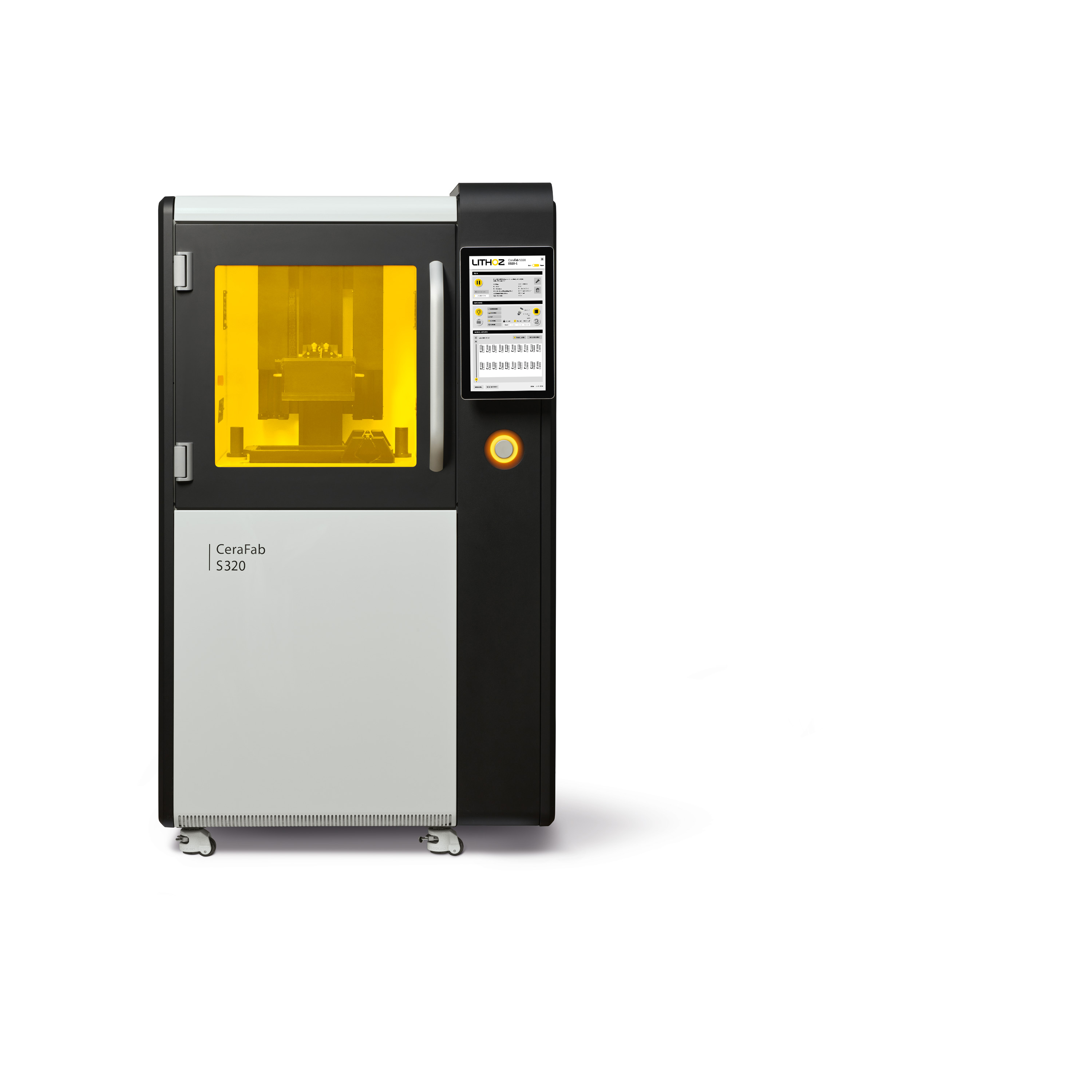

CeraFab S320 NEW

CeraFab System S320 – High-Throughput LCM Printer for Mid-Sized Ceramic Components

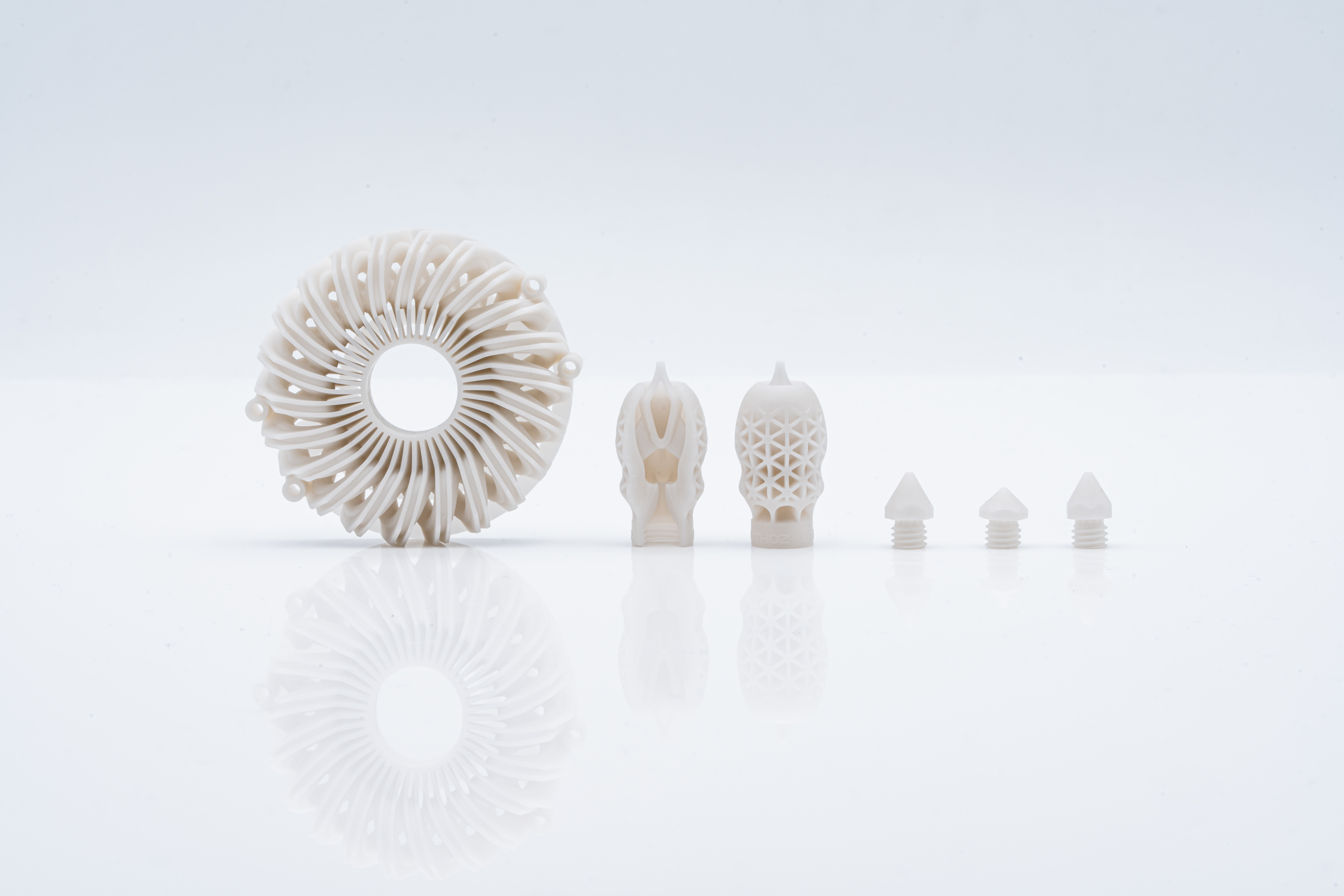

The CeraFab System S320 is the latest advancement in Lithoz’s LCM (Lithography-based Ceramic Manufacturing) platform, specifically engineered for the industrial-scale production of mid-sized technical ceramics. With a fivefold larger build platform compared to the S65, the S320 is optimized for volume production, offering unmatched productivity while maintaining high-resolution output across an expanded surface area.

Key Technical Features 1. Build Volume & Throughput

Build Volume: 246 x 130 x 320 mm

→ ~5× larger than the S65, enabling significantly higher part yields per build job or the printing of much larger components

External Dimensions: Identical to the S65, allowing direct integration into existing production lines without additional spatial requirements

Layer Speed: Up to 150 layers/hour, equal to the S65, but with much greater part throughput per run

2. Optical System & Resolution

Projection System: 4K UV projector (405 nm wavelength)

XY Resolution: Up to 60 μm over the entire build area

Slice Thickness: Adjustable between 20–200 μm, enabling flexible trade-offs between precision and speed depending on application

Compared to the WQXGA projector on the S65, the S320’s 4K optics ensure consistent high resolution over a much larger exposure area, supporting both finer detail and broader geometries

3. Thermal Management

Integrated Twin-Chamber Heating System:

Maintains stable and uniform temperature distribution across the large build platform, ensuring material homogeneity and reliable inter-layer bonding

Advantage over S65: This dual-chamber design improves temperature regulation in larger builds, where heat distribution is critical for process consistency

4. Material Handling & Print Continuity

Dual Automatic Dispensers (2 × 650 g):

Enables extended, uninterrupted print jobs, ideal for overnight or multi-shift operation — an enhancement over the S65’s single-feed configuration

Pinpoint Dosage Control:

Maintains ultra-low material waste, consistent with S65 performance

5. Software & Process Control

CeraControl software integration for full system automation and inter-printer synchronization

Supports networking of up to 100 systems, enabling synchronized, distributed production across global facilities

Real-time process monitoring and job documentation ensure full traceability for serial production environments