Text: Thomas Masuch; Photos: Zikomm — 29 November 2020

For small and midsize companies, industrial 3D Printing isn’t just an applicable technology – it’s a real field of business. For a perfect example, look no further than Bernstein Mechanische Fertigung of Grüna, Germany. While it was purely a contract manufacturer a decade ago (and still makes use of its machining centers), BMF now produces 20 surface-treatment machines each year, which account for half of its annual turnover.

People who visit Grüna might not expect to find a local company with a good bit of sway in the world of Additive Manufacturing. The village is located along an arterial road to the west of Chemnitz – an eastern German city that, despite its rich industrial heritage, has only just dug itself out of the prolonged hard times that followed the fall of the Iron Curtain. Here, one finds single-family homes with flowery front yards nestled among the rolling hills just to the northwest of the Ore Mountains.

Grüna has one bakery, two hotels, and a brick church steeple that is likely the highest point in the town. BMF’s modern facilities are located right next to a garden that features thriving tomatoes and vegetables in the summer. Its main building efficiently combines several machining centers, a training area, and development and assembly departments. Following its foundation 13 years ago, the family-owned company evolved into a specialized contractor in CNC manufacturing. Among other things, it now produces sophisticated parts for luxury items, high-end vehicles, and medical technology.

"Post-processing is becoming increasingly important in Additive Manufacturing, including from a financial perspective."

»We used to have problems all the time with sandblasting because it would leave parts with an inconsistent surface,« recalls Ronny Bernstein, BMF’s 41-year-old managing director. He points out that particularly in the luxury segment, this makes components unusable. Ever the entrepreneurial engineer, Bernstein then started looking for a solution of his own along with his team. This led to the development of an installation the company began using to meet its internal needs in 2013. »We eventually had a customer come by who asked what the unit was and ended up wanting one of his own,« Bernstein says.

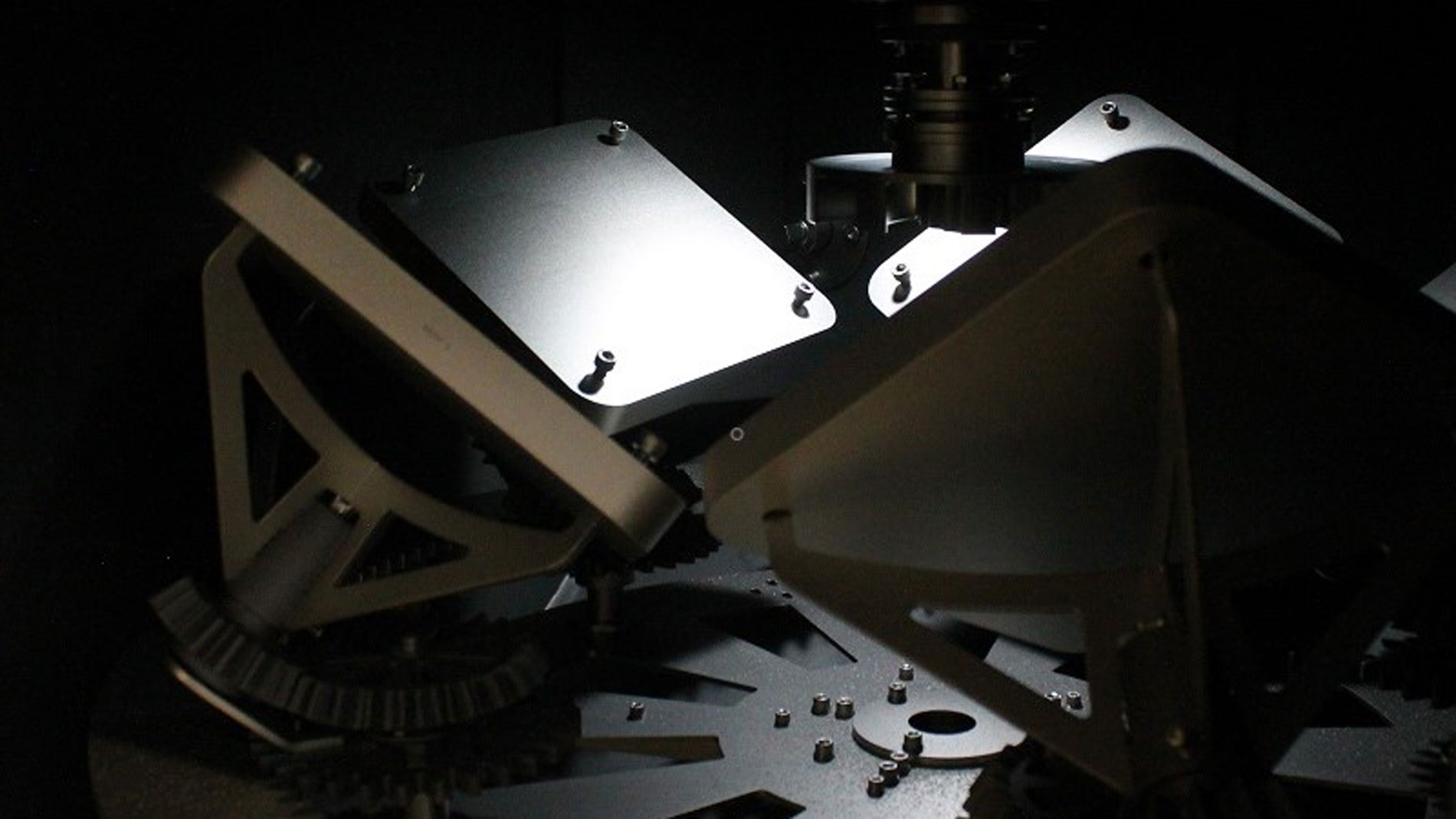

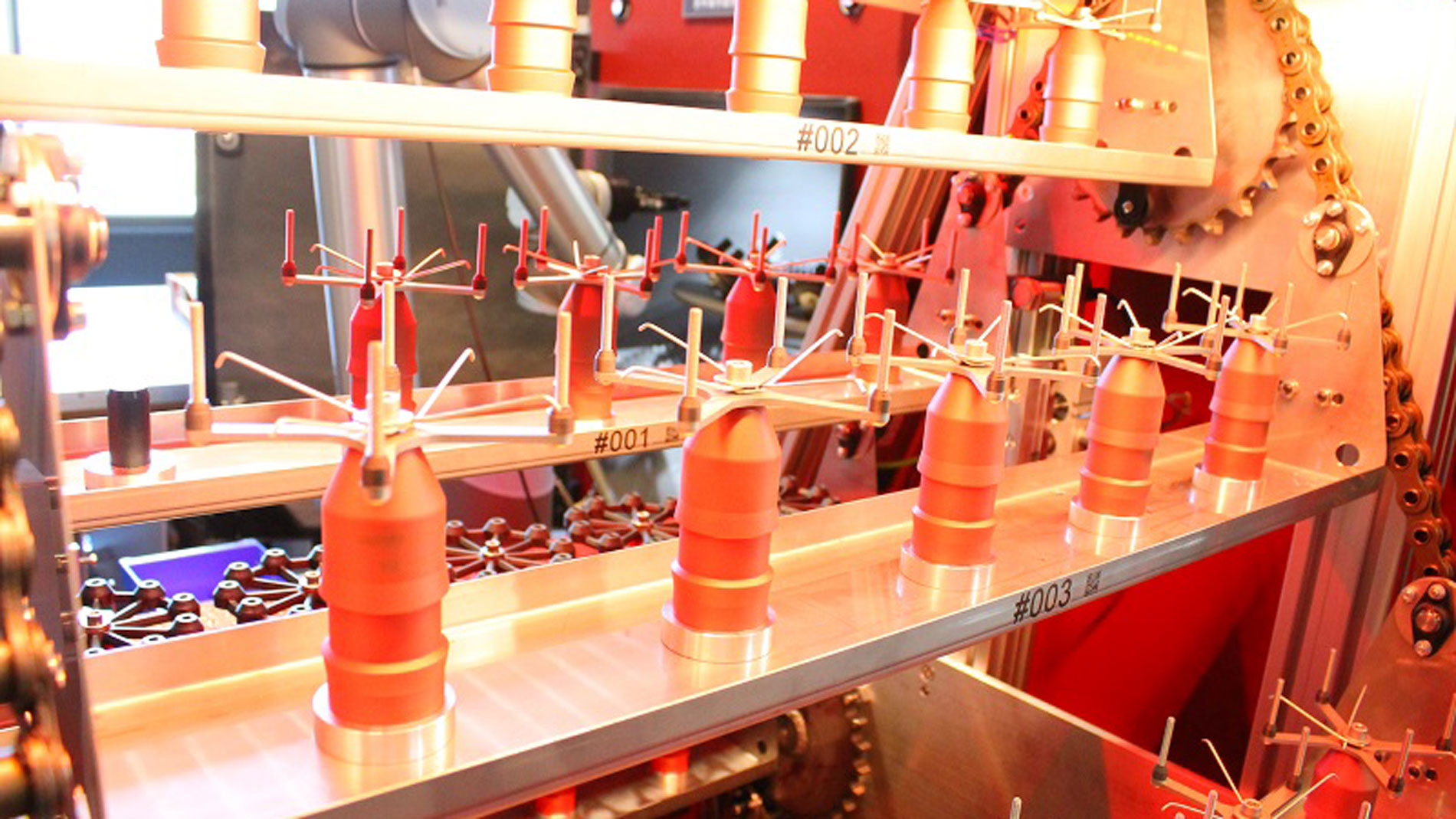

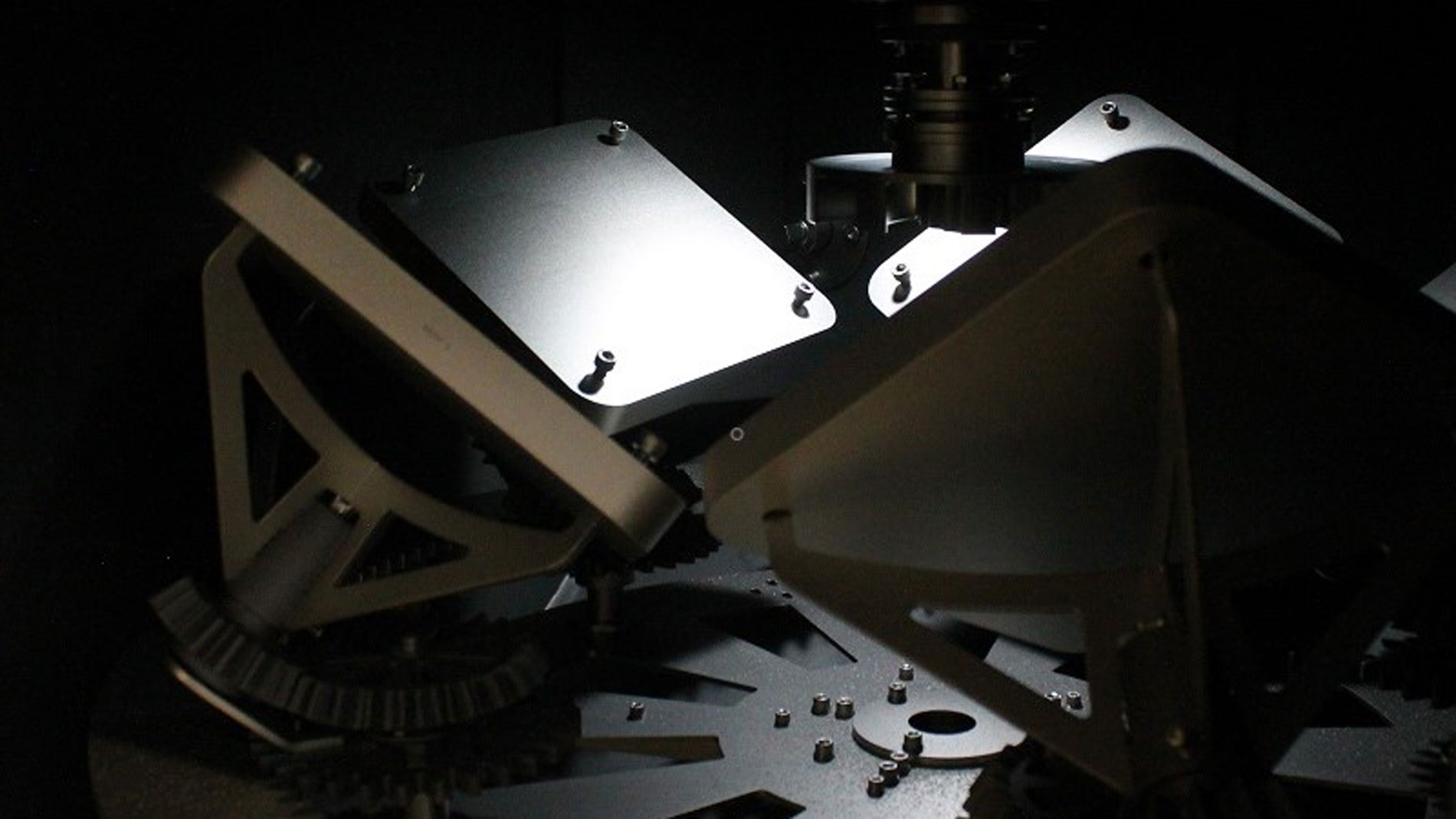

BMF thus turned the system into a full-fledged product: the Twister blasting installation. At its heart is a rotary plate with rotating component mounts. In the middle of this carousel, a rapidly rotating blast wheel featuring patented blade geometry ensures that the blasting material is evenly distributed within the unit.

Die ersten Anlagen gingen an regionale Unternehmen aus der Fräsbearbeitung. Nach und nach erkannte man bei BMF, dass das Potenzial des Twisters noch größer ist. »Bei der additiven Fertigung wird das Postprocessing immer wichtiger, auch in finanzieller Hinsicht«, erklärt Marc Krause, der sich als Mitarbeiter der BMF Vertriebs GmbH seit drei Jahren für den weiteren Erfolg des Twisters einsetzt und dabei den Vertrieb und die Prozessentwicklung betreut. »Bei additiv gefertigten Bauteilen liegt der Kostenanteil der Nachbearbeitung an den gesamten Produktionskosten inzwischen bei 30 bis 40 Prozent. Während der Druckprozess in den letzten Jahren immer günstiger geworden ist, blieb das Postprocessing etwa gleich teuer, da die Arbeiten hier zu 90 Prozent manuell getätigt werden.«

Seitdem BMF mit dem Twister auch die additive Fertigung entdeckt hat und die Anlage auch auf Messen wie der Formnext präsentiert wird, hat der Verkaufserfolg deutlich angezogen. Inzwischen sind 80 Anlagen installiert – neben zahlreichen europäischen Ländern auch in Indien und seit Herbst 2020 in den USA.

Den Erfolg der Strahlanlagen, die zu 90 Prozent aus der eigenen BMF-Fertigung stammen, führt Krause im Wesentlichen auf die technischen Vorteile zurück, die sich wie der heilige Gral des Strahlens anhören: »Wir erreichen reproduzierbare Ergebnisse in einem automatisiertem Prozess, der auch in eine automatisierte Fertigung eingebunden werden kann«, schwärmt Krause. Zudem werde das Strahlmittel nicht per Druckluft, sondern mittels Schleuderrad beschleunigt, woraus eine hohe Energieeinsparung allein durch den Wegfall der Druckluft resultiere. Die Oberflächengüte in Form von Ra- (Mittenrauwert) und Rz-Werten (gemittelte Rautiefe) lässt sich anhand der Drehzahl des Schleuderrades in der Anlage einstellen.

Requirements with regard to surface quality have risen

This is how the Twister – and its big brother, the Tornado, which was unveiled in 2016 – ensure that the right type of surface is applied to shifting forks for transmissions, trays for blood plasma centrifuges, dental implants, retrofits for automotive engine comproponents, and many other products. These blasting units continue to be used for machined parts, as well. »Our customers’ requirements with regard to surface quality have generally risen over the past several years,« Krause reveals. »More and more often, functional components you normally can’t see are also being blasted to improve their appearance and promote sales.« At the same time, the 49-year-old (who already has 25 years of experience in building prototypes) is seeing increased demand from AM service providers, whose expectations have also changed. »Instead of just one part, customers are now ordering 50 or more, and they all need to look the same,« he reports.

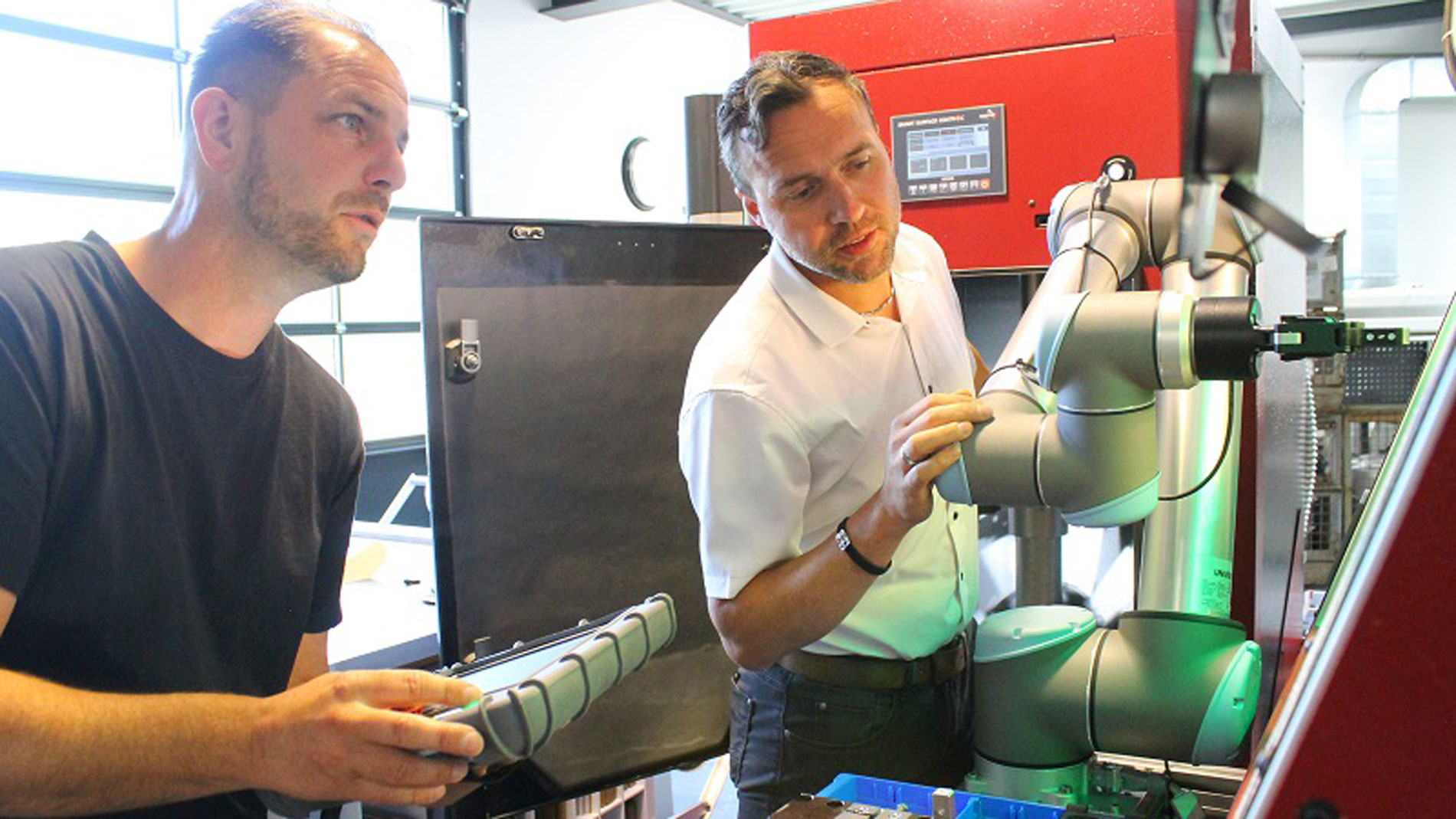

The innovative ways in which BMF is taking advantage of Additive Manufacturing are also apparent in the area of spare parts. The drive wheels of the Twister’s rotating component mounts, for example, were created in a 3D printer from Markforged. To make sure that replacements for these wear parts will always be readily available, identical printers have been installed at customer facilities in places like Denmark and India to produce the spares required on-site when ordered. The printers are controlled from Grüna; the customers only have to insert fresh spools and remove the parts when finished. »We don’t have to ship anything, and nothing has to go through customs checks,« points out a pleased Ronny Bernstein. For Markforged, this innovation was so compelling that the global manufacturer made the trip all the way from bustling Boston to BMF’s peaceful hometown to check out its applications in person before adding them to its international marketing campaign.

FURTHER INFORMATION

Tags

- Surface treatment