17 May 2023, by Thomas Masuch

The manufacturing of prototypes and small series is a rather traditional industry that is largely made up of small and midsize companies. This is where the young enterprise Priomold has turned in an impressive run of growth, one that has made it one of the largest providers of its kind in Germany. Having initially perceived Additive Manufacturing as a threat to its business, Priomold is now hoping that the technology will help it write the next chapter of its success story.

The fields of the northern Black Forest are covered in frost this winter morning. An icy wind is blowing across the gently rolling mountain landscape that surrounds the town of Schömberg (elevation: 650 meters). In the business park of this community – which is otherwise most known for its spa and wellness facilities – a few electric vehicles stand in a row next to the entrance of a three-story building that looks like it was made to house both offices and industrial operations. Up on the second floor, we find employees dressed in t-shirts attending to their machines. The conditions outside would otherwise make their attire surprising, but not here: The heat emanating from the injection molding units that fill the space in two long rows is providing for a rather balmy temperature.

Pellets of plastic are being melted down and injected into molds, producing components that roll off the conveyor belts alongside the machines nearly every second. We’re not allowed to take pictures of the parts; they’re prototypes and small series, some of which are meant for automotive customers that plan to build them into their next-generation vehicles. That makes them closely guarded secrets, and the people who make them are required to sign corresponding NDAs.

There must be hundreds of companies with similar product portfolios in Germany alone. In this highly concentrated market, Priomold has nevertheless managed to advance from a start-up to the country’s largest manufacturer of prototypes and small batches in just eight years. The company and its 65 employees generated €8 million in revenue last year – and that’s without any investment backing, just a clear strategy. “For us, the ability to deliver quickly is key,” explains 32-year-old Thomas Schönbucher, who founded Priomold in 2015 along with Moritz Zumdick, a friend from university with whom he shares management responsibilities at the company. In prototype manufacturing, Priomold guarantees turnaround times as short as one week.

Worry and motivation

Even though the company used nothing but injection molding machines in its early years, Schönbucher and his team still made sure to exhibit at Formnext. “We were something of an exotic animal among the other exhibitors,” he admits with a grin. The aerospace engineer then reveals the secret of Priomold’s success back then. “Firms that were looking for 3D-printed parts usually needed injection-molded prototypes or small series, too.”

Priomold’s first appearance also had a memorable anecdote in store for Schönbucher, one that would go on to have a certain amount of influence on the company’s future development. “A company that was all about providing AM services was presenting at a booth next to ours, and one of their staff told me Priomold wouldn’t be around in five years because soon, everything would be 3D-printed,” he recalls. For Schönbucher, who had just gotten his company off the ground, that claim was a source of both worry and motivation. Today, he can have a good chuckle about hype-driven predictions like these, which seldom have a long shelf life.

Additive Manufacturing has actually been a constant companion for Schönbucher over the course of Priomold’s development. “In our SWOT analyses, 3D printing keeps popping up as a threat to our business,” he affirms. “We eventually decided to go ahead and incorporate the technology into our own operations.”

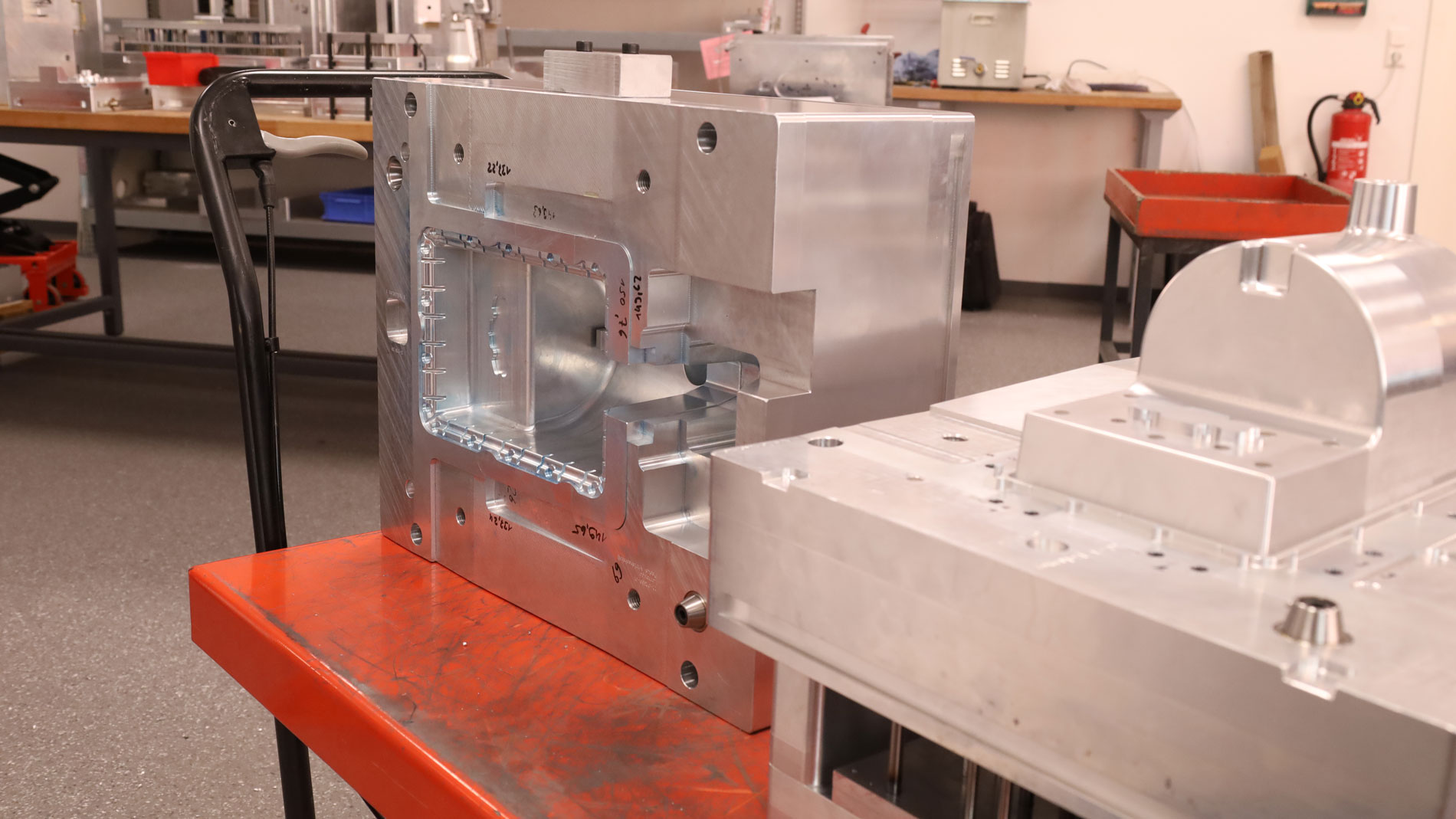

On dozens of cutting machines Priomold manufactures aluminum segments. Later, by assembling them, these injection molds are produced.

After all, Priomold needed to have AM technology and corresponding expertise in order to hold its own in the new market in case this innovation does turn the production of plastic parts entirely on its head one day, as Schönbucher points out. “Plus, it was a chance to turn that threat into an opportunity.”

SLS manufacturing “no longer an experiment”

Fast-forward to 2021, which was when Priomold made the decision to get into SLS technology in order to “be able to offer prototypes with the same kind of surface quality and mechanical characteristics as mass-produced parts,” as Schönbucher recalls. He attributes this move to the tremendous rise in related expectations, which now has customers demanding prototypes with at least the same level of quality as serial components – if not higher. “Prototypes get passed around a lot, after all, and at an automotive corporation, they sometimes make it all the way up to the board,” Schönbucher points out.

Just a week after acquiring an EOS Formiga in 2022, Priomold was ready to ship out its first sintered plastic components to customers. Felix Parsch, who oversees the company’s AM production project, believes that Priomold was able to implement this new technology so quickly because “SLS is no longer an experiment; it’s an industrial manufacturing process that works.”

While Parsch has only been with the company officially since last year, he had already helped out previously in its production operations while studying for an aerospace degree. More than anything else, 3D printing is enabling Priomold to stay competitive even when jobs involve very small production runs. “We didn’t want to risk losing that kind of business to AM service providers,” Schönbucher reveals. “With our own SLS equipment, we’ve already been able to score some wins.”

Image left: Thomas Schönbucher (32) started Priomold in 2015 along with Moritz Zumdick, a friend from university. Image right: Felix Parsch, who heads up Priomold's AM production project, operates the company's Formiga unit.

Second machine on the way

Every week, Priomold’s EOS Formiga unit prints around 400 parts (mainly from PA12), which range from various mounts and fixtures to casings for endoscopes and vehicle charging stations, and even display models of implants. The company supplies customers from a variety of industries, including mechanical engineering, medical technology, automotive construction, and electronics.

Although he acknowledges that the market for AM services is already very price-driven due to the many providers in the business, Schönbucher wants to keep expanding Priomold’s AM division. “Thanks to our speed and expertise, we’re keeping pretty busy in this area, and we’ve already got a second machine on the way,” he reports.

The Formiga can be found on the lower floor of the company’s space next to an unpacking station, a table for powder removal, and equipment for adding color to printed parts. Head through the next door and you’ll enter a room some 20 meters long filled with dozens of milling machines. Everything is clean and has the feel of a laboratory, which due in part to Priomold’s preference for dry machining – that is, milling components without using coolant. This area is where blocks of aluminum are turned into parts for the molds that give other parts their shape in the injection molding units upstairs. Aluminum molds like these can produce around 20,000 components before requiring correction.

Every second counts in the prototype phase

With the help of AM, Priomold wants to keep reducing its already speedy delivery times – to just two or three days, in fact. Felix Parsch is even willing to drive components over to customers himself when time is absolutely of the essence. This is definitely the case in some projects, as Schönbucher knows from working with the major automotive companies in the region around Stuttgart. “When a car company is in the middle of a prototyping phase, every second counts,” he affirms.

This area of southwest Germany is where Priomold generates most of its turnover, 75 percent of which comes from customers across the country (with the remaining quarter attributable to clients elsewhere in Europe). Over time, Schönbucher has grown used to the special rules that apply to the production of prototypes and small series. The lead time for orders is relatively short: just four to five weeks in most cases. Not even Priomold’s two managing directors know what they’ll be manufacturing six weeks from now. “What we do know is that we’ve sent out enough quotes, and that orders always come in,” Schönbucher says. “Doing business like this does come with quite a lot of pressure, though – especially when you’ve got more than 60 employees on the payroll.”

Learning to let go

In spite of that pressure, Schönbucher -- who grew up right here in the northern Black Forest himself – wants Priomold to keep growing. Why? “Because we can; we’re young and we’re having fun doing it,” Schönbucher declares. He then reveals what the biggest challenge has been: “In the beginning, we did everything ourselves. When we had 10 people on staff, I was right there with them, running the machines and writing up quotes. You gradually have to let go of a lot of things, and your role in the company changes a few times over the years.”

While rapid growth does require a constant influx of new employees, this is another aspect Schönbucher sees as an advantage. “Fresh faces are always a source of fresh input, as well, and that helps us evolve,” he says. This has also enabled the company to improve on the technological side, where the CEO cites a case in which Priomold was able to cut its tool machining time by around half. Meanwhile, Schönbucher says that the company’s growth has qualified it to take on larger orders. “That’s another area where we want to keep making progress; we’re just getting started!”

MORE INFORMATIONS:

To learn more about the SLS procedure (Selective Laser Sintering) check out the AM Field Guide.

Tags

- Services

- Tool and die making