See who is exhibiting or create your own watch list. Use the filter options to obtain a list of exhibitors for the respective product group.

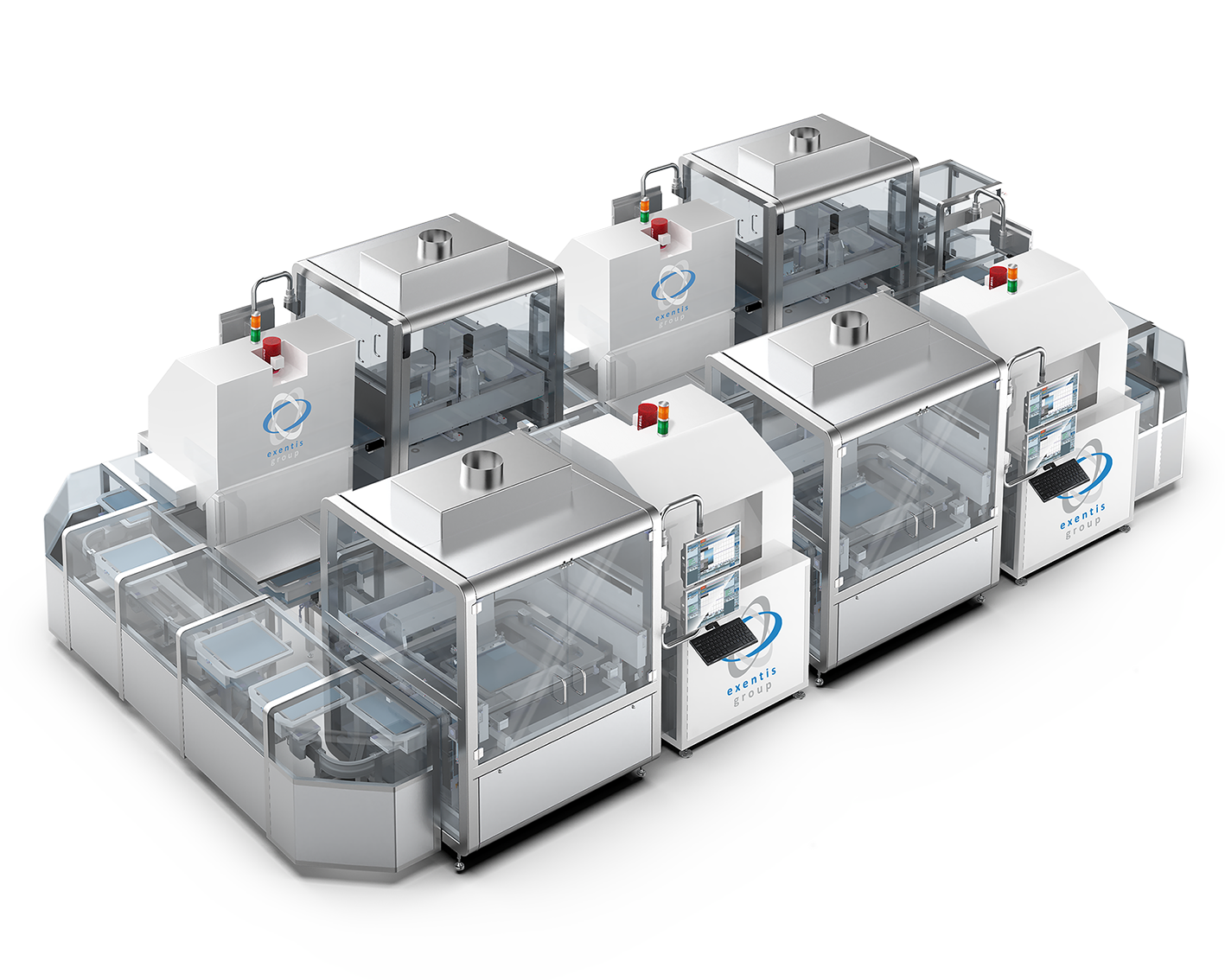

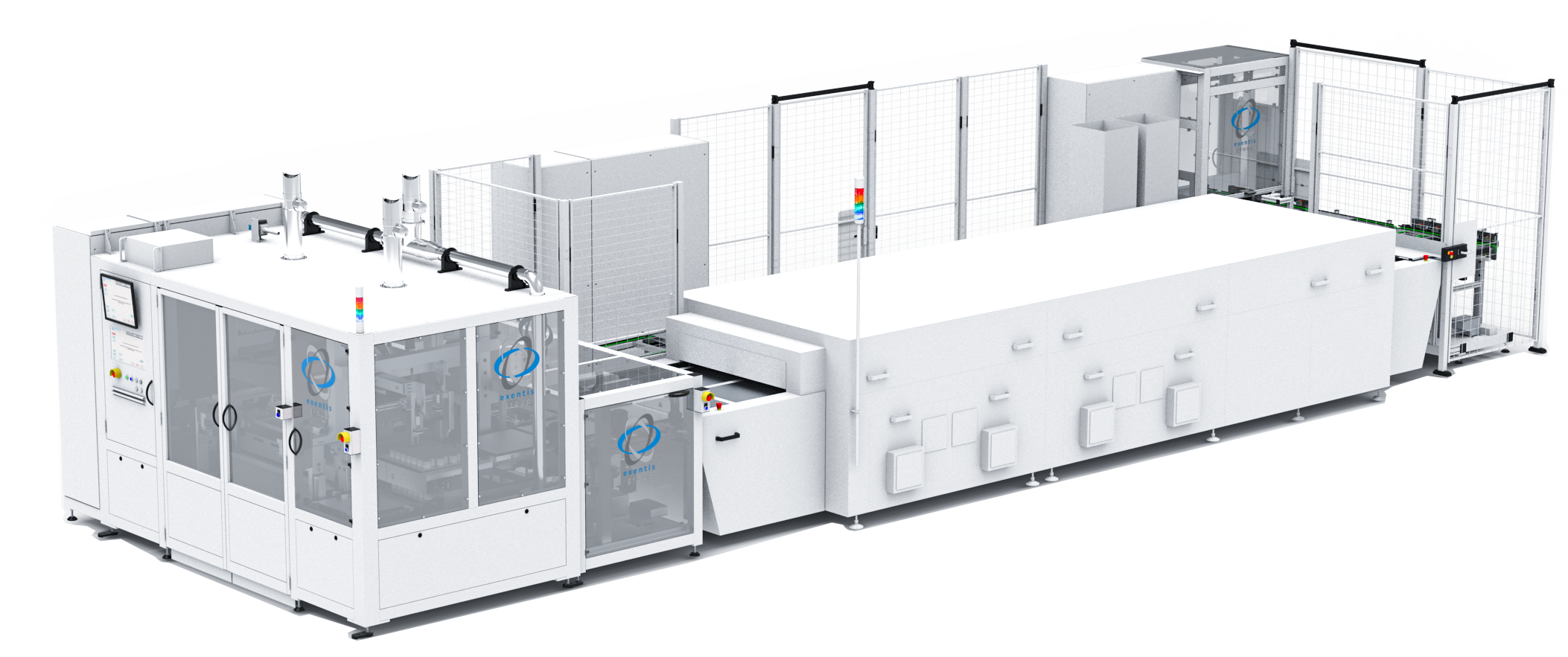

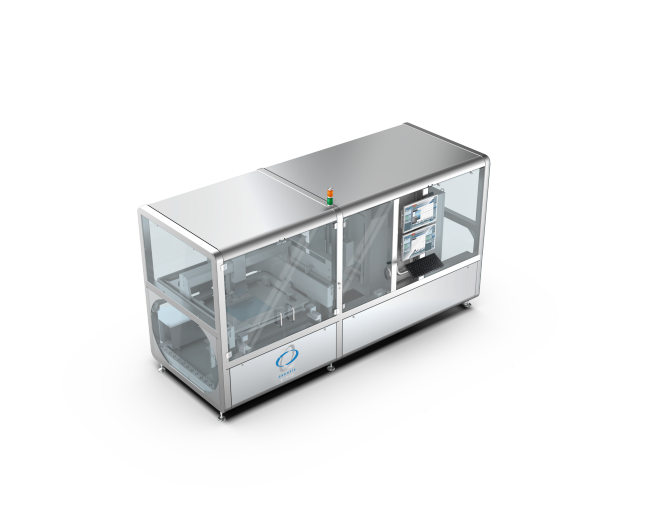

Exentis 3D development and production systems EX431 and EX431 GMP

Exentis 3D development and production systems EX431 and EX431 GMP

Description

The Exentis 3D development and production system EX431 is designed for process development

and additive manufacturing. It is available as EX431 GMP cleanroom-system as well.

It consists of a printing module, an integrated circulating air drying unit and a combined positioning system for quality assurance and workpiece carrier loading and unloading.

The parts or tablets to be printed are transported on the workpiece carrier between the printing position, the measuring station and the drying station by means of a mobile printing table. The parts are printed layer by layer until they have reached their final height. The effective height of each layer is checked by an optical quality assurance system.

Advantages:

Unique Flexibility

• Free choice of material

• Any combination of different materials

Highest precision

• Production of ultra-fine structures

• No post-processing, no depowdering

Time and cost efficiency

• Material or part change within minutes

• Resource-saving cold printing process

Available as cleanroom production system:

• Adaptation to customer-specific GMP criteria

• Designed for class D / ISO8 cleanroom operation