Exentis Industrialized Additive Manufacturing Technology for large-scale production

The unique Exentis 3D screen printing technology sets new standards in Industrialized Additive Manufacturing. It enables the large-scale production of millions of parts with geometries never before possible: very small parts with ultra-fine structures down to 125 µm channel width, or even larger parts up to 400 mm in diameter. Micro precise structures such as cooling channels may be integrated within components during manufacturing process. All material available in powder such as ceramics, metals, polymers, active pharmaceutical ingredients, and biomaterials can be processed.

The Exentis 3D Mass Customization® technology is a sustainable, low-energy cold printing process with no excess material. Material is applied as a paste, printed layer by layer through screens, creating parts in minutes. The technology is highly flexible, with new screens available within 48 hours for geometry changes.

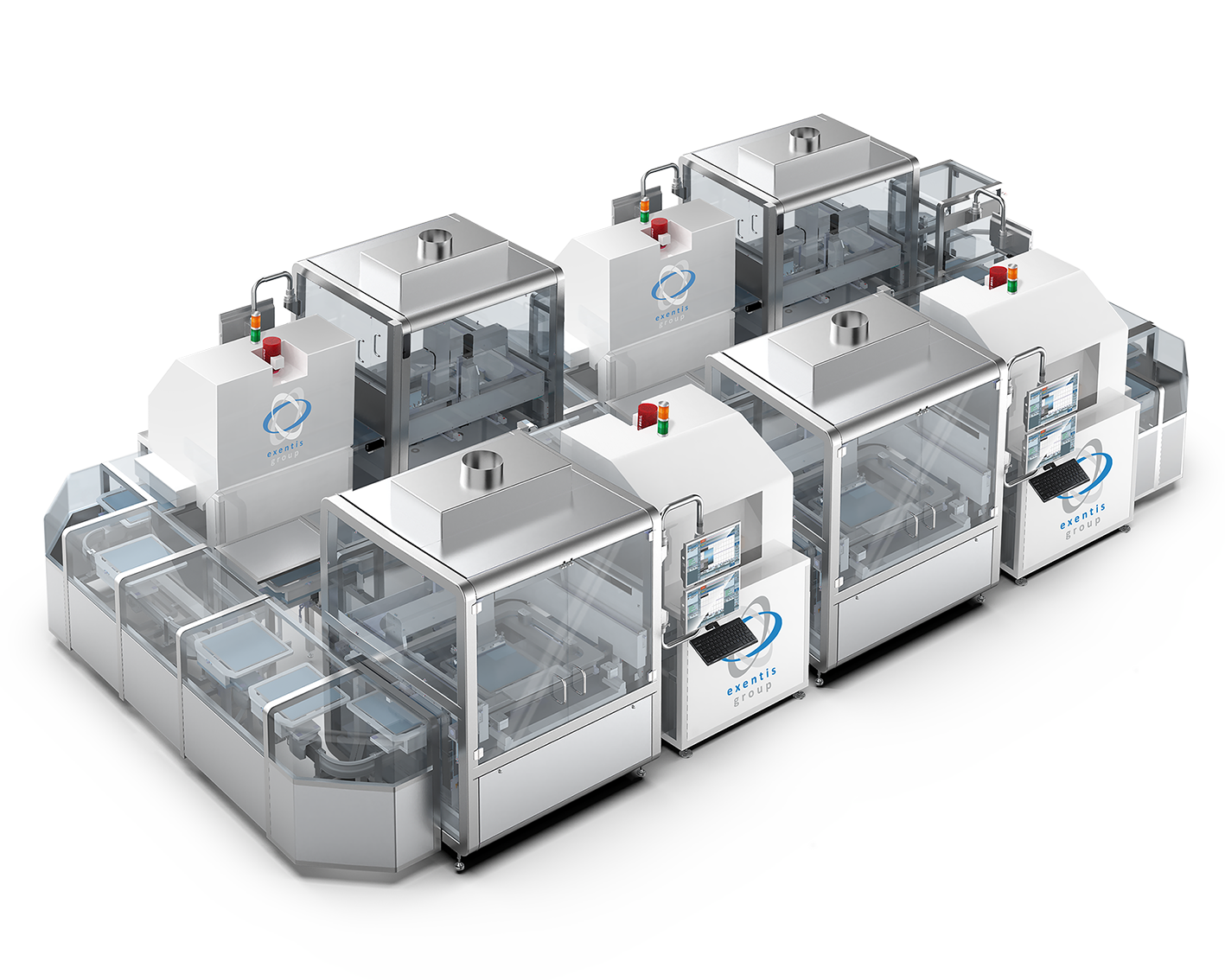

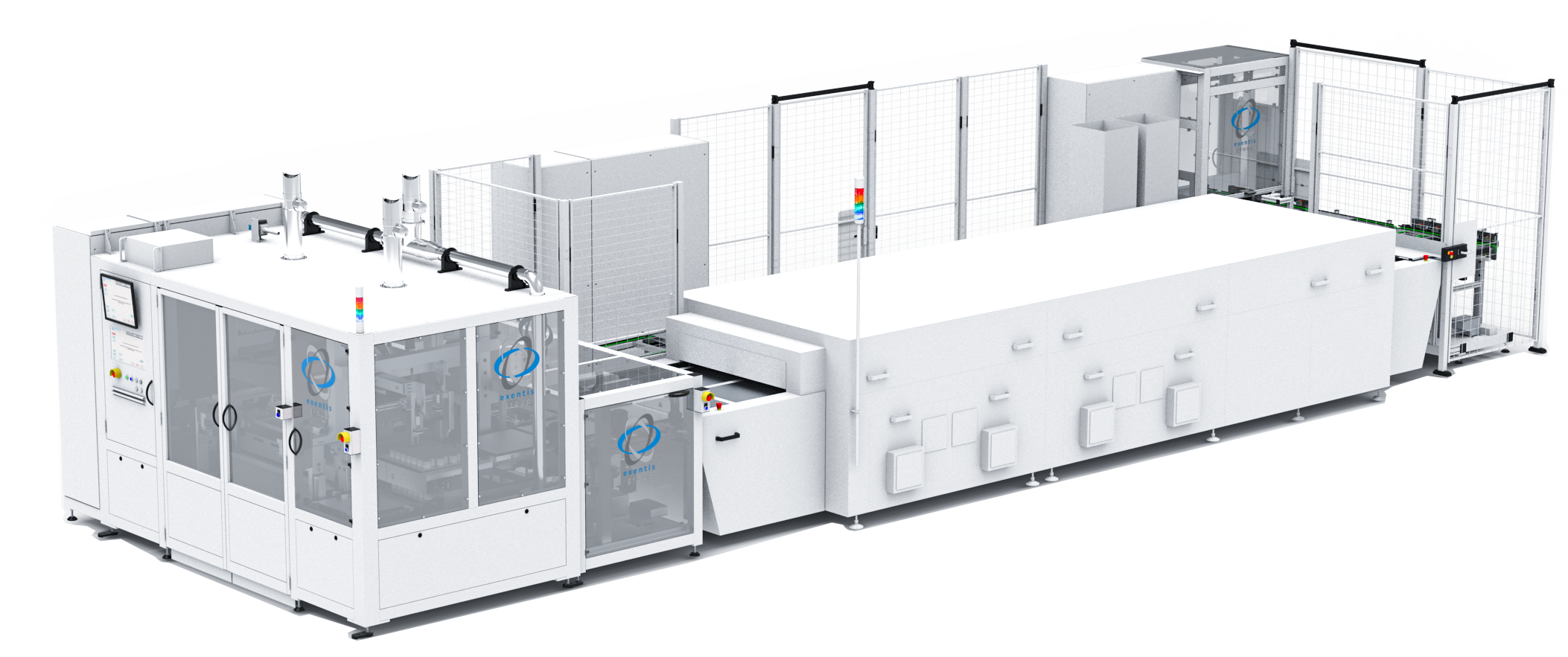

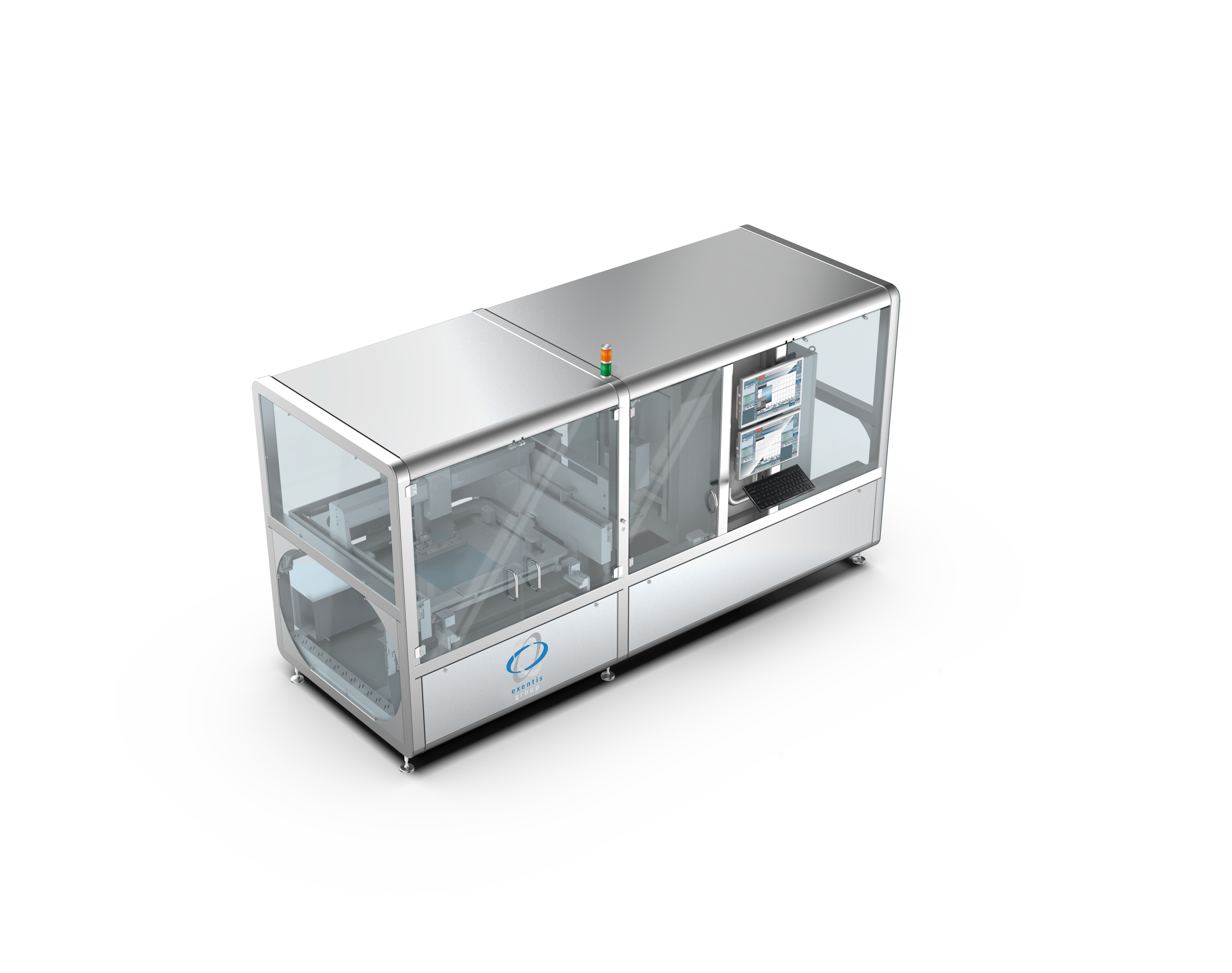

The 3D production systems are modular and can be flexibly configured for both industrial and cleanroom applications. Exentis offers a comprehensive all-in-one service: production systems, part development projects, materials and services, as well as contract manufacturing. With the purchase of a production system, the customer can acquire a license for his specific applications and thus exclusivity.

Customers from a wide range of industries worldwide appreciate the benefits and flexibility of Exentis 3D production systems.