Trends: Lynxter - reducing dependence on animals and cadavers

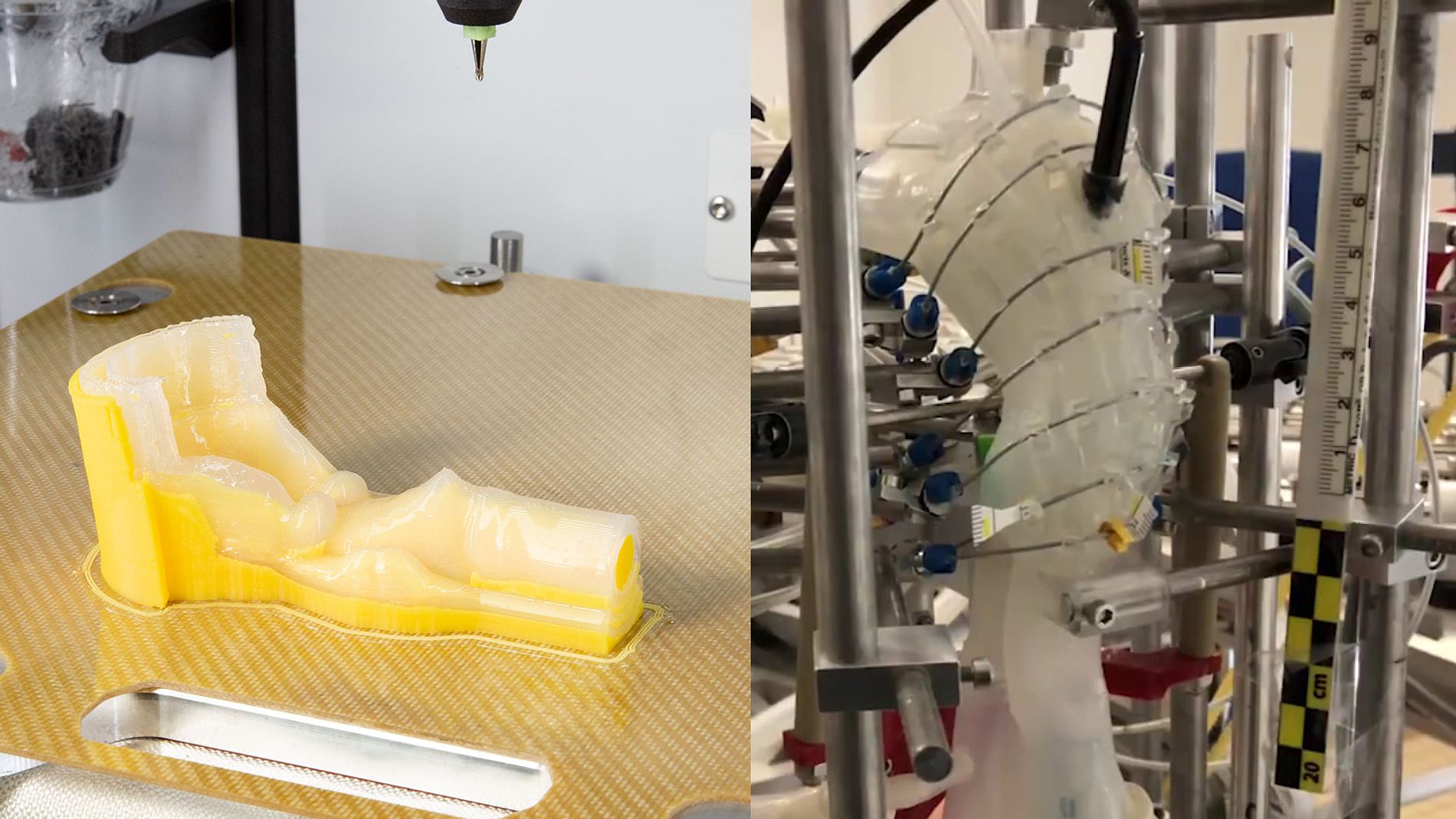

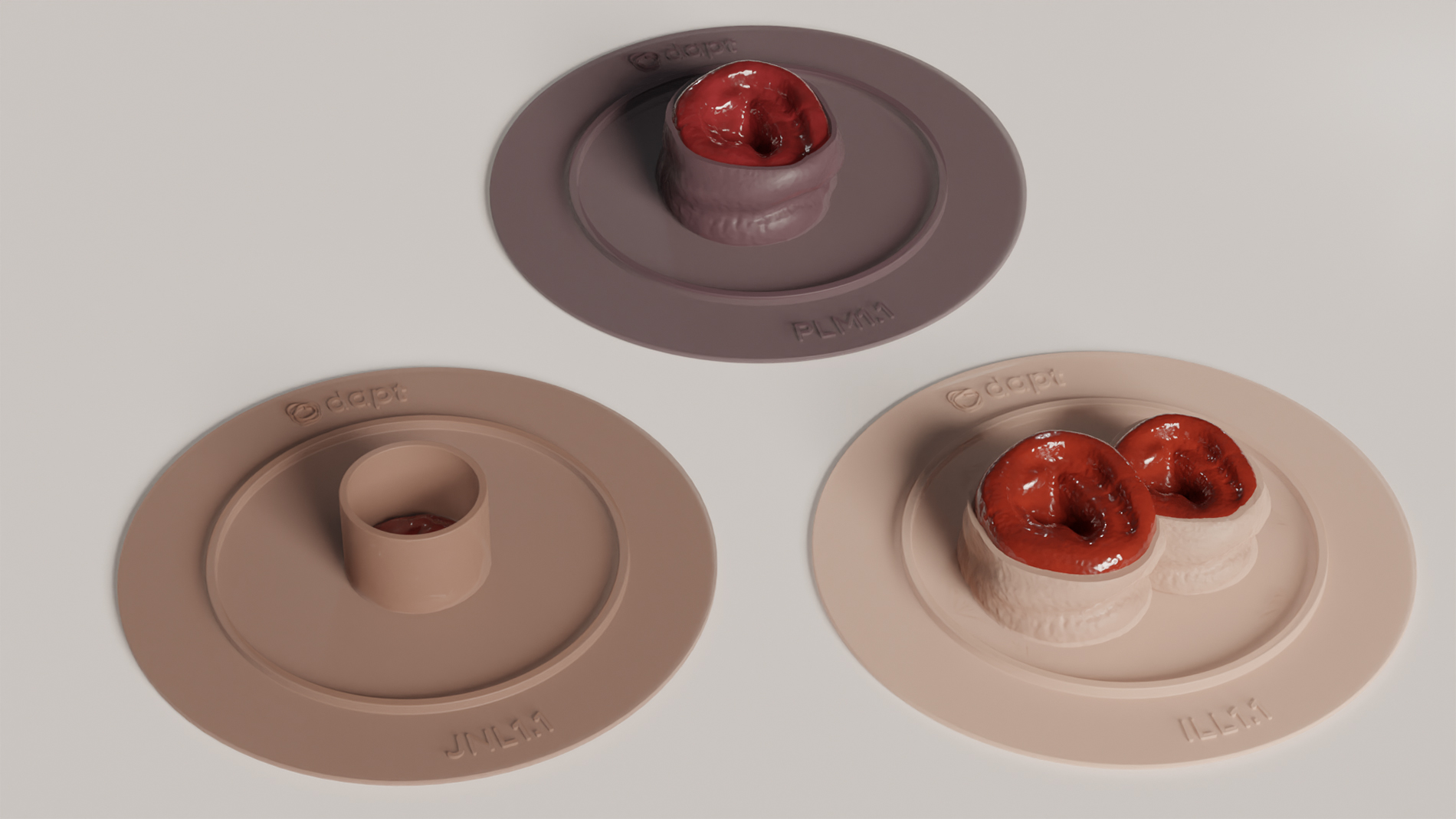

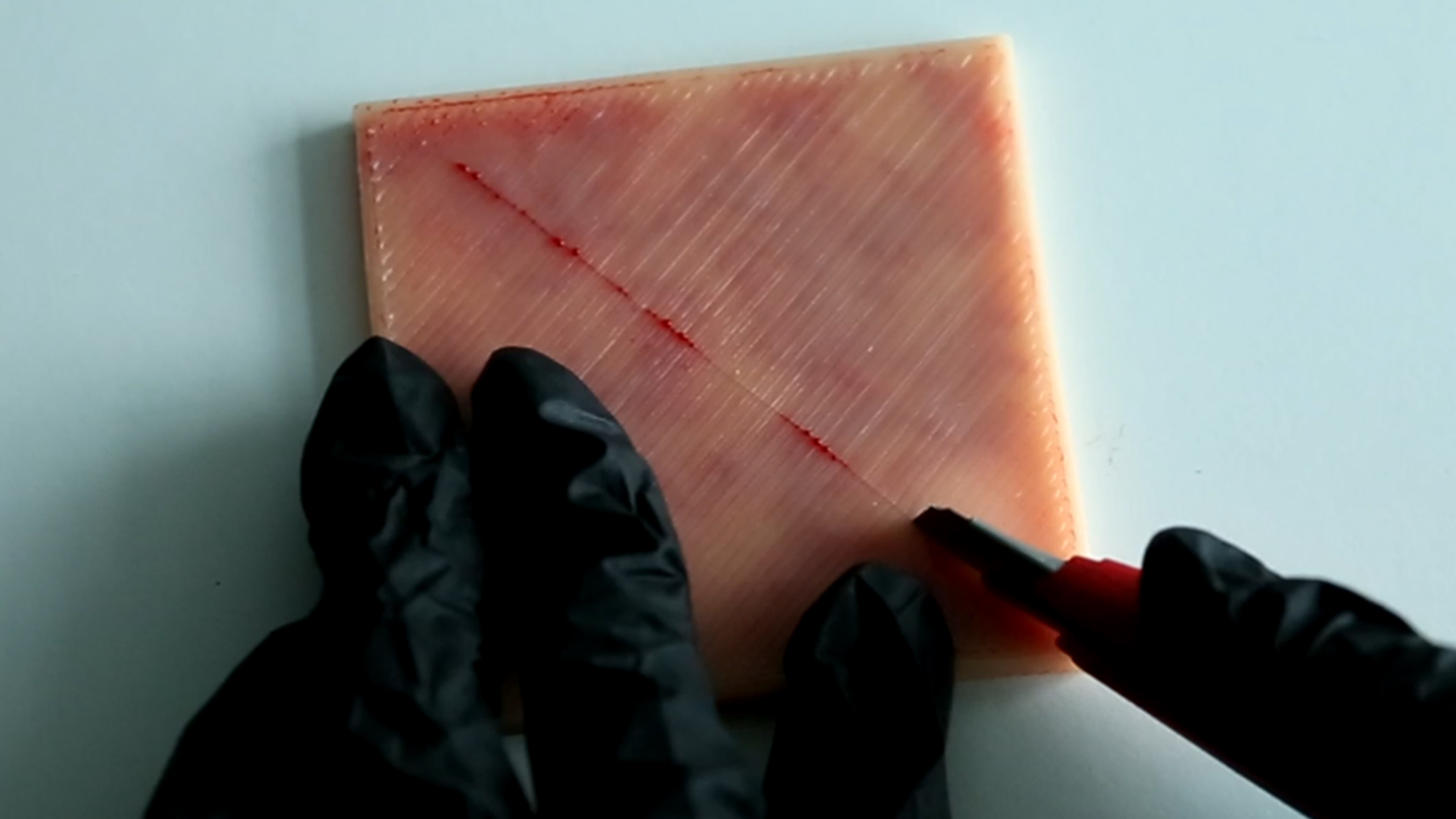

Lynxter has entered into a partnership with Assistance Publique Hôpitaux de Paris (AP-HP) and its 3D printing platform, Prim3D, with the aim of integrating silicone 3D printing into everyday hospital life. Among other things, this is intended to enable the development of medical simulators and ultimately reduce dependence on cadavers and animals for training purposes. Launched in January 2023 as an internal service provider for AP-HP, the Prim3D platform is aimed at medical professionals, researchers, industry players, and start-ups. As part of the collaboration, Lynxter's S300X – LIQ21 | LIQ11 and S600D machines have been installed at Prim3D, where they are enabling the production of realistic surgical simulators, complex anatomical models, and customized components for training or surgical planning, among other things. Prim3D acts as a beta tester that evaluates the integration of these technologies into the hospital environment.

Lynxter at Formnext 2025: Hall 11.1, Booth C69

Trends: Bayern Innovativ Printing at over 400°C

At this year’s Formnext, the Hutthurm Technology Campus of the Deggendorf Institute of Technology is presenting the Sim3dAPP research project, which is funded by the Bavarian State Ministry of Economic Affairs, Regional Development, and Energy. Sim3dApp's high-performance 3D printer operates at temperatures above 400°C, enabling it to process even high-performance polymers such as PEEK – something many industrial FFF systems have not yet been able to achieve. Sim3dAPP combines high-end hardware, AI, and simulations to make industrial FFF printing more efficient and precise. The system monitors the process in real time, detects errors, and automatically optimizes parameters. AI-supported simulations control post-processing and significantly reduce waste.

Technology Campus Hutthurm at Formnext 2025: Hall 12.1, Booth C71

Trends: Uni Bayreuth - complex silicone components with variable properties

Together with seven medium-sized companies, the University of Bayreuth is currently researching the further development of the Additive Manufacturing process Fluid Material Extrusion (“Fluid-MEX”). The aim is to produce complex components made of silicone with variable mechanical and physical properties. Fluid-MEX enables the tool-free production of functional components with locally variable properties such as elasticity, stiffness, or electrical conductivity. The focus is on elastomers: dimensionally stable, but elastically deformable plastics that return to their original shape after being subjected to stress. According to the University of Bayreuth, Fluid-MEX has enormous potential for the production of components that require special hardness (> Shore 80A) and functionality, such as seals, flexible connections, or shock-absorbing elements with complex geometries.

University of Bayreuth at Formnext 2025: Hall 12.1, Booth C71

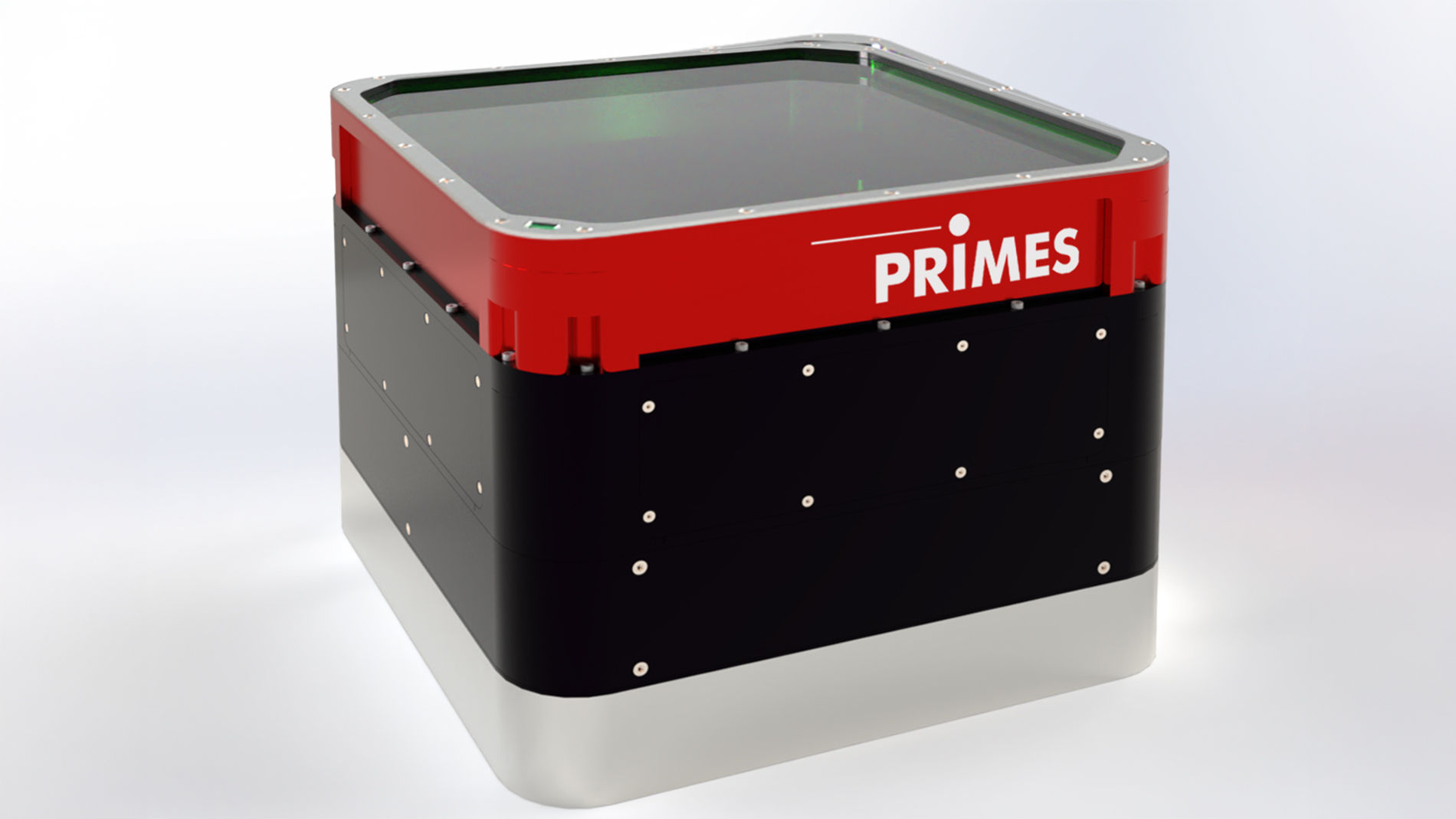

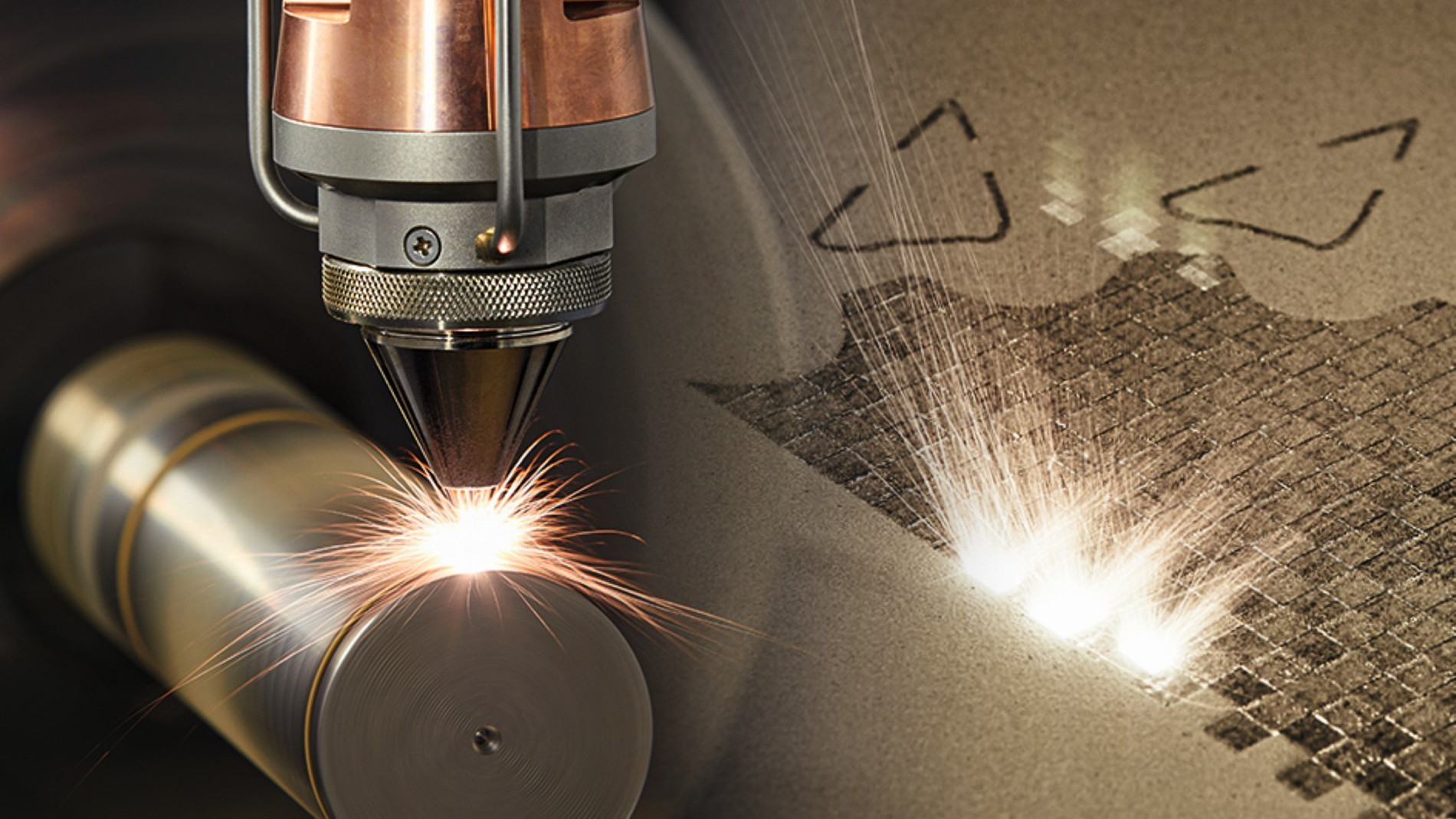

Metrology: Primes - measuring the entire scan field

Primes' ScanFieldMonitor 2D (SFM 2D) is the first system capable of measuring the entire scan field of laser scanner systems, enabling comprehensive calibration and process optimization. In less than a minute, the SFM 2D, which will be presented at Formnext, determines the positional deviations of the laser throughout the entire working area, calculates correction data, and checks its implementation. According to Primes, this reduces the time required for conventional scan field correction to a fraction of the several hours that are normally necessary. At the same time, the system records other key parameters such as marking speed, laser spot size, power distribution, and laser duty cycle. Primes has been developing and manufacturing systems for characterizing industrial laser beams for use in the automotive industry, plant engineering, Additive Manufacturing, research and development, and laser material processing for over 30 years. Based in the Rhine-Main area, the owner-managed company employs around 140 people.

Primes at Formnext 2025: Hall 12.0, Booth B101

Images: Primes

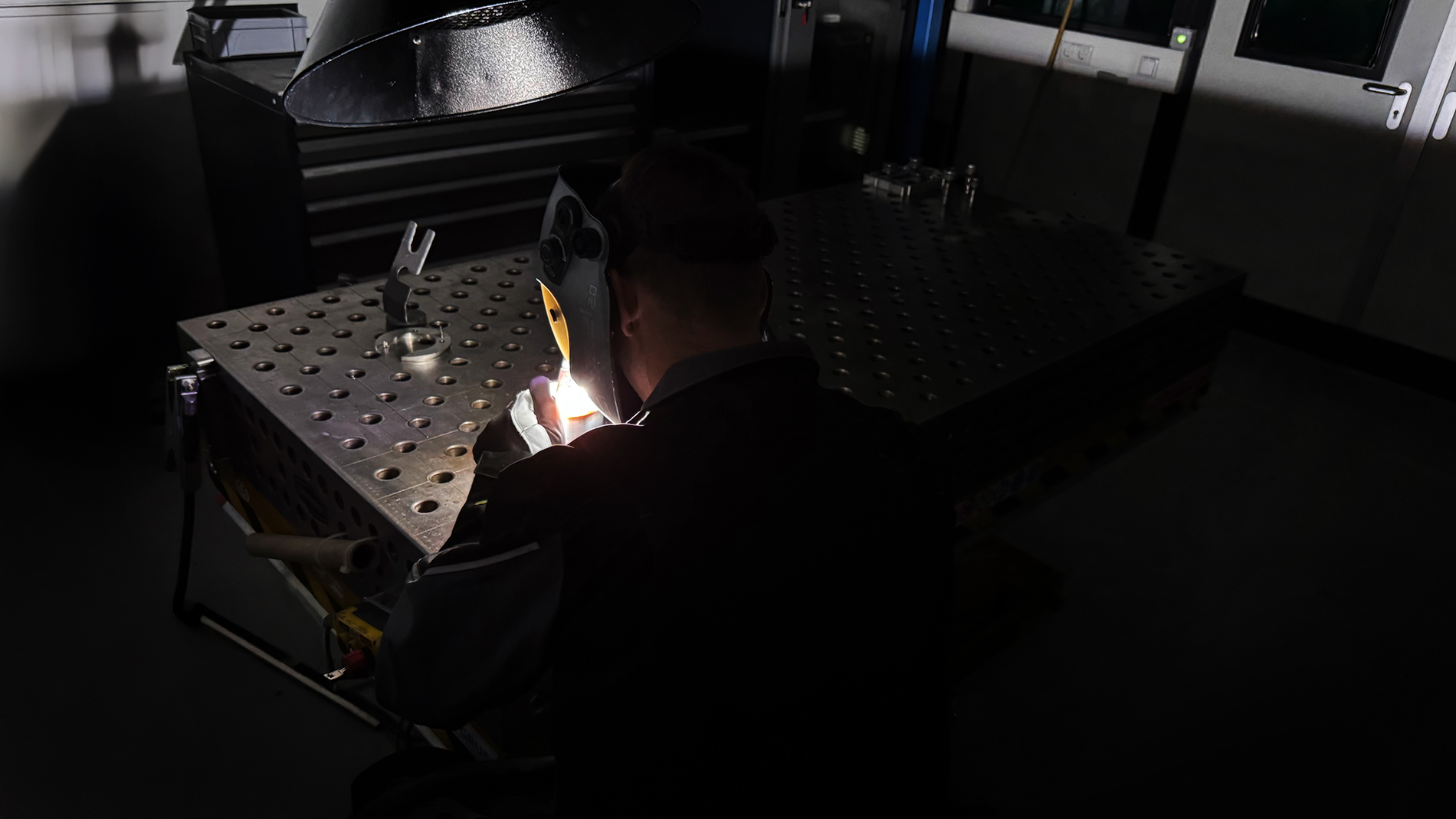

Joining processes for high-quality visible welds

Toolcraft AG is expanding its portfolio with additional joining technologies for precise and demanding applications. “In TIG welding, an electric arc is created between a non-consumable tungsten electrode and the workpiece. With or without filler material, precise, clean, and spatter-free welds can be produced,” says Christoph Barth, materials engineer and welding engineer (IWE) at Toolcraft. The process is particularly suitable for high-quality visible seams and materials with special requirements. According to Toolcraft, the advantages include universal applicability, precise heat control, and durable joints with high strength and corrosion resistance. Toolcraft uses the technology for a wide range of materials, including steel, nickel-based, and aluminum alloys. Typical areas of application are in aerospace, defense technology, mechanical engineering and fixture construction, and the semiconductor industry. Complex assemblies also benefit from the advantages of the process: Large-format structures can be joined and costs reduced through intelligent hybrid manufacturing. In addition, Toolcraft is developing innovative solutions for joining additively manufactured aluminum components.

Toolcraft at Formnext 2025: Hall 12.0, Booth D88