Text: Thomas Masuch

In the automotive industry, there are probably few AM service providers with as much experience as Cirp, which is based near the southern German capital of Stuttgart. Ralf Detlef Nachreiner and Petra Nachreiner founded their supplier business 31 years ago and focused on automotive prototyping right from the start. Initially, these prototypes were fully 3D-printed at Cirp, while conventional manufacturing methods and manual model-making still played a major role in the industry. And even today, the automotive industry is still very important for the medium-sized company, accounting for more than 50 percent of its sales. At the same time, Cirp’s high level of focus is not without risk in times when European car manufacturers are facing major challenges.

The company has grown thanks to prototyping, and this area is “still very important to us,” explains Thomas Lück, head of sales and innovation. In order to offer the best solutions in this field, Cirp not only has various AM technologies at its disposal, but also uses classic injection molding when necessary. “Because AM is not always the most sensible solution,” Lück points out.

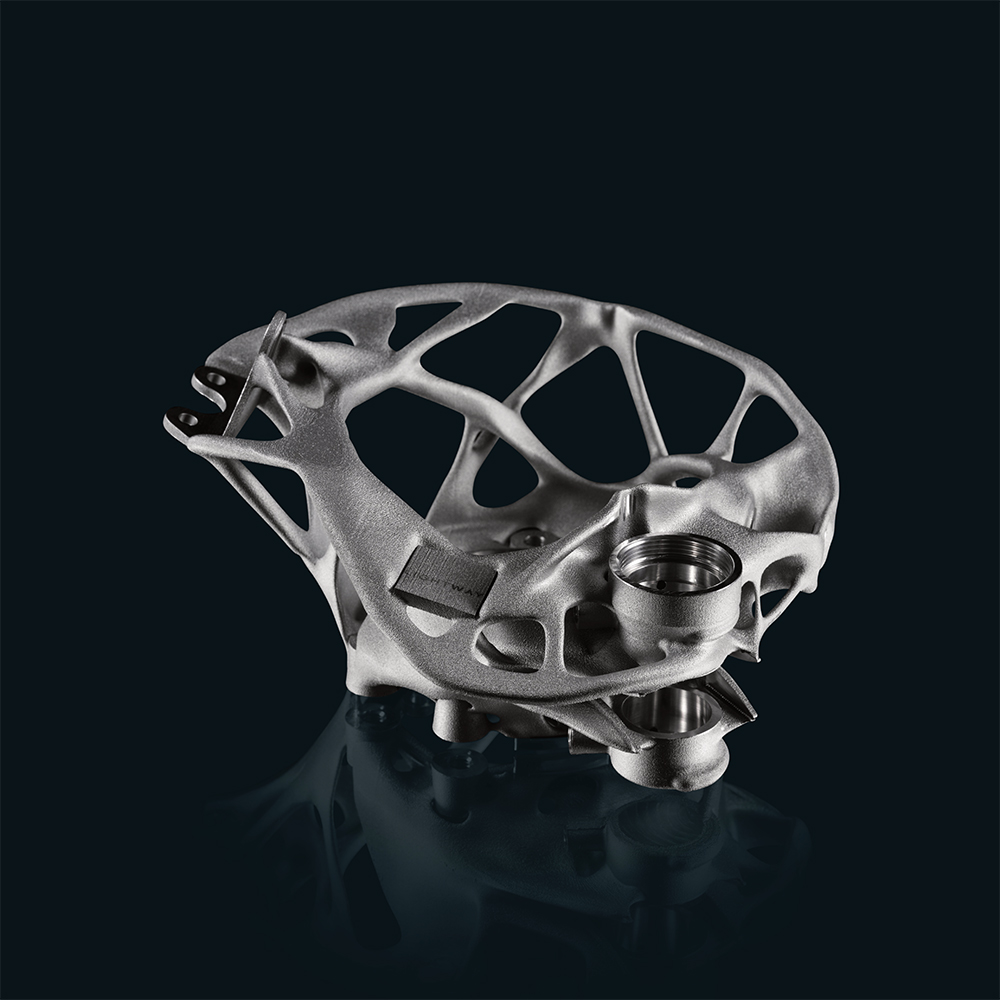

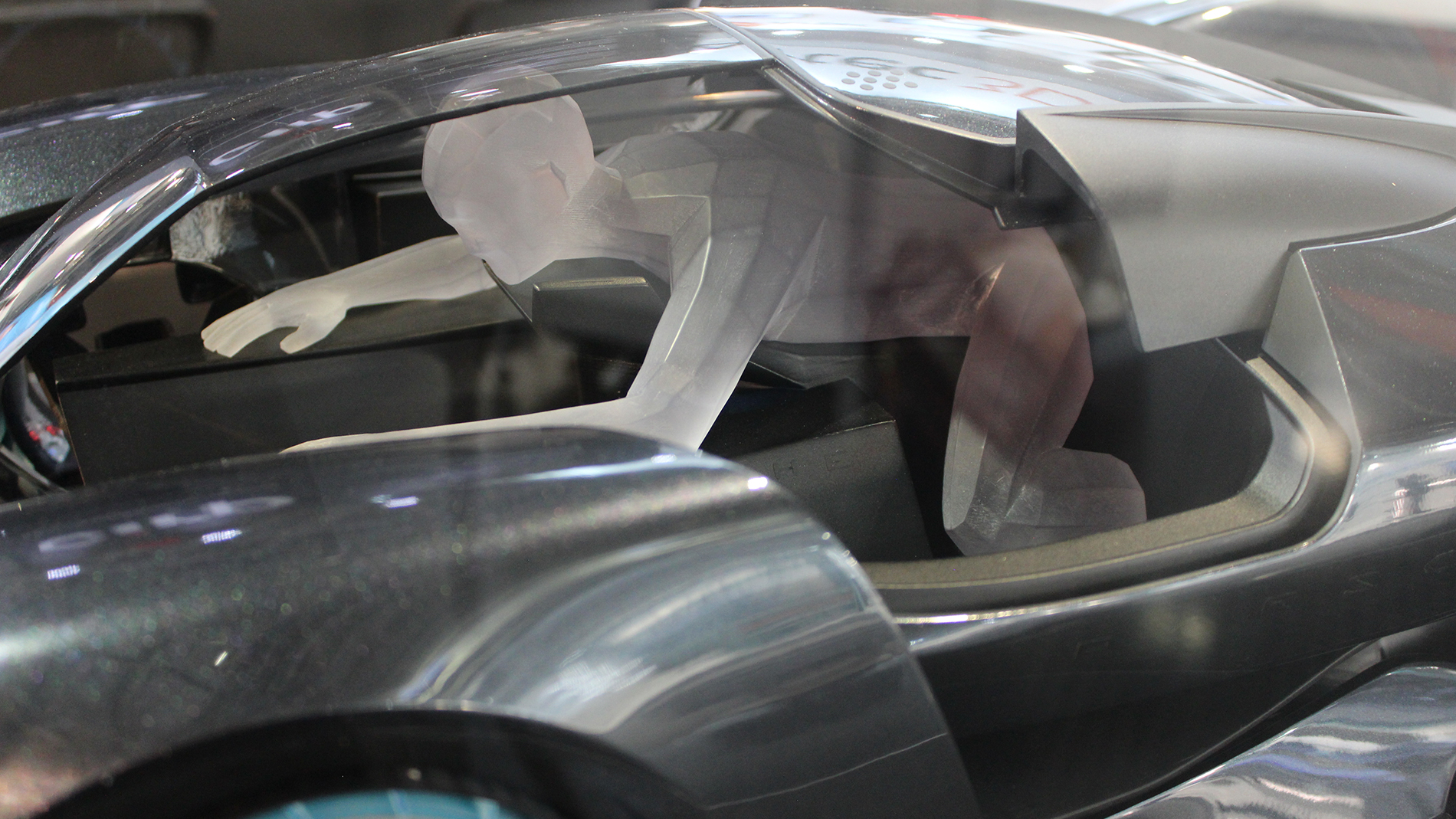

Prototyping in the automotive sector is a very complex topic and covers all phases of automotive development for series vehicles. This ranges from components for internal models to design approval, where high demands are placed on surface quality (which requires post-processing of 3D-printed components), to cars that are tested in wind tunnels or later on the road.

Various technologies are used, such as stereolithography for optically demanding parts and laser sintering for test parts. Cirp uses injection molding, for example, when components have to be manufactured in the original material and require a very high degree of precision. Think of the interior trim in front of an airbag, where a precise predetermined breaking point must be implemented. The quantities for testable parts like these are often between 100 and 5,000. Cirp uses the experience it has gained from these orders to produce corresponding finished parts series for niche markets in the automotive sector (e.g. trucks or sports cars), as well. These are then sometimes delivered directly to the OEMs' assembly lines in just-in-time arrangements.

A demanding industry

A company like Cirp often does not know what happens to individual 3D-printed components on the customer side. Often, however, conclusions can be drawn about their use based on quantities and necessary properties. Thomas Lück therefore assumes that “most of our components end up in the testing environment.”

According to Lück, the automotive industry is generally a very demanding market for additively manufactured components. In addition to reliability and a broad material portfolio, a high level of quality is also a prerequisite for long-term success as a service provider. “This is because the industry applies strict criteria,” explains Lück, who considers his company's ISO 9001 certification very helpful. Although Cirp does not have automotive-specific certification such as IATF 16949 (favoring speed and flexibility instead), there have been “several customer audits conducted with this in mind.”

Another important aspect is the ability to achieve and verify guaranteed component properties over and over again in AM production. To this end, Cirp has optimized its production as part of an Industry 4.0 project, installing things like sensory monitoring and “raising production to a measurably higher level through better handling of machines and peripherals,” as Lück explains.

Haptic prototypes still very important

The fact that the automotive industry remains one of the most important user industries for Additive Manufacturing “is also due to the fact that it was one of the first industries to draw its designs with 3D CAD – because of its complex products, among other things,” explains Lück. "This design data also created the basis for the Additive Manufacturing of components. Overall, AM therefore remains a very important development tool," says Lück.

Despite many advances in virtual reality, haptic models continue to play an important role in design approvals. “Sure, managers may occasionally wear VR glasses, but designs are often still decided on the basis of real models,” Lück reveals. These are traditionally molded or milled from clay at a one-to-one scale and supplemented with plastic components (e.g. radiator grilles or exterior mirrors). And even when the so-called prototypes are later tested in camouflage on roads in real traffic, numerous additive components are integrated depending on the stage of development – to install and maintain the hard camouflage, for instance.

A great deal of uncertainty

When it comes to access to the automotive industry, Cirp, which has more than 60 employees at its headquarters in Heimsheim, benefits from its location in the Stuttgart area with several large German OEMs in the immediate vicinity. As a service provider, the company is feeling the current tension in the industry. “We are experiencing a great deal of uncertainty in the automotive industry. The picture is very heterogeneous for us today and is changing rapidly,” reports Lück. “That uncertainty has increased in decision-making, which means the process takes longer, and it is also becoming more difficult to predict how projects will proceed.” Ultimately, however, Lück also sees a certain opportunity in this development. “When decisions are delayed, components are sometimes needed very quickly at the end – which can often only be achieved using AM or a fast prototype tool from us.”

Further exclusive information:

Here, you'll find further information and exclusive in-depth articles on: