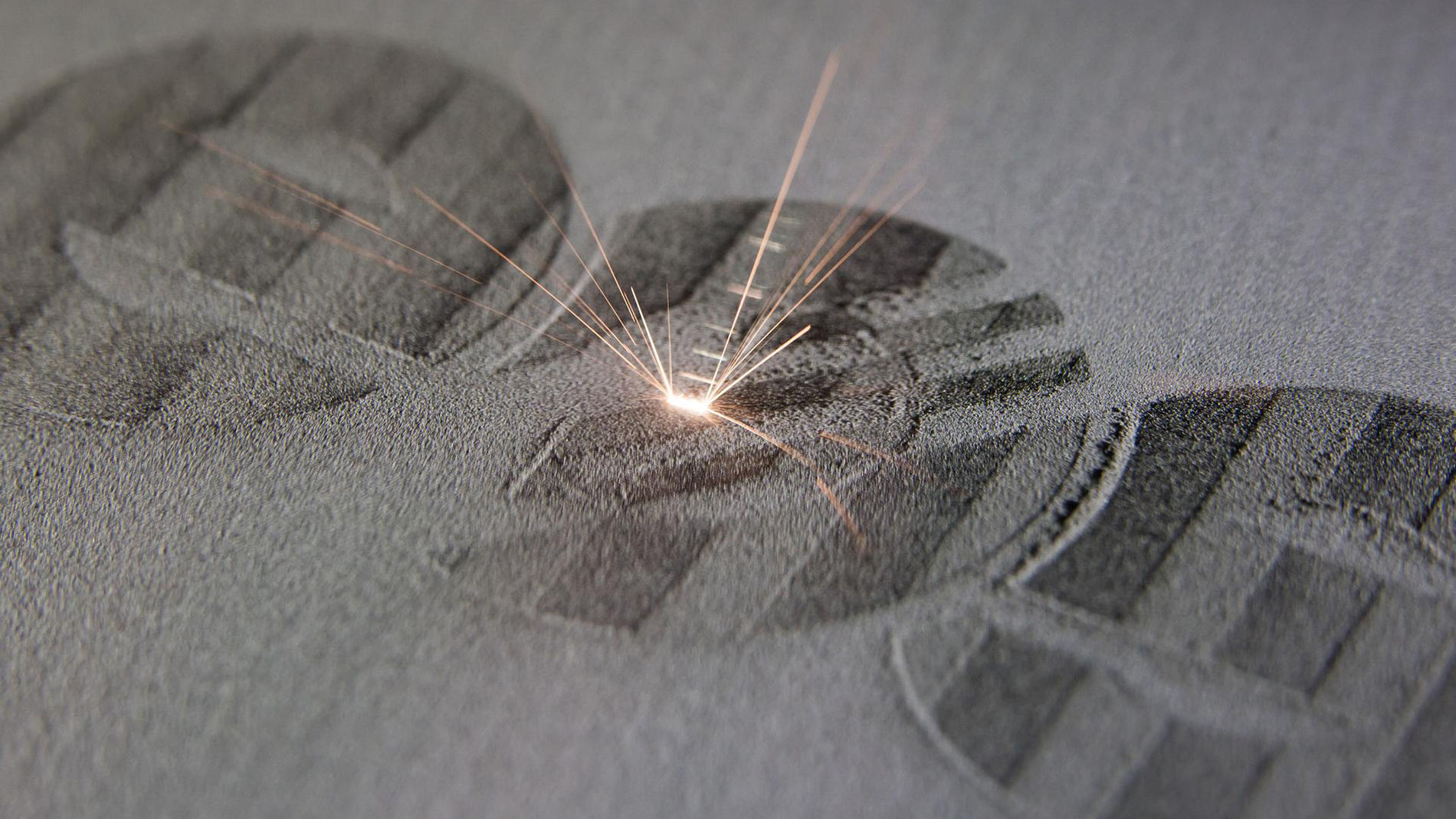

Metal-based Additive Manufacturing (AM) offers great potential for sustainable production, but it also presents hidden challenges – particularly the formation of reactive by-products such as condensate, soot, and ultrafine particles. These are classified as hazardous waste and not only lead to high disposal costs but also cause additional CO₂ emissions due to transport and chemical treatment.

EOS addresses this issue with a new and innovative filtration system that neutralizes these by-products directly within the process. The next-generation recirculation filter system transforms highly reactive particles into stable metal oxides – making them safe for disposal or even suitable for recycling. At the same time, reusable powder is recovered from the waste stream, significantly reducing material consumption

Thanks to chemical-free filtration and integrated oxidation technology, operating costs are lowered and environmental impact is minimized. Less waste also means significantly fewer emissions – and greater efficiency throughout the entire production process. A comprehensive life cycle analysis has shown that, when considering all consumables, system manufacturing, and waste disposal, more than 90% of climate gas emissions associated with operating the filter system can be saved.

This creates a true win-win situation: the solution is not only environmentally beneficial but also economically sustainable – paving the way for responsible and future-ready manufacturing.

EOS at Formnext: Hall 11.1, D41 and at the Formnext Awards Showcase: Hall 11.0, D82

Finalists

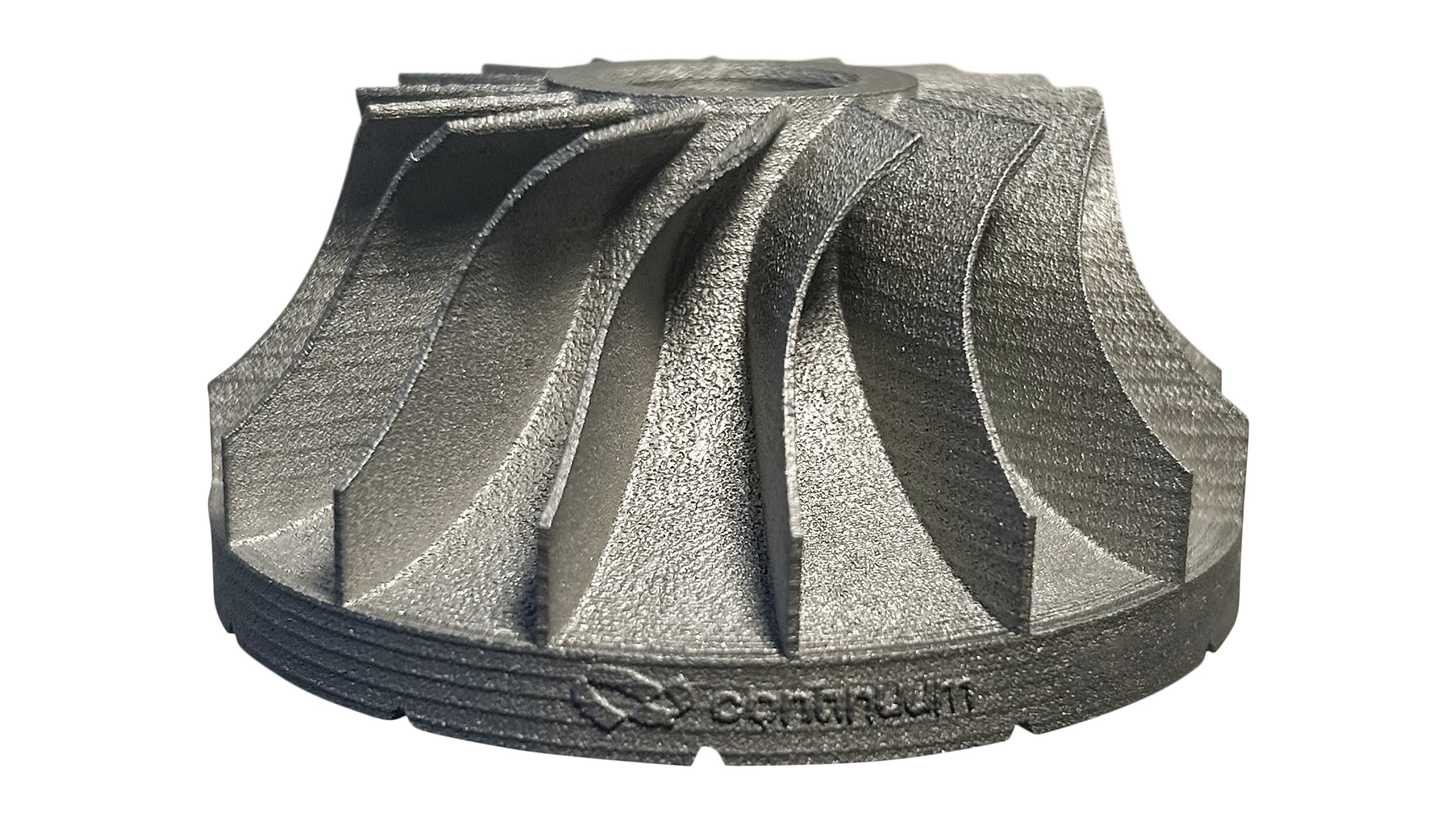

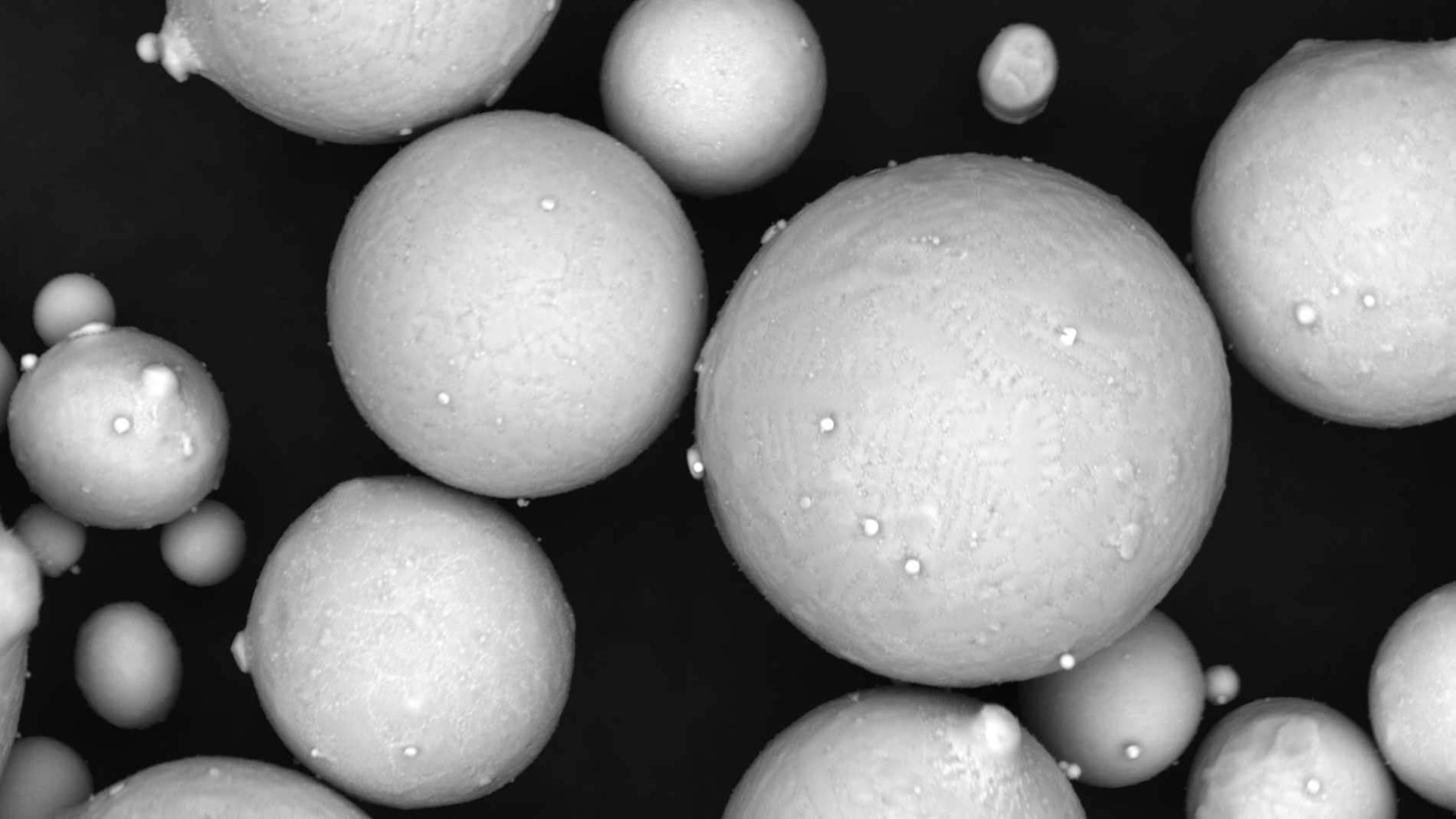

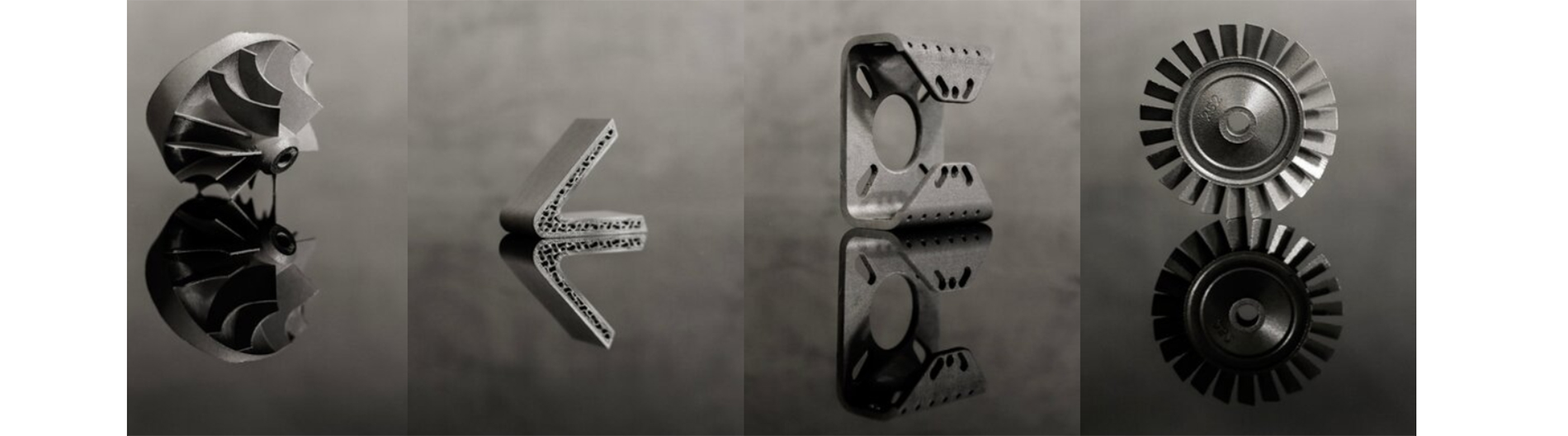

Continuum Powders

Continuum Powders recycles aerospace waste into high-quality metal powders, creating a near-zero-emission circular economy for Additive Manufacturing through its M2P platform.

At Continuum Powders, we believe that advanced manufacturing should not come at the expense of our planet. Our mission is to transform high-value scrap into premium, application-ready metal powders—reducing waste, strengthening supply chains, and cutting greenhouse gas emissions at scale.

Through our proprietary Greyhound Melt-to-Powder (M2P) platform and OptiVantage quality framework, we reclaim certified aerospace-grade scrap and convert it into high-performance alloys such as Ni718, Ti64, CoCr F75, and M247. This process not only ensures powders meet the rigorous specifications required by aerospace, defense, energy, and industrial manufacturers, but also creates a closed-loop, circular economy for critical materials.

A recent Life Cycle Assessment (LCA) conducted by Oregon State University found that Continuum’s process reduces greenhouse gas emissions by 99.7% compared to conventional powders produced from virgin material. This data-driven validation underscores our commitment to measurable sustainability and provides manufacturers with a tangible way to achieve their environmental goals without compromising on quality or performance.

Our powders are already being qualified and deployed across a range of additive manufacturing platforms—including binder jetting, laser powder bed fusion, and directed energy deposition—ensuring accessibility for OEMs, service bureaus, and end-users alike.

As a finalist for the Formnext Sustainability Award, we are honored to stand among innovators who are reshaping the manufacturing landscape. We see this recognition as a platform to highlight the importance of responsible materials sourcing, circular supply chains, and data-backed solutions that can scale globally.

Together with our partners and customers, Continuum Powders is proving that sustainability and performance can go hand in hand—and that the future of manufacturing is not only advanced, but also accountable.

Continuum Powders at Formnext: Hall 11.0, E31 and at the Formnext Awards Showcase: Hall 11.0, D82

Smart Materials 3D

Sustainability project by Smart Materials 3D: From organic waste to high-quality materials for 3D Printing.

Smart Materials 3D, based in Alcalá la Real (Jaén, Spain), has developed an exemplary model of sustainable innovation by transforming agro-industrial waste into high-performance technical materials for 3D printing. The project began with the development of OLIVE, the world’s first filament made from olive pits, a locally abundant by-product. The resulting material is biodegradable, compostable, and compatible with both FDM and LFAM technologies, combining PLA with organic fillers that enhance texture and mechanical performance.

This approach led to the creation of the SMARTFIL® ECO range — a full line of sustainable materials manufactured through a common process: local sourcing of organic waste, drying, micronizing, and compounding with biopolymers. The result is a portfolio of pellets and filaments suitable for both desktop 3D printers and large-format robotic arms.

The developed materials include:

- OYSTER: made from oyster shells, rich in calcium carbonate, with a unique ceramic-like aesthetic.

- PINE: based on PEFC-certified pine wood flour, offered in seven natural tones with a non-plastic finish.

- CORK: sourced from Mediterranean cork oak forests; lightweight, insulating, and 100% recyclable.

- COFFEE: contains 18% recycled coffee grounds collected from local cafés, with no added pigments and a natural aroma.

- ALGAE: includes over 15% dried spirulina, offering a rustic, organic look without synthetic coloring.

All materials are developed under a circular economy model, aiming to reduce virgin plastic usage, minimize carbon footprint, and promote local, responsible production. The company has also obtained key certifications (ISO 9001, ISO 14001, REACH, PEFC, Biocompatibility) and participates in R&D projects such as FISOS3D and AGROSEC, reinforcing its environmental commitment.

This innovation model has proven to be scalable, adaptable to a wide range of residues and industries, and capable of turning the environmental impact of organic waste into high-performance materials for industrial, educational, creative, and design applications.

Smart Materials 3D at Formnext: Hall 12.1, D181 and at the Formnext Awards Showcase: Hall 11.0, D82

Sponsors & partners

As in the industry as a whole, we also work hand in hand with the Formnext Awards. These partners and sponsors support the Formnext Awards and pave the way for young, innovative developments in the AM world.

Contact & sponsorship

Do you want to pave the way for young innovative ideas in the AM world? Then become a sponsor of the Formnext Awards 2025 – we still have space on the sponsor wall! You can find all the details here:

If you have any questions about taking part in the Formnext Awards or the sponsorship options, feel free to reach out: