See who is exhibiting or create your own watch list. Use the filter options to obtain a list of exhibitors for the respective product group.

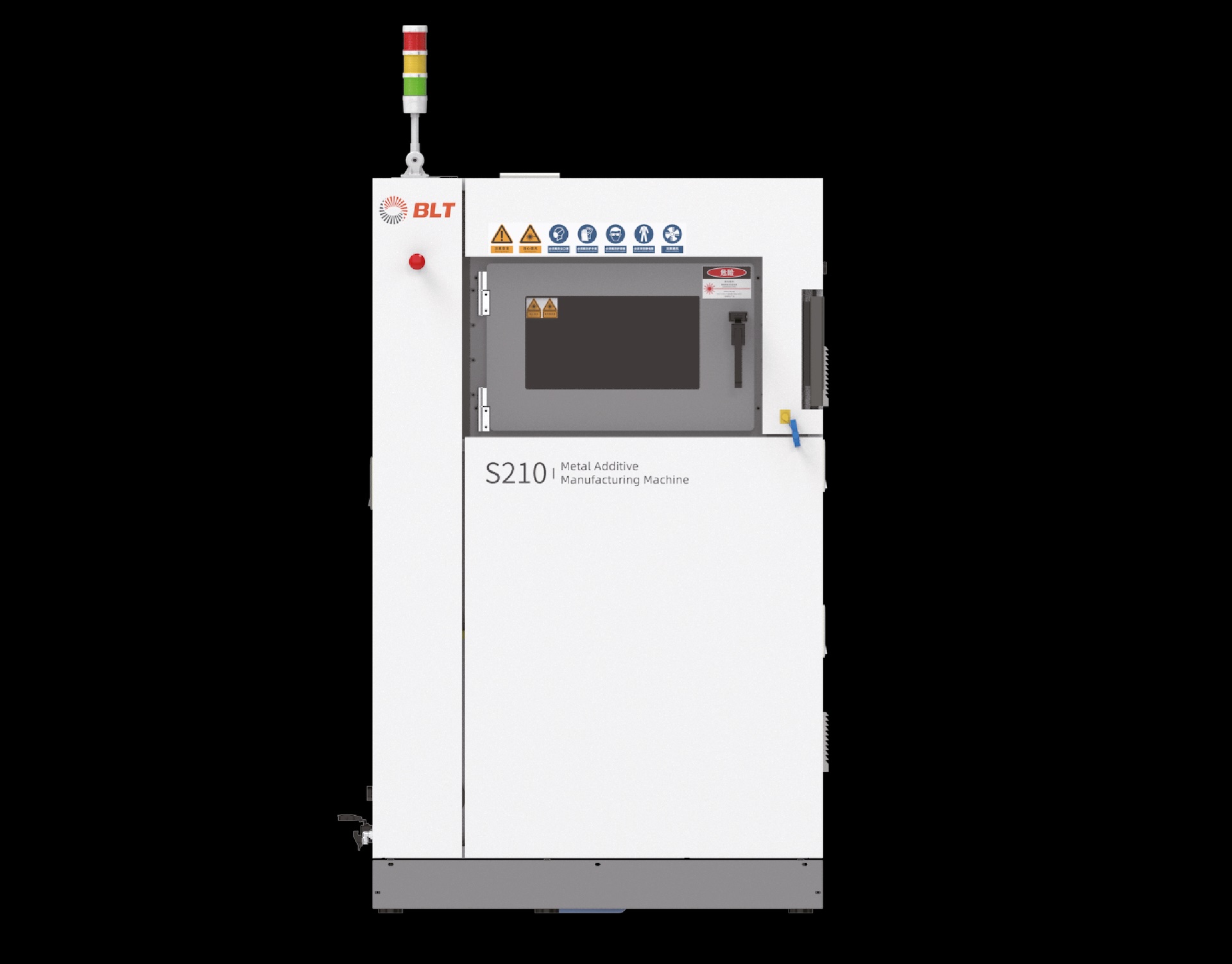

Description

The BLT-A160 from Bright Laser Technologies is a compact yet high-performing metal additive manufacturing system engineered for small-parts batch production. With a 160 × 160 × 200 mm build volume, dual-laser configuration, and aerospace-grade stability, it offers a powerful solution for dental labs, medical device manufacturers, and small-format industrial parts suppliers.

The A160 supports a wide range of materials—titanium alloys, cobalt-chromium, stainless steel, and superalloys—making it well-suited for complex geometries and demanding applications like dental stents, crowns, and micro-mechanical components. With up to 2×500W lasers and build speeds up to 30 cm³/h, it delivers high-throughput production with tight dimensional accuracy.

This system is designed with real-time process monitoring, variable-speed synchronized recoating, and exclusive software options tailored to dental workflows. Its tool-free substrate design and low power requirements maximize uptime and ease of use, while multiple safety interlocks, inert gas handling, and ATEX-referenced safety standards ensure consistent, safe operation.

Whether you’re scaling up digital dentistry or looking to increase the efficiency of small-parts AM production, the BLT-A160 offers reliable performance, low maintenance, and flexible deployment—all in a compact footprint.