Text: Thomas Masuch

One of the hallmarks of Additive Manufacturing is its ability to respond quickly to current economic and social trends and challenges. This is currently evident in innovations in the field of pellet-based AM, for example, and in new 3D printers that are so robustly designed that they are suitable for independent use in harsh environments. The former is a response to major cost-cutting efforts, while the latter is certainly a consequence of the changed security situation in Europe.

Significant savings with granulate printers

While 3D Printing with pellets has been established in the AM world for years, the material is still not as widely used as filaments. In the plastics sector, experts estimate the share of pellet printing at 5 to 10 percent, but things are trending upward. The applications mainly include large-volume components in the automotive industry, boat building, architecture, and mold making, among other fields.

With their new developments, Pollen AM and Ginger Additive are responding to two trends at once: cost reduction and large-format plastic parts. Both companies are focusing on granulate-based 3D printing, which they claim offers significant savings potential compared to FDM printing.

The new large-format 3D printer Pam Pro from French manufacturer Pollen AM uses the company's proprietary Pellet Additive Manufacturing (PAM) technology and works with thermoplastic granulates. The Pam Pro offers a build volume of 680 × 680 × 500 mm and a printing speed of up to 500 mm/s. The heating bed can reach temperatures up to 150°C, and the extrusion temperature ranges up to 300°C. An integrated camera performs automatic calibration. Pollen AM promises a cost advantage of up to 90 percent compared to FDM printing. The use of standard materials would facilitate certification of the Pam Pro, and its manufacturer also sells its own plastic granulates in smaller batches. The system can be operated with either one or two extruders, with the nozzle diameters ranging from .25 to 2.5 mm. Delivery is scheduled to start in Western Europe in fall 2025.

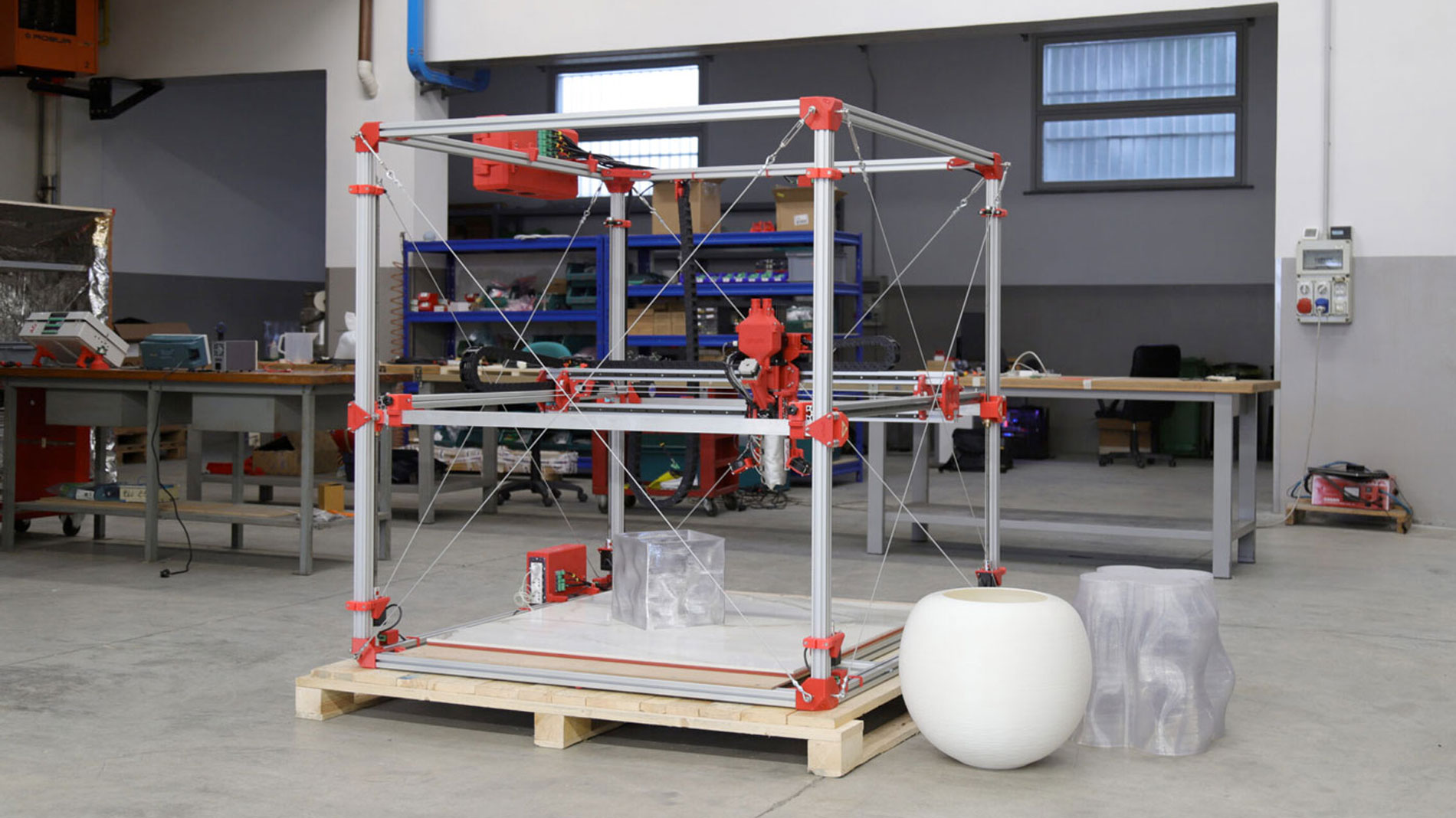

The pellet printer G1 offers a build volume of one cubic meter. Image: Ginger Additive

Italy’s Ginger Additive has also unveiled a new large-format pellet 3D printer, the G1. It offers a build volume of one cubic meter, an open material system, and Klipper firmware that receives regular updates. Ginger Additive is also aiming for significant cost savings: According to the manufacturer, material costs can be reduced to as little as €6/kg – significantly less than the average price range of €15 to €35/kg for PLA filaments. Ginger Additive claims that the G1 can process up to 3 kg of material per hour. Its open ecosystem enables the use of materials ranging from standard plastics to custom material mixtures, and its calibration is automatic.

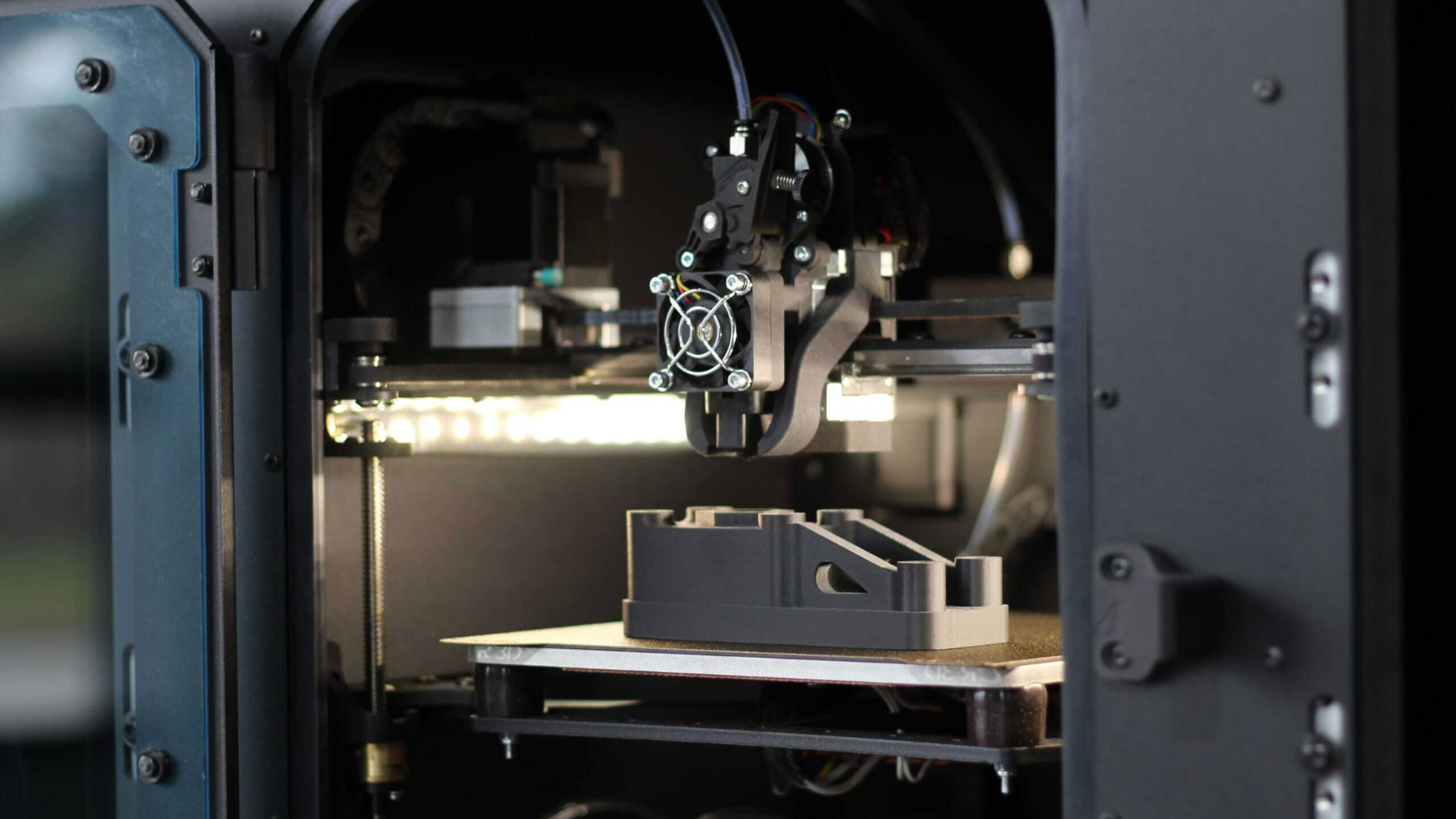

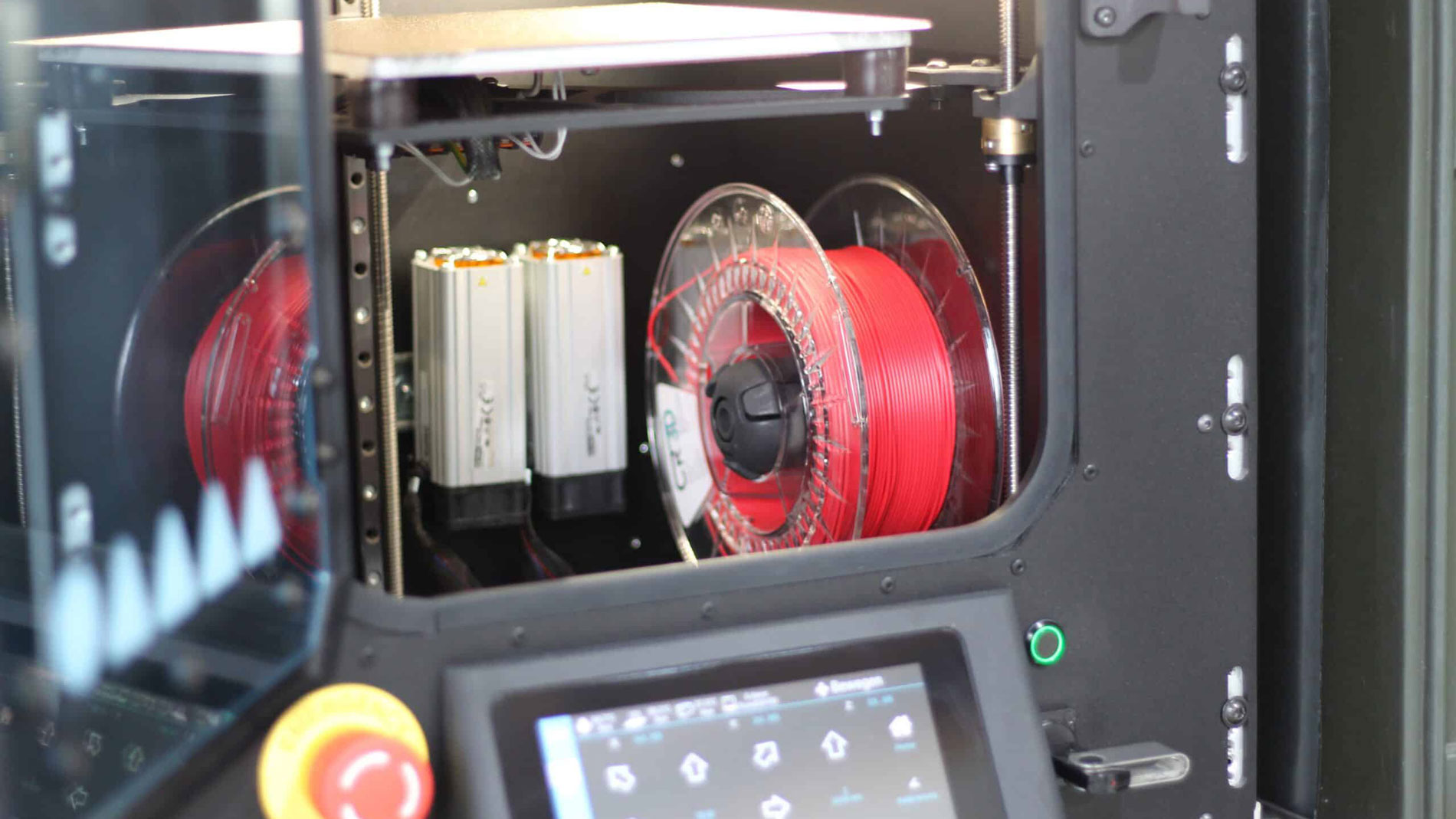

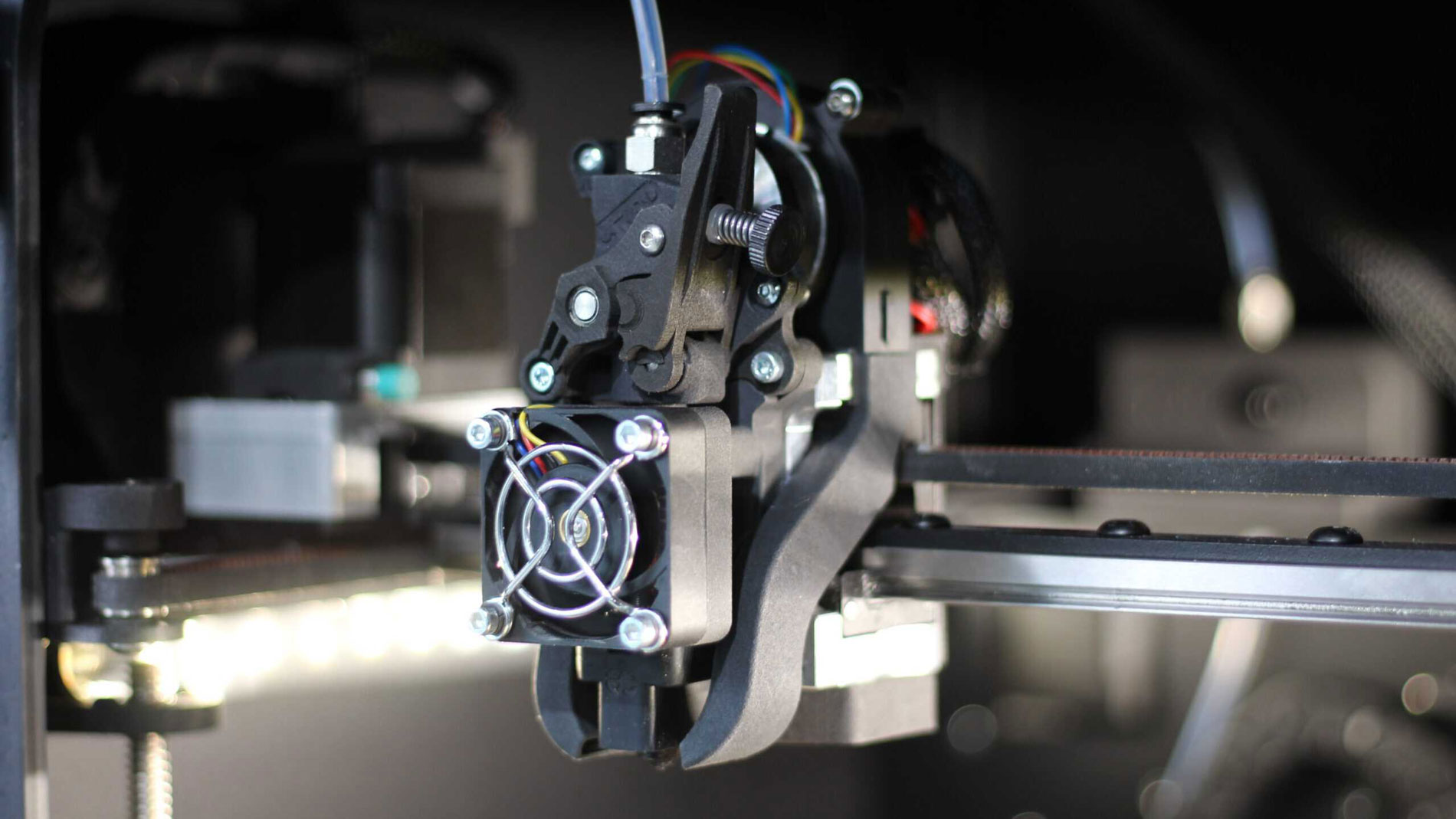

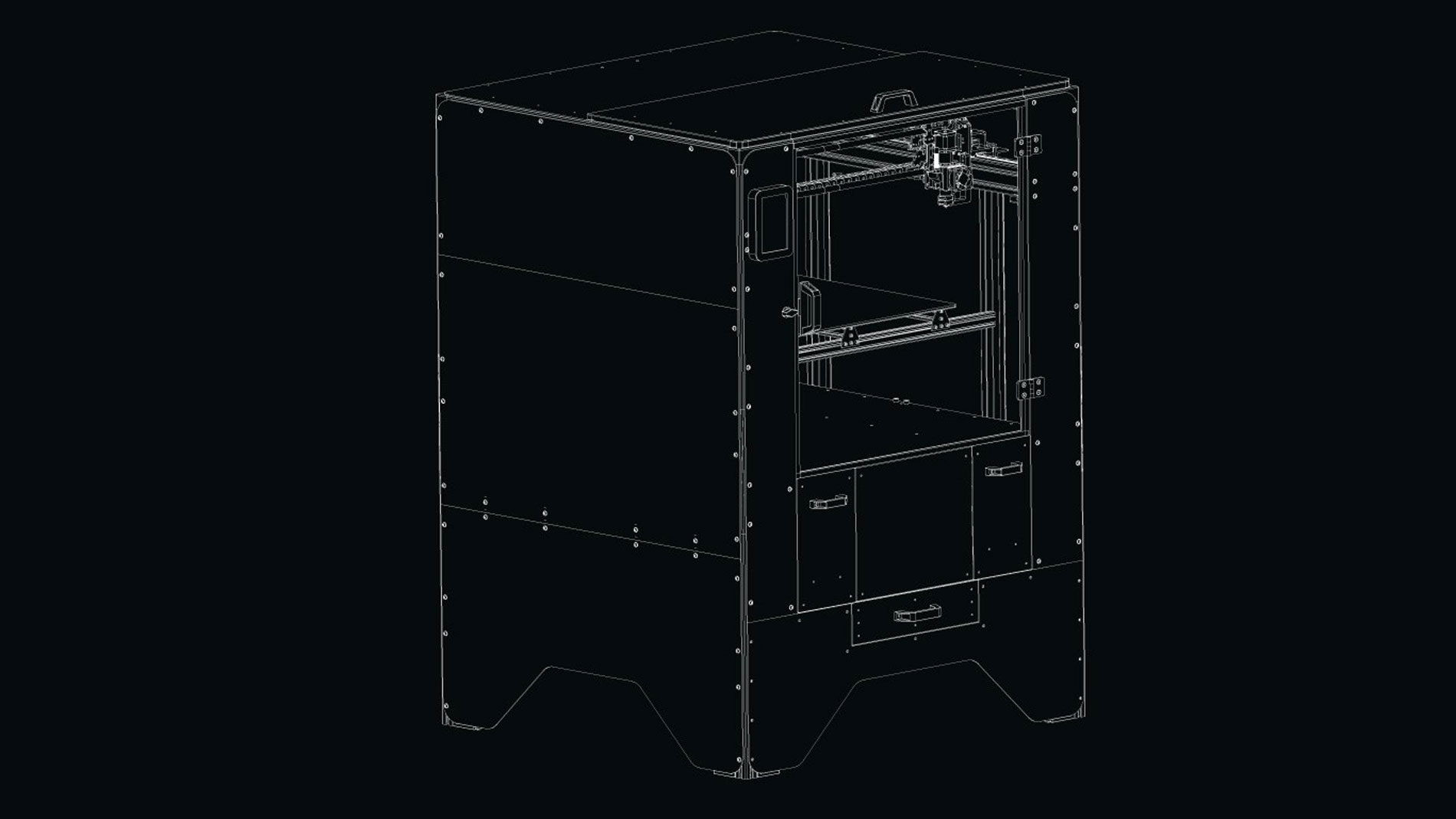

The Fieldrack 3D printer from CR-3D is designed for applications in harsh or mobile environments. Image: CR-3D

For the harshest environments

The Fieldrack 3D printer from CR-3D is designed for applications in harsh or mobile environments – in vehicles, on ships, or outdoors, for example. Its build volume (210 × 205 × 250 mm) can be heated to 60°C, and its extruder operates at temperatures up to 350°C. The print bed is measured using sensors and calibrated automatically via the nozzle tip, while integrated vibration suppression enables mobile operation. In addition to Wi-Fi and Ethernet, the Fieldrack can also be controlled via a local touch display or in standalone mode via a USB flash drive. This means that the printer can also be used in safety-critical industries.

The US company Chicago Additive has secured a “co-exclusive” license for U.S. Patent Application 18/926770 (“Advanced Manufacturing Operational Apparatus, System, and Method”) and is using this as a basis for developing its new Amos printer series. The target group is industrial users, educational institutions, and military users in particular. The Amos 300 has a build volume of 300 × 300 × 220 mm and can be mounted in standard server racks. The Amos series also includes the Amos 200 and 500 models, which, according to the manufacturer, are particularly suitable for rugged operating conditions. The printers feature a closed build volume, integrated material storage, optional heated print chambers, and automated humidity control. All the devices are based on a Core-XY motion system. The Amos printers have already been tested as part of the international naval exercise RIMPAC. Production takes place at Chicago Additive’s site in Demotte, Indiana.