4 November 2024

As a contract manufacturer, Bosch Advanced Ceramics specializes in the innovative field of the Additive Manufacturing (AM) of ceramics and produces high-performance, innovative components for various industries worldwide.

One of its most recent projects, the production of a very small, intricate sleeve for a medical technology company, showcased the company’s highly specialized expertise. The sleeve electrically insulates a 0.5 mm wire in a laparoscopic instrument (used to carry out procedures such as laparoscopies). With an outer diameter of just 3.5 mm, the compact dimensions of the instrument mean that the wall thickness at the top of the sleeve is only 90 µm. This delicate structure, which is almost impossible to produce using substractive manufacturing methods, requires exceptional precision throughout the entire process, including the cleaning of components.

This level of detail can only be achieved with the right material and the perfect process parameters. This compensates for over-polymerization and ensures accurate reproduction of the most intricate features.

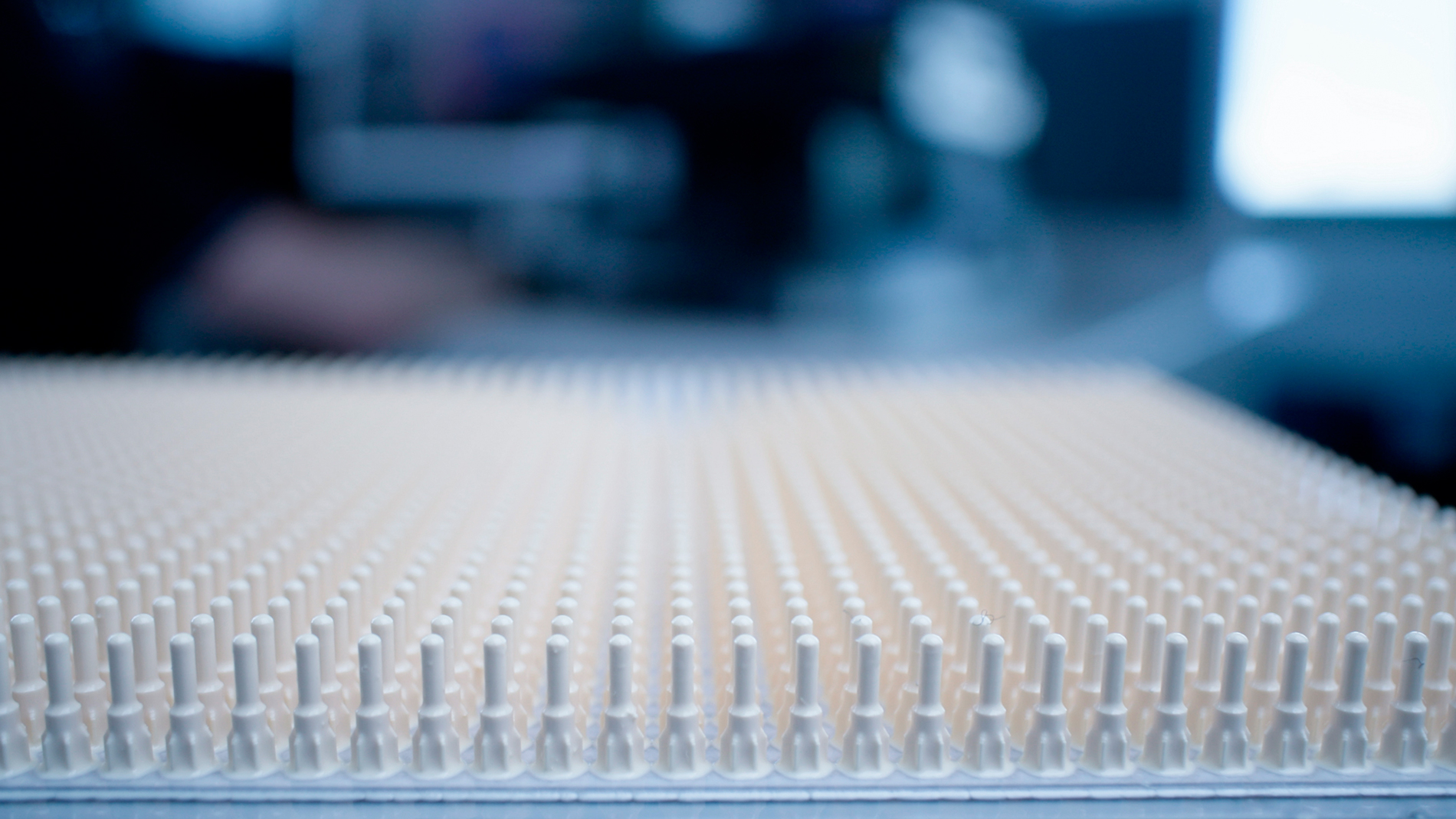

During a 5-month development phase, the Bosch Advanced Ceramics team determined the ideal balance of wall thickness and electrical insulation. Producing the sleeve using additive manufacturing is also highly efficient. Up to 1,400 parts can be produced in one printing process, meeting the annual requirement of up to 50,000 parts.

Thanks to innovations such as the sleeve, laparoscopic instruments are continually decreasing in size, enabling smaller incisions during operations and faster healing. Bosch Advanced Ceramics is one of the few companies in the world with the necessary expertise to successfully execute AM ceramic manufacturing projects of this nature.

FURTHER INFORMATION:

Bosch Advanced Ceramics at Formnext 2024: Hall 11.1, Booth B21

Tags

- Additive Manufacturing