At first glance, the white tower of Mulegns looks like a movie set from The Lord of the Rings. And yet the filigree concrete structure, which is located in a small Swiss mountain village surrounded by peaks over 3,000 meters high, is not the work of elves or hobbits, but a symbol of technological progress: It’s the tallest 3D-printed building in the world.

The approximately 30-meter-high "Tor Alva" shows what is possible with this technology, including unusual shapes that could not be produced any other way. But prestigious architectural gems like this are only one side of this special industry. In the construction and architecture in general, 3D printing is growing rapidly thanks in part to new developments in hardware, software, and materials. And while ribbons are being cut on more and more 3D-printed buildings (such as offices, data centers, restaurants, or residential buildings), the number of "components" that add value to architecture – lightweight connecting elements, water-conducting roof tiles, sound-absorbing walls, and more – is also growing. That’s not even considering the world of interior design, either.

The rise of Additive Manufacturing in construction and architecture is also borne out by the figures: Although Wohlers Report 2025 says that the industry has a share of around 1.7 percent of the overall market – well behind the leading automotive, aerospace, and medical sectors (each with more than 10 percent) – the current growth rates are enormous. According to Mordor Intelligence (seriously!), the 3D-printed construction market is set to expand by an average of 37% per year until 2030. Precedence Research even anticipates average annual growth rates of 65% until 2034.

Demanding industry

Despite these impressive figures, Prof. Oliver Tessmann takes a positive, but more sober view of current developments. "The practical relevance of the industry continues to increase, but many projects still have an experimental character," says Tessmann, who, besides teaching and conducting research at the Technical University of Darmstadt, also organizes the BE-AM Symposium and the special show of the same name in cooperation with Prof. Ulrich Knaack and his team. "Overall, the current growth is also limited by the lack of uniform standards in Germany and Europe at large. If we make progress in that area, Additive Manufacturing could open up huge potential in the construction industry."

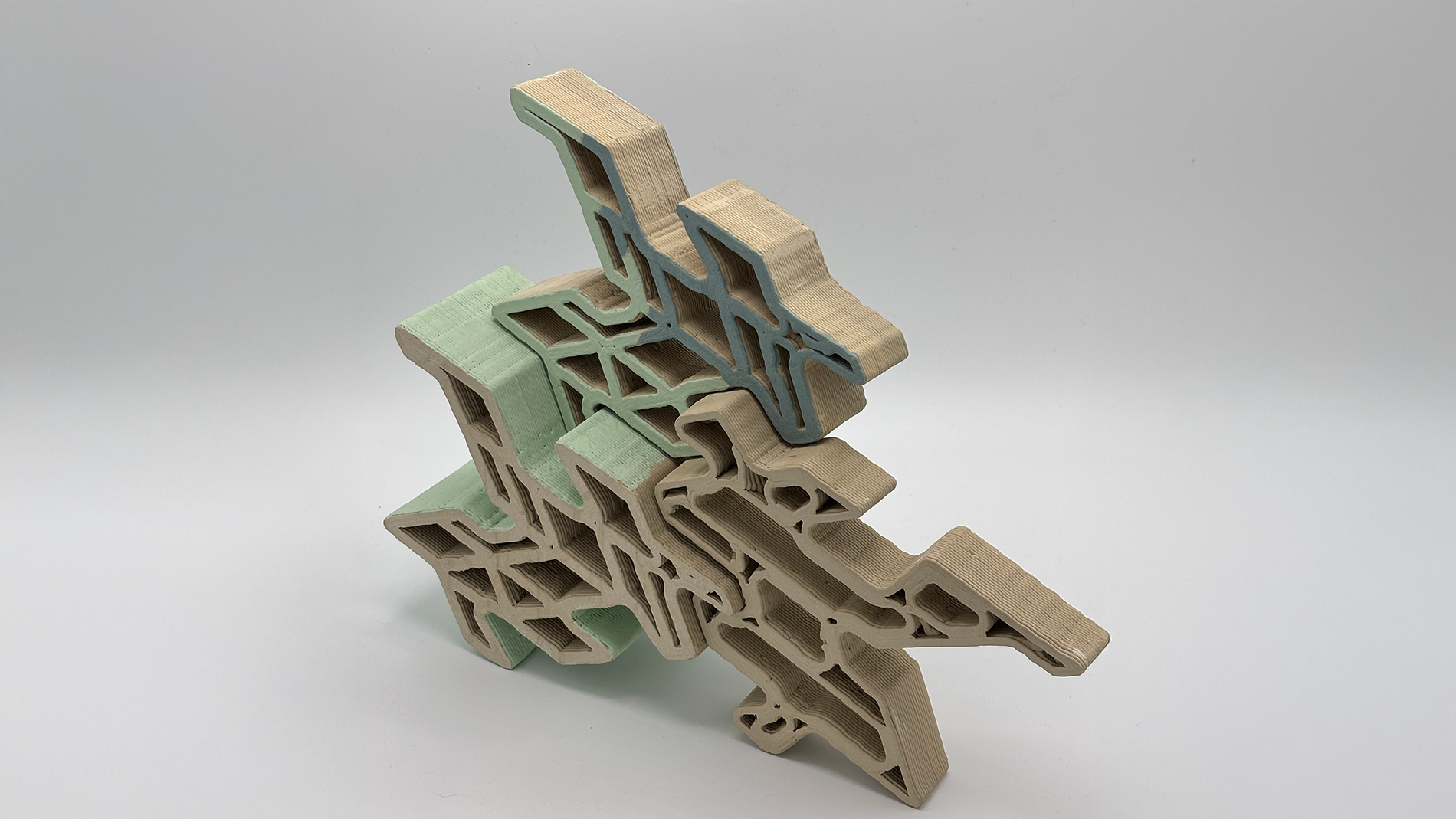

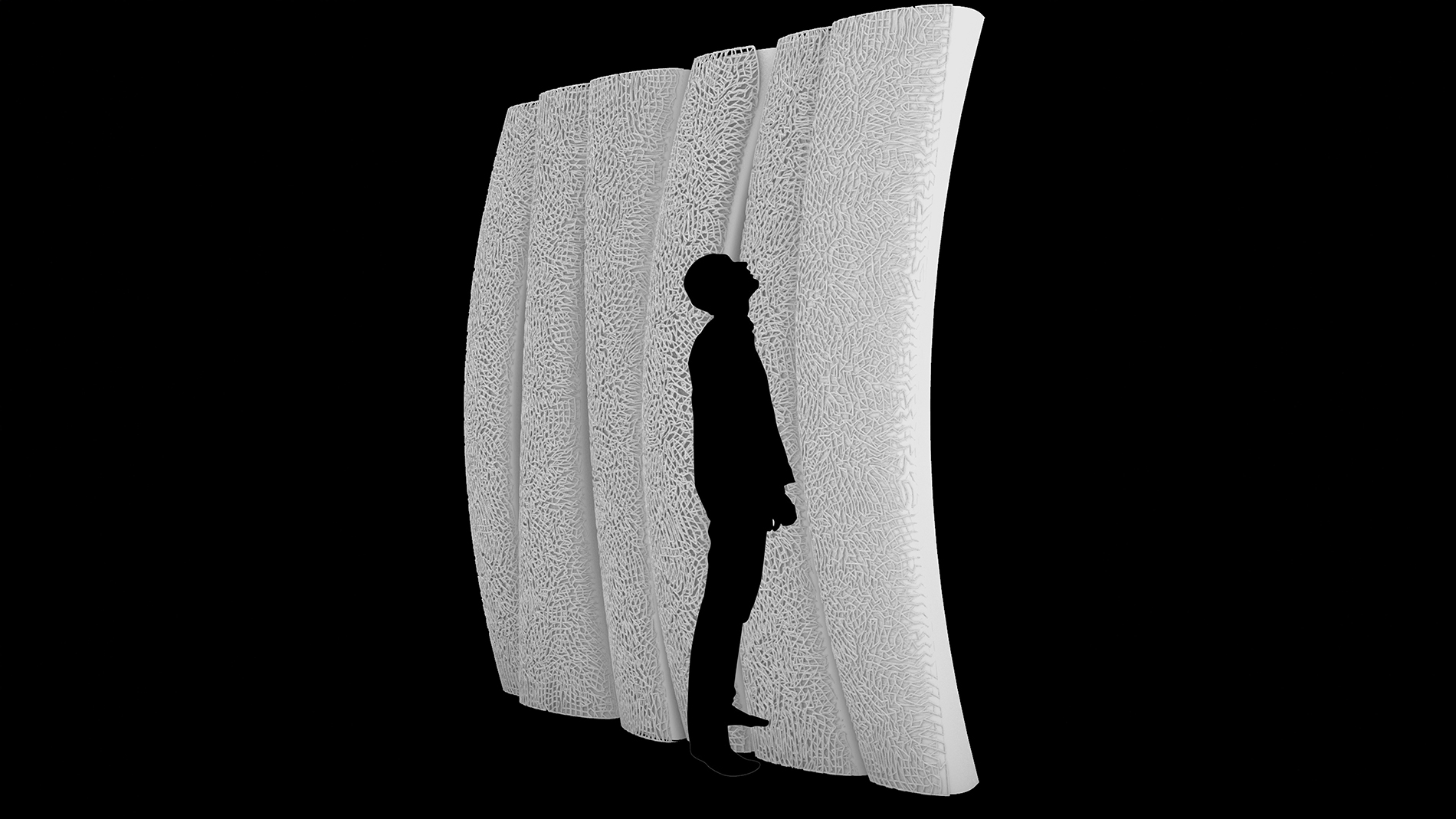

Despite the technological advances that have been made, the construction of many buildings is still far from being 100% automated. In the case of walls, only the outer façade is usually created using a 3D printer; the interior, including the reinforcement, is filled in by traditional means (i.e. by hand). On the other hand, Additive Manufacturing makes far more than just extravagant building shapes possible, as a look at the smaller scale shows. At TU Darmstadt, research is also under way on things like nest clinkers – that is, clinker bricks that include individual holes and recesses in which certain bird species can nest. This is because construction projects are often delayed or canceled altogether if a protected bird is found nesting in a tree or barn in the neighborhood. According to Tessmann, another promising future-oriented application involves 3D-printing with clay and other sustainable materials for soundproofing purposes – for instance, in open-plan offices (examples of this will be on display at the BE-AM special show).

"3D printing can also lead to mass customization in modular production," Tessmann continues. “Architects and manufacturers still need to rethink this, however; simple shapes are still being used, primarily because they are easy to produce." The situation is different in 3D printing, where geometries have a much smaller influence on manufacturing costs.

BE-AM Symposium and special show

The BE-AM (Built Environment Additive Manufacturing) Symposium and special show, which are taking place for the eighth time as part of Formnext and are open to all Formnext visitors free of charge, offer a detailed look at how far Additive Manufacturing has already come in construction and design.

This year’s edition will focus on projects that have been completed in 2025: Spanish design studio Nagami will present interior and furniture pieces, while Etcetera will show how computational design and close collaboration with manufacturers can be condensed into market-ready products and spaces. In addition to the aforementioned Tor Alva, the "Wavehouse" will be discussed. Europe's largest 3D-printed building, which was designed by SSV Architects in Heidelberg, sports a striking façade while serving as a data center. In addition to robot-assisted 3D concrete printing technology from Vertico, BE-AM 2025 will be dedicated to research and discuss topics like flexible insulation and absorption panels made of natural fibers, the use of 3D printing with clay for acoustic applications and wildlife protection, and mycelia as sustainable building material.

Visitors to Formnext can experience further examples at the BE-AM special show in Hall 11.0. Around 30 exhibits from research and industry will include columns made from shell waste and recycled plastics, various 3D-printed functional bricks, innovative connecting nodes, and unusual pieces of furniture.

That said, Formnext not only shows what is possible; it’s an important platform for professional exchange, as well. "With the BE-AM Symposium and the associated special show, Formnext offers researchers, start-ups, and other innovative AM companies important access to the construction industry, provides an understanding of the sector’s special requirements, and makes it possible to meet the right contacts," says Christoph Stüker, Vice President of Formnext. Oliver Tessmann adds: "Many of these young companies have often developed very good solutions, but have little access to the complex construction universe due to their origins in the technology sector. That’s what we want to change."

Further information:

www.formnext.com/fonmag

www.be-am.de/symposium

BE-AM special show: Hall 11.0, F49

BE-AM Symposium on 19 November 2025, Portalhaus, Transparency room