Additive Manufacturing has been used in the aerospace industry for more than 30 years, and today all major aircraft and engine manufacturers have integrated the technology into their production processes. AM is also playing an increasingly important role in the construction of satellites and rockets in the aerospace sector.

The sky’s no limit

Additive Manufacturing (AM) holds major benefits for the aviation and aerospace manufacturing industry. From faster prototyping and shorter time to market across improved design flexibility, reduced material waste to lightweight construction and increased sustainability AM plays a growing part in the aerospace industry.

All the more reason to shine a spotlight on this dynamic application-driven industry with the diverse formats of the Formnext Industry Insights. Get inspired, stay informed, and be fully prepared when this key topic takes the stage at Formnext this November.

We’ve curated a powerful selection of insights and facts just for you:

Whitepaper – Additive Manufacturing in aviation & aerospace

In our exclusive white paper "The sky’s (not) the limit”, we highlight the advantages of Additive Manufacturing for aviation and aerospace, especially the potential for cost reduction, material efficiency, and design freedom. We also examine the important certification processes for this industry and present application examples that illustrate the practical use of this technology.

We will provide you with in-depth insights in 6 chapters

- Introduction

- Advantages of AM in aerospace

- Materials and technologies

- Main applications at a glance

- Future prospects

- Checklist for a successful implementation

Formnext Technology Talks – our new digital webinar series

Step beyond the trade show calendar with our engaging webinar series! Each session dives into a key focus topic, offering a fast-paced, insightful talk featuring the latest market trends, fresh industry insights, practical solutions, and direct interaction with leading experts.

Technology Talk aviation & aerospace

In the recording of our session on aerospace an aviation, you can look forward to a lineup of leading industry experts and engaging presentations on current developments and challenges:

- Christoph Hauck, Member of the Executive Board, toolcraft AG

Talk: Additive Manufacturing in aerospace – opportunities and challenges - Scott Sevcik, Director Advisory Services & Strategic Solutions, Wohlers Associates

Talk: Implications of AM in the aviation aftermarket - Maximilian Strixner, Senior Additive Manufacturing Engineer, The Exploration Company

Talk: Printing the future of space: Metal Additive Manufacturing for rocket engines

The session will be moderated by Davide Sher (Co-Founder & CEO, VoxelMatters), who will guide the discussion with up-to-date market data and thought-provoking questions.

Register now and get access to the recording of our Technology Talk aviation & aerospace.

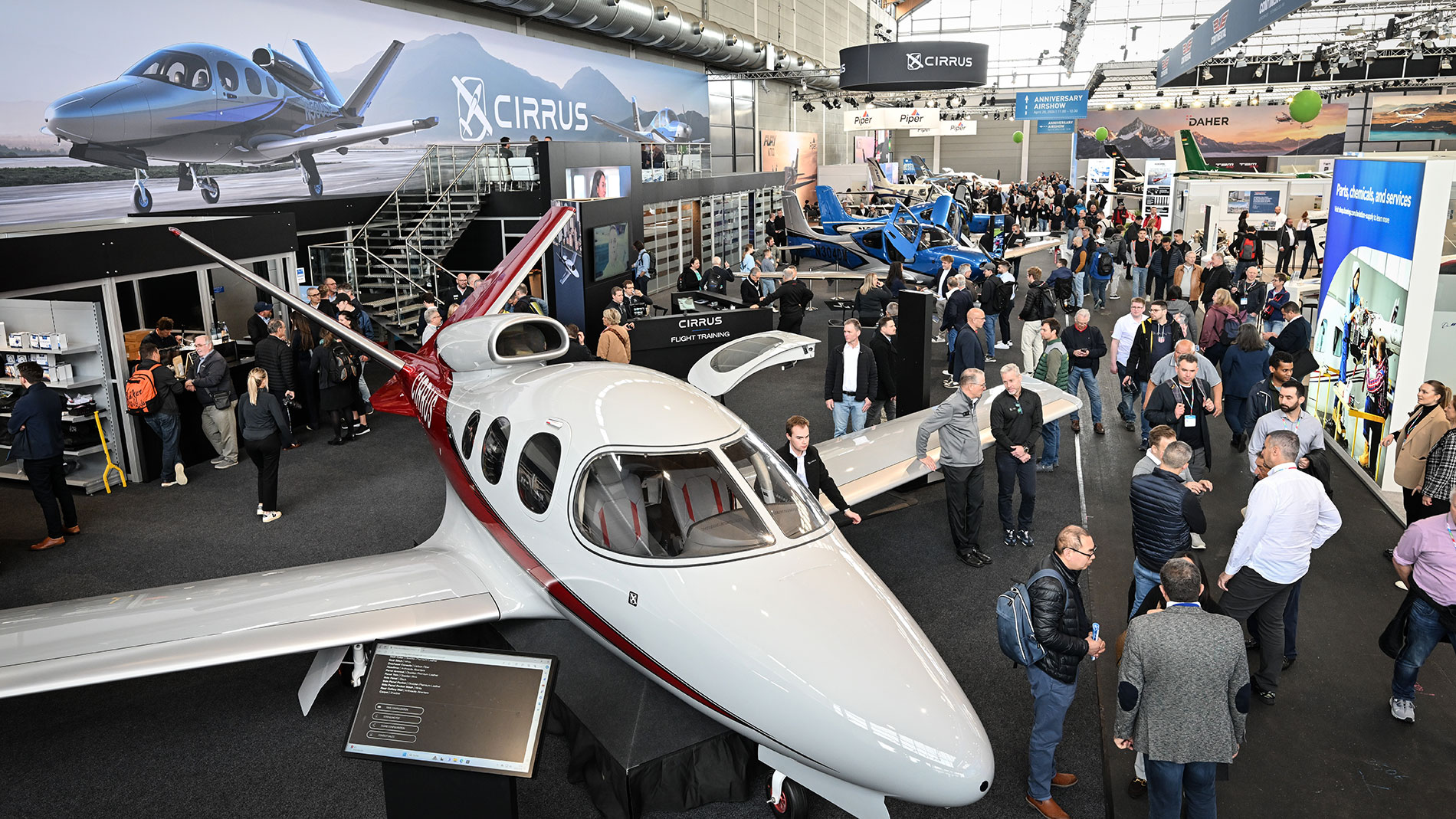

AERO AM Summit presented by Formnext

In early April, Formnext hosted the very first AERO AM Summit. This new conference format, held one day before AERO Friedrichshafen, brought together Additive Manufacturing and the aerospace industry. It impressively demonstrated how AM technologies are transforming aviation – from more efficient production processes to entirely new design possibilities.

A big thank you to Colibrium Additive, International Additive Manufacturing Group, Materialise, Omni3D, Renishaw und Stratasys for their valuable contributions and engaging discussions.

You’ll find a selection of the presentations (in English) just below.

Taking Off: Strategies for Scaling Additive Manufacturing in Aerospace

Additive Manufacturing (AM) is a powerful tool for driving innovation in aerospace. This presentation shows how companies can leverage AM to tackle challenges, seize opportunities, and establish certified, repeatable, and traceable processes. Real-world examples demonstrate how to produce high-quality, lightweight, and cost-efficient parts—whether through expert manufacturing services or in-house capabilities. It also highlights how digital process chains and software solutions can streamline AM workflows and ensure top-tier quality standards.

The Future of Aerospace Powered by 3D Printing

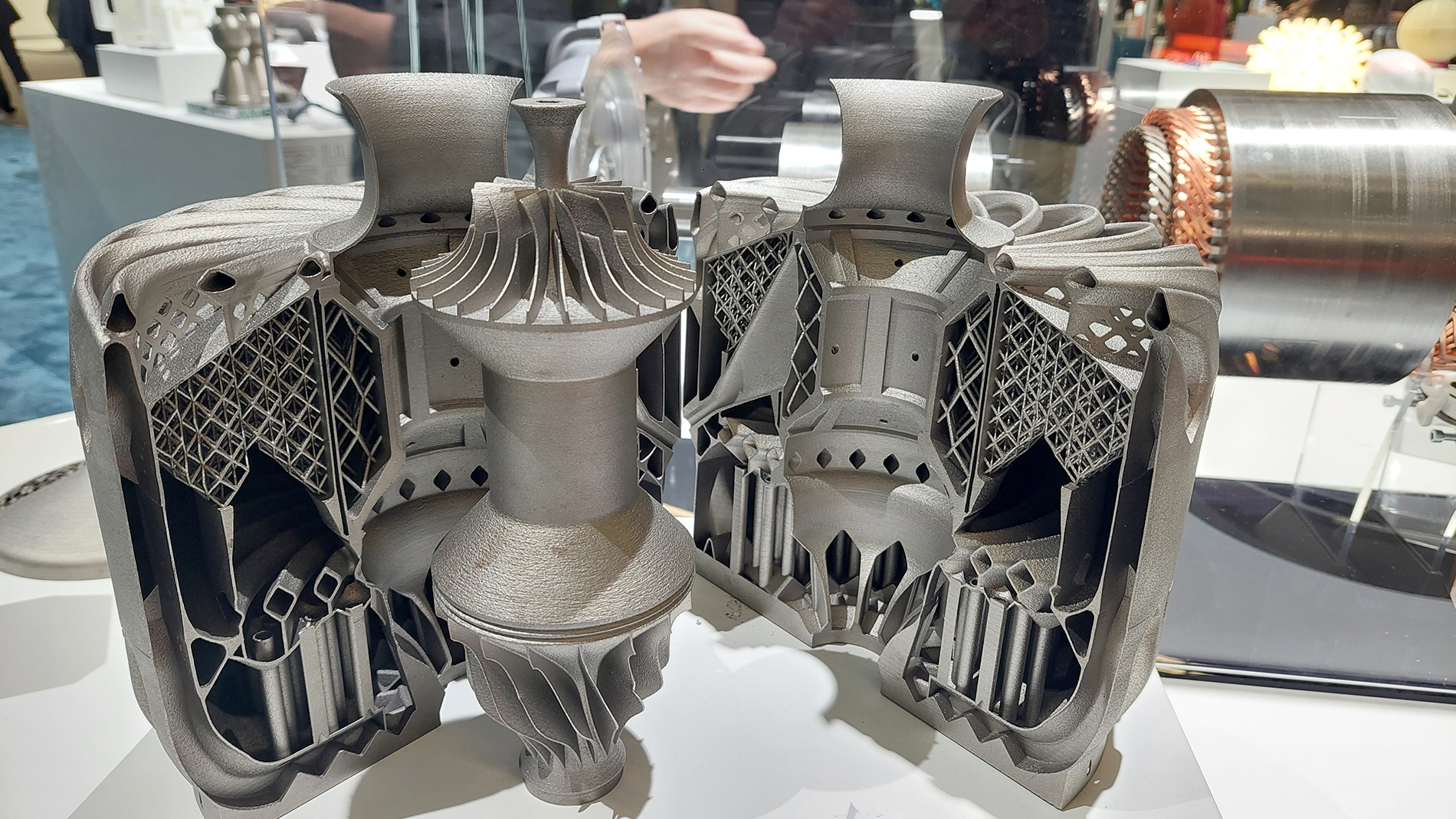

Discover the cutting-edge applications of 3D printing in aerospace, including the production of complex, lightweight structures, optimized engine components, and on-demand spare parts.

TEMPUS Technology – same build, half the time

TEMPUS technology: a new innovation from Renishaw that delivers a substantial increase in AM productivity and reduction in cost per part without compromising on part quality – up to twice as fast.

Stratasys Additive Manufacturing for Aerospace: Technologies, Materials and Avanced Solutions

The presentation explores Stratasys' additive manufacturing technologies for aerospace, highlighting high-performance materials like Nylon 12 CF and ULTEM 9085, and showcasing applications for Airbus and Boeing.

We would also like to thank the other presenters:

Fon Mag Special aviation & aerospace

Engines, antennas and luxury vases

AM is driving the aerospace industry and plenty of potential remains untapped. In our special in issue 1/2025, we reported in detail on this important AM user group, the latest solutions in the space and aviation sector and the challenges and prospects.

Expert Insights from Formnext 2024

At the Application Stage of Formmext 2024, application examples from aviation and aerospace were presented and discussed. It is definitely worth “tuning in” again!