See who is exhibiting or create your own watch list. Use the filter options to obtain a list of exhibitors for the respective product group.

POSTPRO DP - AUTOMATED DEPOWDERING

POSTPRO DP - AUTOMATED DEPOWDERING

Description

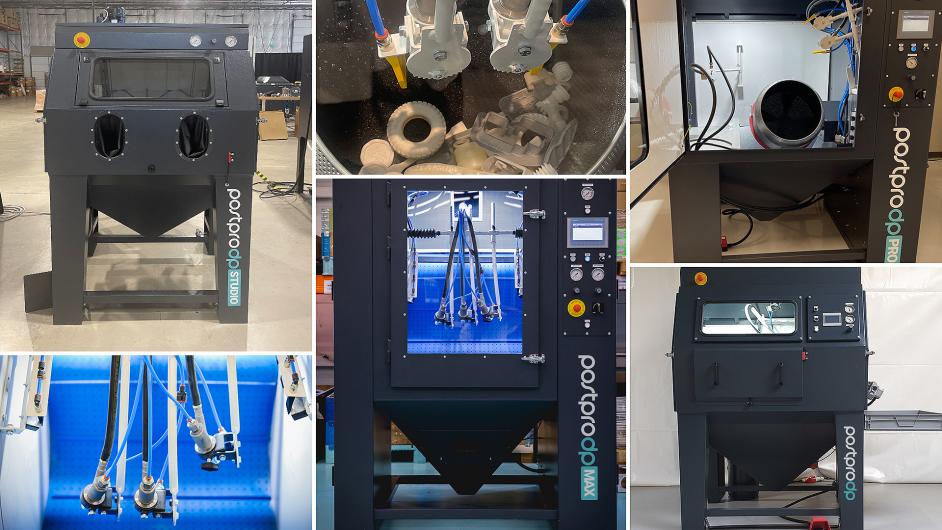

AMT offers a wide range of Depowdering systems tailored to various production throughputs and delivers precisely depowdered parts ready for surface finishing. PostPro depowdering systems offer a gentle powder removal process that is safe for complex geometries and features an operator-friendly design.

POSTPRO DP MAX

Powered by continuous tumble belt technology for maximum throughput and process and part-size flexibility, the PostProDP MAX is a fully automated depowdering and shot blasting system designed for large component runs and/or use in large batches.

Continuous automated production:

Providing an efficient user and production experience, the cabinet is front-loading at an ergonomic working height with reversible belt controls enabling automatic loading and unloading of parts to and from the transport container, thus maximizing throughput.

Industry 4.0 automation:

The PostPro DP MAX is computer-controlled to enable Industry 4.0 compatibility and can be connected with and integrated with other Manufacturing Execution Systems (MES) in a production workflow. Users can program and store recipes and processing parameters making cleaning 3D printed parts more efficient than ever.

POSTPRO DP PRO

The PostPro DP PRO is the solution for cleaning or shot blasting parts hour after hour, eliminating time and cost-consuming interventions in your post-processing chain. It is ergonomically designed and equipped with features to increase your throughput.

The generously sized basket allows for optimization of the blasting angle, cleaning parts fast, while also allowing to easily switch between batches. Once you have found the ideal recipe for blasting your parts, you can store the settings, and reuse them again and again.

Watch the video to learn more about the POSTPRO DP PRO: https://youtu.be/lLhVSibEMY4

POSTPRO DP

The PostPro DP is our affordable cleaning and shot blasting system. It has everything needed to start with your automated post-processing workflow. The machine is robust and is built to last enabling you to be up and running in the blink of an eye and maximizing output for years to come.

PostPro DP is operator-friendly. With the operating panel and basket at an ergonomic height, the user can comfortably load the machine and adjust the parameters.

Watch the video to learn more about the POSTPRO DP: https://youtu.be/C57EVoARtpM

POSTPRO DP STUDIO

AMT’S PostPro DP Studio is designed for operation in studio environments and depowdering of smaller part sizes and loads.

The PostPro DP Studio makes it possible for anyone to produce pristine depowered parts in small-scale additive manufacturing without compromising on part cleaning quality.

ALL OF AMT’S DEPOWDERING SYSTEMS FEATURE THE FOLLOWING:

Engineered for AM:

Equipped with an ionization unit and conductive powder coated cabinet to further reduce static build-up within the blasting process, a built-in cyclone for efficient blast media cleaning and dust separation, and a ventilator system with a high extraction rate to prevent dust build-up in the working chamber. Thus resulting in ‘dust-free’ products with no need for any additional cleaning steps once the process has finished.

Suitable for all common abrasives:

AMT’s range of PostPro Depowdering systems are 3D printer material agonistic and works with all powder-based printer platforms including HP Multi Jet Fusion, EOS, and 3D Systems, as well as a range of thermoplastic polymers such as polyamides and elastomeric materials.

The system can be run with multiple media, such as corundum, glass beads, ceramics, nutshells, plastics, and fine grain sizes of stainless steel and steel. Taking 10 minutes to remove all the powder without damaging any of the parts.

AMT’s range of PostPro Depowdering are CE and ATEX certified and is constructed as one compact unit to minimize the machine footprint and maintenance cost. The system has been tested with customers across Europe and is available now to order from AMT.