Text: Thomas Masuch; Pictures: Gienanth — 2021/05/15

The gradual electrification of the automotive industry is impacting many sectors, but perhaps nowhere are the effects being felt as strongly as in the foundry industry. At the moment, more than half of the metal components cast in Germany are built into road vehicles, but many of them will no longer be needed in future electric vehicles. Of course, e-mobility does present new business opportunities in this regard. However: »There won’t be enough alternative business to go around in the foundry industry in the years ahead,« predicts Simon Geib, head of project management and business development at Gienanth Group GmbH. This is why Gienanth, which boasts a centuries-long history in the aptly named town of Eisenberg (western Germany), has already adapted its strategy to the new challenges ahead – and could thus be blazing a trail for its entire industry. The 3D Printing of sand molds plays a key role in its approach.

The drivetrains of electric cars require only around half the parts of vehicles that run on conventional combustion engines. "As e-mobility continues to gain significance, you’re going to see more and more excess capacity in this regard," Geib reveals. "That makes for a very challenging future – especially for foundries that mainly supply the automotive industry." On the one hand, he believes this trend hasn’t yet arrived in the marketplace, and that the spare parts trade will mitigate its effects to some extent in the coming years. "Over the long term, however, there’s going to be a kind of natural selection in the casting market, and companies that only supply parts for combustion engines will inevitably leave."

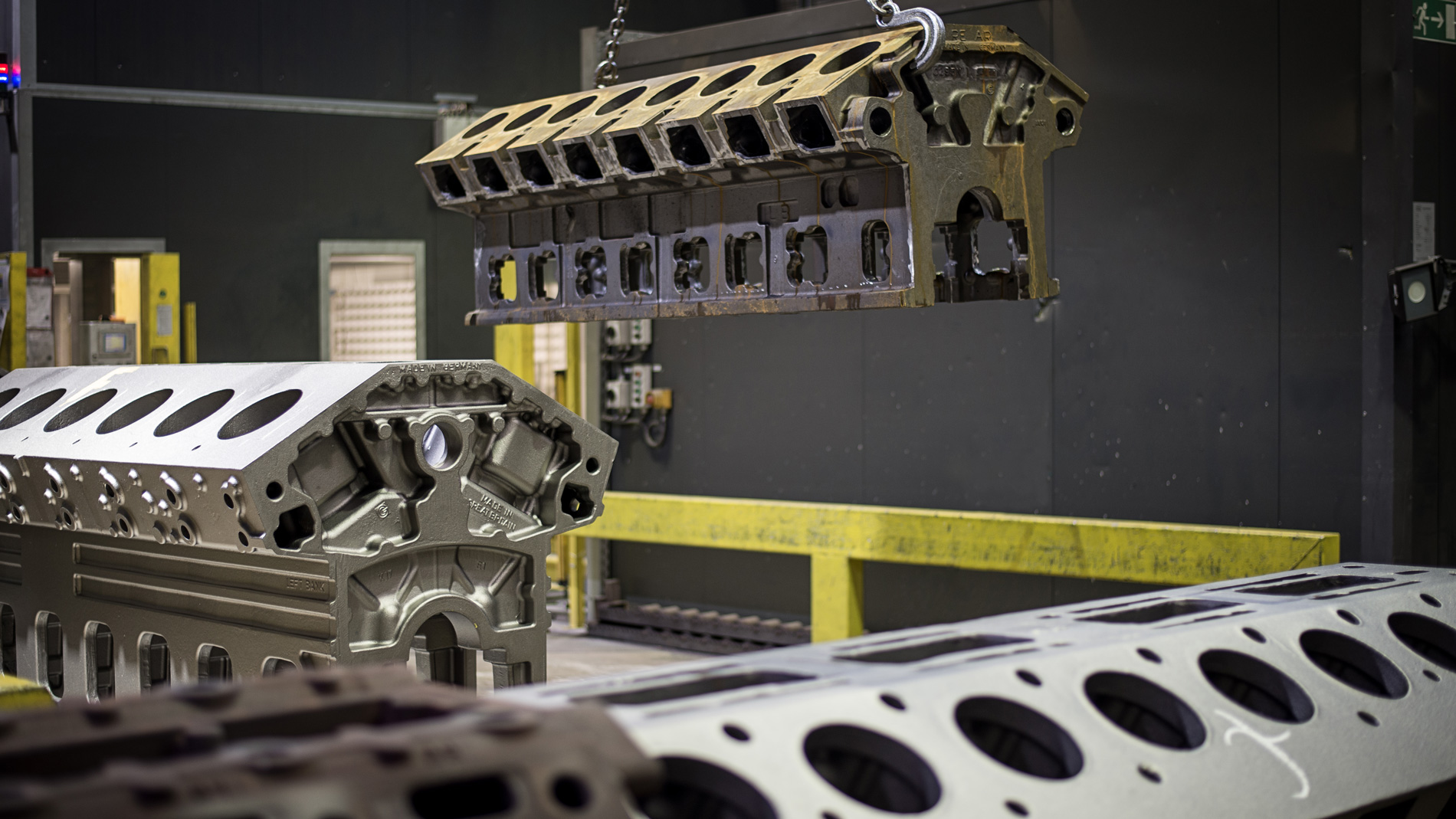

Founded all the way back in 1735, the Gienanth Group now does 20-25 percent of its business in the automotive sector, which means the impact of this development has been rather moderate. It has nevertheless already realigned its strategy to prioritize products that aren’t connected to the drivetrains of combustion vehicles. At the same time, Gienanth’s iron casting division is exploring the possibilities afforded by 3D-printed sand molds and cores (in metal casting, a core is the part of a mold that prevents metal from filling the entire mold) with a focus on new component designs and smaller lot sizes.

"3D Printing is a tool that takes engineering to the next level."

MORE EFFICIENT COMBUSTION

Elsewhere, Gienanth recently provided metal casting support to the Austrian engine developer AVL List GmbH in a research project to make heavy-duty engines even more efficient. The two partners wanted to optimize the combustion of these units – many of which weigh tons and see use in naval and power-generation operations – by achieving higher levels of ignition pressure with diesel, natural gas, and alternative fuels. Besides increasing efficiency, this reduces consumption, and emissions and operating costs along with it.

What might sound simple enough involved some profound technological challenges: Increasing ignition pressure beyond the maximum allowed by the current state of the art puts a great deal more stress on an engine, and in particular on its cylinder head. If the engine’s design is not modified, its useful life will be considerably shorter. To counteract this issue, the research project devised a new type of cylinder head with much better cooling properties and improved stability.

The cylinder head features reduced thickness and narrower conduits that optimize the flow of coolant and are thus capable of dispersing more heat. This innovative design, which AVL has since patented, used to be "technically impossible to realize in this way, but it can now be done by 3D-printing sand cores," explains Benjamin Heil, head of hand-molded casting projects at Gienanth. Heil has thus grown to appreciate 3D Printing as a "tool that takes engineering to the next level".

With AVL heading up this research project, Gienanth handled the development of the cast and the actual production of 10 cylinder heads. Some of the challenges involved had to do with achieving a very precise level of surface quality – and removing all the sand residue from the cast pieces.

Gienanth acquired the casting molds and cores it needed to form liquid iron at over 1,370 degrees Celsius from the service provider voxeljet. For the moment, the Eisenberg-based company is not planning to run its own 3D-printing equipment. "Placing orders with service providers gives us flexibility with regard to sizes and unit quantities," Simon Geib points out.

JUST A FEW MINUTES

For the casting experts at Gienanth, lot sizes in the single digits are rare; indeed, it usually deals in quantities that are many times greater. The group, which generates around €250 million in annual turnover, produces more than 15 million brake parts each year. According to Geib, this gives Gienanth a sizable share of the corresponding market in Europe.

For mass production purposes, the sand cores used in making the aforementioned cylinder heads will be manufactured using core shooting machines. Depending on the design in question, this takes between three and seven minutes. The production time on a 3D printer is much, much longer, but the traditional method requires tools that are very complicated to manufacture and can cost several hundred thousand euros. As a result, 3D-printed sand cores can be much more cost-effective when dealing with small lot sizes. That said, time is a factor: While 3D-printed cores can be made available in a matter of days, assembling the tools for a core shooting machine sometimes takes several months.

The use of 3D-printed sand cores in production processes nevertheless remains rather marginal, which Gienanth’s experts mainly attribute to the "considerably higher costs compared to traditional manufacturing". At the same time, it is possible to incorporate 3D-printed sand cores into mold consisting of other cores produced the conventional way. "This means 3D Printing can be a useful addition in the production of large quantities," Geib affirms.

"A LOT OF MOMENTUM IN ELECTRIC VEHICLES"

Meanwhile, the quantity at which 3D-printed sand cores make economic sense appears to be constantly rising thanks to the development of new 3D printers. Small series (meaning those of less than 1,000 units) and very small series (less than 20 units) have become the norm for service providers like voxeljet in recent years, but CEO Ingo Ederer could imagine six-figure amounts being produced in a cost-effective manner. "That would require things like automated unpacking solutions, though," he says.

At voxeljet, Bavaria’s pioneer in 3D sand printing, the upheaval brought on by the electrification of the automotive industry is already having a tangible impact. "We’re definitely seeing a decline – or at least a shift – in orders from the automobile industry," Ederer reports. "We’ve already been noticing a significant reduction in requests from projects involving combustion engines for some time. Meanwhile, we handled a number of major orders last year that showed us there’s a lot of momentum in e-mobility." In one example, voxeljet has 3D-printed molds for body components on behalf of larger manufacturers of electric vehicles. Ederer suspects these molds were initially used in the production of smaller lot sizes before being replaced by die casting tools.

PRESSURE TO OPTIMIZE PROMPTING A CHANGE IN MINDSETS

Back at Gienanth, the people in charge can foresee their new cylinder heads being manufactured with the help of 3D-printed sand cores – assuming the tests currently being conducted yield positive results, of course. If they do, a small production series will be the next step. Depending on the number of cylinders at hand, up to 24 cylinder heads can be screwed onto a heavy-duty engine one by one. Corresponding demand is on the rise with regard to both new engines and replacement parts.

The megatrend toward customization – and thus to relatively small lot sizes – is also evident in the casting industry, which Simon Geib says was almost never the case in the past. After all, larger series were (and still are) more profitable most of the time. Geib reports that this is another area where mindsets are changing, however, and 3D Printing could play a more prominent role going forward. As for other applications in the casting industry, Geib and Benjamin Heil believe Additive Manufacturing has potential in the ongoing pursuit of greater environmental awareness and energy efficiency, which is what has led to more pressure to optimize things like heavy-duty engines. They say this is changing the way people think about design and manufacturing processes, as well. "The development cycles in these industries are relatively long, though: For heavy-duty engines, they’re several times longer than for utility vehicles or passenger cars," Geib explains. "Still, things are starting to get rolling."

GIENANTH GROUP GMBH

Founded as the "Hammerwerk" in Eisenberg (western Germany) in 1735, Gienanth is now one of the longest-standing companies in Germany. One of its locations in Bavaria even dates all the way back to the year 1449. Gienanth has since evolved into an international corporate group that employs some 1,800 people and generates around €250 million in turnover each year. Its products and solutions include highly complex cylinder crankcases and cylinder heads designed for heavy-duty engines with between 1,000 and 15,000 horsepower. Among other settings, these engines see use in power generators, locomotives, and ships.

gienanth.com

AM TECHNOLOGY:

Additive Manufacturing for metals/Binder Jetting

A structured overview of the complex and multi-layered world of Additive Manufacturing, the process chain and areas of application is provided by our AM Field Guide.

Tags

- Automotive