Text and pictures: 3D Adept, 28 December 2025

Every November, there’s only one destination for anyone building a business in additive manufacturing (AM): Frankfurt. Formnext.

This year, though, feels a little more special. Formnext is turning ten, and if you’ve been part of this journey, you’ll know it’s not just another trade show anniversary. It’s a celebration of how far this industry has come, and, for many of us, a reminder of how much we’ve learned (and unlearned) along the way.

As our team prepared this special edition of 3D ADEPT Mag, we found ourselves reflecting on what a decade of building, scaling, failing, pivoting, evolving, and learning looks like for this team and the industry they serve in our event section.

But this issue isn’t just about looking back. It’s also about looking forward, especially when it comes to sustainability. More than ever, companies are realizing that sustainability isn’t a box to tick; it’s a strategy that must run through every stage of production. In this issue, we go beyond the usual narratives to explore how AM’s unique strengths (traceability and circularity) can directly support broader ESG goals.

Our focus on maritime and energy brings this conversation to life, as both sectors wrestle with the realities of decarbonization. You’ll discover the strategies being used to measure the carbon footprint of 3D printed parts and the ways AM applications can help energy equipment manufacturers meet climate targets without compromising performance.

And because innovation rarely stands still, we’re also turning our attention to mechanical and plant engineering, a field where AM is now proving its worth in very practical ways: by creating customized, functionally optimized parts, reducing development cycles, and improving maintenance efficiency.

Add to that a deep dive into new materials shaping the industry and the quiet revolution robotics is bringing to depowdering, and you’ve got a mix that perfectly captures where AM stands today: dynamic, mature, and still evolving.

So, as we all gather in Frankfurt to celebrate ten years of Formnext, let’s also celebrate the people and ideas that continue to push this industry forward. Here’s to the next decade of breakthroughs, collaboration, and bold thinking.

Enjoy the read — and enjoy the show!

Exclusive features

Dossier: Is additive manufacturing the key to cutting spare part emissions in energy and maritime?

The focus on energy and maritime is simple: when we compare across sectors, the energy industry (oil, gas, coal, electricity generation) and the maritime industry are indeed among the largest sources of emissions globally, though in different ways.

With key data, Lloyd’s Register (LR), Wärtsilä, and Berenschot discuss how AM should be part of the equation to address these problems.

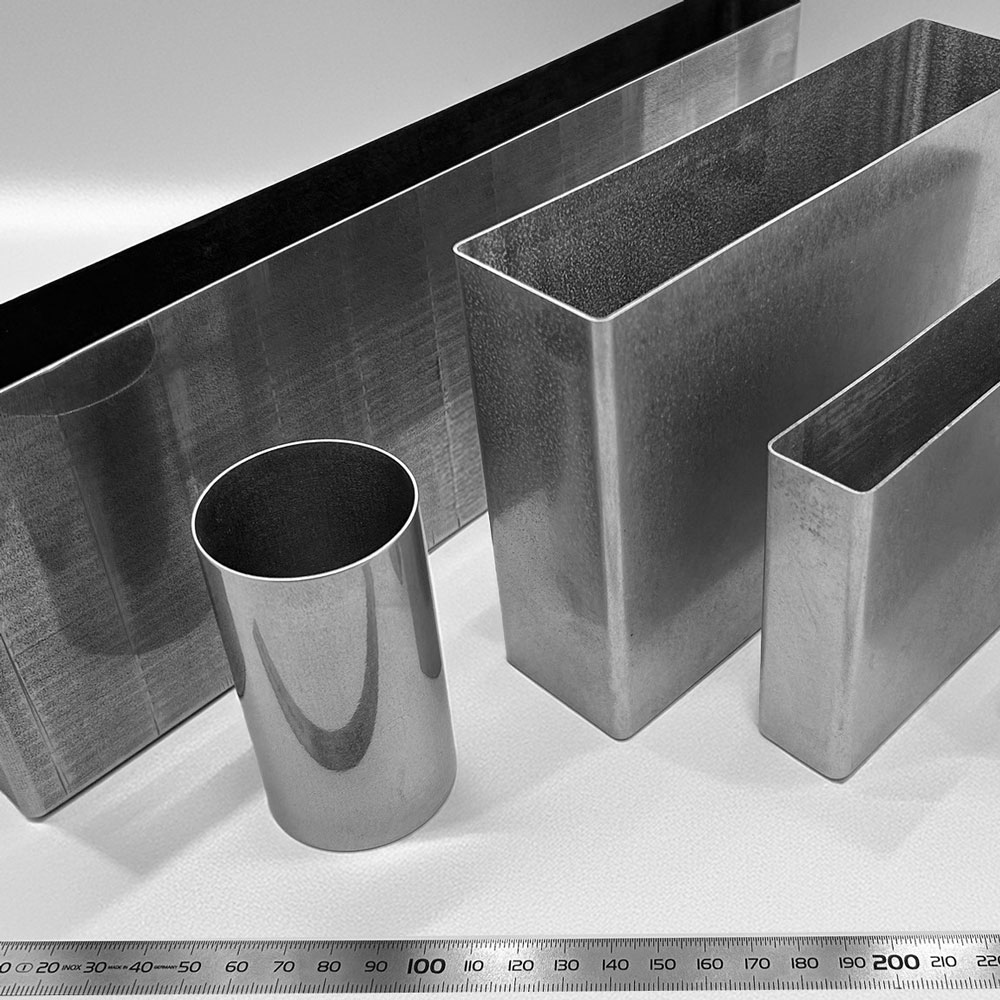

FOCUS | What applications can help energy equipment manufacturers address decarbonization challenges? 3D Systems discusses.

Every megawatt of renewable energy and every drop of cleaner fuel depends on the equipment that makes it possible. Yet, the manufacturing process of this equipment carries a heavy carbon footprint. For energy equipment manufacturers and energy companies in general, the question is no longer whether to act to reduce carbon footprint, but which applications can truly move the needle.

Pierre Van Cauwenbergh, Ph.D., Senior Application Engineer, Application Innovation Group at 3D Systems shares key insights here.

AM Shapers | Sponsored by Formnext

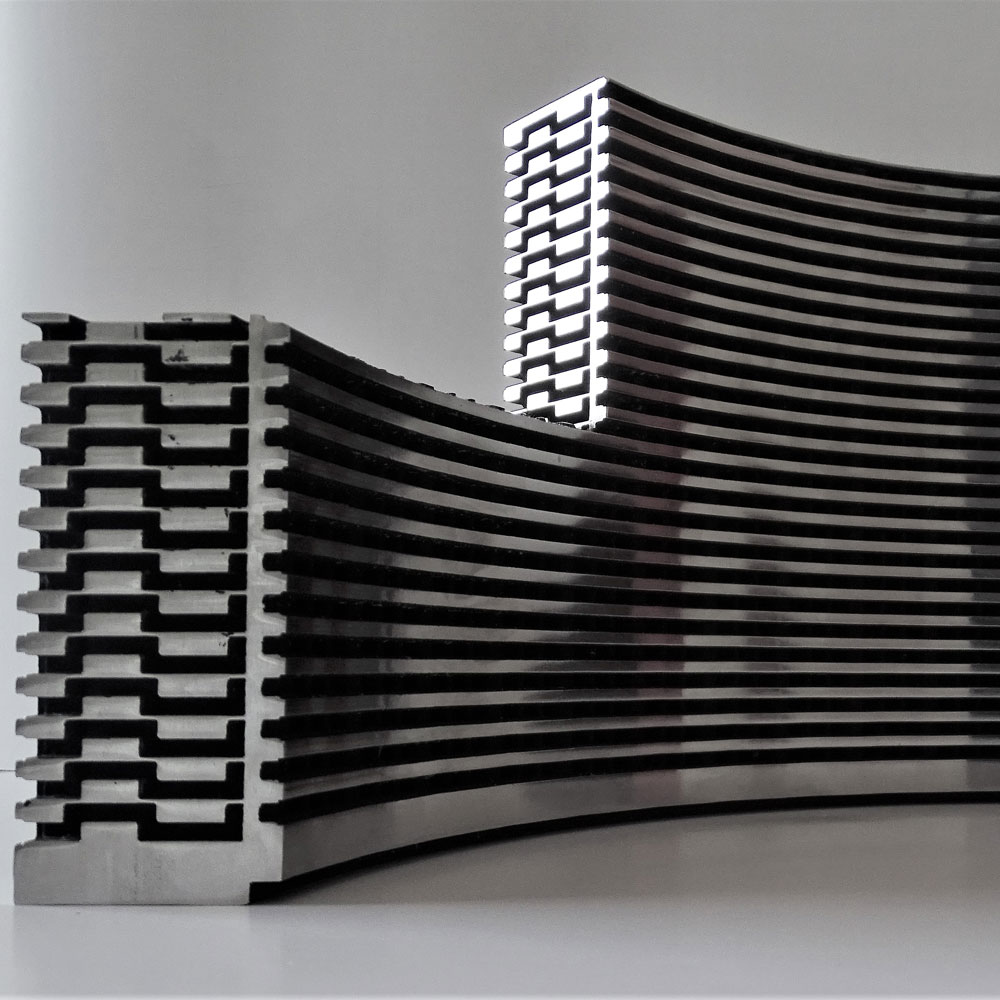

Evove: Making “filtering the unfilterable” sustainable with additive manufacturing

When people talk about technologies that could enable a net-zero future, water filtration rarely makes the list. Yet filtration membranes can consume up to 95% less energy than conventional thermal purification methods in desalination, for example. Beyond the obvious benefits (longer operating lifetimes and cleaner water), Evove is on a mission to cut both the cost and environmental impact of filtration and separation. Their use of additive manufacturing made me want to explore how.

Materials | What if refractory metals didn’t need all that post-processing?

We’ve always been the first to praise manufacturing approaches that focus on perfecting post-processing stages. For years, we’ve reminded the industry that this step, which can account for up to 50% of total production time and cost, is what turns 3D-printed parts into reliable ones. Researchers at Cornell University recently reinforced that view, showing how a carefully tuned heat treatment can bring out the best in AM IN718 by removing unwanted phases and improving elongation without compromising strength. But what if we looked at it from another angle? What if we designed materials that didn’t need all this extra work in the first place?

With key insights from Foundation Alloys’ Jake Guglin.

Post-processing | Why do you need a robot for depowdering? - Solukon explains.

Solukon is going one step further: envisioning a depowdering solution powered by robotics. In the following article, Andreas Hartmann, cofounder and CEO explains the why and how of this concept and what it could mean for the future of depowdering.

Opinion | How traceability in additive manufacturing (AM) drives ESG impact

It’s been a few years now that, alongside the growing number of AM applications driven by sustainability, we’ve dedicated one issue of 3D ADEPT Mag each year to this crucial topic. The goal has always been the same: to keep track of how AM companies are advancing on their sustainability journey.

Event | 10 questions for 10 years of Formnext

Formnext and industry voices reflect on what a decade of building, scaling, failing, pivoting, evolving, and learning looks like.