Reading time: 5 minutes

DWS: Carbon fiber and biomass for motor sports and interior design

In racing, one of the main challenges is to produce extremely lightweight, yet durable components. This is why carbon fiber is often the material of choice. Here, DWS used autoclave-compatible molds to manufacture aerodynamic parts for an electric race car that hit the track in the summer of 2025. The material used, Therma DM570, withstood 135° C and pressure levels up to 6 bar. In addition, DWS has investigated new sustainable production methods for industries such as interior design and packaging. In these techniques, biomass containing cellulose is processed in an ultrasonic compression process, while the sonotrode used vibrates at high frequencies and reaches a temperature of 200° C.

DWS at Formnext 2025: Hall 12.1, Booth D31

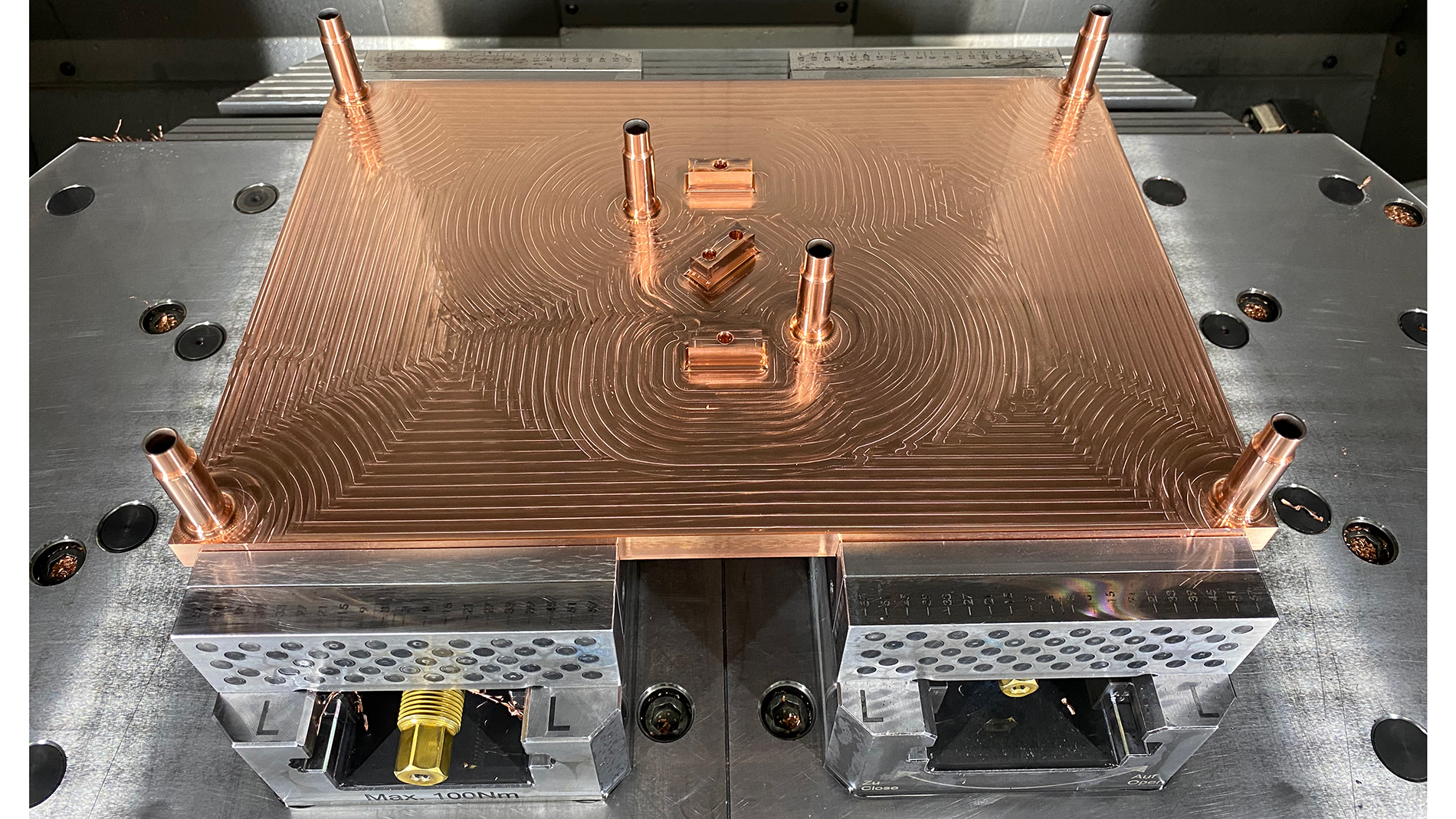

Hermle: Monolithic copper plate heat exchanger

Hermle Additive Manufacturing has produced a monolithic copper plate heat exchanger using the Hermle MPA process (cold spray Additive Manufacturing) combined with precision CNC finishing. The component measures 220 × 330 mm and integrates two independent cooling circuits within a single plate – eliminating solder joints and their associated leak risks. The MPA process deposits copper in its solid state, avoiding melting and preserving material properties such as thermal conductivity up to 400 W/m·K. A key enabler of this innovation is Hermle’s water-soluble support material, which allows the creation of fully enclosed internal channels without post-joining steps.

Hermle at Formnext 2025: Hall 12.0, Booth C71

Tritone: Scaling up production of eyeglass hinges

Baars, the Paris-based premium eyewear brand known for its minimalist designs and patented magnetic hinge technology, has successfully scaled up the production of its signature frames by leveraging Tritone Technologies’ MoldJet AM system in partnership with MIMplus Technologies GmbH & Co. KG. Baars faced the challenge of producing thousands of high-precision hinges for its eyewear collection. The hinges required a visible face area with a decorative surface finish (8 × 5.6 mm), 3D-printed layered textures on both side faces, and large-scale production volumes at cost-efficient levels. MIMplus applied Tritone’s MoldJet technology, a sinter-based AM process, to deliver scalable mass production, which includes the ability to produce 16,000 parts (for 4,000 pairs of glasses) in less than 20 hours (800 parts per tray).

Tritone Technologies at Formnext 2025: Hall 12.0, Booth C72

Images: Tritone

Eplus3D: Rocket engine for Race 2 Space

Eplus3D, in collaboration with University College London (UCL) and the student-led UCL Rocket team, has successfully designed and additively manufactured Excelsior – a regeneratively cooled, bipropellant rocket engine for the UK’s Race 2 Space 2025 competition. Manufactured using AlSi10Mg and laser powder bed fusion (LPBF) on an EP-M400S quad-laser system, the project has demonstrated how Additive Manufacturing enables advanced cooling channels, integrated features, and rapid development. As a technical partner in the project, Eplus3D handled process consultation and manufacturing execution for Excelsior’s complex thrust chamber and injector components. The rocket engine achieved its target thrust of 5 kN during hot-fire testing, ranking fourth in the Nitrous Bipropellant category, and was one of only eight engines out of 17 to survive all the competition’s tests.

Eplus3D at Formnext 2025: Hall 12.0, Booth E101

Lithoz: Various applications set to premiere

In its presentation at Formnext, Lithoz is clearly focusing on real series applications in ceramic 3D printing from various user industries, ranging from aerospace and the semiconductor industry to medicine and luxury goods. One of the highlights is an S320 build platform equipped with 36 near-series ceramic casting cores for aircraft turbine manufacturing. The complex design of the casting cores on LCM printers enables increasingly delicate branching of the cooling channels in the turbines. The Austrian company is also exhibiting a complex aluminum oxide gas distribution ring with a diameter of 380 mm. The ring features an exceptionally thin-walled, lightweight design with highly optimized flow channels. A critical wear part in the semiconductor industry, the ring – designed by Plasway (Germany) and manufactured in series by Alumina Systems (Germany) – offers a verifiable nine-month extension in service life while tripling production output. Another complex series-produced component for the semiconductor industry is a gas injector for etching processes that is manufactured by Bosch Advanced Ceramics (Germany) on Lithoz CeraFab printers in series of 2,000 units per year. This year will also witness a world-first in the medical and dental sector with the ceramic ear molds (otoplastics) for hearing aids designed by Swiss OC GmbH and mass-produced by CADdent (Germany) on Lithoz CeraFab printers.

Lithoz and Steinbach at Formnext 2025: Hall 11.1, Booth C35 and Hall 11.1, Booth B39

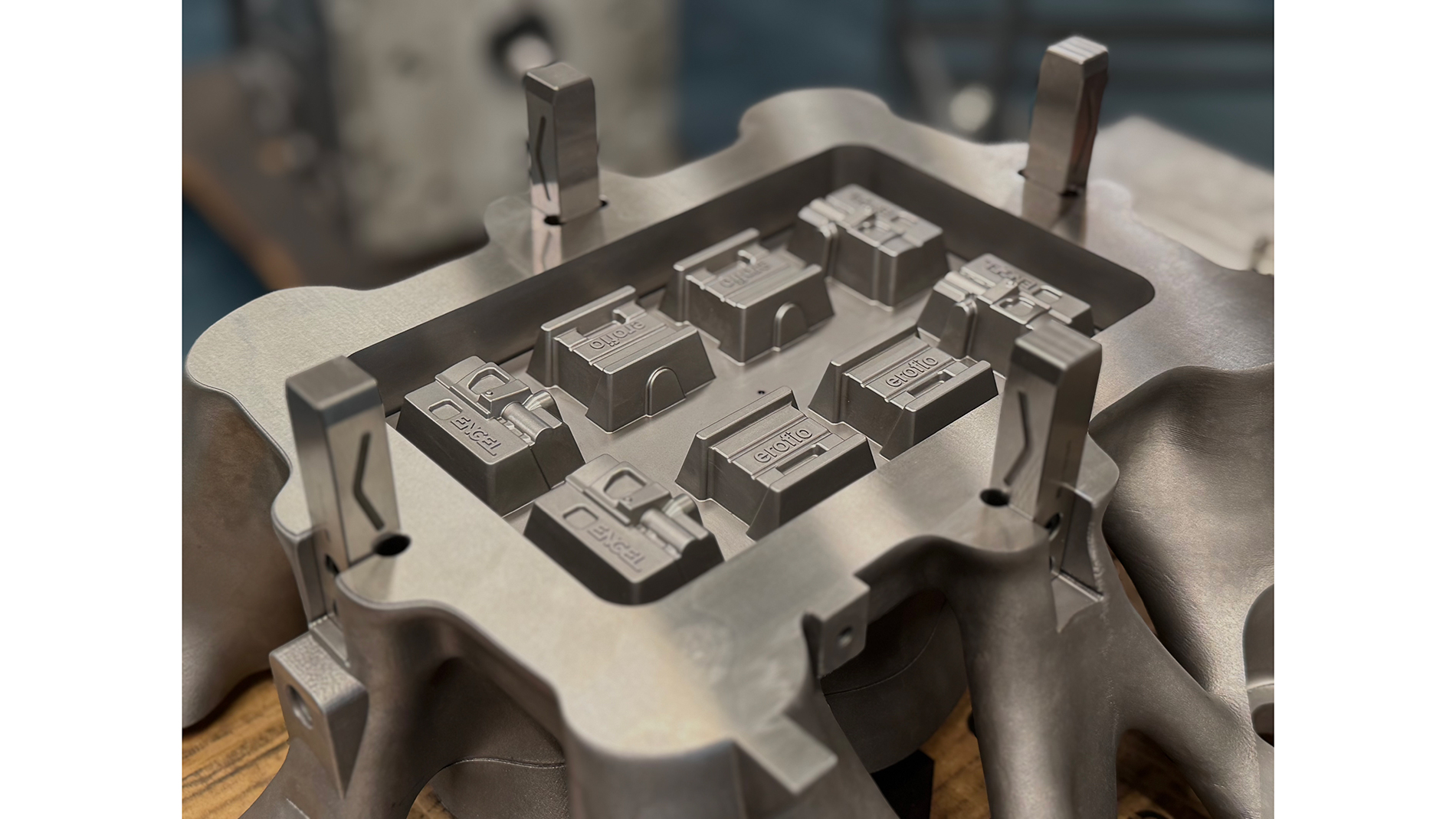

Erofio: Injection mold for ultra-thin parts

Inov.iQ is an additively manufactured metal injection mold designed specifically for a 100-ton injection molding machine and ultra-thin parts with wall thicknesses of just 1 mm. It is also designed to fully exploit the potential of Engel's iQ injection molding systems. The mold was designed specifically for Engel's e-mac 100. Erofio developed the geometry and conformal cooling channels in direct response to the requirements and tolerances specified by Engel's virtual assistants. Inov.iQ was manufactured out of Uddeholm Corrax stainless steel, a precipitation-hardening alloy, utilizing LPBF technology on a Colibrium Additive MLine system. According to Erofio, topology optimization reduced the mold’s weight by 75%, down to just 80 kilograms. When paired with Engel’s iQ platform, Inov.iQ enables a 15% reduction in clamping force and a 30% decrease in energy consumption per injected part. These improvements translate directly into increased productivity, lower operational costs, and improved sustainability.

Erofio at Formnext 2025: Hall 11.0, Booth A79