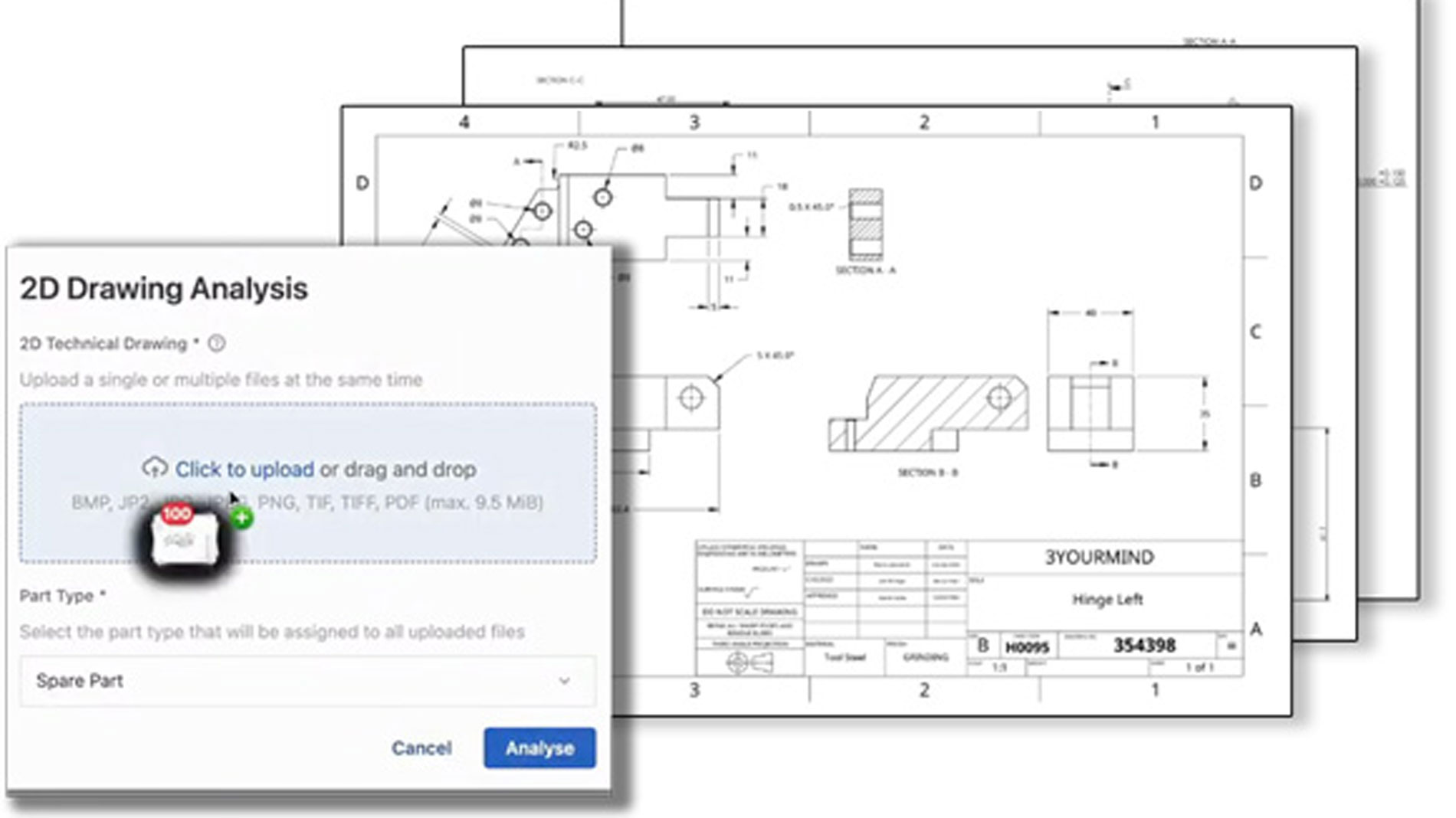

Designed to accelerate spare part digitization, the software can analyze 2D technical drawings up to 200 times faster than manual methods according to the Berlin-based company. The solution is now ITAR-compliant and available through secure cloud hosting.

“In many industries, technical drawings remain the primary reference for manufacturing spare parts,” says Stephan Galozy, chief product officer at 3Yourmind. “By streamlining this otherwise manually intensive process, we’re helping to accelerate the next step: creating the 3D file. Our long-term vision for this functionality is text-to-3D.”

Technical Drawing Analysis extracts and interprets data across various formats and layouts using optical character recognition (OCR) and large language models (LLMs) to extract and analyze metadata from title blocks, drawing notes, and annotations. The software then uses this information to evaluate spare part manufacturability and determine whether parts can be produced using standard manufacturing methods, including AM techniques like laser and electron-beam powder bed fusion (PBF-LB and PBF-EB), material extrusion (MEX), vat polymerization, directed energy deposition, and binder jetting.

Technical Drawing Analysis can also forecast costs and lead time, thus shortening the decision-making process when considering whether legacy parts should be manufactured through traditional means or Additive Manufacturing. The software also helps engineers identify which parts to digitize by extracting key information, such as notes and annotations.

The feature can also analyze individual parts or process thousands of technical drawings simultaneously, streamlining the process of creating new 3D models and addressing a common bottleneck in equipment sustainment workflows. In addition, 3Yourmind says it addresses long-term challenges in digitizing spare parts by creating a centralized hub with standardized data practices.