29 June 2021

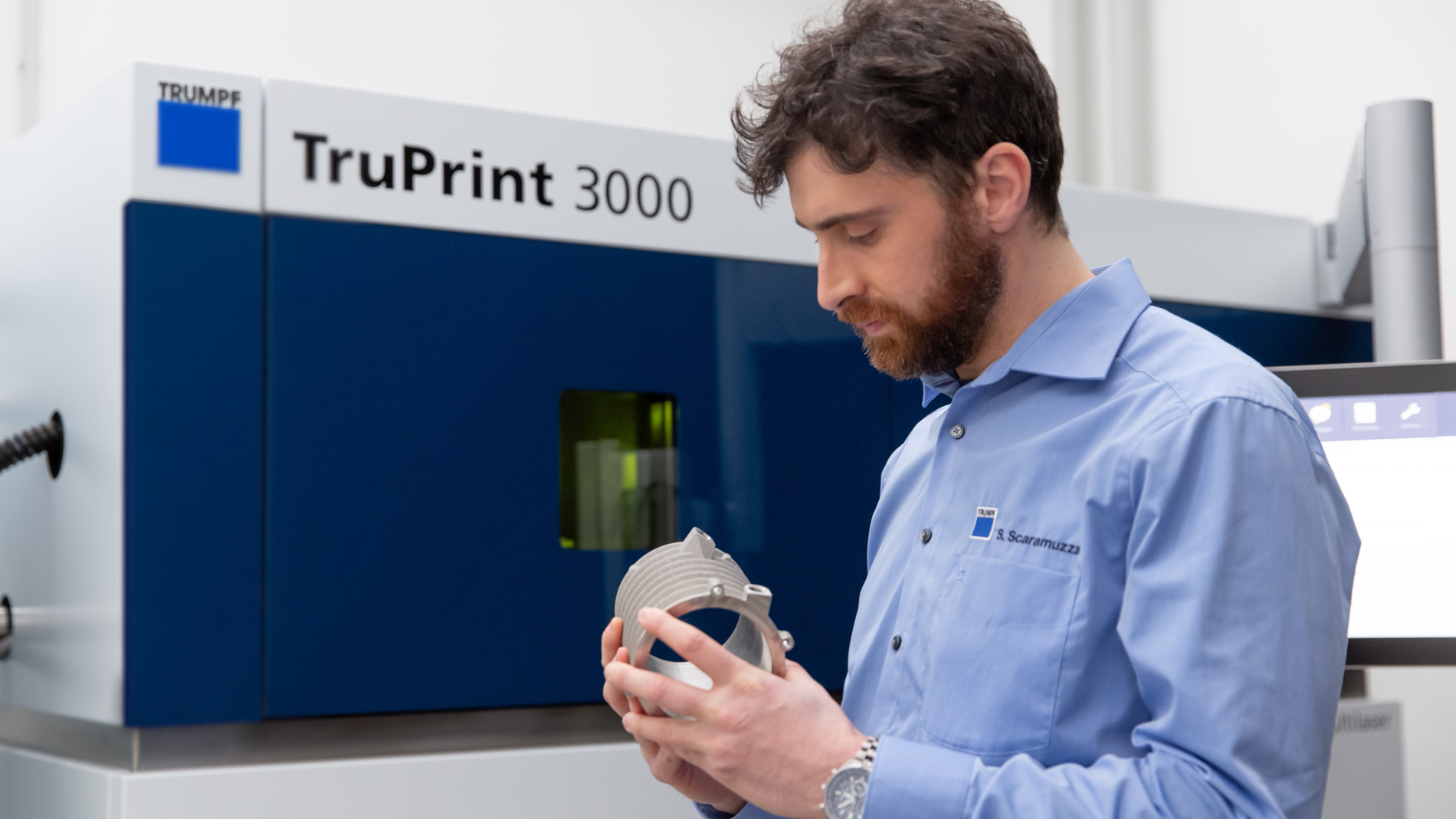

Trumpf GmbH & Co. KG, Germany, recently unveiled its new Truprint 3000 metal additive manufacturing machine. The medium- format machine uses Laser Beam Powder Bed Fusion (PBF-LB) technology to produce parts with a diameter of up to 300 mm and a height of up to 400 mm.

It can reportedly handle all weldable materials including steels, nickel-base alloys, titanium and aluminium. Klaus Parey, Managing Director of Trumpf Additive Manufacturing, stated, "We’ve improved key aspects of the TruPrint 3000 to tailor it even more closely to the quality requirements, certifications and production processes of various industries."

The new AM machine can be equipped with a second 500-watt laser that is said to almost double its productivity and to facilitate the move into mass production. Trumpf also has transformed the movement of inert gas. The way in which it flows through the machine from back to front is now steadier and more uniform which, according to Trumpf improves the quality of additively manufactured parts.

In addition, the new machine concept allows the operator to remove excess powder from the part while it is still inside the machine. Previous models required the operator to take the part out and remove the powder at a separate station. The new machine is designed to process the powder in a shielded environment, using inert gas to prevent the powder from becoming contaminated during the build. A crucial advantage for sensitive industries such as medical device manufacturing notes Trumpf.

AM TECHNOLOGY:

Additive Manufacturing for metals/SLM

A structured overview of the complex and multi-layered world of Additive Manufacturing, the process chain and areas of application is provided by our AM Field Guide.

Tags

- Additive Manufacturing