See who is exhibiting or create your own watch list. Use the filter options to obtain a list of exhibitors for the respective product group.

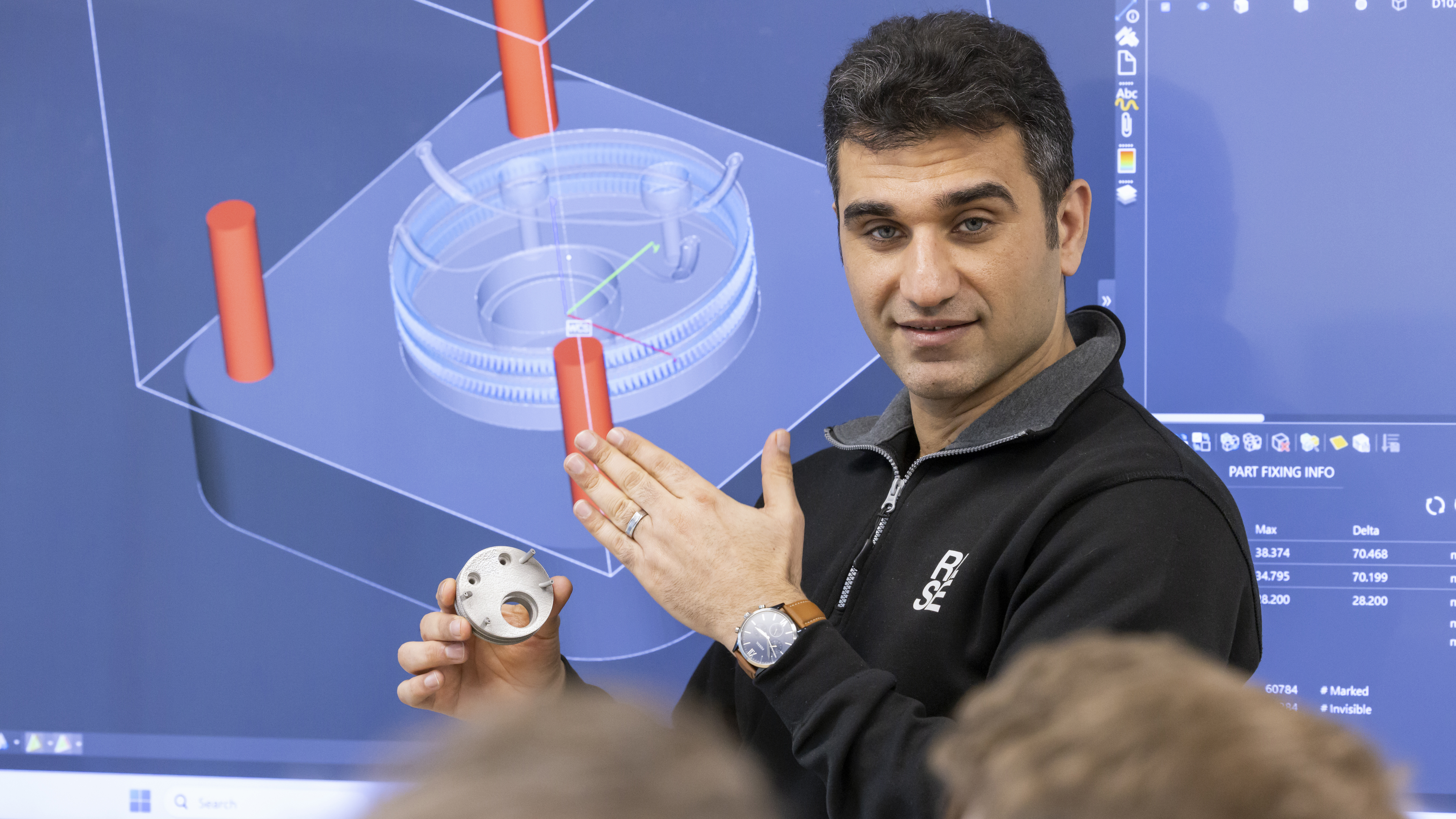

From Idea to Finished Product: Making the Most of AM

From Idea to Finished Product: Making the Most of AM

Description

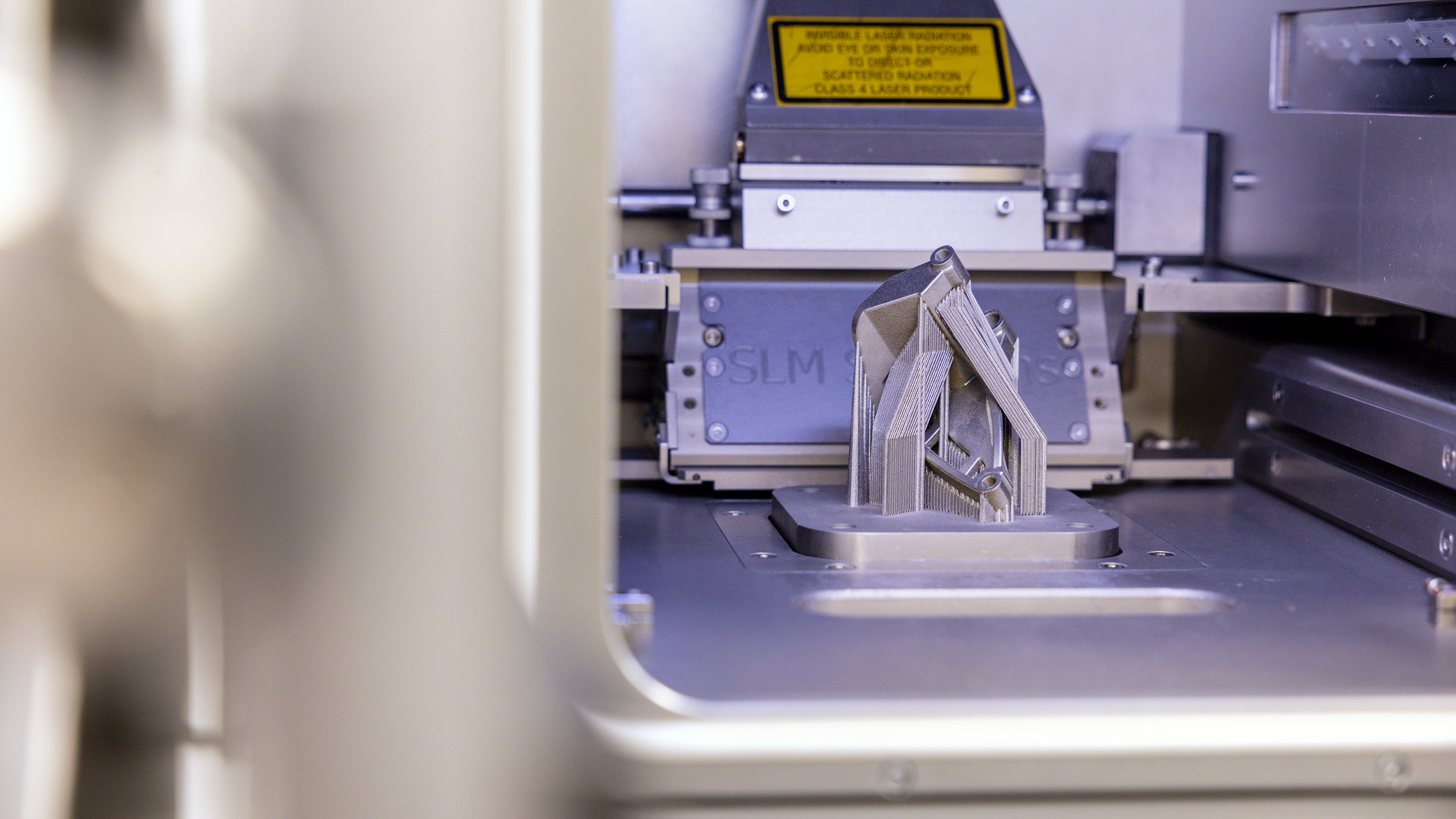

Additive manufacturing is increasingly being recognised as a viable solution for industrial applications. Its ability to create complex geometries, minimise material waste, and consolidate multiple components into single designs offers transformative potential across sectors. However, transitioning AM from prototyping to a fully integrated production solution is not without challenges.

At the Application Center for Additive Manufacturing at RISE, we understand the complexities of scaling AM for industrial applications. Our expertise spans all stages of the process, from initial feasibility assessments to selecting and commissioning the right equipment.

We offer

- Assistance in identifying the most suitable components to begin with.

- Support in creating a business case.

- Competence development.

- Product design, production planning, process development, and material optimisation.

- Testing, demonstration, and manufacturing.

- Methodology for monitoring the quality of production processes and products.

- Assessment to determine the necessary process steps and investments.

- Guidance on standards, regulations, occupational health, and safety.

- Change management strategies.

If you’re interested in a consultation, reach out to us!