See who is exhibiting or create your own watch list. Use the filter options to obtain a list of exhibitors for the respective product group.

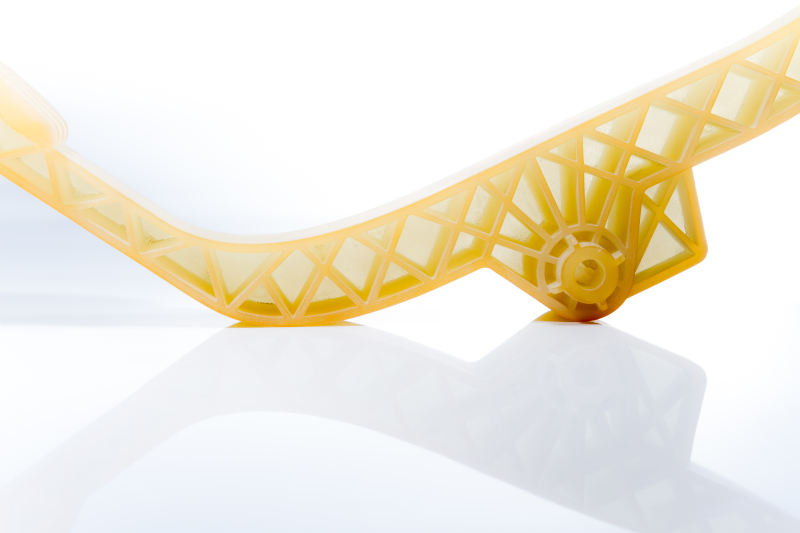

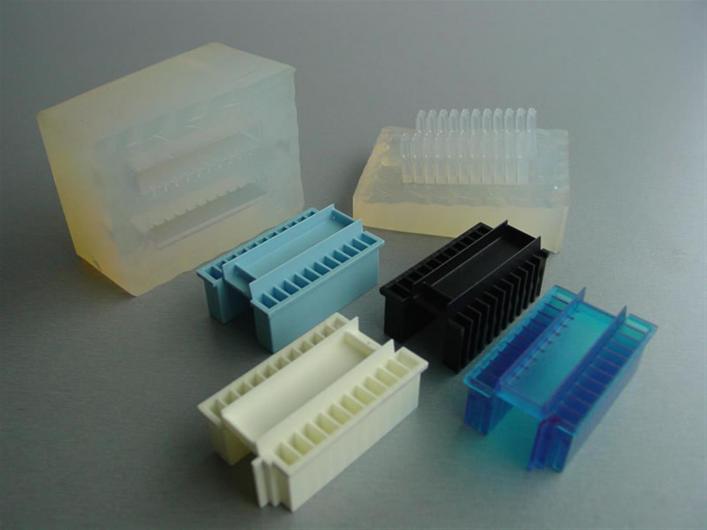

PU parts made in Vacuum Casting

PU parts made in Vacuum Casting

Description

Vacuum casting is the technology that allows us to reproduce pieces in polyurethane resin using a silicone mould. For the manufacture of this mould we use, generally, a first model of stereolithography (SLA). However, this technique allows us to use as a master almost any type of piece made with other technologies, such as laser sintering (SLS), molten deposition modelling (FDM) or machining (CNC).

We can produce short series of pieces with polyurethane resins whose characteristics (flexibility, transparency, resistance to high temperature, fiber loading, fire retardant -V0-) are similar to those of the final product: ABS, Polypropylene, Polycarbonate, etc. There are also polyurethanes with FDA approval suitable for food use.

Different types of surface finishes, such as painted, chrome, tinted or metallic, among others can be applied to the parts that have been manufactured using this technique.