Text: Thomas Masuch

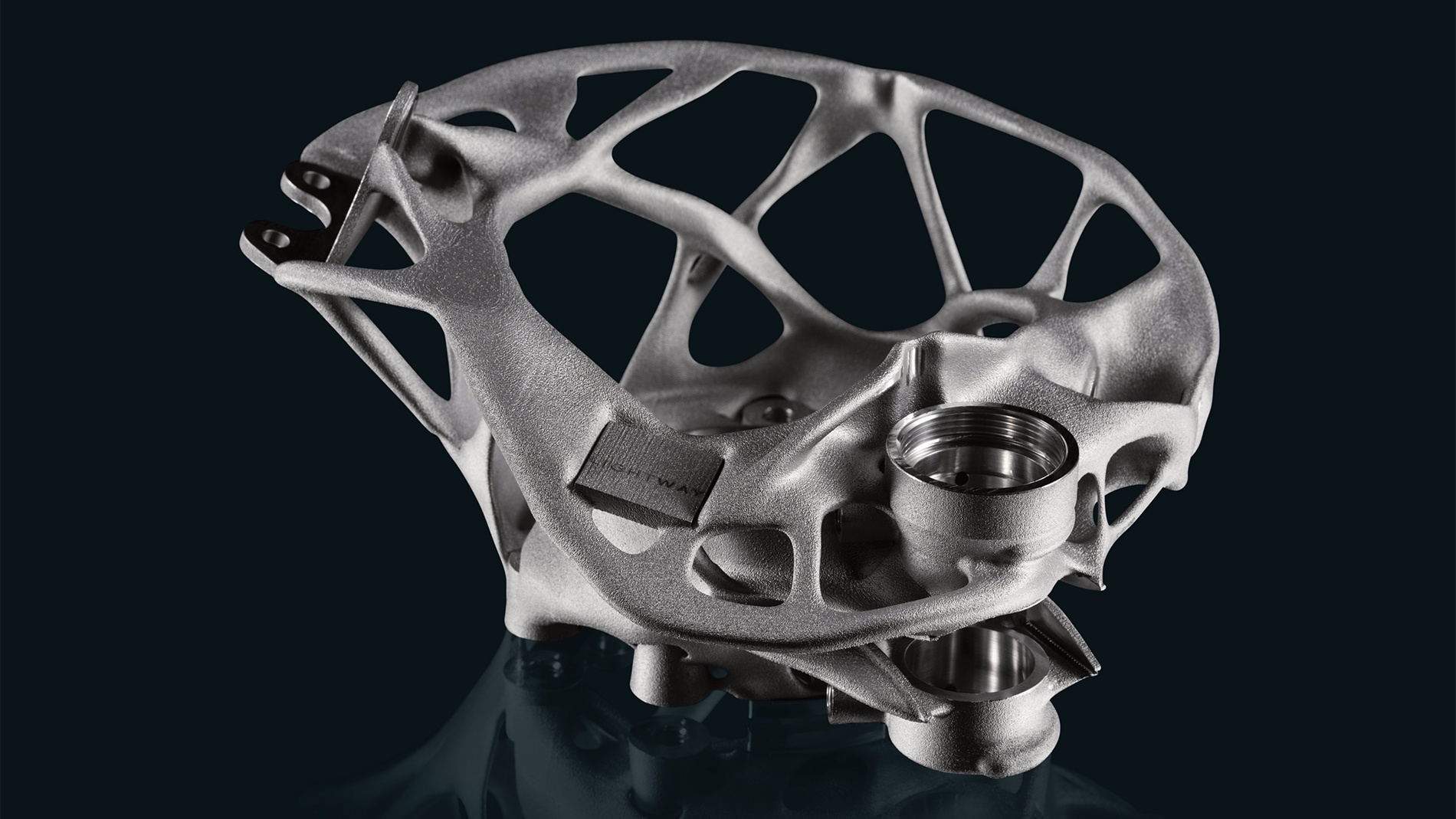

When Formula 1 cars race around prestigious circuits such as Monaco, Monza, and Montreal, there is almost always a piece of Lightway's additive expertise under the bodywork. The medium-sized supplier has a strong focus on metal components for motorsports and supercars – and thus operates in a lucrative, but also extremely demanding industry. The metal components are usually both 3D-printed and machined.

Founded in 2016 and based at the former Formula 1 race track at Nürburgring in Rhineland-Palatinate, Lightway’s workforce is now 18 employees strong. Its modern production hall houses three five-axis machining centers and four metal printers (three EOS M290s and one DMG Mori Lasertec 30 SLM 3rd Gen). The company manufactures more than 25,000 individual parts annually, primarily in small and medium series – not only for motorsports, but also for industries such as mechanical engineering, medical technology, and semiconductor technology.

Trend toward outsourcing

The Additive Manufacturing of metal components has been established in Formula 1 for around 10 years. “A few years ago, many racing teams began to increasingly build up these technologies in-house,” recalls Jan-Steffen Hötter, director of global business development at Lightway. “However, it quickly became clear that it's not enough to just have a printer. You also need milling machines, automation, quality assurance – and the relevant expertise in the processes and design of the components. You have to have the entire process chain under control, right up to the ready-to-install part.”

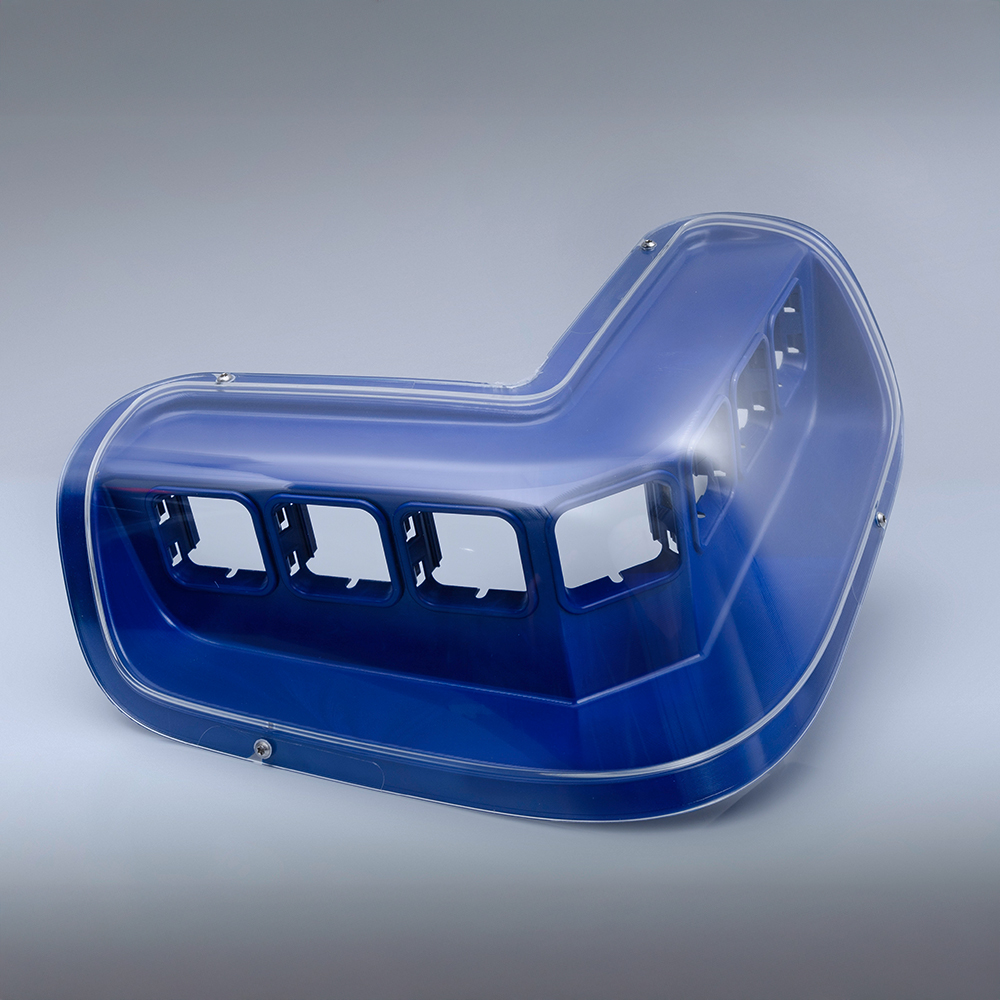

Lightway supplies directly to F1 teams, GT3 racing teams, and hypercar manufacturers, as well as through tier-one suppliers. The company produces distributor-like geometries, tubes, heat exchangers with internal channels, and safety-critical components and structural parts such as wheel carriers and roll hubs. The latter are made of titanium and offer the driver vital protection in the event of a rollover. All these components benefit from real functional added value thanks to AM – for example, through flow-optimized channels, topology-optimized lightweight structures, or customized wall thicknesses. Sophisticated materials such as AlSi10Mg, Scalmalloy, titanium, Inconel, stainless steel, or CuCrZr are used – all with specific advantages, such as extreme strength or high density (e.g. in hydrogen applications).

Growth market

“Although the number of F1 cars manufactured each year remains constant, the number of additively manufactured components is growing steadily,” explains Hötter. The regulations of the FIA, the sport’s world governing body, have also supported this trend – for example, by approving 3D metal printing for structurally loaded components like wheel carriers from 2026 onwards. For AM service providers, this means high requirements for documentation, material data, verification, and testing procedures – but also a competitive advantage after successful qualification. Components that have been successfully introduced in Formula 1 often find their way into other racing series or the supercar sector later on.

Further exclusive information:

Here, you'll find further information and exclusive in-depth articles on: