See who is exhibiting or create your own watch list. Use the filter options to obtain a list of exhibitors for the respective product group.

Farsoon Technologies Co., Ltd.

Farsoon Technologies Co., Ltd.

Hunan Changsha Hunan

Yuelu District

No. 2710 Yuelu West Boulevard

410000

China

About us

FARSOON Technologies, founded in 2009 in China, is a system supplier of industrial grade plastic laser sintering and metal laser melting systems. Farsoon has developed a team of world-class experts with competencies in electrical/mechanical engineering, laser, scanning and optics, thermal controls, as well as material development and applications engineering. As a globally diverse company, Farsoon was founded with the clear vision and core commitment to creating open platform systems which will give the industry the freedom to innovate and expand the implementation of additive manufacturing in the global product’s marketplace.

Learning from the market about customer needs, Farsoon has moved to address the need for higher levels of productivity, improved feature details, and enhanced operational efficiency and flexibility. Farsoon’s latest innovations like the Continuous Additive Manufacturing Solutions (CAMS) and the very accurate and ultra-fast Flight™ Technology stand for highest production rates and real industrial use of Additive Manufacturing.

Farsoon´s subsidiary FARSOON Europe GmbH (Stuttgart, Germany) provides the whole range of machine portfolio after technical confirmation in China, as well as local service and maintenance activities.

Keywords

- Industrial 3D printing machines

- Additive manufacturing

- Laser powder bed fusion technology

- Large-format metal 3D printing

- Laser sintering

- SLS

- SLM

Our Products

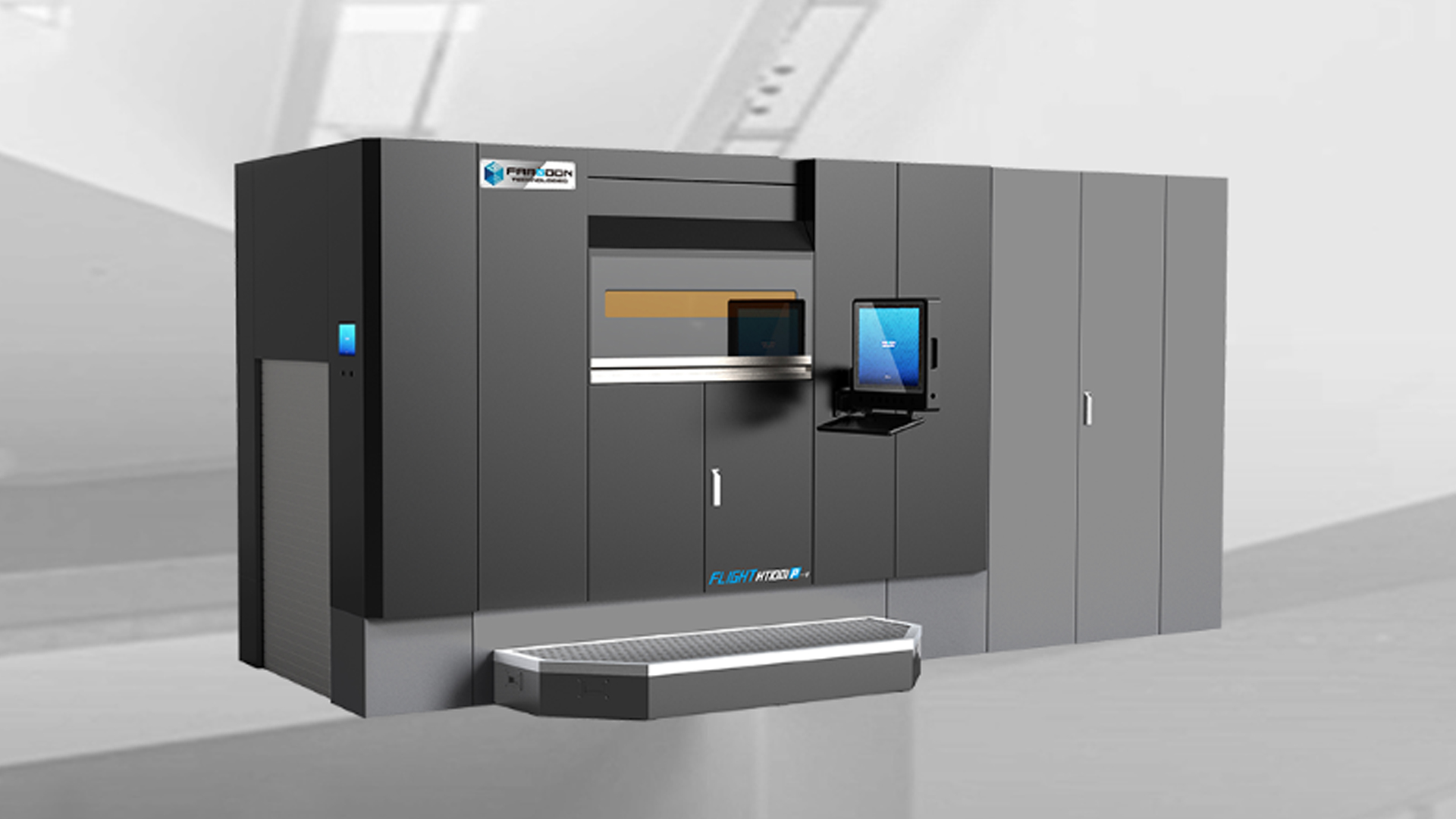

FLIGHT HT1001P-4

The Farsoon FLIGHT HT1001P is an advanced 3D printing system designed for large-scale, industrial applications. It features a 1000mm x 500mm x 450mm build envelope, equipped with quad 300-watt fiber lasers for high-speed sintering at up to 20 m/s.

The system supports a wide range of engineering materials, including high-temperature options, and includes a modular, open-material model for flexibility. Its closed-loop powder handling and automation streamline production, ensuring high efficiency, consistent part quality, and minimal operator interaction.

Integrating CAMS Technology (Continuous Additive Manufacturing Solution), the FLIGHT HT1001P is designed with an exchangeable build cartridge and an integrated conveyor system that allows for intensive, continuous manufacturing cycles with minimum machine down time between the builds; can offer up to 5.6 times production yield compared to a single CO2 laser machine.

In addition, the Flight® HT1001P platform is capable of achieving chamber temperatures up to 220℃ to process high-temp materials such as PA6 for end-use parts. With a patented multi-zone heater & intelligent temperature control system, the Flight® HT1001P platform can achieve uniform thermal distribution throughout the platform, ensuring consistent mechanical properties and surface quality.

Learn more:

https://www.farsoon-gl.com/products/flight-ht1001p/

FLIGHT HT403P-2

The Farsoon FLIGHT 403P-2 Dual-Laser Series is an industrial 3D printing system designed for high-speed, large-scale production. It features dual 300-watt fiber lasers for ultra-fast sintering with speeds up to 20 m/s and a build envelope of up to 400 x 400 x 540 mm.

This open-platform system offers flexibility in material choices and supports a variety of applications, including electronic components, robotics, and consumer products. The dual fiber-laser configuration boosts productivity by 3 to 4 times compared to single-laser CO2 systems.

The optimal performance of FLIGHT® 403P-2 Series combining extreme sintering speed and high feature resolution has opened up many potential markets and applications for true series production, such as electronic components, robotics, specialized tools & models, battery units, filter modules as well as many consumer products.

Learn more:

https://www.farsoon-gl.com/products/flight-403p-2-dual-laser-series/

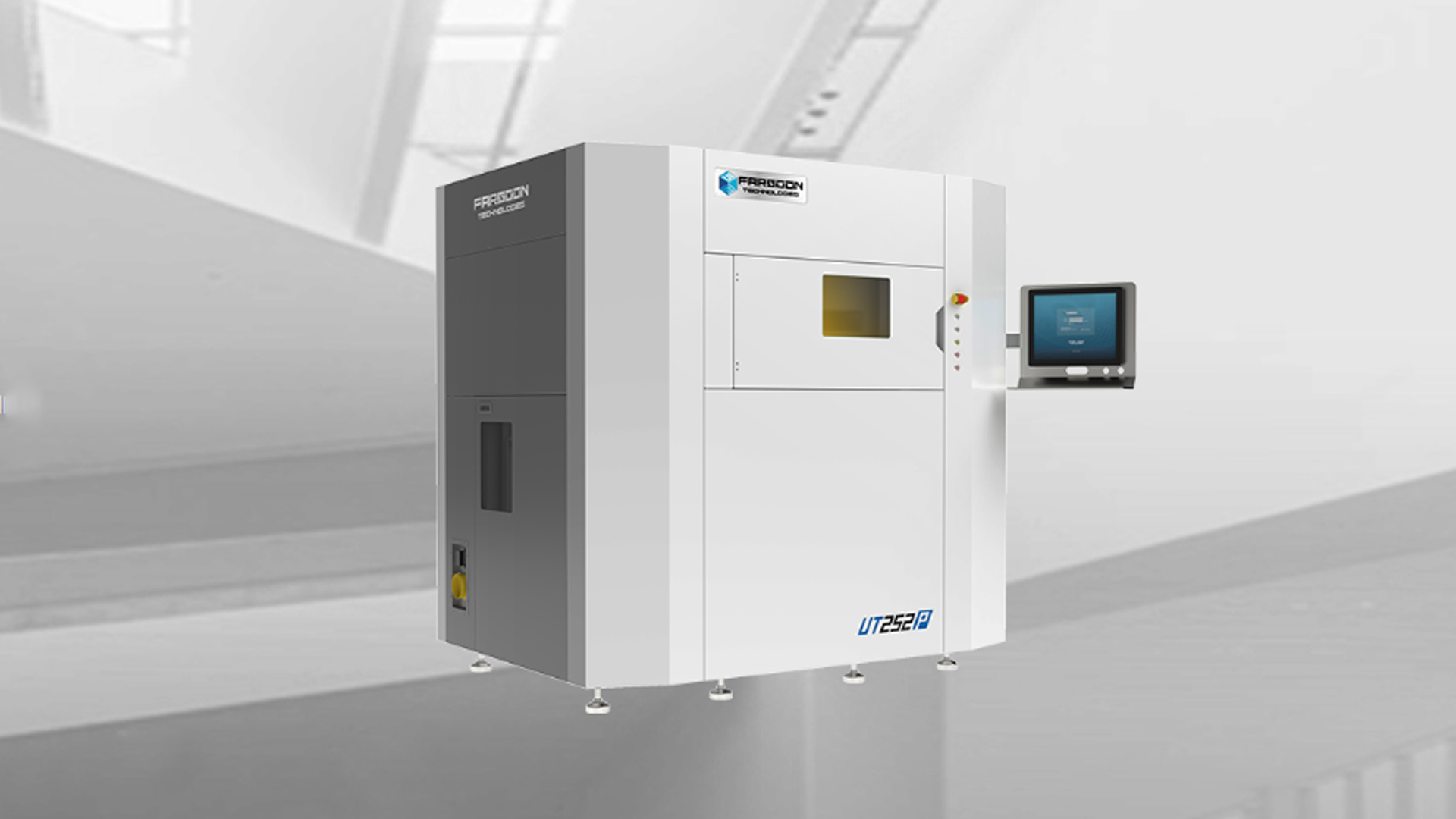

UT252P

The Farsoon UT252P is the latest addition to the 252P series family, optimized for ultra-performance polymer additive manufacturing with chamber temperature capacity of processing materials with high melting point over 340°C. It features a compact footprint and offers a versatile 250 x 250 x 320 mm build volume.

The UT252P is featured with enhanced 8-zone temperature shielding, and thermal control enable the UT252P to process high-temperature, high-performance engineering materials such as PA6, PA66, PPS, PAEK, PI, PTFE for end-use applications.

Learn more:

https://www.farsoon-gl.com/products/252p-series/

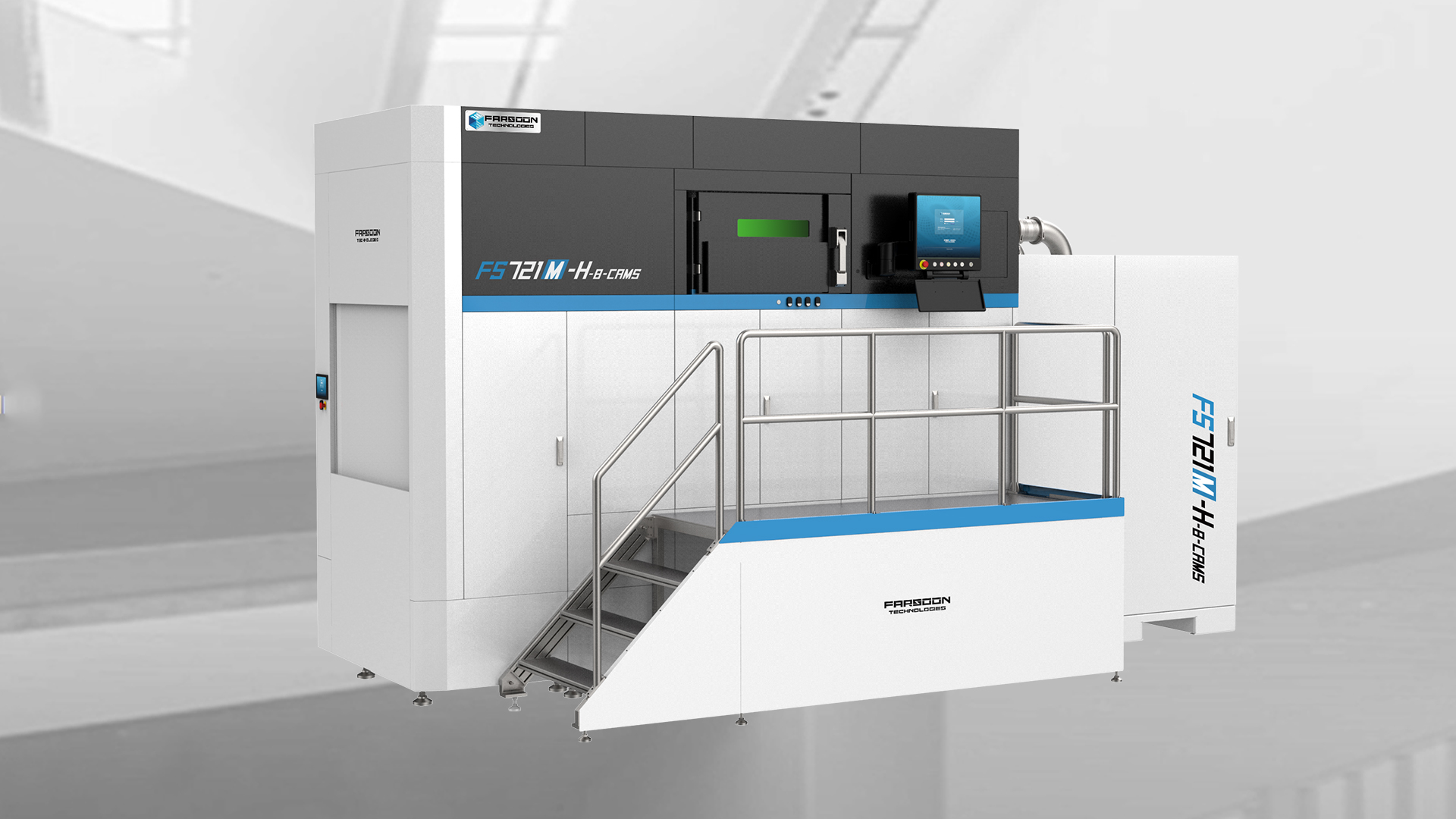

FS721M-H-8-CAMS

The Farsoon FS721M-H-8-CAMS is a large-format metal 3D printing system designed for continuous production in industries like automotive, molds, and tooling.

Integrating Farsoon’s innovative CAMS concept, the FS721M-8-CAMS is equipped with the internal conveyor system and unique exchangeable cartridge strategy. It allows for quick transfer of the completed build cartridge to the inert breakout station, load the 2nd build cartridge to the system and start the production job; while the breakout process is conducted in parallel. This highly efficient exchangeable cartridge strategy enables maximized machine “Laser-on” time, true continuous production capability, intensive manufacturing turnovers with minimal machine downtime between the build jobs.

Equipped with an expanded rectangular build cylinder of 720 x 420 x 390 mm, highly efficient eight 500W or 1000W fiber lasers, the FS721M-8-CAMS can boost productivity and lower production cost per part; it is the ultimate series manufacturing tool for large-format industrial applications favors one axis; including automotive, molds & tooling fields and many other manufacturing industries.

Learn more:

https://www.farsoon-gl.com/products/fs721m-cams/

FS422M-4

The FS422M is the next-generation medium-large metal laser powder bed fusion system offering continuous production capability with single or quad fiber lasers. With its expanded build envelope size up to 425 x 425 x 550 mm, the FS422M is capable of producing large metal parts for aerospace, automotive and manufacturing industries. Equipped with high-precision digital scanning system, the FS422M offers optimal volume build rate up to 150cm3/h for significantly improved throughput for industrial scale series production.

Equipped with advanced multi-laser scanning strategy and calibration algorithms, the FS422M offers optimal build efficiency, and uniformed part performance in overlapping areas. Continuous close-loop top-feed powder delivery system, optimized in-chamber gas flow, and inert gas protection allow for uniform melting process of metal powder. Powerful build process control and real-time recoating monitoring ensure the optimal industrial build quality.

The new FS422M system is integrated with a permanent filter system allows for the processing of active materials with lifespan more than 10 years. In addition, like all Farsoon machines the FS422M is a truly open platform which offers the user a high degree of control to tailor processing parameters for industrial application requirements and cost-competitive metal additive manufacturing.

Learn more:

https://www.farsoon-gl.com/products/fs422m/