See who is exhibiting or create your own watch list. Use the filter options to obtain a list of exhibitors for the respective product group.

BLT Europe GmbH

Address

BLT Europe GmbH

Hessenstr. 11

65719 Hofheim am Taunus

Germany

Discover more from us

Follow us on

About us

BLT Europe is the European subsidiary of Bright Laser Technologies, operating in EMEA. Bright Laser Technologies, BLT, is a global leader in providing comprehensive turnkey solutions for metal AM.

We have developed an ecosystem with industrial metal 3D printers, metal powders, printing services, software and consulting.

Drawing on years of expertise in metal AM technology, we cater to a wide range of industries, like aerospace, energy, medical, tooling and automotive.

With a presence worldwide, BLT boasts a dedicated team of approximately 1,800 employees, with over 30% engaged in research and development.

BLT has also filed applications for thousands of independent intellectual property rights related to metal AM technology.

With this continuous innovation, we strive to meet the evolving needs of our customers, regardless of challenge or industry.

Our product groups

Keywords

- powder bed fusion

- metal am

- metal 3d printing

- metal materials

- metal powders

- 3d printing services

Our Products

BLT-S400

The BLT-S400 from Bright Laser Technologies represents a new benchmark in industrial metal additive manufacturing. Designed for high-volume, high-precision production, it integrates intelligent features and automation to meet the rigorous demands of aerospace, automotive, and tooling industries.

With a generous build envelope of 400 × 300 × 400 mm, the S400 supports a wide range of metal powders including titanium alloys, aluminium alloys, superalloys, stainless steels, and tool steels. It delivers consistent, aerospace-grade quality through stable full-substrate printing and closed-loop powder circulation.

Engineered for production efficiency, the BLT-S400 offers multiple laser configurations (up to 6×500W) and impressive build speeds up to 150 cm³/h. Its intelligent modules—like self-adaptive powder spreading, deep learning-based printing correction, and real-time process monitoring—enable smarter, more traceable manufacturing with minimal manual intervention.

Certified to global safety and quality standards (CE, FDA, ISO, ATEX), and supported by BLT's advanced ecosystem of software (BLT-BP, BLT-MCS, Magics) and automation equipment, the S400 ensures reliable, scalable, and cost-effective part production in demanding industrial environments.

Whether you're scaling batch production or targeting aerospace-grade builds with tight traceability, the BLT-S400 is the metal AM system designed to grow with your business.

BLT-S450

The BLT-S450 is Bright Laser Technologies’ flagship solution for industrial-scale metal additive manufacturing—combining precision, throughput, and intelligent automation to meet the demands of modern manufacturing environments.

Built upon a mature platform, the S450 features a 450 × 450 × 500 mm build envelope and scalable multi-laser configurations (up to 8×500W), enabling high-volume part production at speeds of up to 200 cm³/h. Whether for aerospace, energy, tooling, or automotive applications, it delivers consistent quality and repeatability across a wide range of materials, including titanium alloys, superalloys, and tool steels.

Engineered for continuous, safe operation, the S450 integrates a closed-loop powder circulation system, long-life filtration, and inert gas protection, reducing material waste and operational costs. Its intelligent modules—including deep learning-based powder spreading correction, real-time recoating detection, and process traceability—ensure consistent part quality while minimizing manual intervention.

With a focus on operational efficiency, the BLT-S450 supports advanced software (BLT-BP, BLT-MCS, Magics) and integrates into automated production lines with options for powder handling, sieving, and supplying systems. Certified to ISO9001/14001/45001 standards and compliant with global safety norms, the system is optimized for long-term industrial deployment.

For manufacturers seeking to scale metal AM with high efficiency, lower cost per part, and production-ready reliability, the BLT-S450 delivers a future-ready solution.

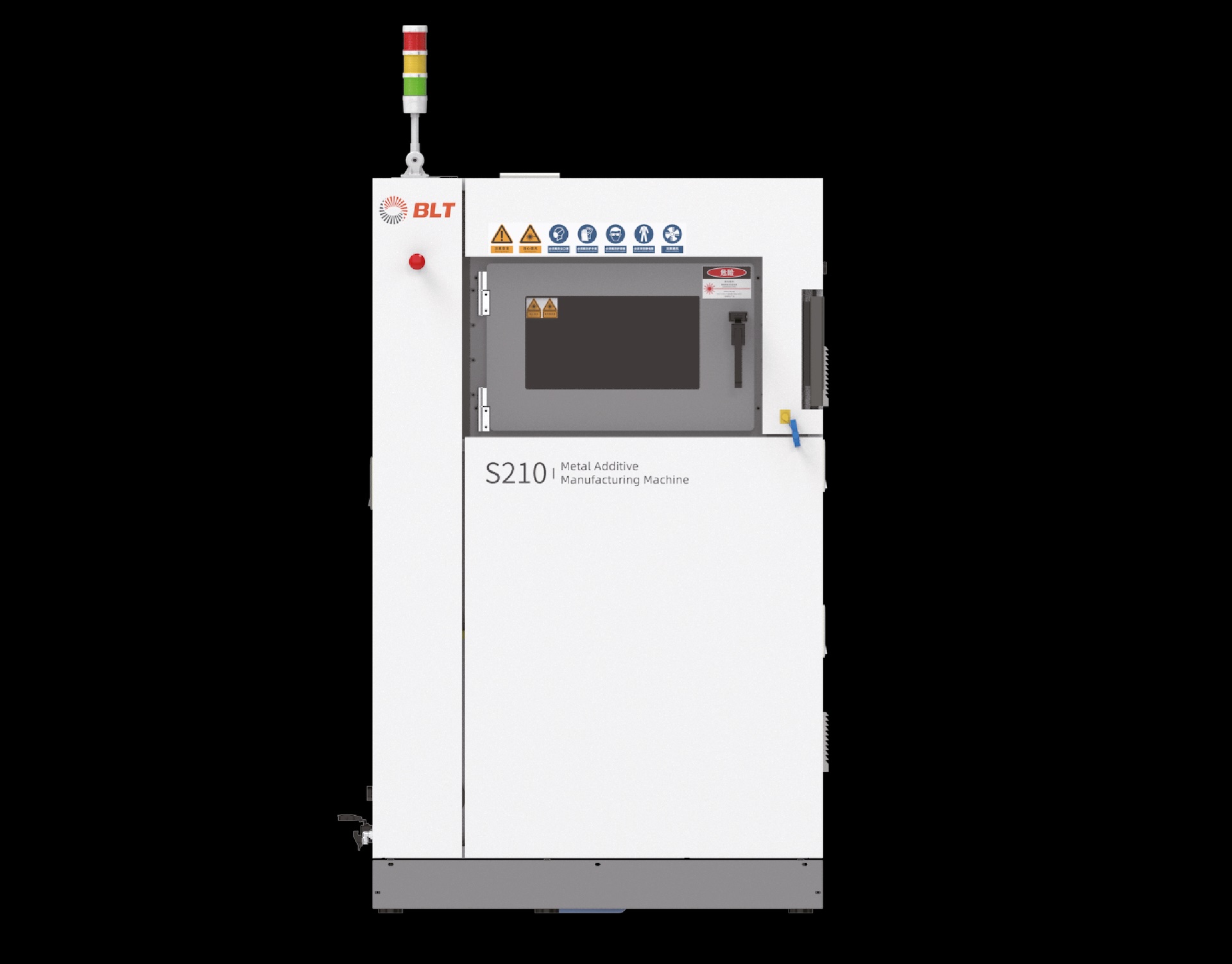

BLT-S210

The BLT-S210 is Bright Laser Technologies’ compact, intelligent metal additive manufacturing system purpose-built for R&D, universities, and small-batch innovation. Compact in size yet rich in capability, it is trusted by academic institutions and research facilities seeking to explore advanced materials and novel AM applications.

With a build volume of 160 × 160 × 200 mm and support for a broad spectrum of materials—including titanium alloys, cobalt-chromium, tantalum, tungsten, silver, and copper alloys—the S210 is engineered for flexibility in material experimentation. It features ultra-fine oxygen control (≤10 ppm possible), variable laser configurations (up to 2×500W), and high-temperature preheating (up to 350°C) to support complex metallurgy.

Its modular, open-layout design enhances operability and ease of maintenance, while smart functions like real-time monitoring, powder spreading control, and temperature field mapping bring industrial-grade traceability to research-scale builds. Safety remains paramount with multi-level interlocking, customizable glove box integration, and compliance with CE, FDA, and ATEX design standards.

Supported by BLT’s advanced software suite (BLT-BP, BLT-MCS, Magics), the S210 allows researchers to precisely control every step of the build process—empowering material innovation, biomedical prototyping, and process development in a safe, efficient, and customizable environment.

If your focus is on discovery, development, or micro-batch part validation, the BLT-S210 is the tool engineered to support your ambition with accuracy and confidence.

BLT-A160

The BLT-A160 from Bright Laser Technologies is a compact yet high-performing metal additive manufacturing system engineered for small-parts batch production. With a 160 × 160 × 200 mm build volume, dual-laser configuration, and aerospace-grade stability, it offers a powerful solution for dental labs, medical device manufacturers, and small-format industrial parts suppliers.

The A160 supports a wide range of materials—titanium alloys, cobalt-chromium, stainless steel, and superalloys—making it well-suited for complex geometries and demanding applications like dental stents, crowns, and micro-mechanical components. With up to 2×500W lasers and build speeds up to 30 cm³/h, it delivers high-throughput production with tight dimensional accuracy.

This system is designed with real-time process monitoring, variable-speed synchronized recoating, and exclusive software options tailored to dental workflows. Its tool-free substrate design and low power requirements maximize uptime and ease of use, while multiple safety interlocks, inert gas handling, and ATEX-referenced safety standards ensure consistent, safe operation.

Whether you’re scaling up digital dentistry or looking to increase the efficiency of small-parts AM production, the BLT-A160 offers reliable performance, low maintenance, and flexible deployment—all in a compact footprint.

BLT-S310/320

The BLT-S310/S320 series represents a flagship platform for metal additive manufacturing, engineered for businesses that demand reliability, production-grade quality, and intelligent process control. With a 250 × 250 × 400 mm build envelope, flexible optics configurations (up to 2×500W lasers), and robust multi-material compatibility, it delivers optimal balance for aerospace, tooling, energy, and precision component applications.

These systems are built on proven BLT architecture with aerospace-grade quality assurance, stable full-substrate printing, and deep integration of automation—from intelligent powder circulation to real-time defect detection and self-adapting powder spreading. The result: consistent builds, reduced downtime, and tighter process control.

With build speeds up to 50 cm³/h, oxygen levels controlled to ≤100 ppm, and preheating up to 200°C, the S310/S320 supports high-performance metals such as titanium, aluminum, stainless steel, tool steel, and copper alloys. Integrated software modules (BLT-BP, MCS, MES) enable full process traceability, 3D reconstruction, and data connectivity—making it a smart fit for regulated industries and batch production workflows.

Designed with operational safety and scalability in mind, the BLT-S310/S320 complies with ATEX, FDA, CE, and ISO 9001/14001/45001 certifications. It also supports advanced automation modules including powder sieving, collection, and supply systems, making it a ready-to-scale solution for manufacturers advancing their metal AM capabilities.

If you’re seeking a flagship AM system to transition from prototyping to production—without compromising traceability, flexibility, or part quality, then the S310/S320 delivers both performance and peace of mind.