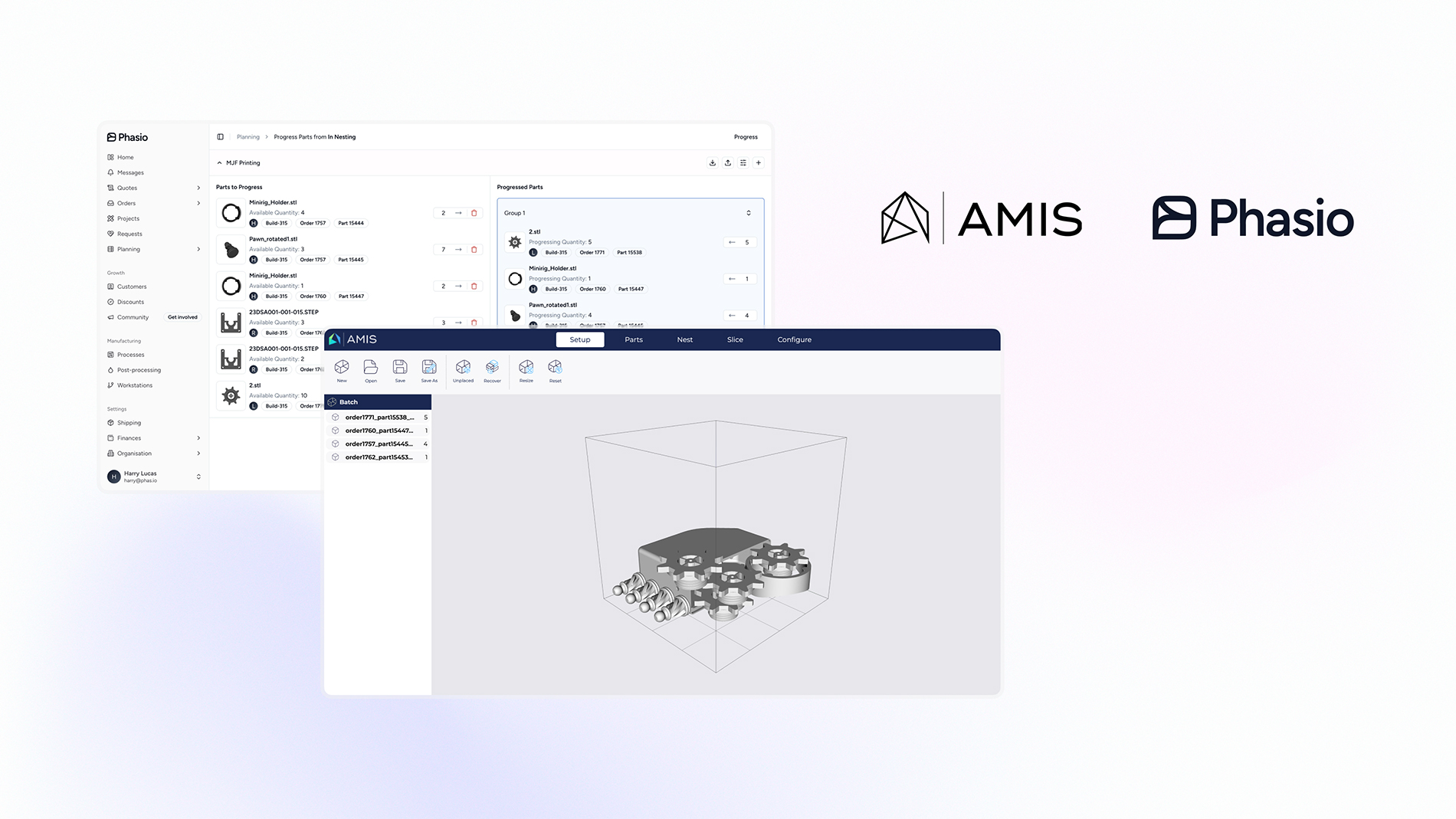

AMIS: Live demonstrations highlight seamless data flow

Phasio and AMIS will be presenting their newly integrated software solution for optimizing Additive Manufacturing workflows with live demonstrations at Formnext 2025. The companies’ collaboration brings together two powerful platforms: Phasio’s end-to-end digital production workflow and AMIS’s build preparation software. According to the two partners, this integration enables manufacturers to proceed from quote to delivery with unprecedented speed, accuracy, and efficiency while minimizing human error. At Formnext, visitors will have the opportunity to experience the solution firsthand through live demonstrations at both the Phasio and AMIS booths. These sessions will highlight how data flows seamlessly between the platforms, how builds are automatically prepared for various 3D printing technologies (including MJF, SLS, binder jetting, and material jetting), and how the system ensures full traceability and repeatability for future orders.

AMIS at Formnext 2025: Hall 12.0, Booth B19

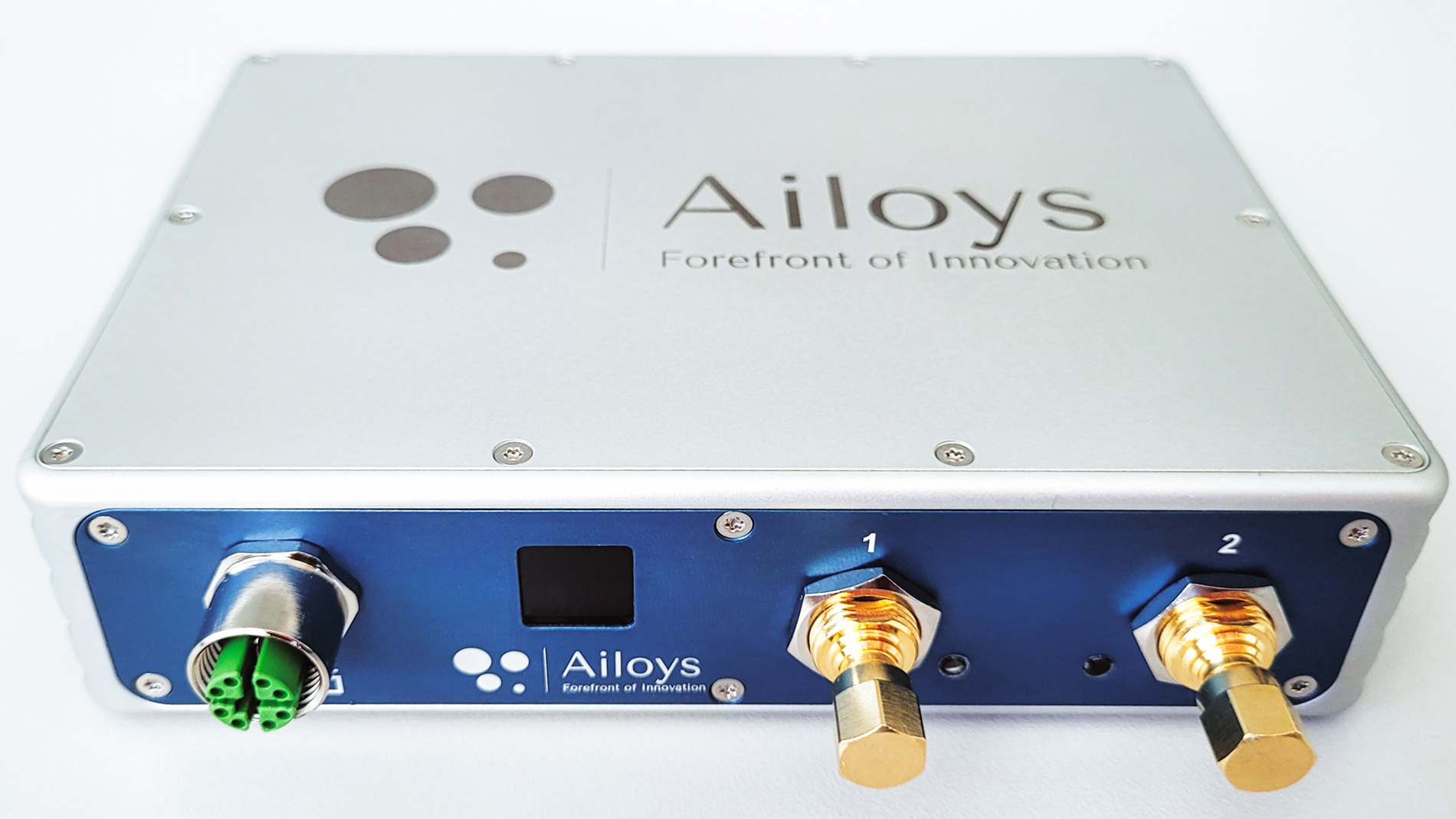

Ailoys: AI brain for machines

Ailoys GmbH, a Berlin-based industrial AI company, will showcase its plug-and-play AI device at Formnext 2025. Marketed as the “brain for your machinery,” the compact system enables additive and other advanced manufacturers to integrate AI into their existing equipment both quickly and affordably. Within hours, operators can carry out real-time root cause analysis and process adjustments without costly retrofits. “We give machines a brain that’s similar to Amazon Alexa, but for industrial production. Our AI listens to machines 10 million times per second, delivers real-time root cause analysis of defects to operators, and even adjusts machine settings automatically based on process performance,” says Sergei Altynbaev, CEO and founder of Ailoys GmbH.

Ailoys at Formnext 2025: Hall 11.1, Booth D31

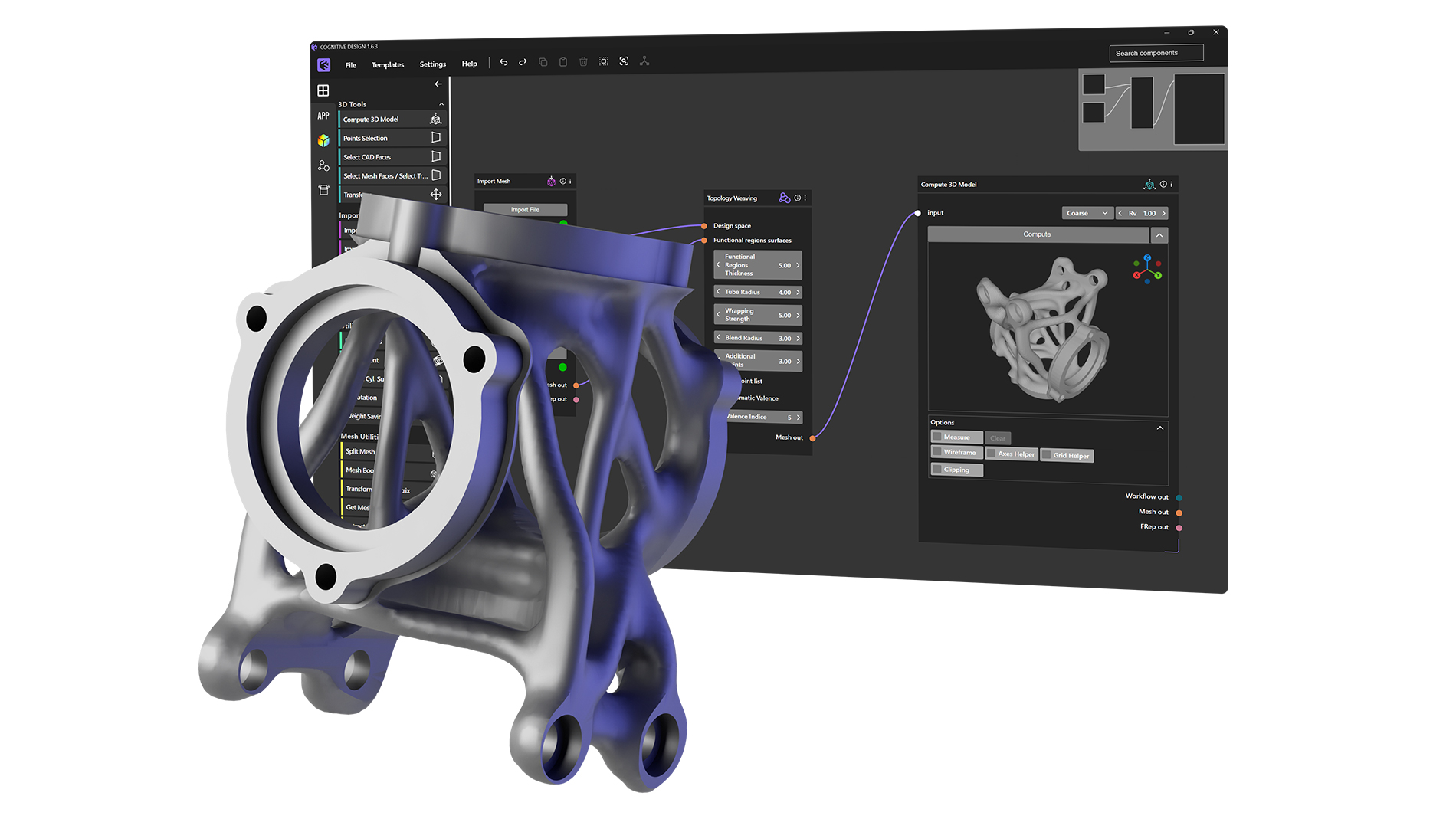

Cognitive Design Systems: A faster path to high-performance parts

With the new Cognitive Design 2.0, Cognitive Design Systems (CDS) promises that engineers will be able to determine the best manufacturable design for high-performance parts more quickly and accurately. According to CDS, this engineering platform combines generative design, integration of manufacturability, and data-driven decision-making. The new Design Explorer feature centralizes all design iterations, simulations, and cost analyses in one place, enabling informed design decisions. According to CDS, the platform also allows concepts to be precisely identified and compared in a single dashboard based on multiple KPIs, such as cost, weight, performance, CO₂ emissions, and manufacturability. Design Explorer, meanwhile, offers a comparative multi-criteria view that enables engineers to quickly filter, sort, and visualize design concepts based on key metrics.

Cognitive Design Systems at Formnext 2025: Hall 12.0, Booth D15

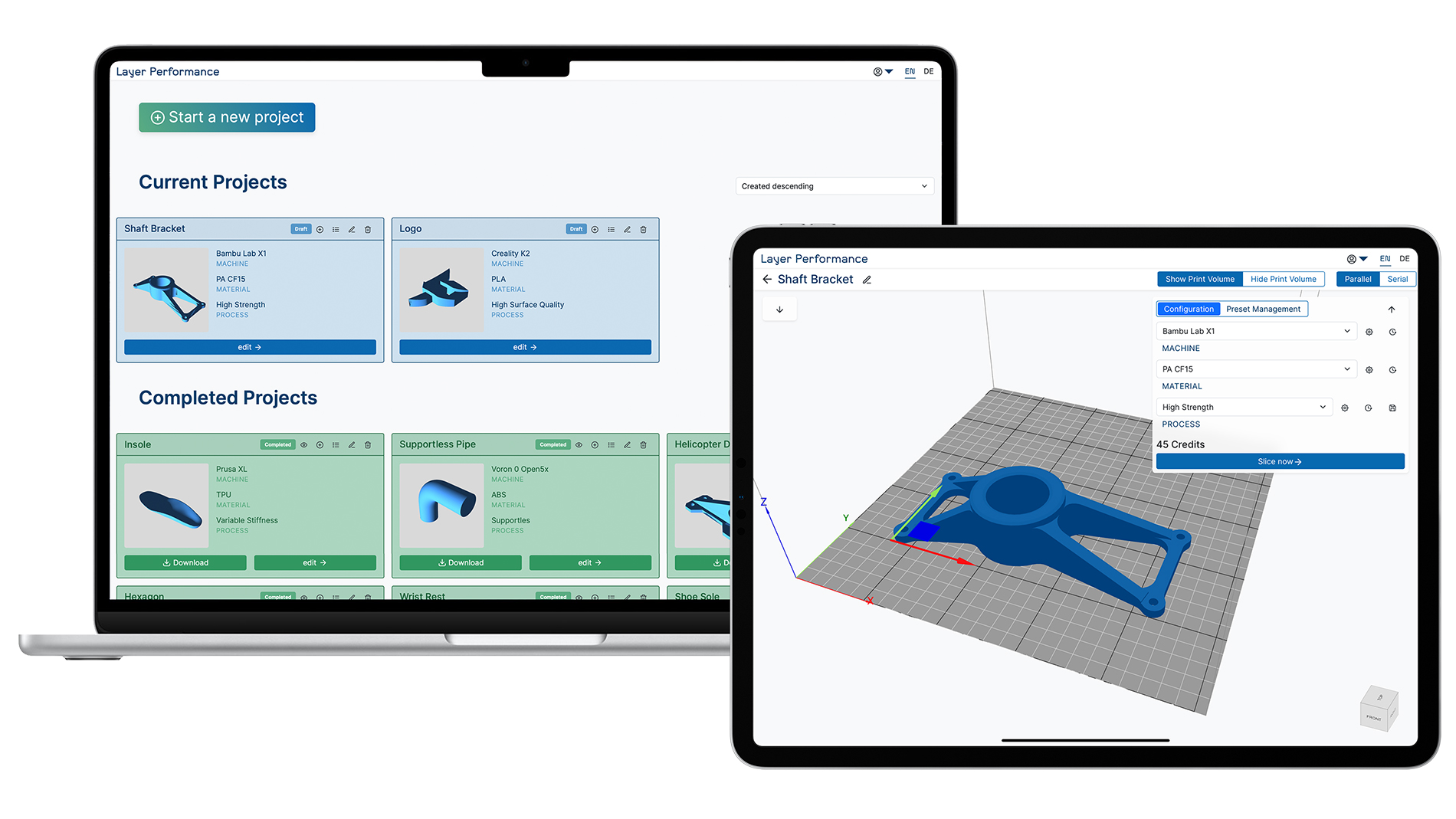

Layer Performance: Software for non-planar AM

The new version 2.0 of its slicing software, which Layer Performance GmbH is presenting for the first time at Formnext, enables both planar and 3D-optimized (non-planar) path planning for all systems – from conventional filament systems with three axes to robotic systems with granulate extruders. A wide variety of materials are supported, from plastics to metal and ceramics to concrete. Even the most complex geometries are translated into optimized machine code. According to Layer Performance, this results in the first universal slicer for non-planar Additive Manufacturing. With version 2.0, it is also possible to define different hardness zones within a component for the first time. This makes it possible to adapt functional properties to the respective application. One example is shoe soles that offer both comfort and stability thanks to customized softer and harder areas. Thanks to its open architecture, Layer Performance says its latest slicing software can be integrated into existing process chains without restrictions.

Layer Performance at Formnext 2025: Hall 12.1, Booth A98