In the days leading up to Formnext, it has become something of a tradition for some of the major players in the AM industry to announce innovations that were previously kept strictly under wraps. Exciting developments have also been added to the list of inventions and world premieres that we already presented in our edition for the Formnext 2025 trade fair. The latest innovations to be presented for the first time at Formnext include various AM systems (from Prima Additive/AltForm, Trumpf/Atlix, AMCM, XJet3D, Formlabs, and AIM3D) and a number of extraordinary applications (from Caracol, Gefertec, and Wayland, among others) that demonstrate the ever-expanding spectrum of Additive Manufacturing – from 3D-printed catamarans to 700-kg turbine impellers.

In another bit of news, two important players who have been shaping the AM industry for years are getting new names: Prima Additive by Sodick is becoming AltForm, and Trumpf Additive Manufacturing is presenting a new identity under the name Atlix at Formnext.

Prima Additive by Sodick / AltForm

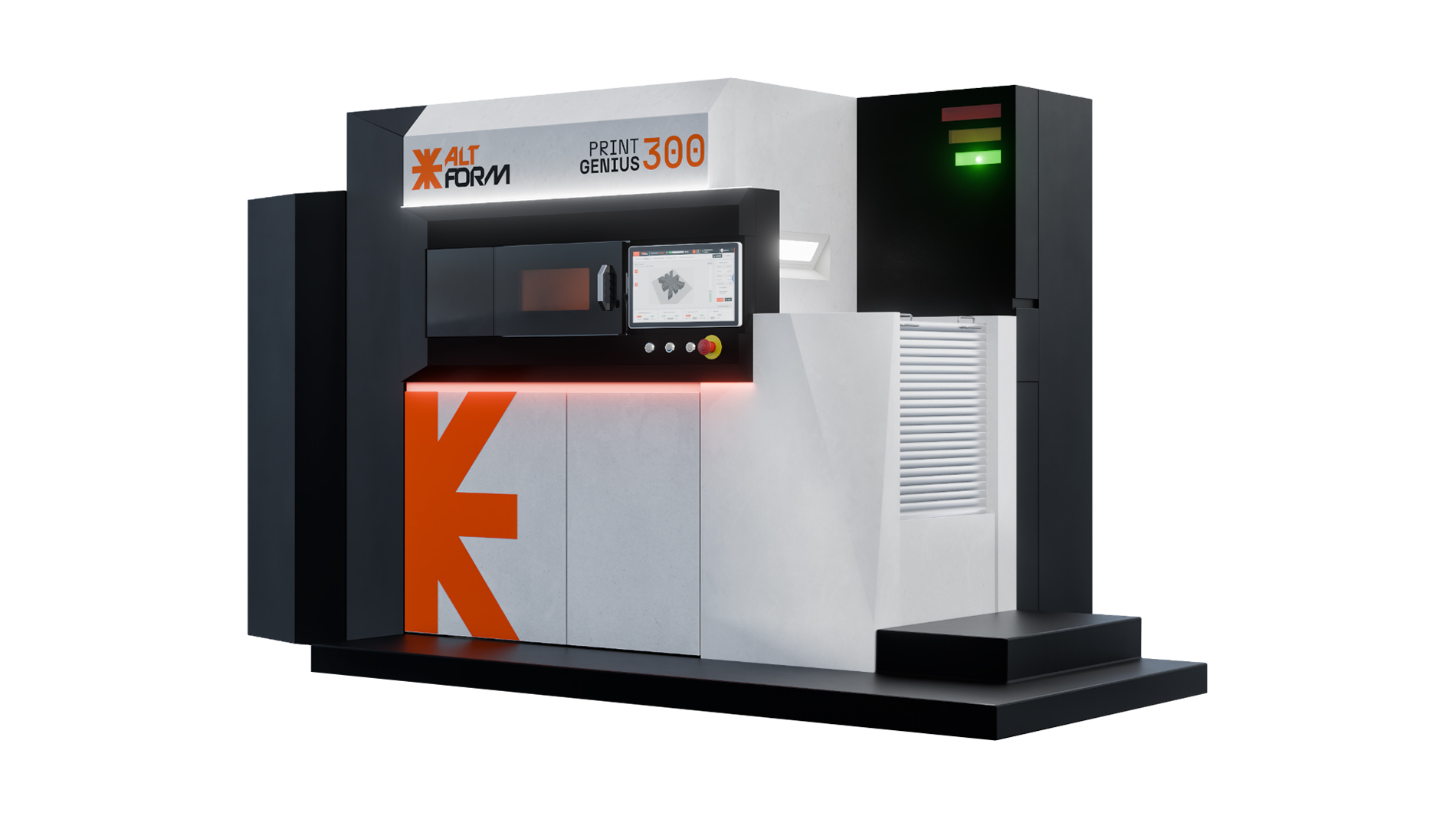

The rebranding of Prima Additive by Sodick as AltForm follows its acquisition by Sodick Co., Ltd., which was completed in May 2025. The name AltForm stands for “Advanced Laser Technologies for Manufacturing.” At the same time, the Print 300 and Print 400 series will celebrate their world premieres and usher in the next generation of AltForm’s LPBF platforms. The new architecture offers modular build chambers, improved gas flow stability, redesigned thermal management, and enhanced multi-laser coordination. Both platforms integrate seamlessly into AltForm's powder management ecosystem and enable scalable production workflows.

AltForm at Formnext 2025: Hall 12.0, Booth E139

Trumpf Additive Manufacturing / Atlix

Trumpf Additive Manufacturing will also be continuing its AM story under a different brand. At Formnext, the company – which was spun off from the Trumpf Group in recent months – will present its new identity, Atlix. This will be accompanied by a technical sensation: Atlix’s new flagship machine, the TruPrint 5000, will be unveiled for the first time at Formnext. According to its maker, the platform was developed to produce large and complex components at a high level of quality. Thanks to the way it automates “high-speed series production,” it is expected to significantly reduce unit costs.

Trumpf / Atlix at Formnext 2025: Hall 12.0, D99

AMCM

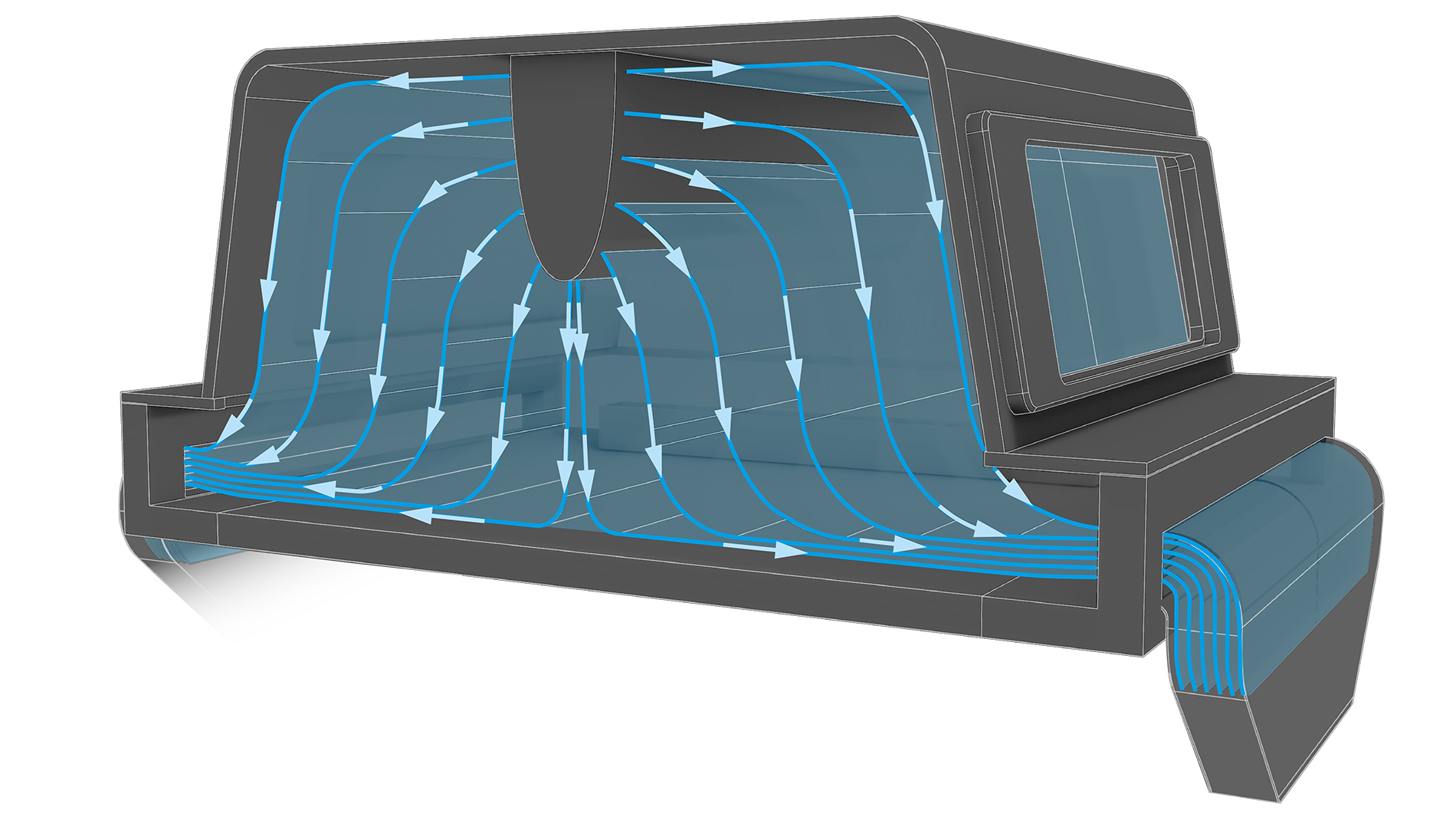

AMCM is presenting another innovation in metal 3D printing: With the M 8K, which features AirSwordTM gas flow technology, the company is promising a milestone in large-format LPBF applications. According to AMCM, AirSword is specifically designed for scalability and process stability in large-volume build jobs.

AMCM at Formnext 2025: Hall 11.1, Booth D49

AIM3D

Further innovations have been achieved in polymer systems, as well. The Rostock-based company AIM3D, for example, is presenting its latest innovations in 3D pellet printing. Its other core topics of development in 2025 include new slicer tools created in collaboration with Create it REAL and, in another premiere, an upgrade for the ExAM 255 and ExAM 510 systems.

AIM3D at Formnext 2025: Hall 12.1, Booth E139

XJet3D

Those who prefer to work with multiple materials will find new innovations at the booths of companies like XJet3D booth. For the first time anywhere in the world, the company is presenting its new Compact Multi-Material Carmel Pro system along with its entire material portfolio. The Carmel Pro system was developed for research institutions, start-ups, and contract manufacturers to enable “exploratory entry.” This is ensured, among other things, by the system’s compact size (175 × 190 × 85 cm with a build volume of 350 × 140 mm) and, according to XJet3D, a 70 percent lower total cost of ownership compared to previous Carmel models.

XJet3D at Formnext 2025: Hall 11.0, Booth D11

Caracol

One of the visual highlights of Formnext will be on display at the Caracol booth: the world's first 3D-printed catamaran, which was printed on the company's Heron AM platform in 120 hours. Caracol, which acquired Hans Weber Maschinenfabrik GmbH this year and completed a series-B financing round of US$40 million, will also be presenting the latest developments in its Eidos Manufacturing Software Suite, which is designed to make the production process for all Caracol robotic platforms even more autonomous and efficient.

Caracol at Formnext 2025: Hall C101, Booth 12.1

Waylandt

Wayland's booth is set to take visitors from the water into the air: The British company is providing detailed insights into its collaboration with the UK’s Royal Air Force. The RAF has been using a Calibur3 system since 2022, and a titanium component (Ti64) manufactured on it is now flying in its Typhoon jets.

Wayland at Formnext 2025: Hall 12.0, Booth B139

.jpg)

Gefertec

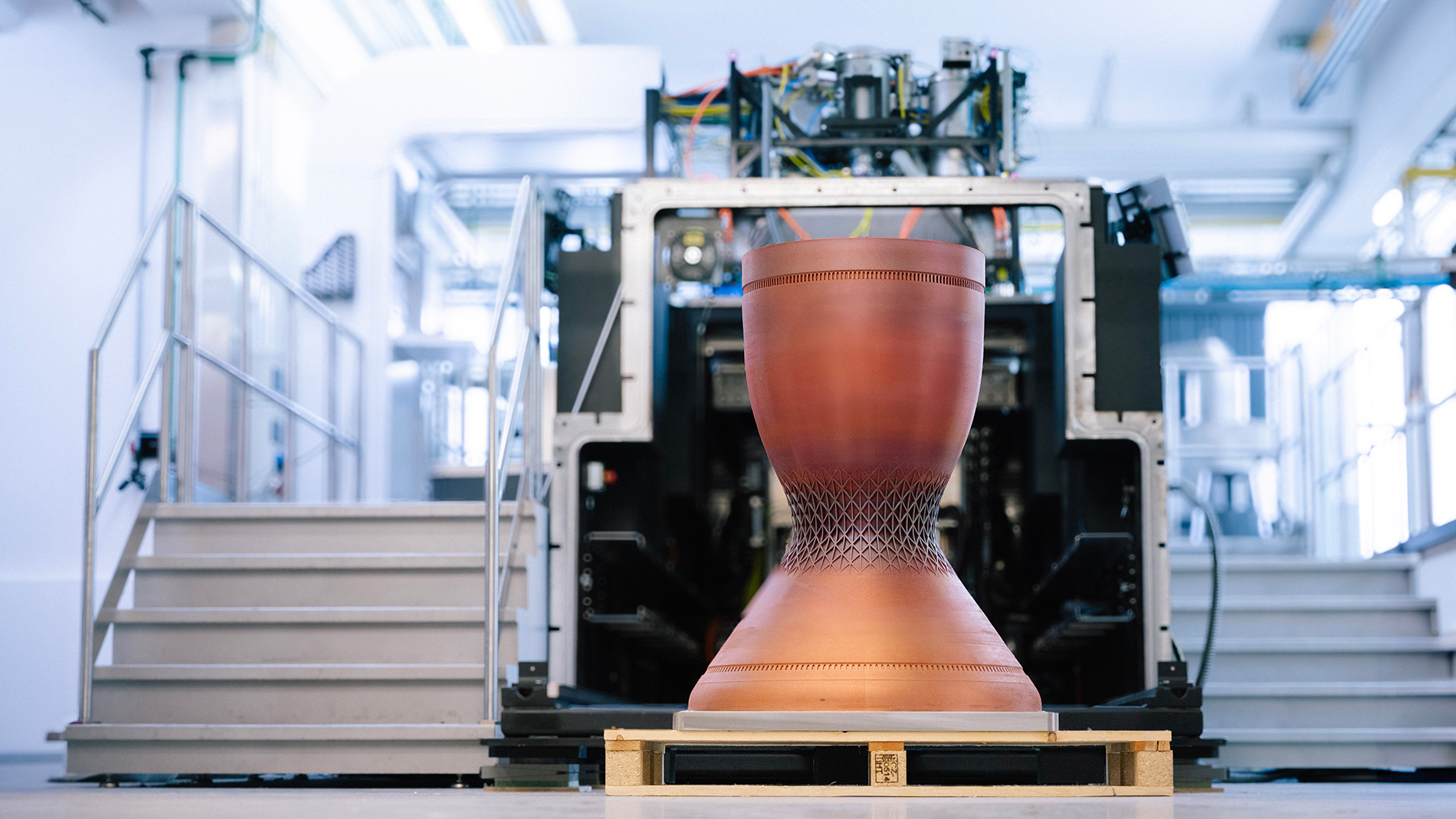

Large components are the focus at Gefertec, which is presenting its latest developments in the field of wire-arc Additive Manufacturing (WAAM) at the Berlin joint booth. These include a 700-kg turbine impeller, an emergency exit frame for aircraft, a printed tool for toolmaking, and a yaw damper bracket for the railway industry. In addition, a load collar – a component of a high-performance turbine – will be presented at the VDMA joint booth.

Gefertec at Formnext 2025: Hall 11.1, Booth D31

Multhem

Multhem (Multi-Material Additive Manufacturing for Lightweight and Thermal Management) develops AM processes that combine aluminum and carbon fiber composites. The possible applications include structural components with improved thermal conductivity for batteries, motor housings, and avionics enclosures, which contribute to lighter and more efficient systems.

Multhem at Formnext 2025: Hall 11.0, Booth E35