Text: James Woodcock

It has garnered less of the limelight than some other processes, notably powder bed fusion, but DED has found its niche in heavy industrial applications where large-format parts, functional repairs and adaptive material use are the priorities. Combining a high-energy power source (laser or electron beam) and a fed or jetted material (typically wire or powder), DED additively constructs parts on a substrate, either for repair or the creation of new parts.

Outgrowing the competition

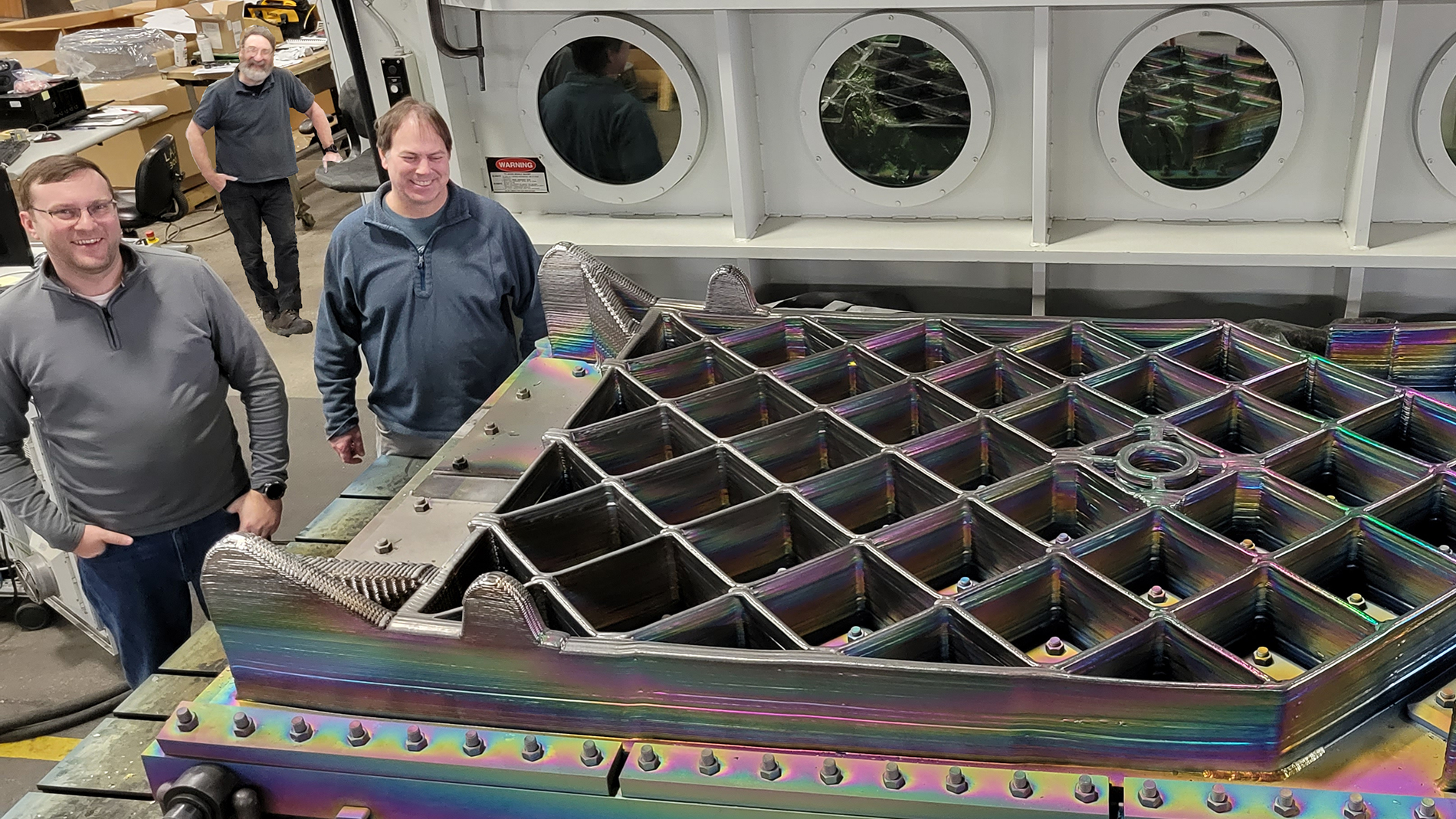

DED's standout improvements are part size and throughput. Sciaky's electron beam DED (EBAM) systems have deposition rates of over 18 kg/hour for titanium, with part sizes at close to six meters in length. Wire-arc systems (WAAM) generally offer 2–10 kg/hour with cheaper welding wire, outstripping powder bed fusion by an order of magnitude in raw throughput. Hybrid systems like FormAlloy's X5R employ powder and wire feeds, offering greater flexibility at these large sizes.

Smarter process control

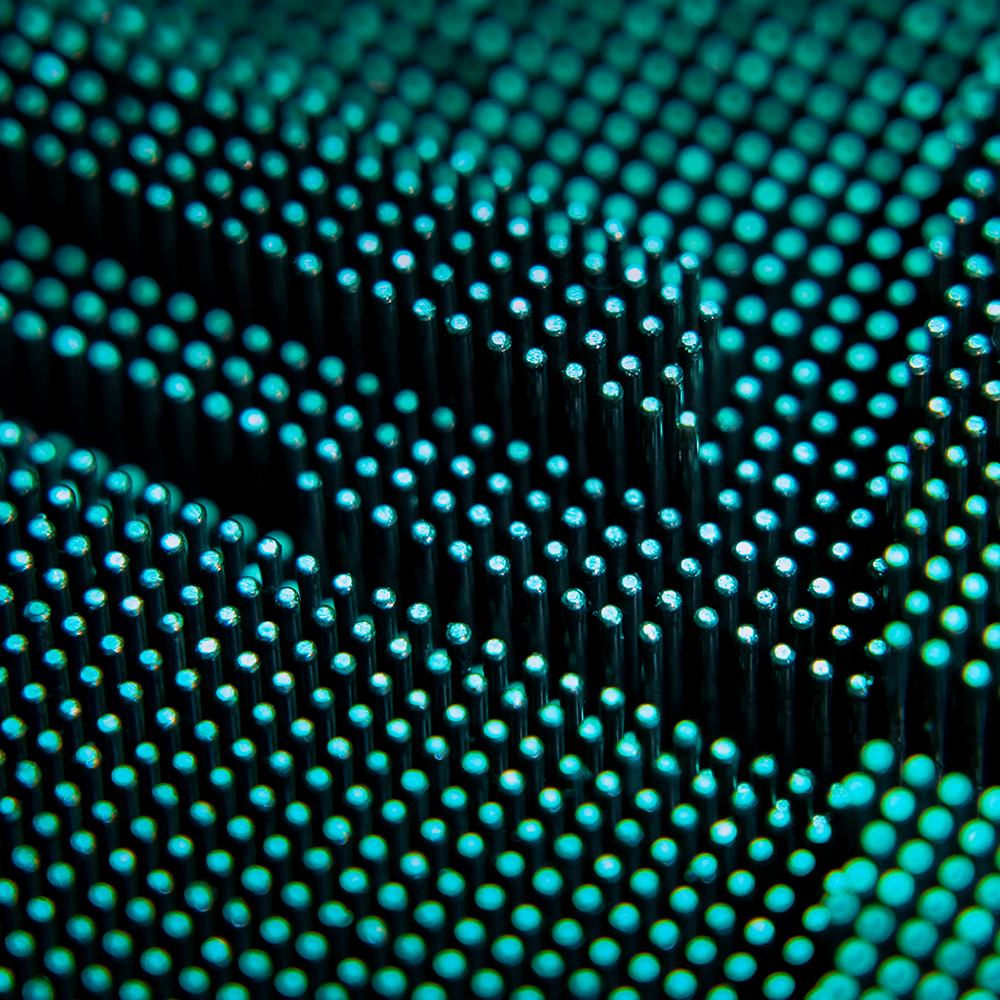

The key to DED's development has been in process control. Consistency is managed by real-time monitoring and adaptive control, adjusting beam parameters layer-by-layer to stabilize geometry, melt pool temperature and reduce porosity.

While DED is improving, it continues to struggle with meeting stringent specifications in industries like nuclear or aerospace where the original parts are wrought or cast. To address this, new systems are being developed that incorporate interlayer mechanical deformation — i.e., rolling or peening — to refine microstructures and achieve near-wrought mechanical properties.

Building material capabilities

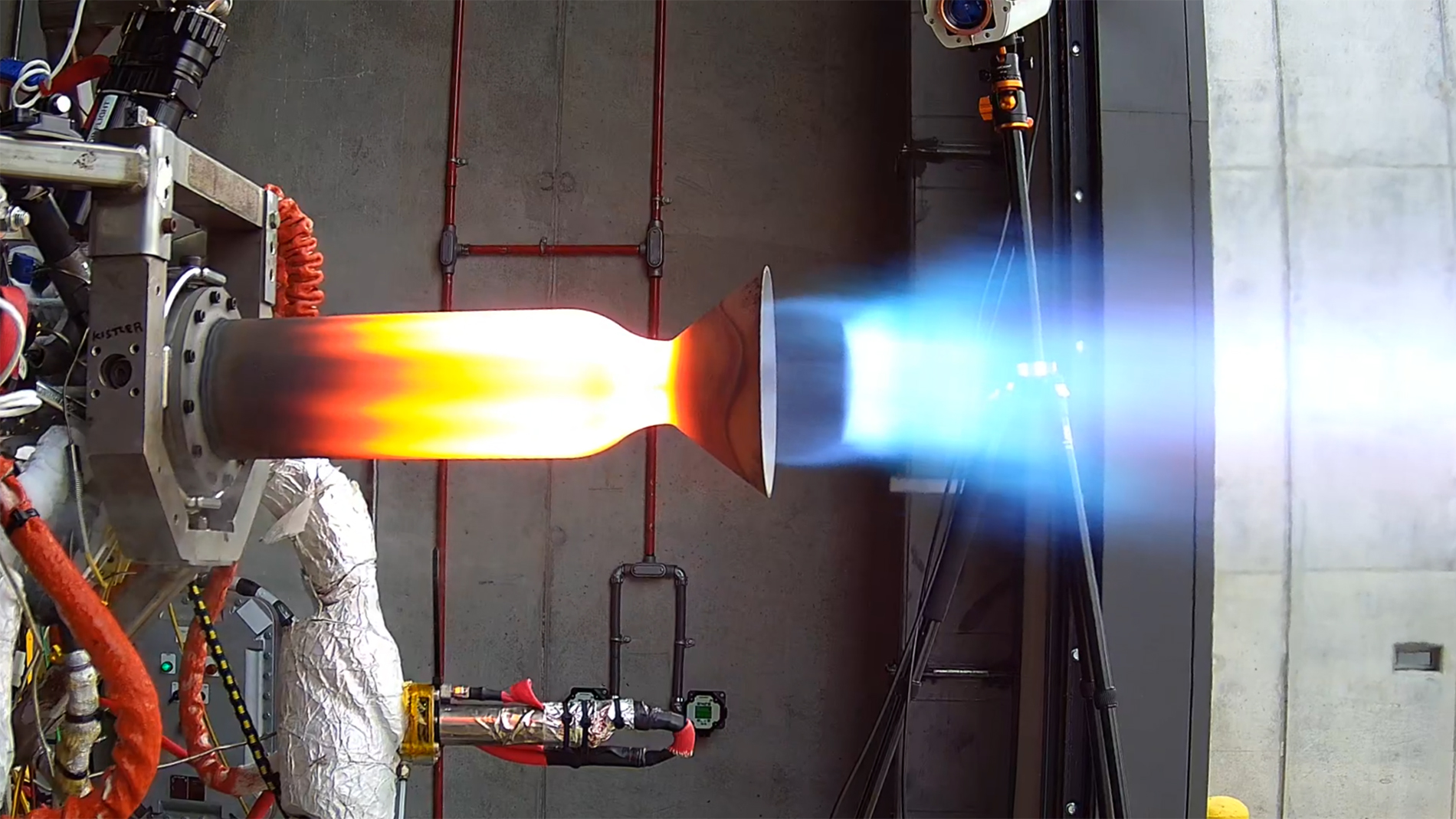

DED material portfolio has expanded rapidly. Crack-prone, high-strength alloys like Al 6061 and 7075 are now available in nanoparticle-reinforced versions (e.g., NASA and Elementum 3D's A6061-RAM2), where they have been successfully tested in hot-fire rocket engine tests. Copper, tool steels, and superalloys are increasingly compatible owing to beam shaping and thermal management.

Multi-material capability is also on the rise and is one of the most encouraging potential directions for DED. Dual-wire or dual-powder systems now create bimetallic parts (stainless-to-nickel transitions or copper heat sinks in steel). Researchers have even demonstrated ceramic-metal gradients and functionally graded ceramic composites in the lab as well.

To process reflective metals like aluminum and copper, laser DED systems are integrating blue lasers (i.e., with a wavelength of ~450 nm) for improved energy absorption.

Surface finish, quality and performance

DED now attains 99%+ dense parts in alloys like Ti-6Al-4V and 316L. Beam oscillation, improved scan strategies, and thermal control optimization reduce grain anisotropy and improve elongation, yield strength and fatigue life. While DED still falls behind powder bed fusion in terms of surface finish (Ra ~10–30 µm), hybrid machines with interlayer milling are narrowing the difference. Fine-mode settings and smaller nozzles are enabling higher resolution.

DED is industrializing fast. Turnkey robotic cells now come packaged with safety systems, slicers, training, and support. DMG Mori’s Scan3D-enabled hybrids support fully automated repair workflow whereby the system can scan, generate a toolpath and deposit in one pass. Sensor-driven QA and digital thread integration are enabling aerospace-grade traceability, with blockchain-based layer certification under investigation.

Field-deployable DED systems are being developed for use in remote defense operations and on-site industrial repairs, enabling rapid part restoration without the need for traditional infrastructure. On the factory floor, DED is increasingly used to add near-net-shape features to forged or cast components, offering the potential to significantly cut down on machining time and material waste.

Polymers and ceramics are the next frontier

Though metal is the dominant material, DED is moving into polymer and ceramic deposition as well. Laser DED of polymers like PA12 has attained <1% porosity and injection-molded-like properties through melt pool real-time control. Ceramic deposition is challenging due to melting temperatures in excess of 2000ºC, but researchers have created graded and eutectic structures in alumina and zirconia via innovative melt dynamics and thermal control.

DED is no longer a niche or ancillary process. Its ability to deliver large components, short lead times and complex, multi-material structures with increasingly sophisticated control positions it as one of the key drivers of AM industrialization. DED will see broader adoption in key verticals with difficult metal and alloy components, while new polymer and ceramic uses indicate where the technology is headed next.

Further information

Directed Energy Deposition: For further information on this procedure, check out the AM Field Guide at formnext.com/amfieldguide