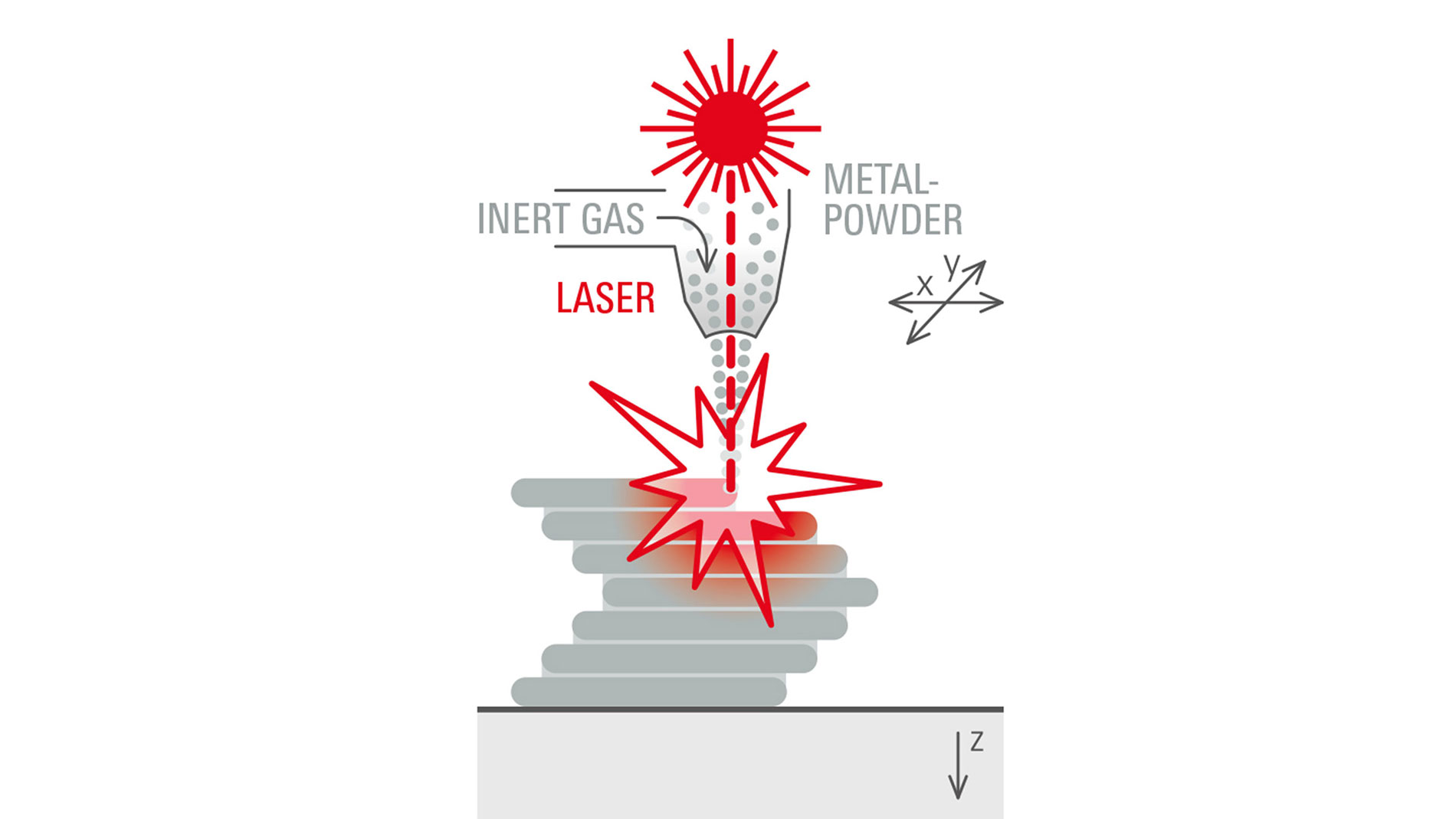

Even though the AM production with metals is considerably more cost-intensive than with polymers, their relevance in industrial use is undisputed. These are the common AM processes for metals.

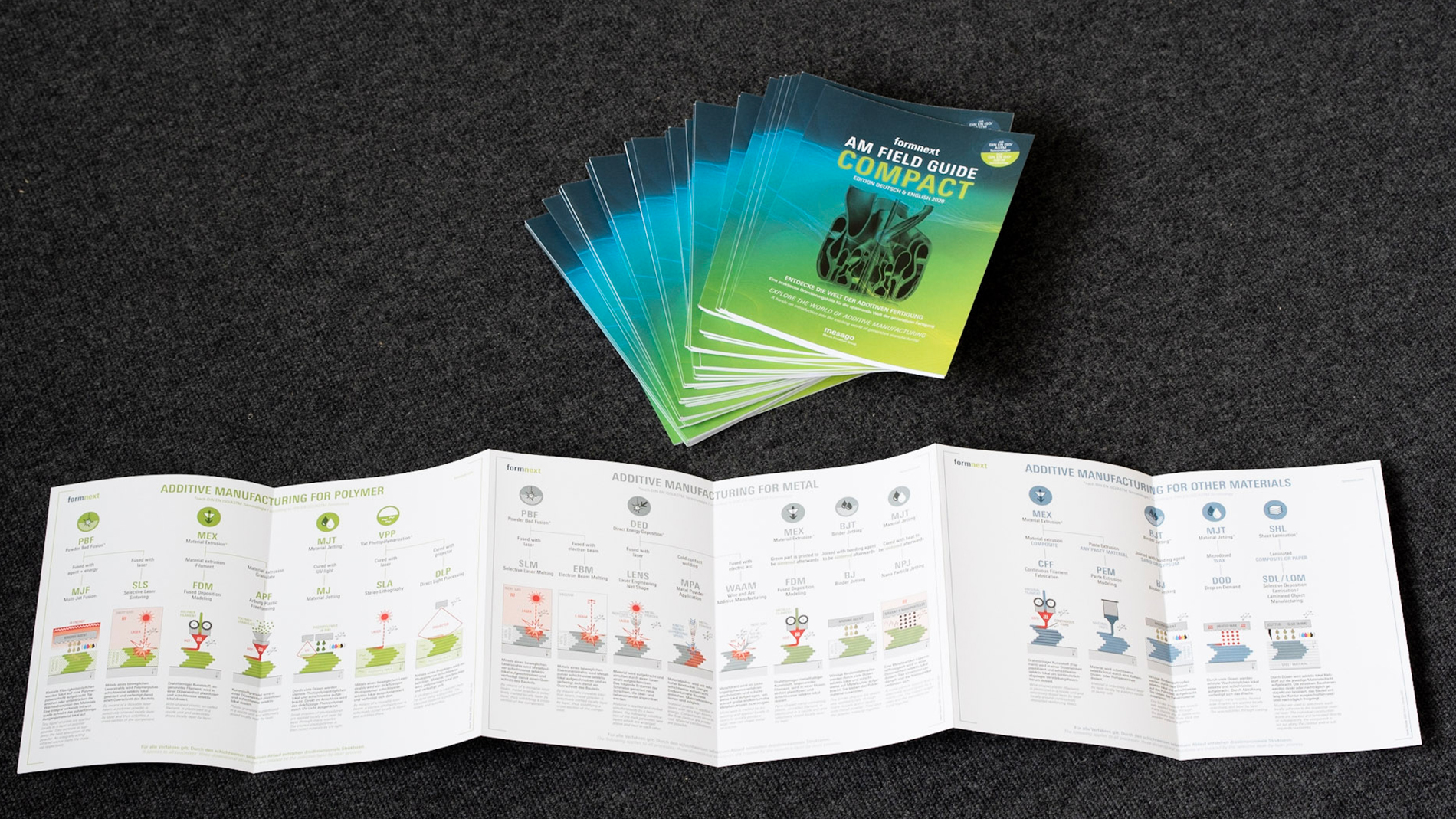

Powder Bed Fusion (PBF)

Fused with laser = SLM (Selective Laser Melting)

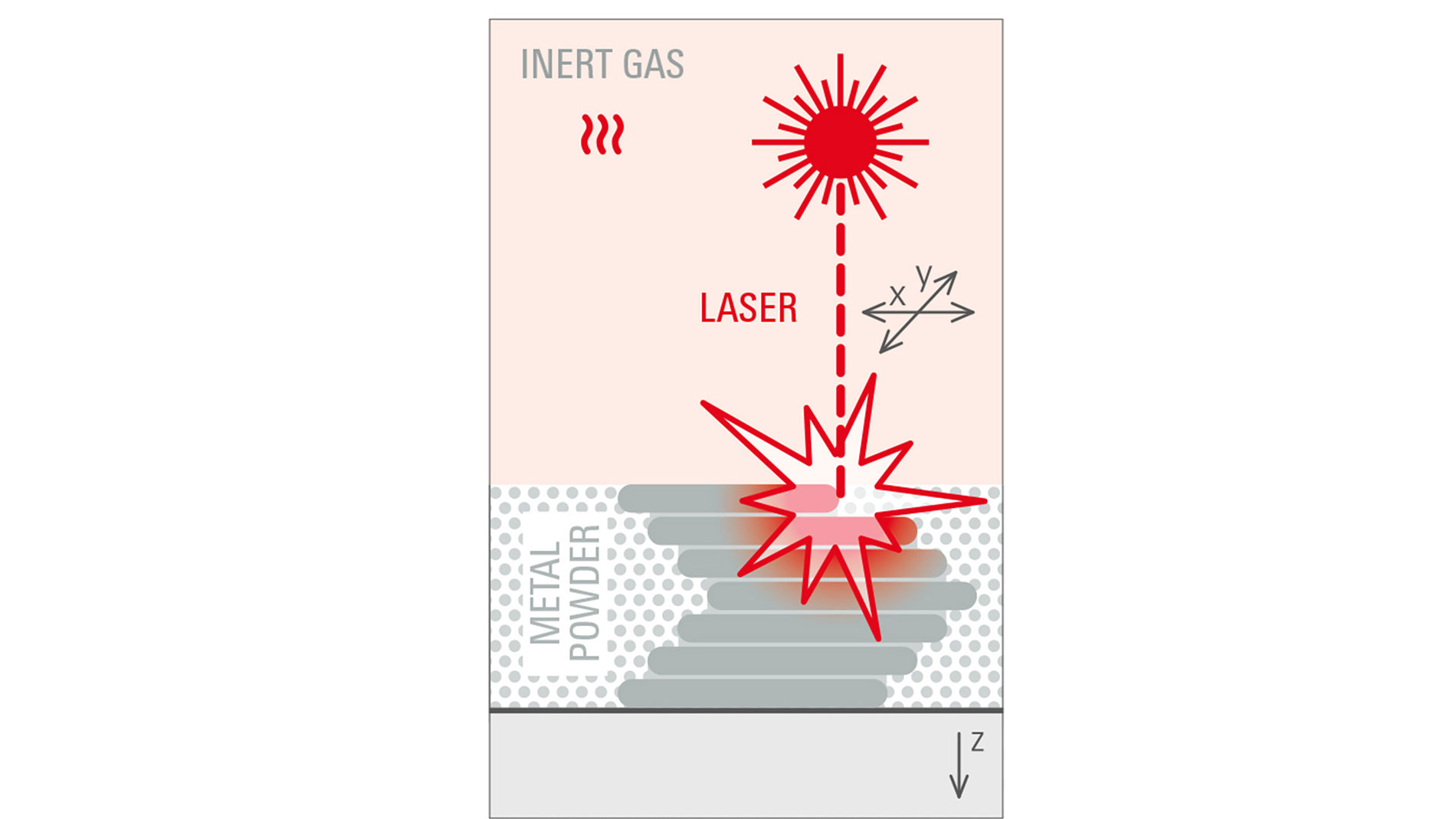

Fused with electron beam = EBM (Electron Beam Melting)

SLM (Selective Laser Melting)

Synonyms: Laser-Strahlschmelzen, LaserCUSING, Laser Metal Fusion (LMF), Selektives Laser Schmelzen (SLM), Laserschmel-zen, Direct Metal Printing (DMP), Laser Forming, Laser

By means of a movable laser beam, metal powder is selectively melted locally layer by layer, thus solidifying a cross-section of the component.

EBM (Electron Beam Melting)

Synonyms: Elektronenstrahlschmelzen, Selektives Elektronenstrahlschmelzen, CAD to Metal, Selective Electron Beam Melting (SEBM), Electron Beam Powder Bed Fusion

By means of a movable electron beam, metal powder is selectively melted locally layer by layer, thus solidifying a cross-section of the component.

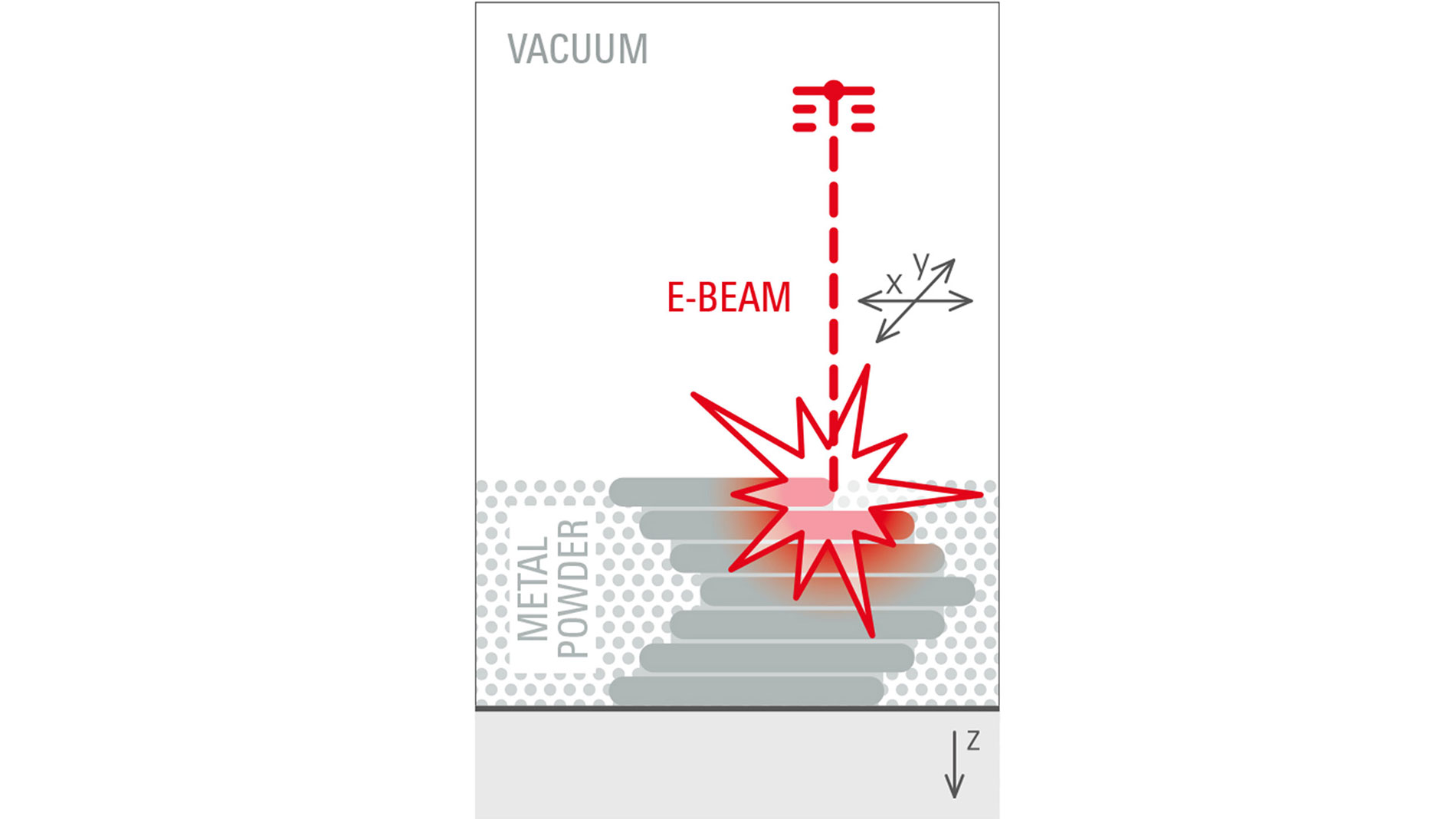

Directed Energy Deposition (DED)

Fused with laser = LENS (Laser Engineering Net Shape)

Cold contact welding = MPA (Metal Powder Application)

Fused with electric arc = WAAM (Wire and Arc Additive Manufacturing)

LENS (Laser Engineering Net Shape)

Synonyms: Laserauftragschweißen, Direct Metal Deposition (DMP), Laser Metal Forming (LMF), 3D Laser Cladding, Laser Gene-ration, Laser-Based Metal Deposition (LBMD), Laser Free-form Fabrication (LFF), Laser Direct Casting, Laser Cast, Laser Consolidation, LasForm, Laser Metal Deposition (LMD)

Material is applied and melted simultaneously by a laser beam. The following solidification of the melt generates new layers which are arranged above and next to each other.

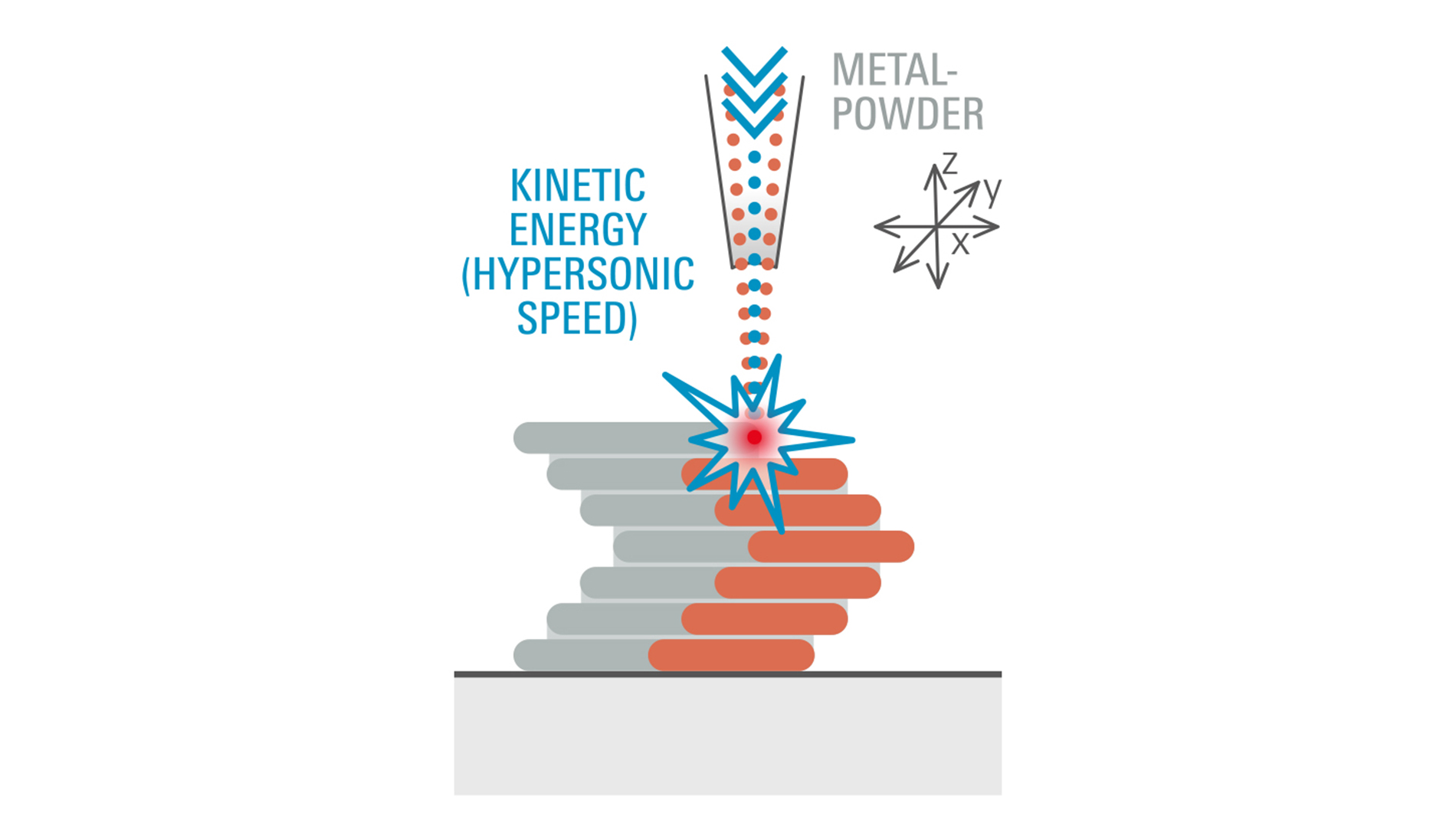

MPA (Metal Powder Application)

Material powder is applied in layers with very high kinetic energy. Components close to the final contour are produced. Material combinations are possible.

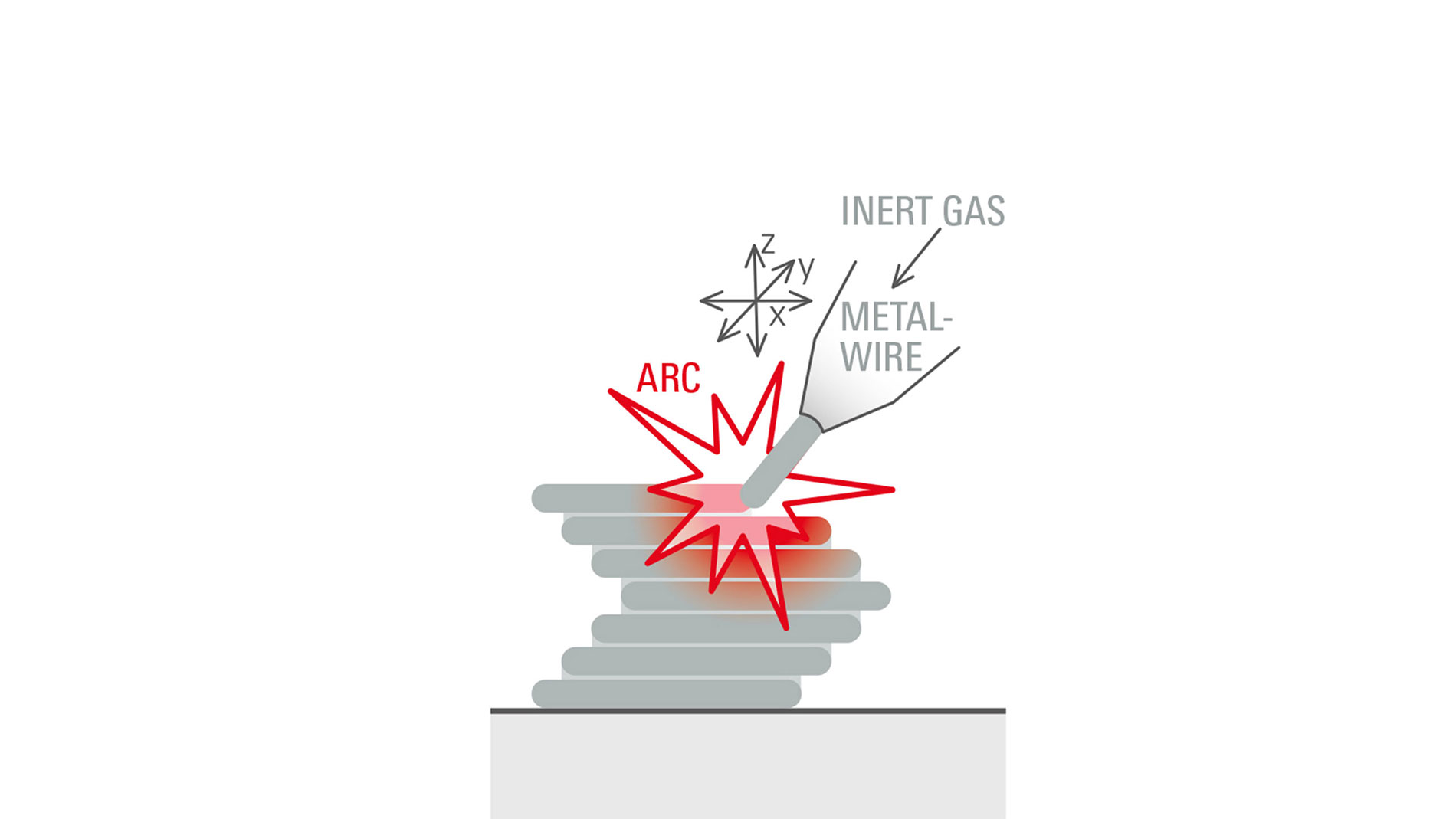

WAAM (Wire and Arc Additive Manufacturing)

Synonyms: 3D Auftragsschweißen, Wire Arc Additive Manufacturing (WAAM)

Metal wire is melted by arc welding and applied locally in layers to quickly produce large near-net-shape metal structures.

Material Extrusion

Green part is printed to be sintered afterwards = FDM (Fused Deposition Modeling)

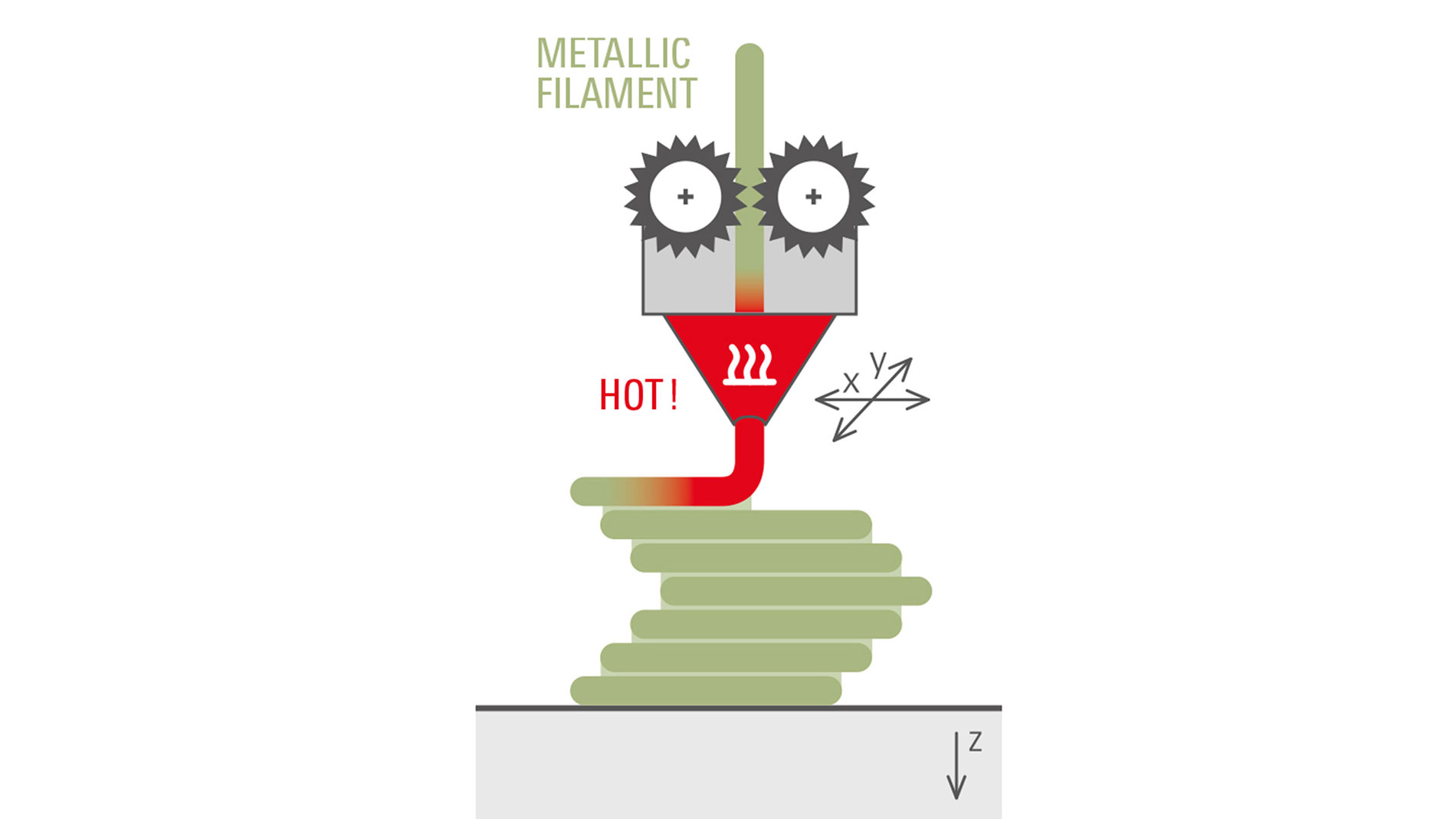

FDM (Fused Deposition Modeling)

Synonyms: Fused Layer Modeling (FLM), Fused Layer Manufacturing (FLM), Fused Filament Fabrication (FFF), Schmelzschichtver-fahren, Strangablageverfahren, Bound Powder Extrusion (BPE), Bound Powder Deposition, Atomic Diffusion Additive Manufacturing (ADAM), Filament Metal Printing (FMP), Metal Fused Deposition Modeling (MFDM)

Wire-shaped metal-containing plastic, so-called filament, is plasticized in a nozzle unit and selectively dosed locally layer by layer.

Binder Jetting

Joined with bonding agent to be sintered afterwards = BJ (Binder Jetting)

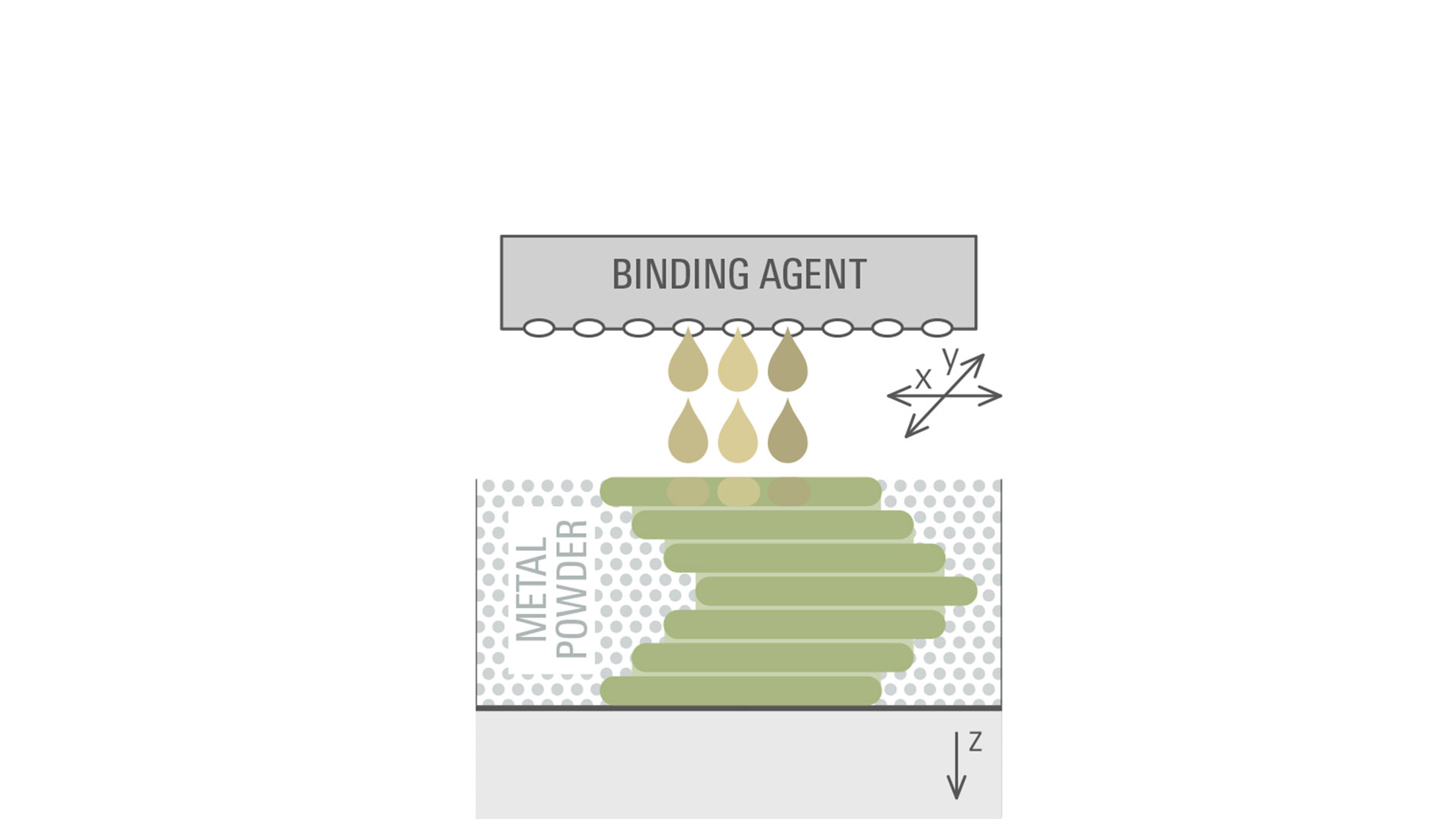

BJ (Binder Jetting)

Synonyms: 3D Drucken, 3D Printing, Three Dimensional Printing (3DP), Inkjet 3D Printing, 3D-Pulverdruck, Single Pass Jetting (SPJ), Freistrahl-Bindemittelauftrag

Tiny binder droplets are selectively applied locally through many nozzles and in layers onto metal powder. They stick the powder material together.

Material Jetting

Cured with heat to be sintered afterwards = NPJ (Nano Particle Jetting)

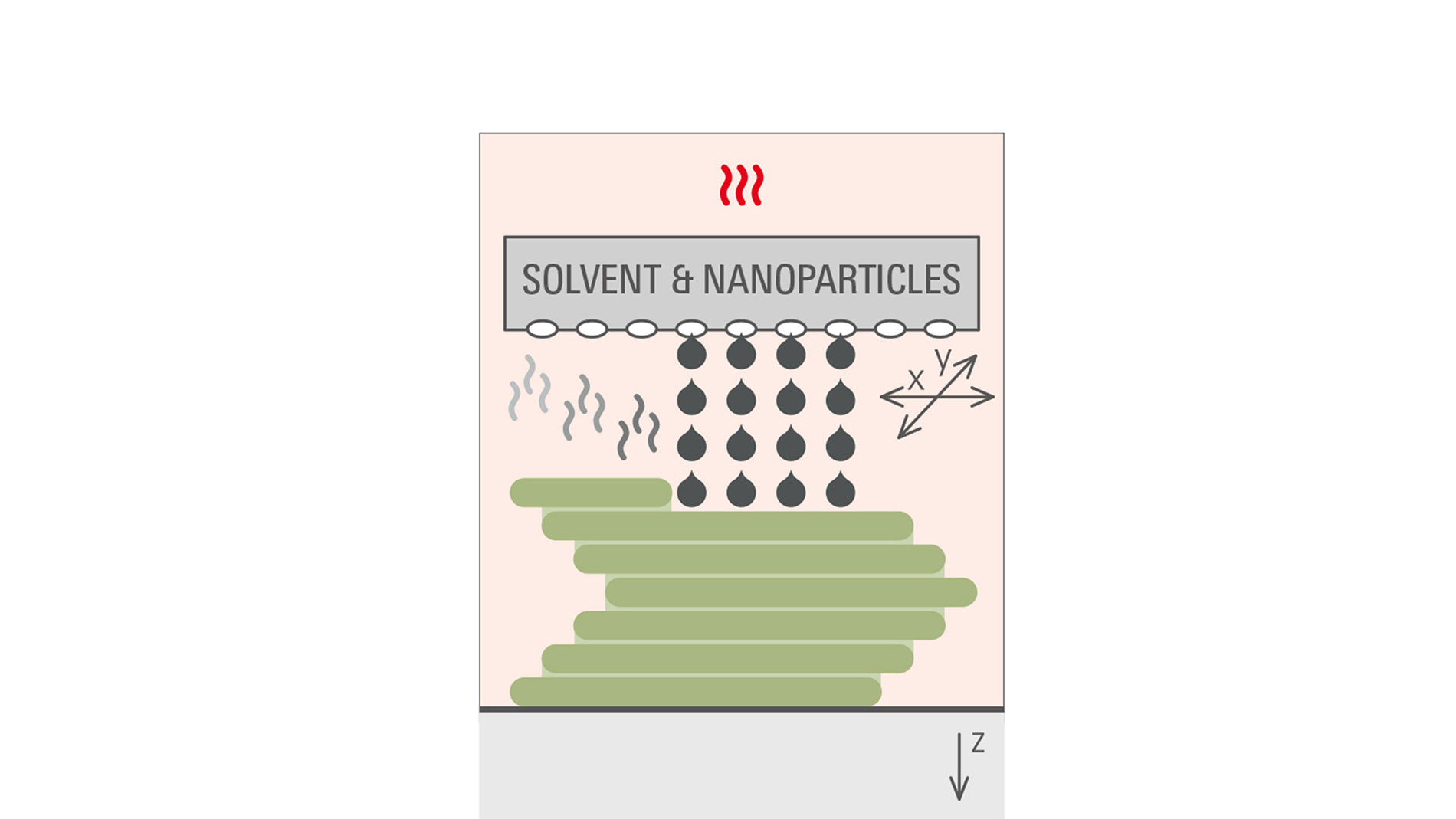

NPJ (Nano Particle Jetting)

A metal particle solvent fluid is selectively dosed locally by a nozzle unit. The solvent evaporates and the nanoparticles bond together.