A GLOBAL LEADER IN THE MATERIALS AND PARTS INDUSTRY

www.eloiml.com | EML@eloiml.com

www.youtube.com/@eloimaterials

EML (Eloi MateriaLs) was founded based on technological innovation and provides total solutions for advanced materials by developing breakthrough technologies and manufacturing world-class products in advanced alloy materials, metal powders, PVD coating/targets and metal 3D printing.

We are committed to delivering innovative products as a global leader in the materials and parts industry. We also promise to grow together with our communities and partners to become a well-liked and respected company.

- Metal powders | High-purity spherical alloy/pure metal powders

Powders for medical applications (Ti-based, Co-based, STS, etc.)

Brazing powders (Ni-based, Cu-based, Ti-based, Ag-based, Sn-based, etc.)

Thermal/plasma/HVOF spray powders (W-, Co-, Fe-, Ni-based, etc.)

Magnetic powders (Fe-, Co-based, etc.)

Functional powders (HEAs, amorphous alloys, hardfacing, etc.)

Powders for aerospace applications (Cu-, Al-, Ti-, Ni-based, etc.)

Superalloy powders (Ni, Nb, Co, Fe-based, etc.)

3D printing powders (Ni Alloy 625, 718, 738, Cu, CuZrCr, Mo, MoTi, CuCrNb, etc.)

Customization

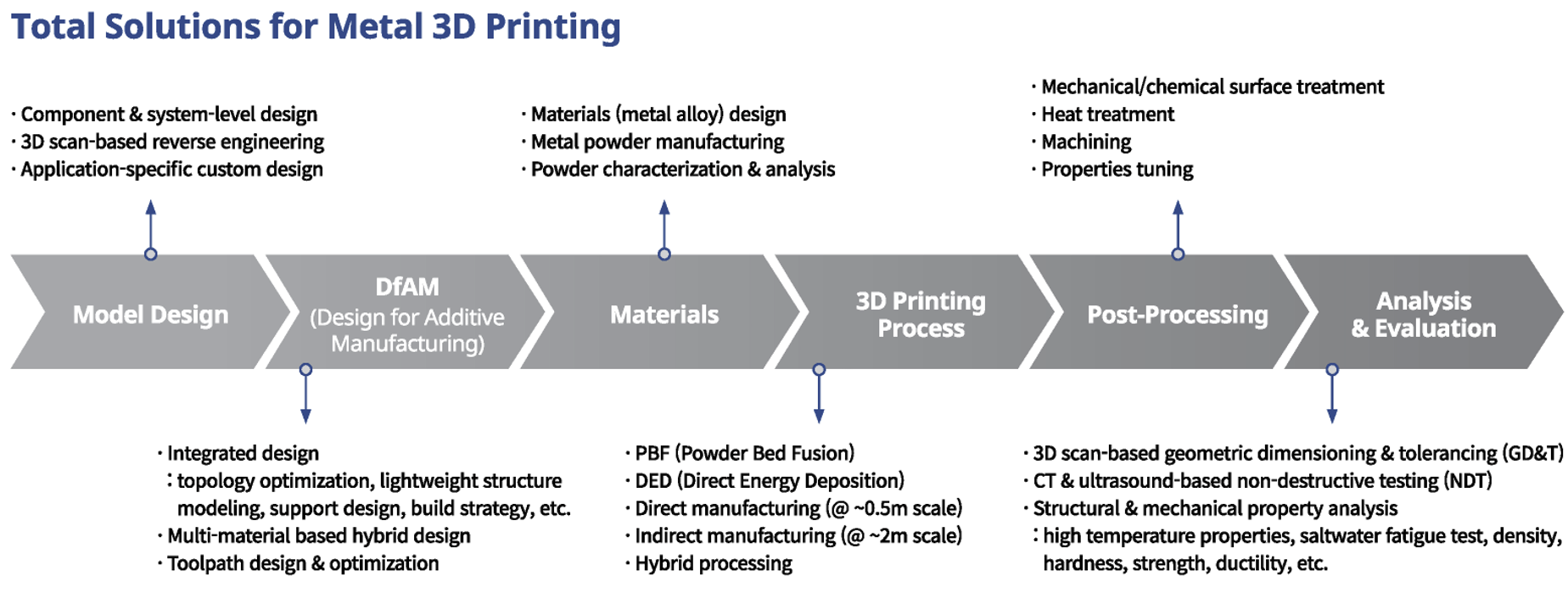

- Metal 3D printing | Total solutions for metal 3D printing

Direct energy deposition (DED) equipment

Material design and development

Metal powder

Pre-processing services (structural analysis, tool path planning, 3D scanning, etc.)

Process optimization

Additive manufacturing services (parts, ASTM standard patterns, repairs)

Post-processing services (HIP, heat treatment, machining, surface treatment, etc.)

- Advanced alloys | Advanced alloys and alloy ribbons

Superalloys (Ni-based, Co-based, Fe-based, Nb-based, etc.)

Functional alloys (high entropy alloys (HEAs), amorphous alloys, etc.)

High-purity alloys and pure metals (Ti, Zr, Mo, etc.)

ASTM standard specimens (tensile test, creep test, etc.)

Customization

- Equipment Technology | Equipment Design & Development

Intelligent gas atomization (VIGA, EIGA)

VIM (Vacuum Induction Melting)

VPM (Vacuum Plasma Melter)

Metal 3D Printer (DED)

Customization

- PVD coating/target | Multi-functional coating/multi-component alloy targets

Colored alloy targets (silver, red gold, yellow gold, platinum, dark blue, etc.)

Low friction and wear resistant coating targets (ZCS)

Hard coating for tools/molds (TiAlCr, AlCr)

Targets for modern display devices (planar and cylindrical rotating Mo-, MoTi-Targets etc.)

Precious metal targets (Ag, Pt, Au, etc.)

Ceramic targets (Y2O3, YSZ, GeTe, etc.)

Customization