High Volume Production Solution for Pure Copper and Copper Alloy

XH-M350G, with a build volume of 350*350*500mm, boasts a robust modular design and can be equipped with one or two green fiber lasers, available in 500W, 700W, or 1000W. The system enables efficient printing of materials like copper copper alloys, and precious metals, which are difficult or impossible to process with infrared lasers.

The machine's modular platform gives flexibility to reproducible production and easy maintenance. Its open-source system supports extensive parameter customization and a wide range of materials. The system is open to integrate seamlessly with upstream and downstream software.

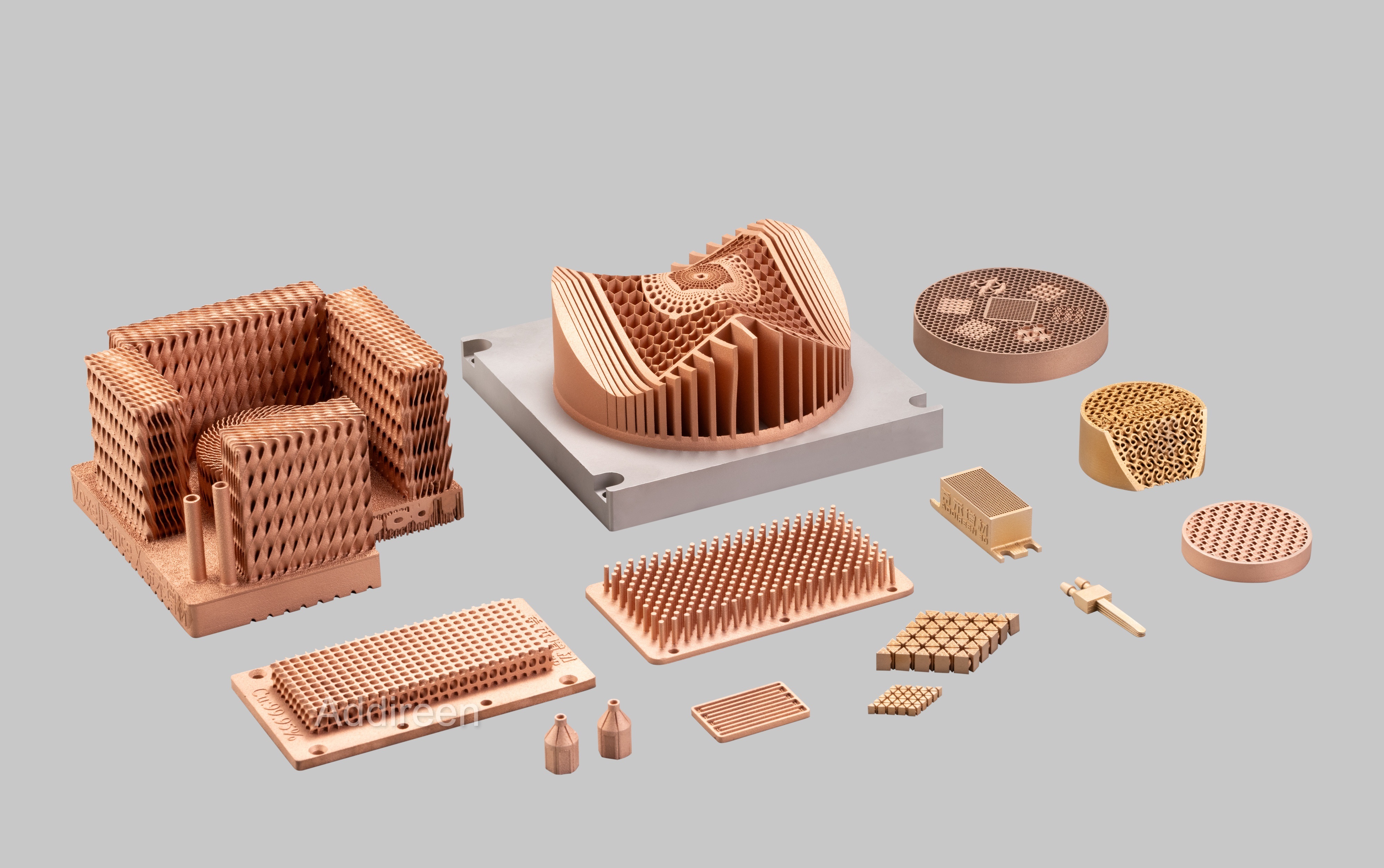

Incredible Printing Performance with Cooper and Copper Alloys

Green laser enables additive manufacturing of highly reflective materials to print more effectively and efficiently. It delivers a high absorption rate and generates less spatter during printing. Finer details can be achieved due to the small spot size of the green laser. The performance of the printed cooper and its alloy parts is enhanced.

Density≥99.8%

Electrical Conductivity≈101%IACS

Thermal Conductivity≈390W/(m·k)

Min. Wall Thickness 0.08mm

Note: Pure copper heat treated. The test parameter can vary according to factors like printing parameters, and material used.

Fast Printing Speed in Copper and Copper Alloys

15-55cm³/h (Green laser) vs 1.7mm³/h (Infrared light)

Note: Typical printing speed of 1kw NIR laser

Efficient Speed and Fine Details

With a dual laser system, bidirectional powder coating, and equipped with large layer thickness printing parameters, printing can be more efficient. With a small spot size down to 40µm, fine details can be realized.