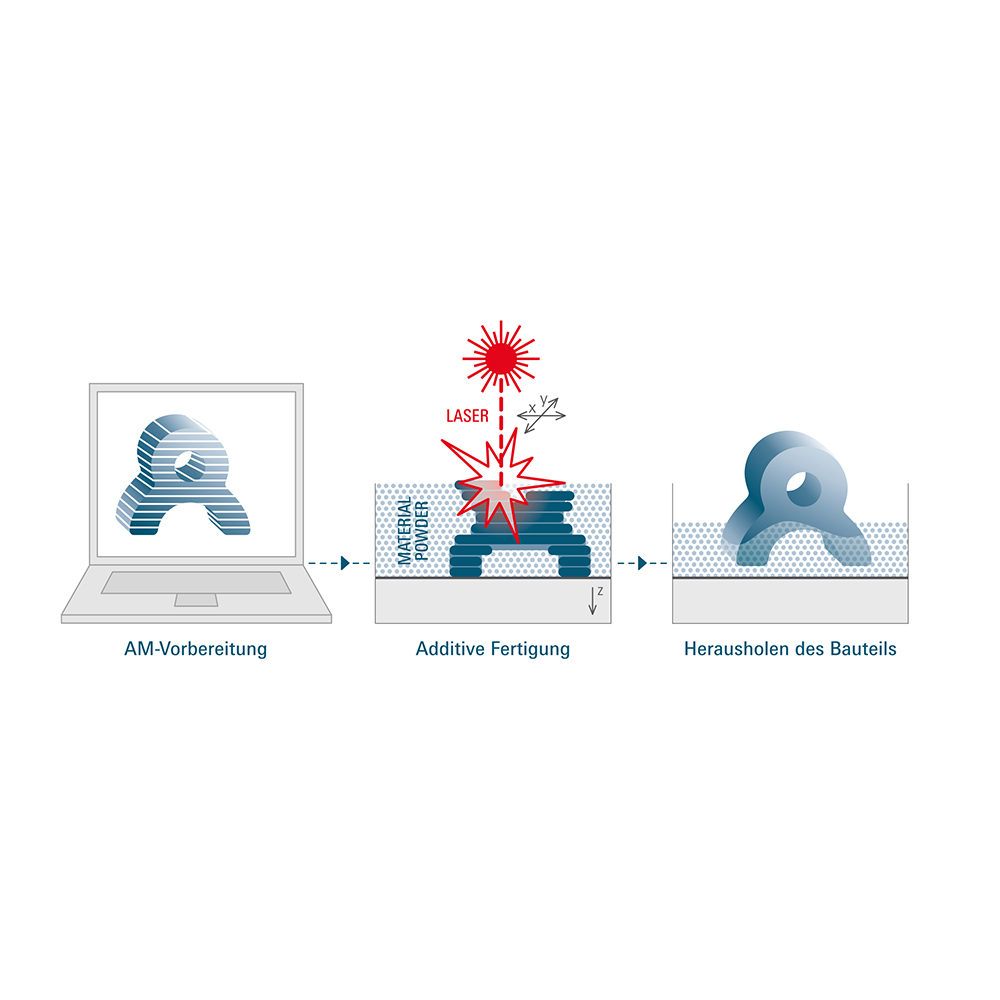

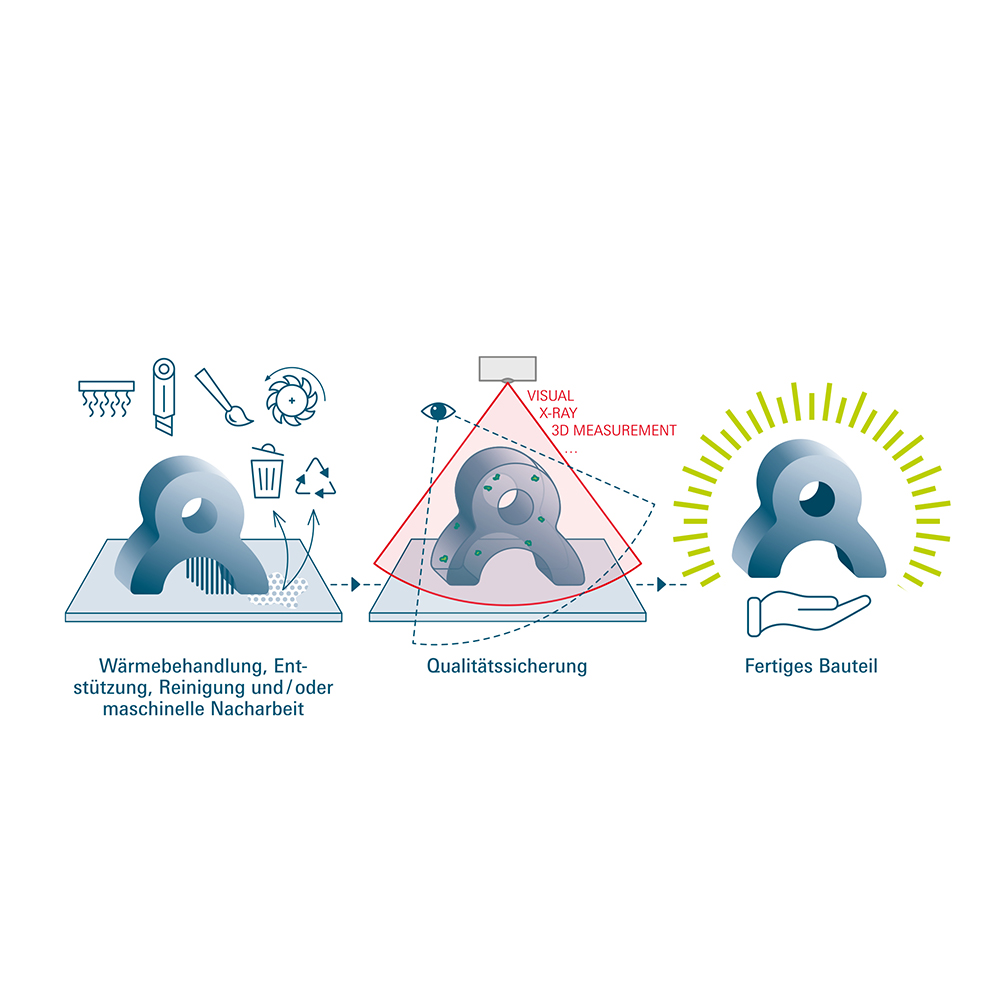

The AM Field Guide gives an initial, structured overview of the complex, multilayered world of additive manufacturing processes.

Welcome to the AM Field Guide!

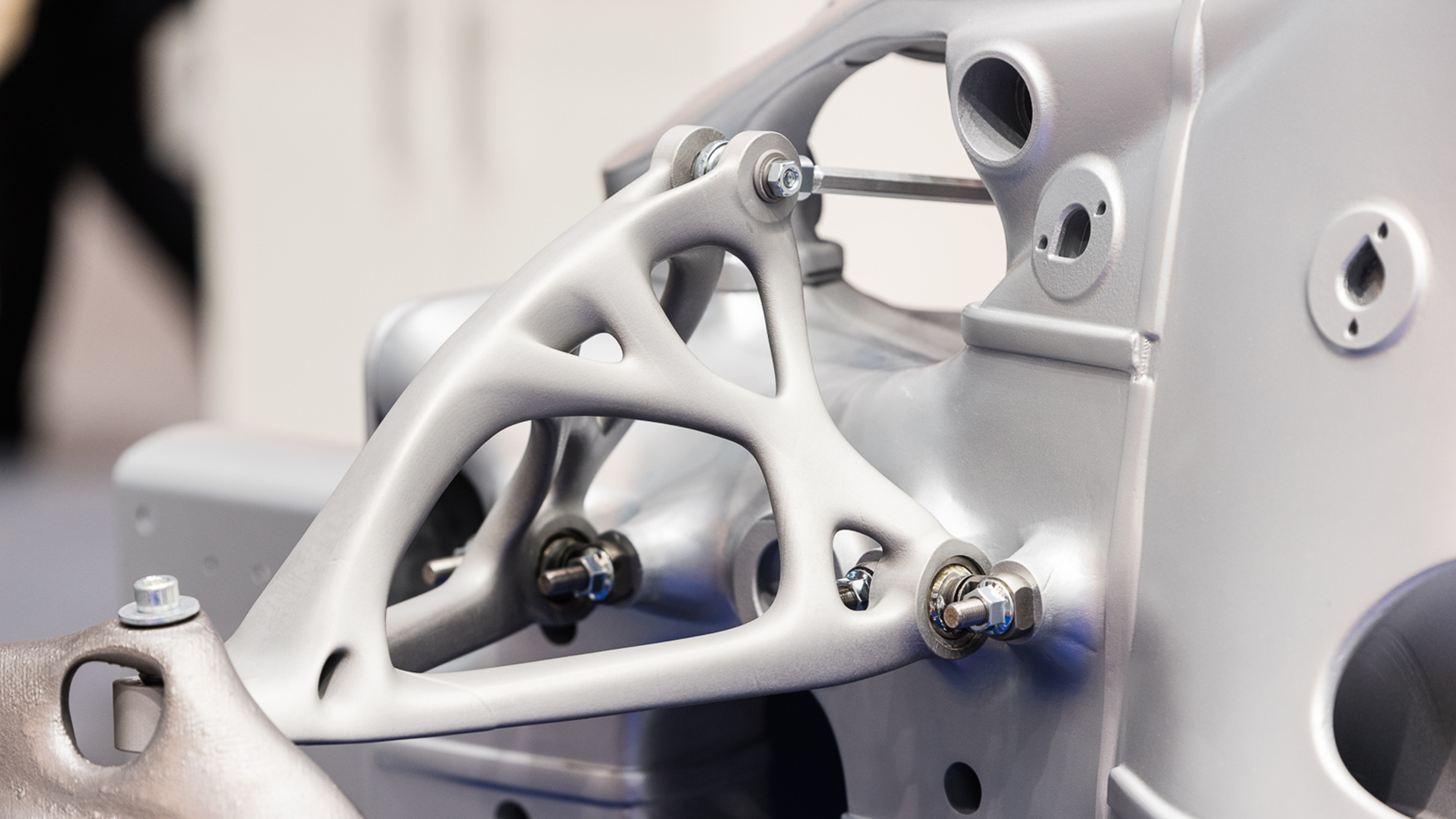

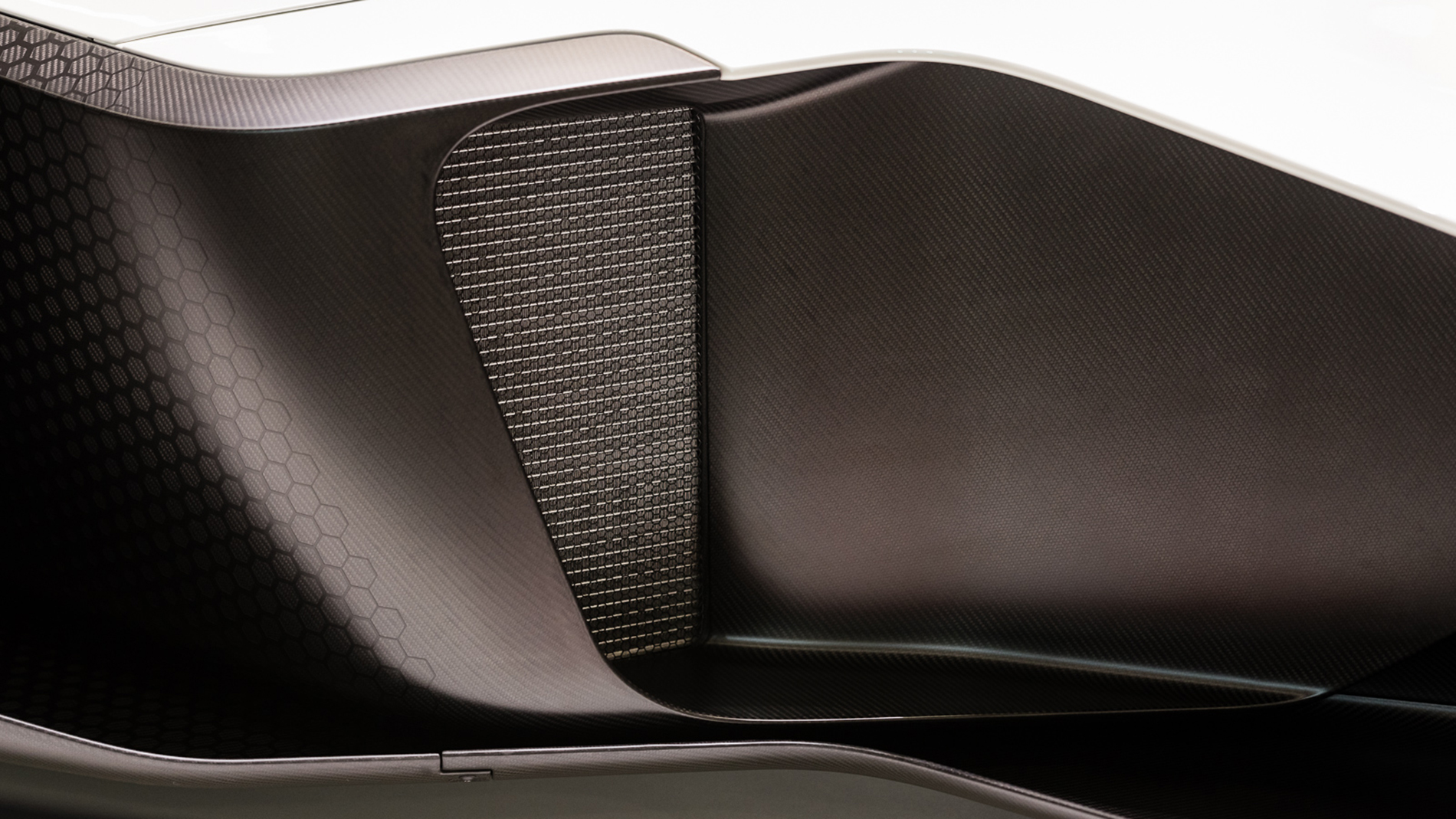

The large number of additive manufacturing processes that have come up and developed in recent years can be very confusing if the process-specific differences are not known. In this respect, the AM Field Guide aims to provide a first basic understanding of the individual process principles, separated according to the material areas metals, polymers and other materials. The AM Field Guide structures the processes and focuses on the main technologies relevant to the market.

Have fun discovering the exciting world of Additive Manufacturing.

Prof. Dr.-Ing. Steffen Ritter