Text: Thomas Masuch

For Daimler Buses, supplying spare parts is a challenging issue due in part to the high quality of its own buses. These are often in service for up to 25 years or more and travel more than a million kilometers. Daimler Buses therefore continues to supply spare parts even 15 years after the end of production, and in some cases even longer for critical parts. And because a single bus consists of up to 70,000 individual parts depending on the model, numerous components and the necessary tools must be kept in stock. At the company's own Omniplus Spare Parts Logistics Center in Neu-Ulm alone, well over 100,000 different spare parts and accessories are stored across 32,000 square meters of warehouse space. Every day, 220 employees ship around 6,800 items worldwide.

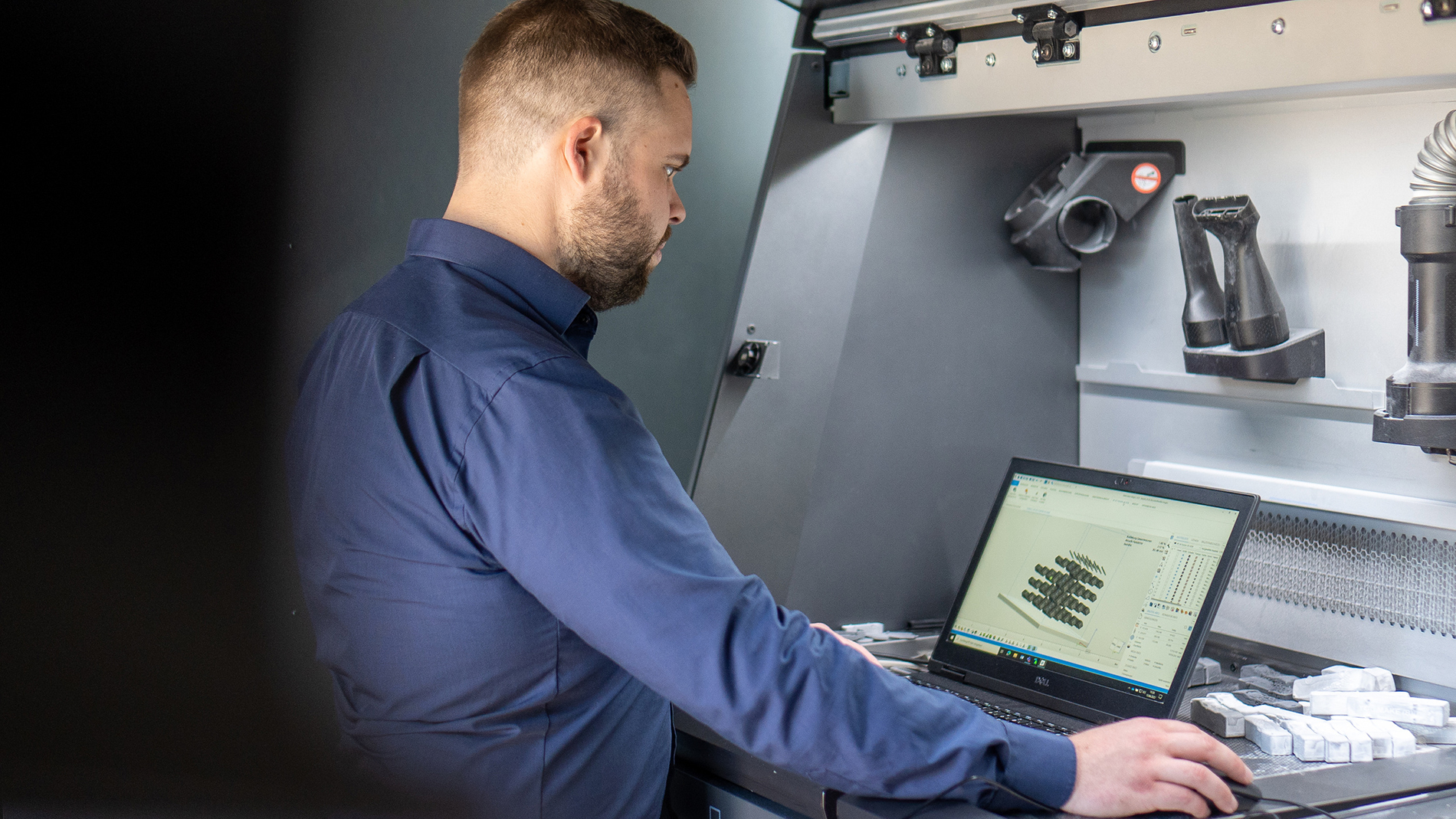

Since the quantities required are relatively small compared to the passenger car market, Daimler Buses began systematically validating spare parts and manufacturing them in series using industrial 3D printing back in 2016. Three years ago, Ralf Anderhofstadt, head of the Center of Competence Additive Manufacturing at Daimler Buses, and his team began to establish and roll out a global partner network for the decentralized Additive Manufacturing of original spare parts.

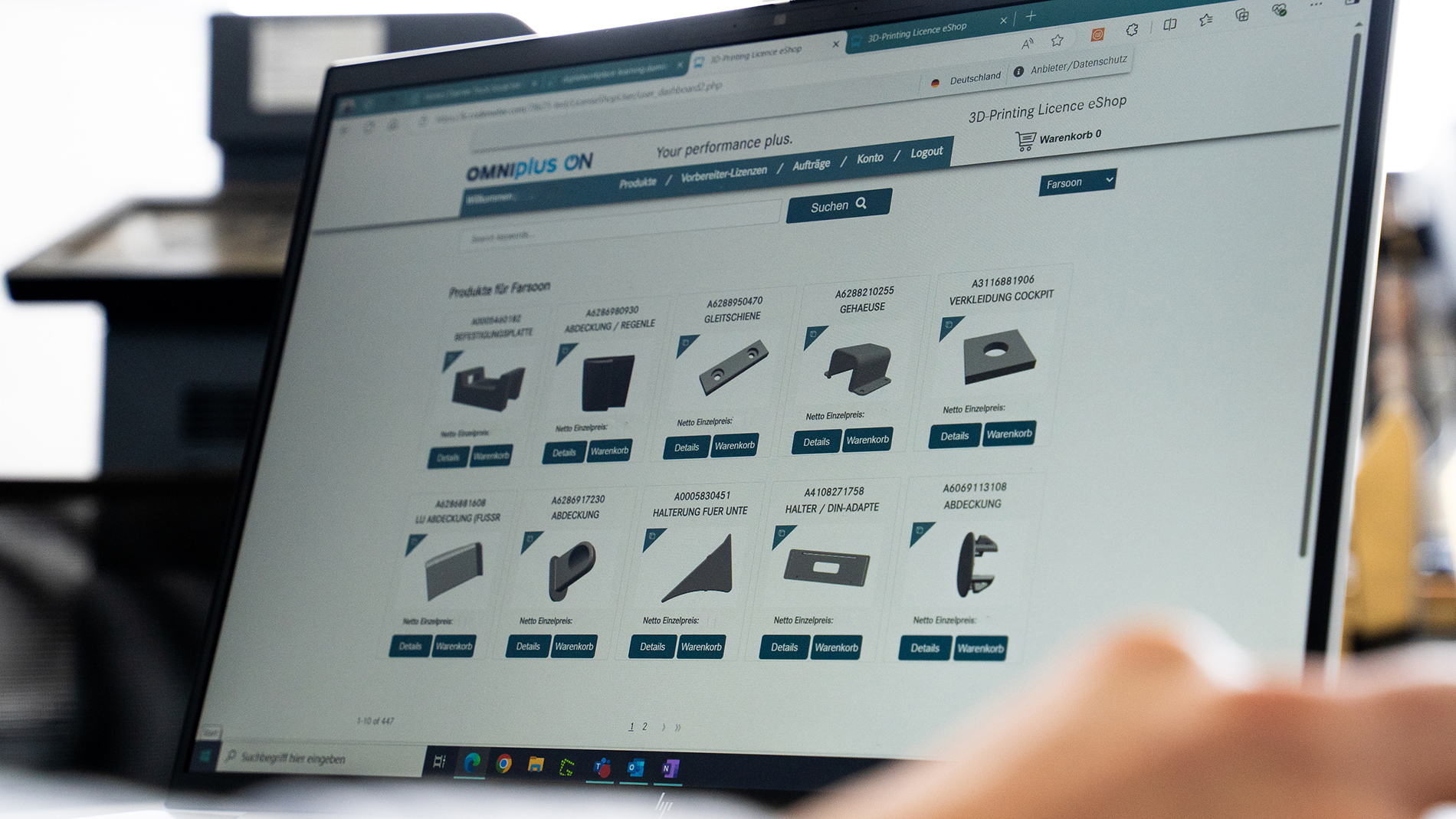

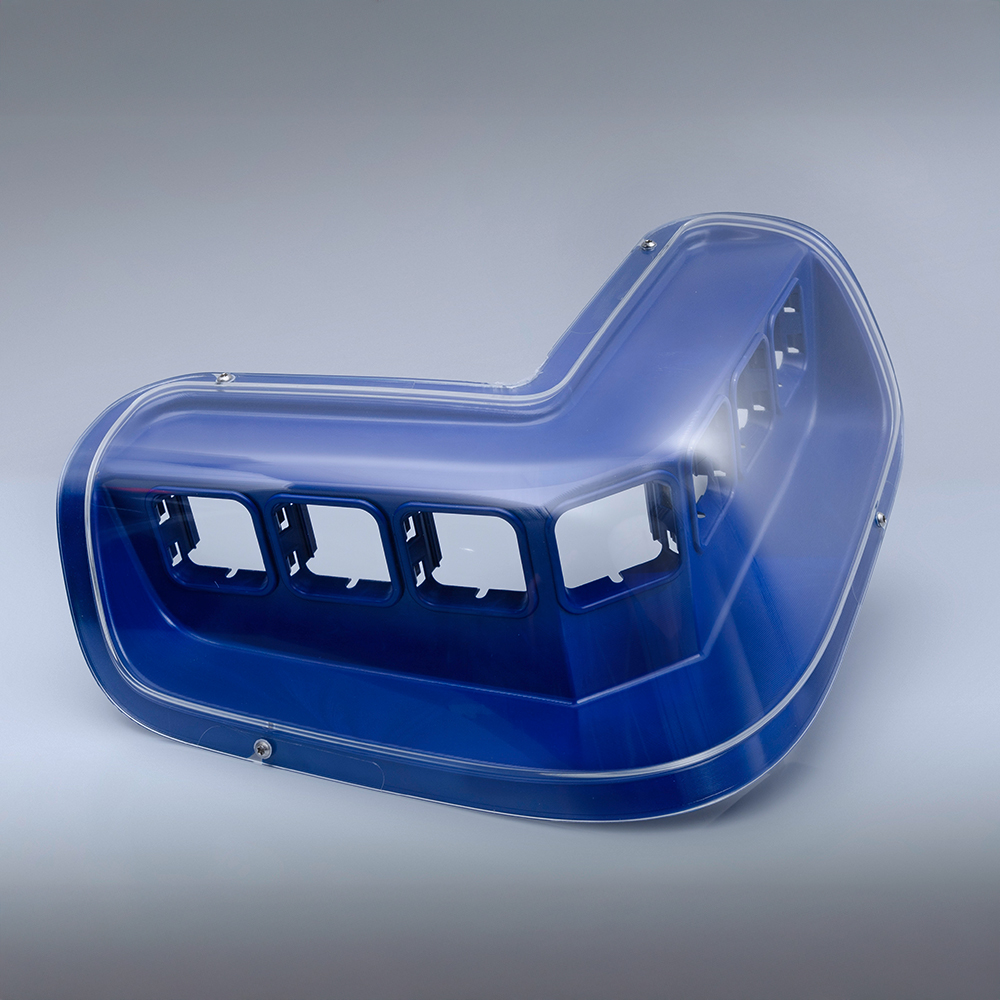

In recent years, Anderhofstadt and his team have tested and validated numerous AM technologies internally. The processes, printers, and materials have been certified to the highest quality standards. Omniplus 3D Printing has now deemed a total of over 20 percent of all spare parts printable, with over 500 different spare parts already validated and approved for industrial 3D printing. The parts are printed by certified partners (among others), who take over the AM processes from Daimler Buses and manufacture spare parts under license on their printers at the point of need. Instead of storing the spare parts in Neu-Ulm and shipping them as needed, “we then only send the printing license with all the necessary data around the world,” explains Anderhofstadt.

From the workshop to the logistics provider

In order to establish and expand Daimler Buses’ network of AM partners, Anderhofstadt first spoke to the obvious candidates: Daimler Buses' own external organizations and the workshops of existing partners. The second step was to approach AM service providers and logistics companies, where Anderhofstadt encountered a surprisingly positive response for the most part. “Some of the companies see 3D printing and decentralized manufacturing as a ‘disruption’ to their existing business model and want to use 3D printing as an opportunity themselves.”

One of the logistics companies that has entered Additive Manufacturing in earnest and is now a certified partner of Daimler Buses is the Seifert Logistics Group. It now offers 3D printing services using SLS and FDM processes, focusing on TPU and PA12 materials. In addition to spare parts for Daimler Buses, the 3D printing and logistics service provider is implementing further use cases with its customers in the fields of orthopedics, sports, cleaning, art, and logistics. “Technological developments in Additive Manufacturing are increasingly opening up opportunities for 3D printing series production. This enables us, as a logistics service provider, to offer new value-added services in the long term – from storage and assembly to the shipping of self-printed components,” explains Fabian Frommer, team leader for data science and digitalization at Seifert.

Various technologies and materials

The technology used, including hardware, software, and materials, has been a key factor in establishing the AM partner network of the Center of Competence 3D Printing at Daimler Buses. After all, customers must receive proven Daimler Buses quality, and the process must be secure and prevent the unlicensed 3D printing of original spare parts.

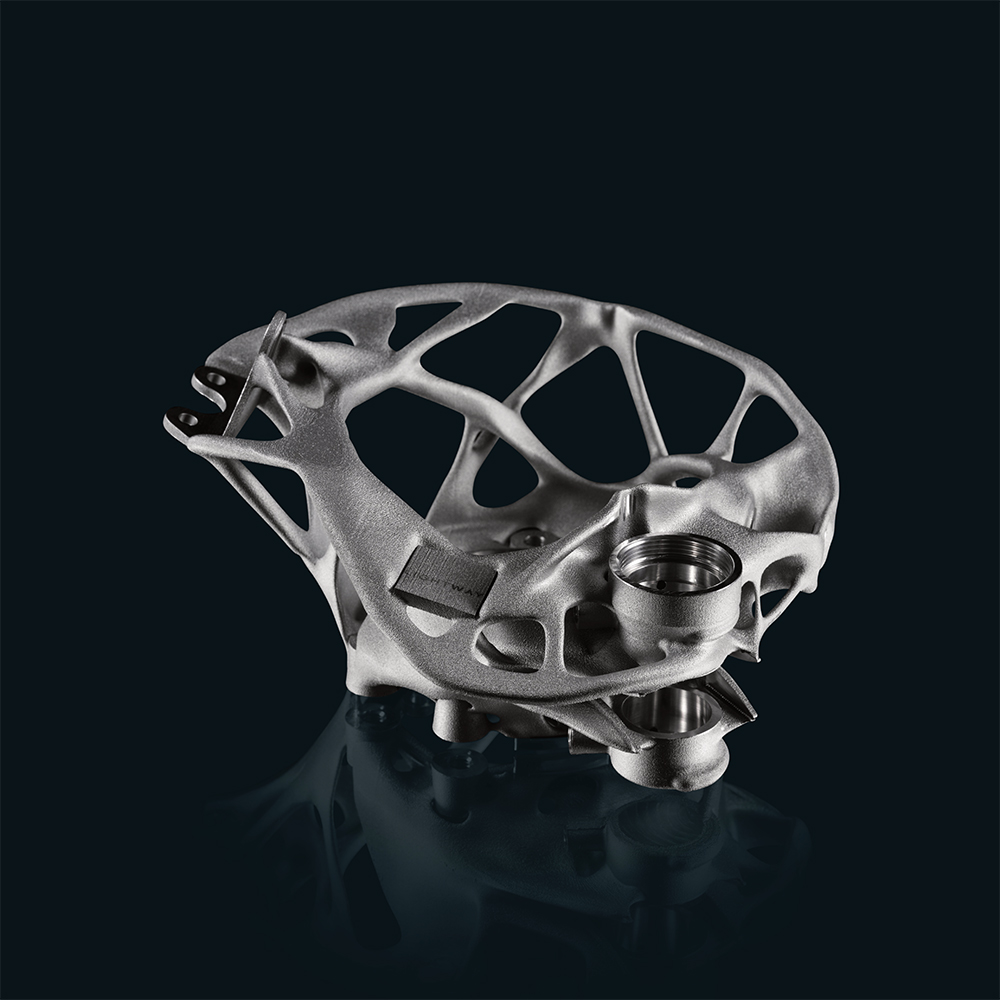

In addition to users, Anderhofstadt and his team have therefore held numerous discussions with various manufacturers of 3D printers, including SLS, multijet, SLM, and FDM varieties. This is because a wide variety of printers, materials, and manufacturing processes can be considered for the production of series and spare parts depending on the application at hand.

The 3D printing systems that have already been validated include various printers from Farsoon and 3D Systems. Additional systems from other manufacturers are currently in the final approval and connection phase. “The prerequisites for connection to our license management system are the highest quality standards, approved certified processes and materials, and the necessary reproducibility of the systems,” says Anderhofstadt. Incidentally, certification is always printer-specific: “We focus on the systems that are already qualified for our certified components. That's why license management is done at the printer level and not at the company level,” Anderhofstadt explains.

Access to the printer

Discussions with printer manufacturers have shown that “the majority of printer manufacturers are very interested in our digital business model and cooperation in the area of license management,” says Anderhofstadt. However, some discussions are proving somewhat more difficult because Daimler Buses’ certified process requires access to the printer's CPU, which some manufacturers are still reluctant to grant. “Some companies are cautious in this regard,” Anderhofstadt says, emphasizing that “we are not interested in the printer technology itself. What matters to us is that our protected licenses are recognized, processed, and then automatically deleted by the printer.”

According to Anderhofstadt, AM manufacturers do not need to make large investments in integration: “Printer manufacturers can already use existing modules from our partner WiBu Systems.” He adds that this software can also be integrated into existing systems.

Business cases

The industrial 3D printing of spare parts for buses is often quite demanding from a technological standpoint – and a desktop printer is usually not sufficient. “On the one hand, many spare parts are too large, and on the other, high quality standards and requirements must be met,” explains Anderhofstadt. Such AM systems often require a correspondingly large investment: Here, amounts in the higher six-figure range can be expected for the industrial 3D printer alone. When you factor in the necessary peripherals, process certification, and employee training, the required investment can exceed €1 million. "This represents a considerable investment for both medium-sized companies and large corporations. That's exactly why we help with individual investment decisions," explains Anderhofstadt. For example, Daimler Buses' consulting unit, Additive Manufacturing Solutions (AMS), has validated and determined figures, data, facts, and empirical values from numerous internal and external projects over the past few years, analyzing the competitive situation in each region individually and working with interested companies to prepare profitability analyses.

An eye toward other industries

To further improve profitability, Anderhofstadt has another concrete idea in mind: The process of licensed spare-part production that his company has developed should not be limited to its own buses. The AM expert is already in talks with manufacturers of caravans and special vehicles, and even with the maritime industry. “Our decentralized licensing model is suitable wherever complex spare parts and products are needed quickly and globally in manageable quantities,” he points out. And the greater the number of industries enthusiastic about it grows, the more successful the partners' business will certainly be.

Further exclusive information:

Here, you'll find further information and exclusive in-depth articles on: